Blade head

A tool head and tool holder technology, applied in milling cutters, gear tooth manufacturing devices, gear teeth, etc., can solve problems such as high structural cost

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

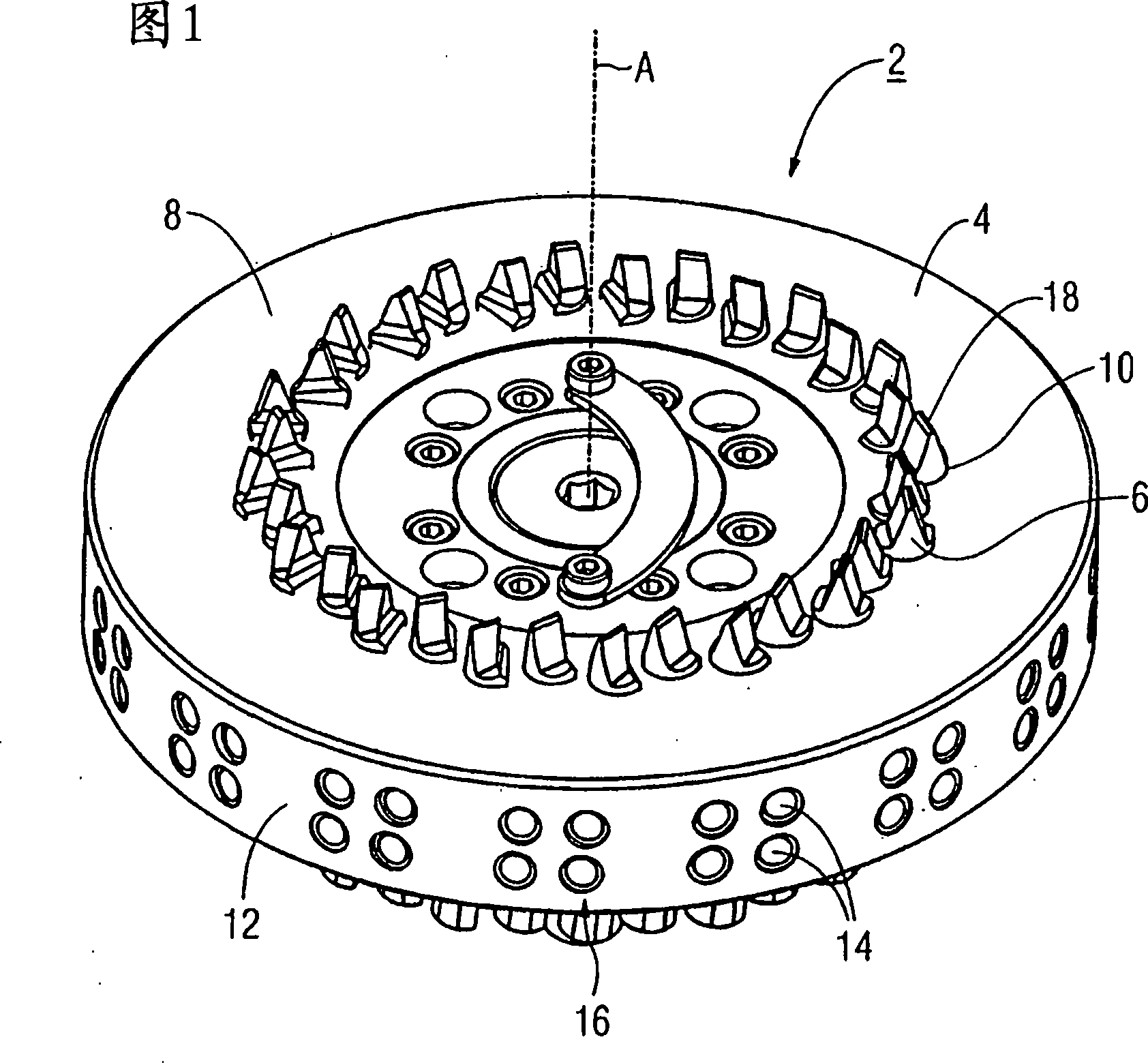

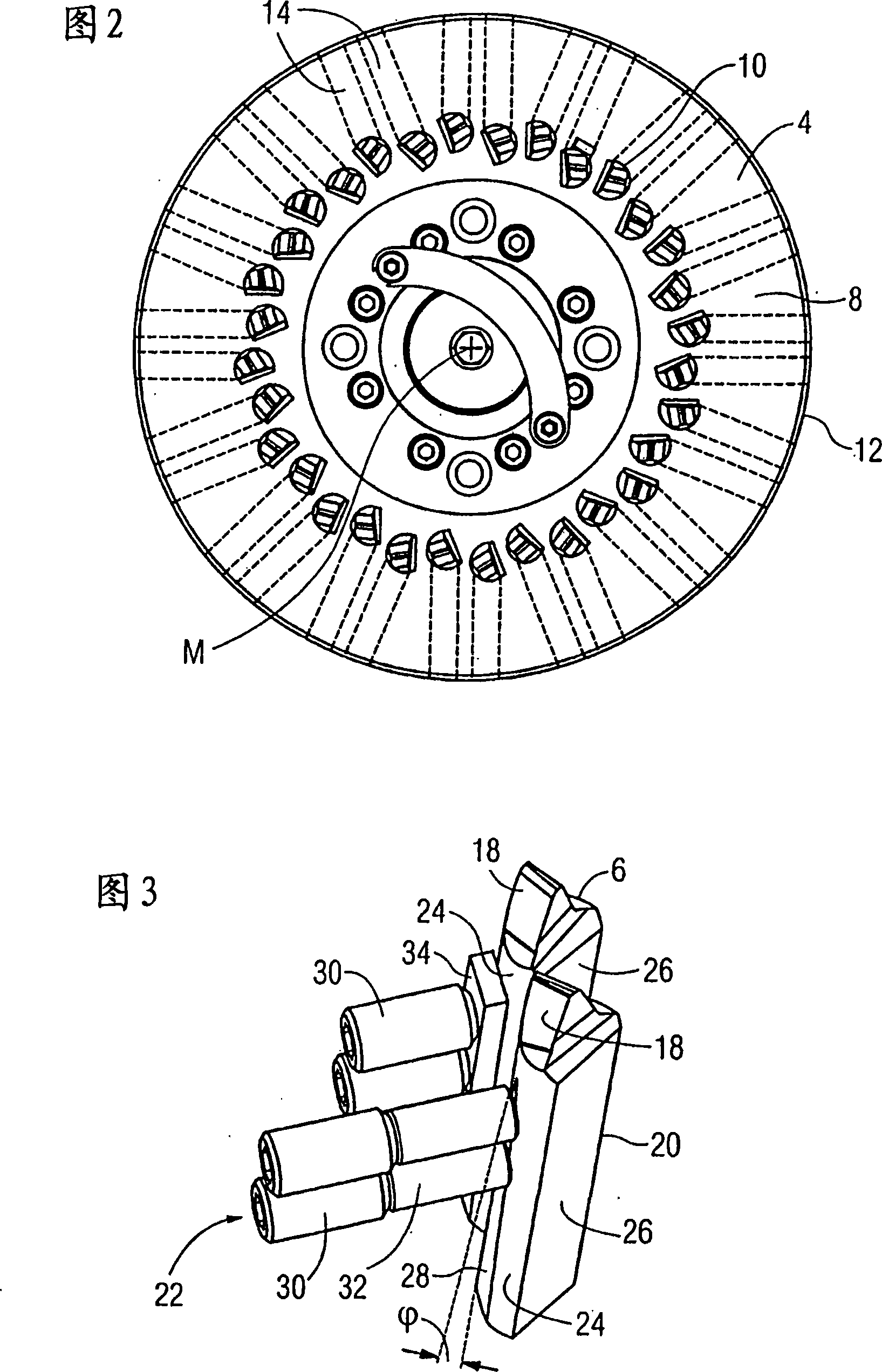

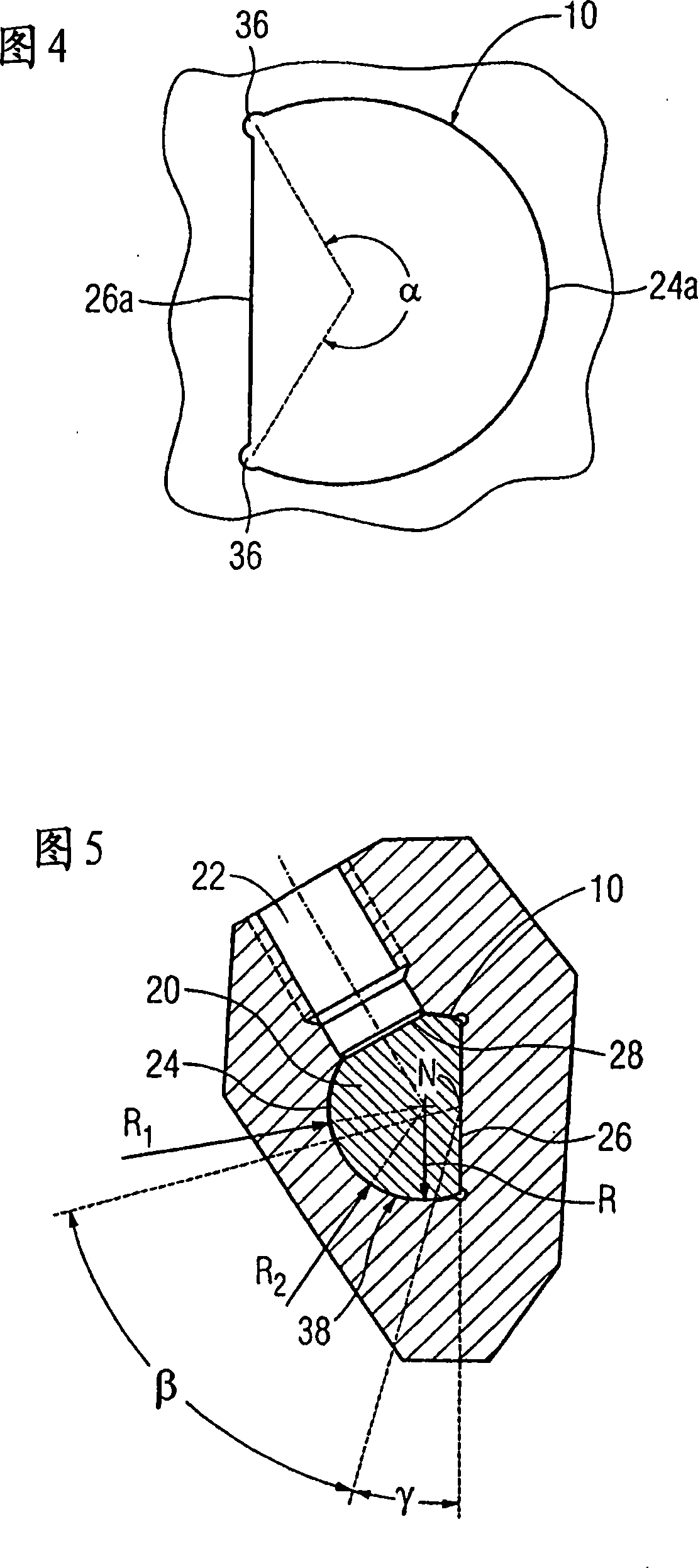

[0026] FIG. 1 shows a cutting head 2 which consists of a disc-shaped, one-piece cutting holder 4 and a plurality of rod-shaped cutting tools 6 . The tool holder 4 is rotatable about the axis A of rotation of the disk. The tool holder has a working surface 8 with a plurality of tool seats 10 in which rod-shaped tools 6 are accommodated. The disk rotation axis A extends through the midpoint M of the tool holder 4 . The tool holders 10 are arranged in pairs in an annular manner around the midpoint M of the disk-shaped tool holder 4 . The seat 10 is formed by etching and has an arcuate cross-section. Furthermore, the tool holder 4 has a peripheral surface 12 on which two rows of fastening holes 14 are formed, which extend approximately in the radial direction of the axis A of rotation of the disk. The lower row of fixing holes is arranged directly below the upper row of fixing holes, thereby forming a column 16 composed of two fixing holes 14 . The number of columns 16 corresp...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com