Mattress production process

A production process and technology for mattresses, applied in the field of mattress processing, can solve the problems of large mattress size, high labor intensity, low work efficiency, etc., and achieve the effect of smoothing the turning process, improving processing efficiency, and avoiding burdens.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

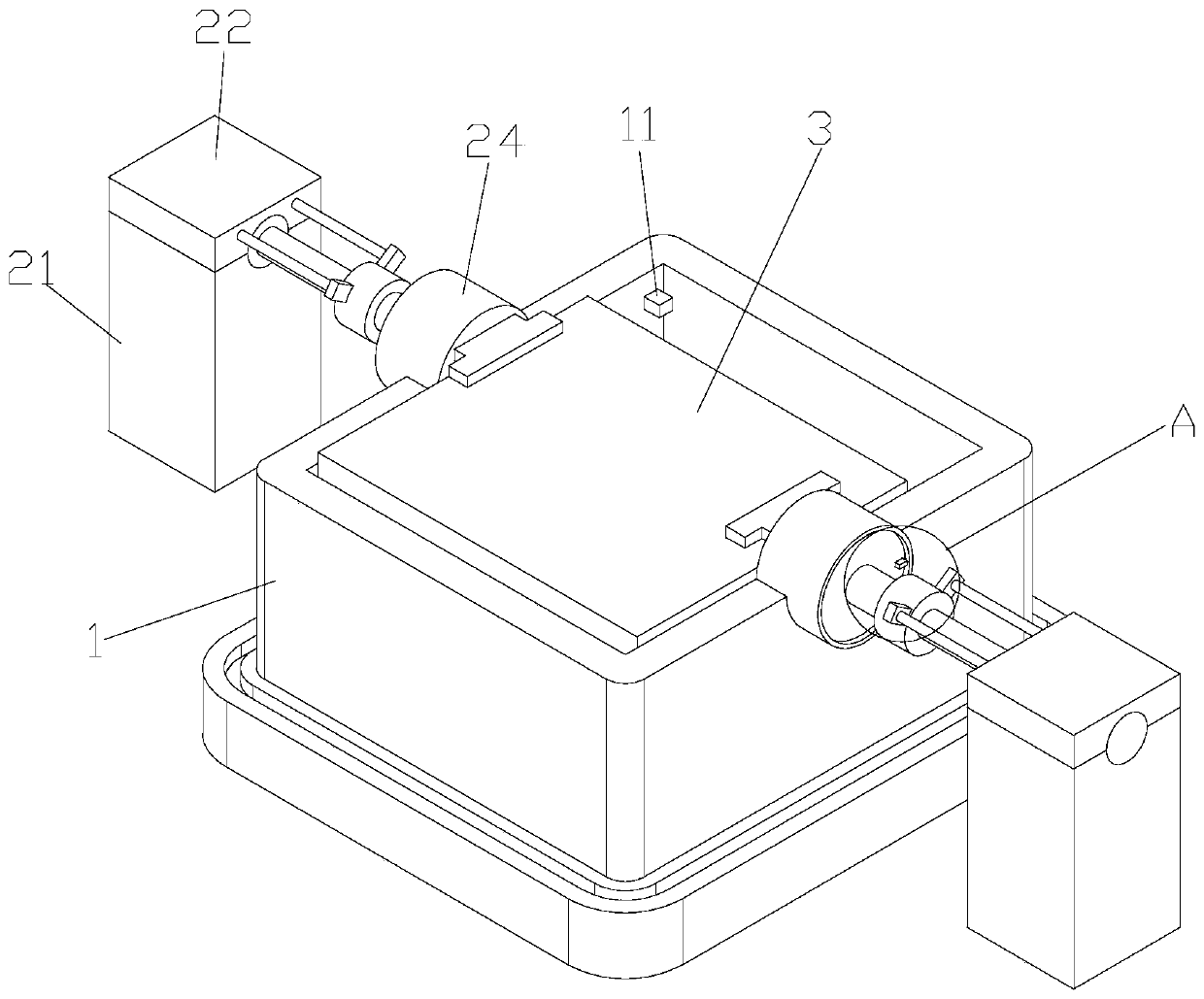

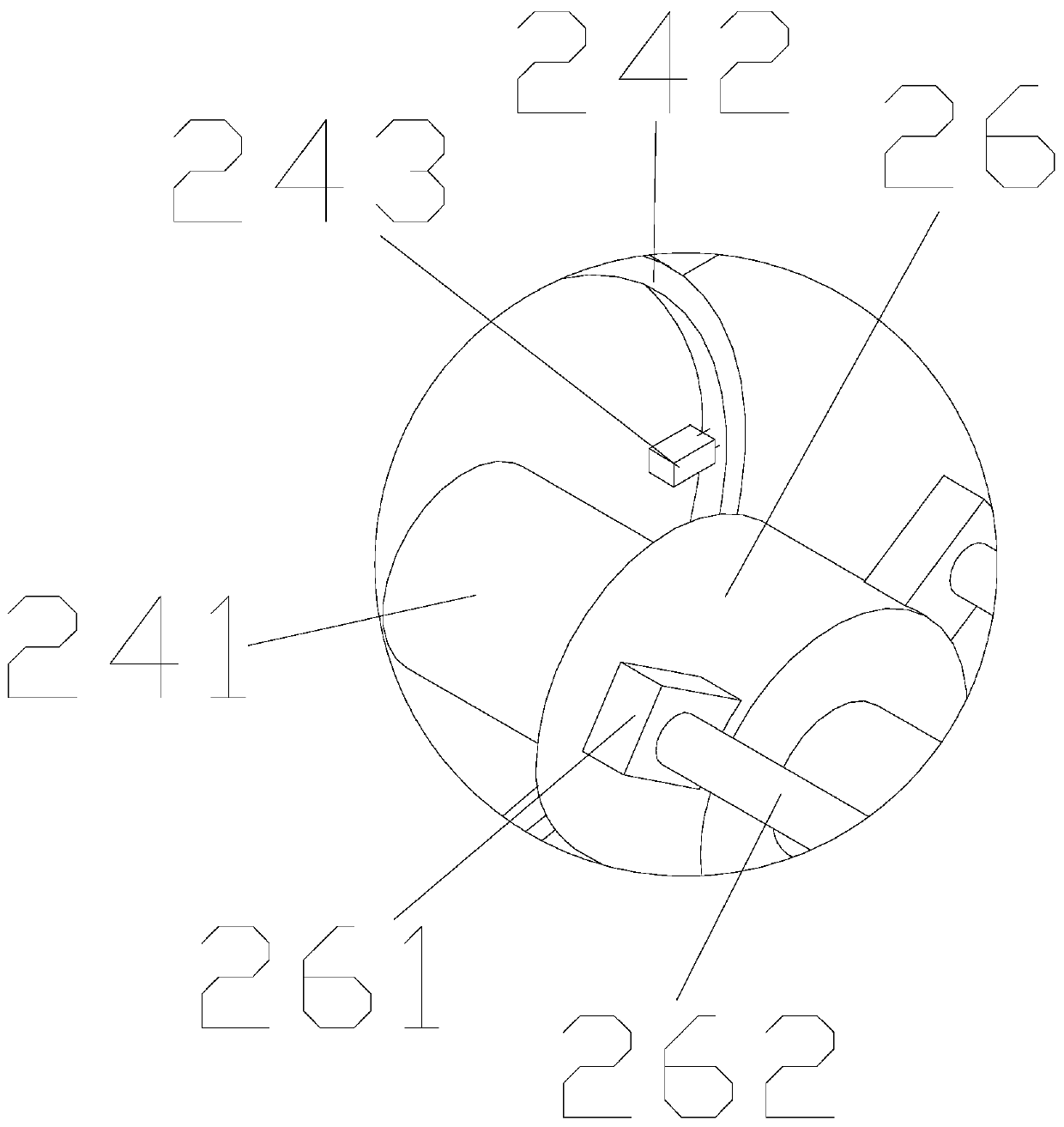

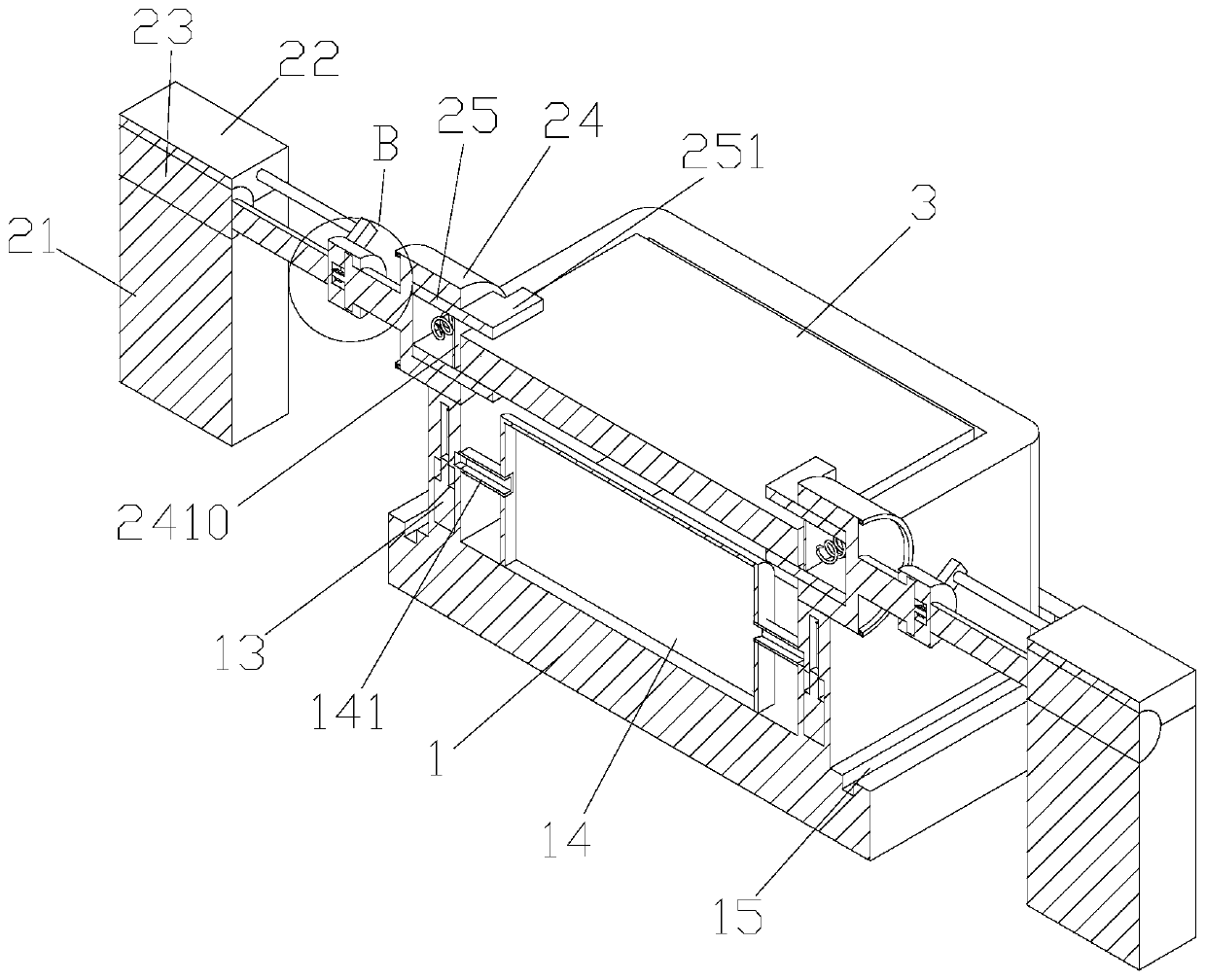

Embodiment 1

[0031]A mattress production process, including: a. Feed and feed inspection: the suitability and qualification of raw materials are directly related to the production and quality of mattress products; b, pleats and springs: pleats are the mattress The cotton car used in the fabric goes to the fabric, and the final form of expression is the top and bottom layer of the mattress; the spring is to connect the coil springs into a whole; c, the cutting bed and the bed net are made: the cutting bed It is to cut the pleated cotton fabric to the size of the mattress; the bed net is made, and the spring net formed by the spring, the interlocking spring net or the independent bag spring net is fixed with a frame iron, thus forming a bed net; d. Bottom: Lay cotton felt or other cushions on the bed net, and then place the pleated cotton fabric; e, edge: place the finished mattress on the processing table, and sew the upper and lower fabrics on the edge through the edge machine. together; f...

Embodiment 2

[0044] A mattress production process, including: a. Feed and feed inspection: the suitability and qualification of raw materials are directly related to the production and quality of mattress products; b, pleats and springs: pleats are the mattress The cotton car used in the fabric goes to the fabric, and the final form of expression is the top and bottom layer of the mattress; the spring is to connect the coil springs into a whole; c, the cutting bed and the bed net are made: the cutting bed It is to cut the pleated cotton fabric to the size of the mattress; the bed net is made, and the spring net formed by the spring, the interlocking spring net or the independent bag spring net is fixed with a frame iron, thus forming a bed net; d. Bottom: Lay cotton felt or other cushions on the bed net, and then place the pleated cotton fabric; e, edge: place the finished mattress on the processing table, and sew the upper and lower fabrics on the edge through the edge machine. together; ...

Embodiment 3

[0046] A mattress production process, including: a. Feed and feed inspection: the suitability and qualification of raw materials are directly related to the production and quality of mattress products; b, pleats and springs: pleats are the mattress The cotton car used in the fabric goes to the fabric, and the final form of expression is the top and bottom layer of the mattress; the spring is to connect the coil springs into a whole; c, the cutting bed and the bed net are made: the cutting bed It is to cut the pleated cotton fabric to the size of the mattress; the bed net is made, and the spring net formed by the spring, the interlocking spring net or the independent bag spring net is fixed with a frame iron, thus forming a bed net; d. Bottom: Lay cotton felt or other cushions on the bed net, and then place the pleated cotton fabric; e, edge: place the finished mattress on the processing table, and sew the upper and lower fabrics on the edge through the edge machine. together; ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com