Integrated production line for label production

An all-in-one, production-line technology, applied in printing, rotary printing machines, printing devices, etc., can solve the problems of inappropriate label processing and production of various types, increase space occupation and cost, and achieve high space utilization, space saving and Cost, compact connection effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0053] The present invention will be described in further detail below in conjunction with the accompanying drawings.

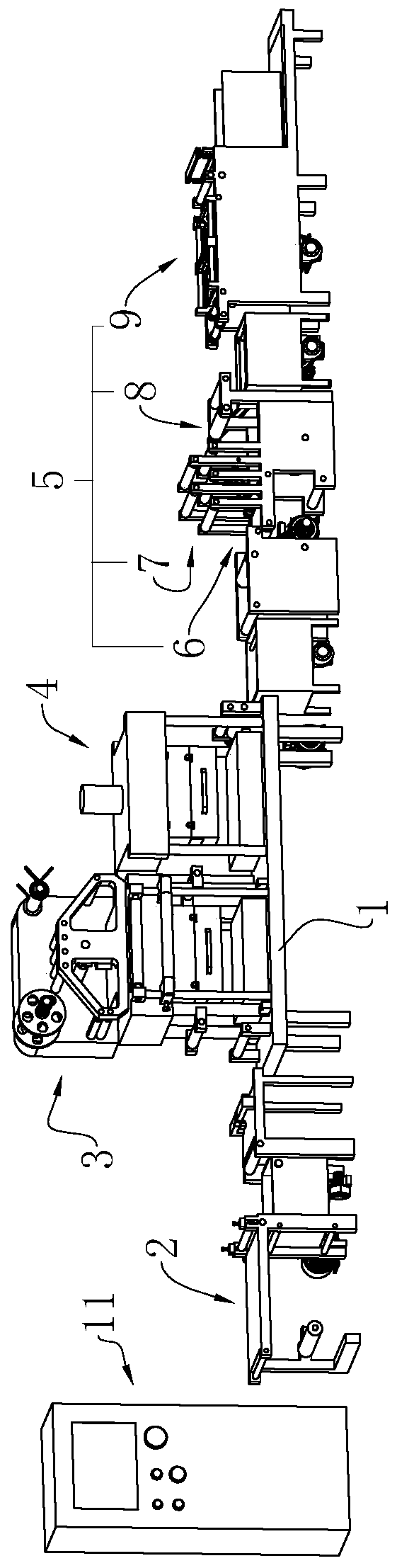

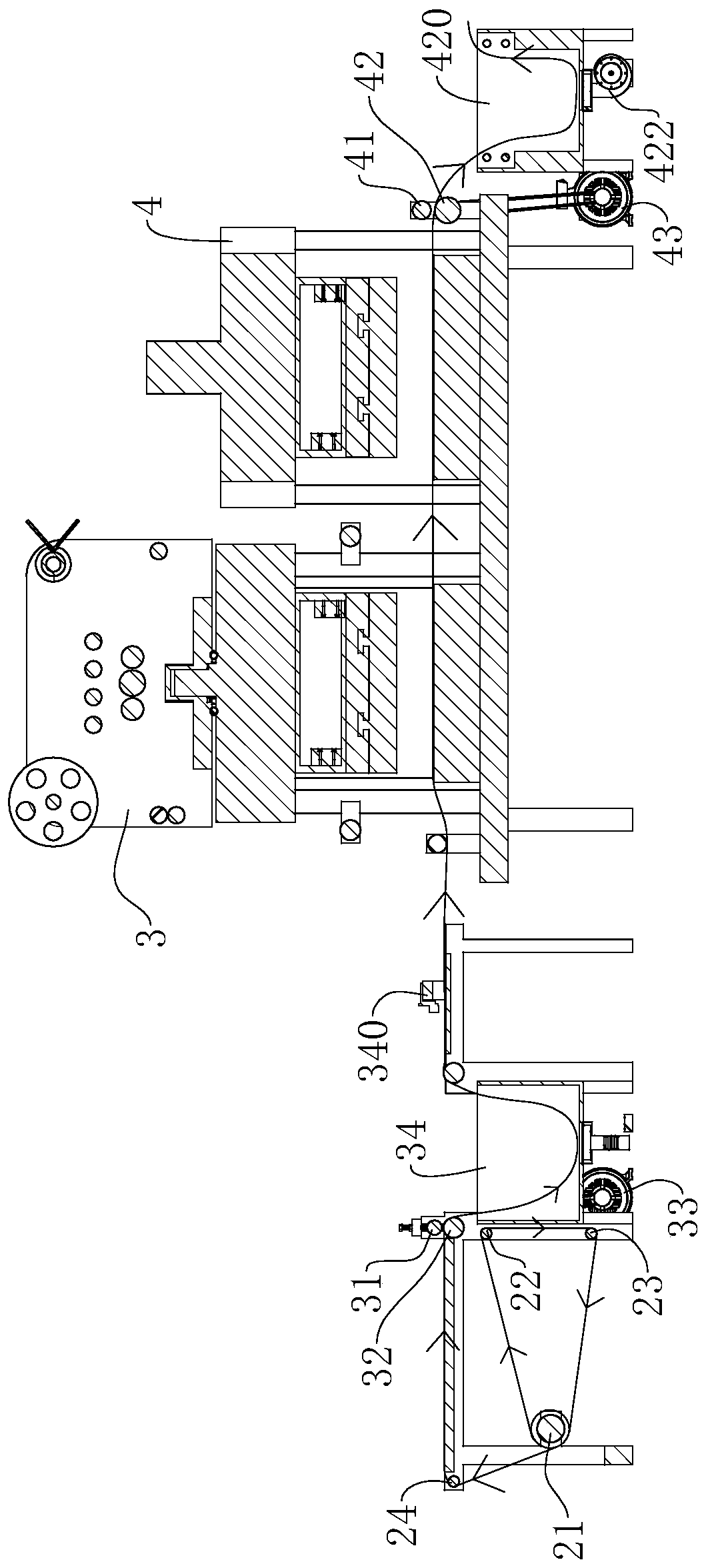

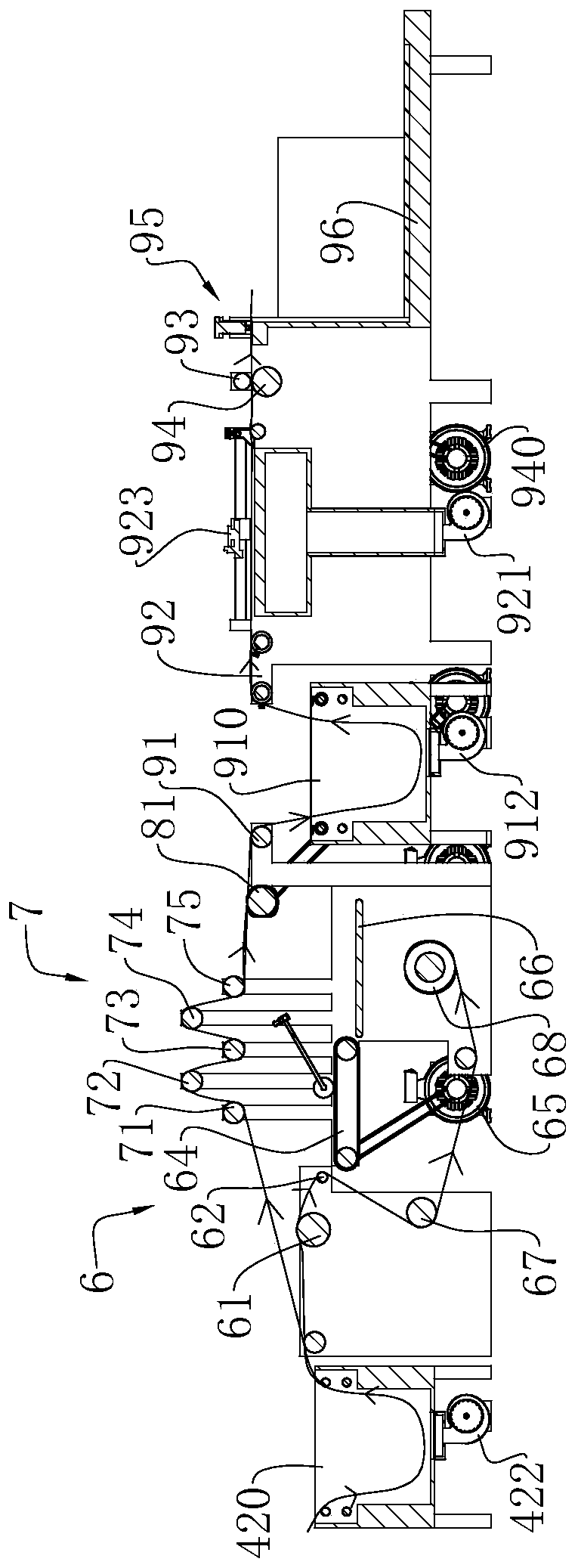

[0054] refer to figure 1 , is an integrated production line for label production disclosed by the present invention, including a control box 11, which is electrically connected with each electrical device in the production line for receiving and sending control signals. One side of the control box 11 is provided with a frame 1, and the frame 1 is provided with an unwinding device 2, a stamping device 3, a die-cutting device 4 and a material receiving device 5 in sequence. Wherein the receiving device 5 includes a material collecting device 6 , a cooling device 7 , a winding device 8 and a retracting device 9 .

[0055] refer to Figure 4 , The unwinding device 2 includes an unwinding roller 21 rotatably connected to the frame 1, the unwinding roller 21 is set as a driven roller, and rotates following the movement of the label substrate.

[0056] refer to ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com