A plastic window hole milling process based on a hole milling manipulator, and equipment

A manipulator and hole milling technology, applied in milling machine equipment, metal processing equipment, milling machine equipment details, etc., can solve the problems of low processing efficiency, low degree of automation, poor consistency of finished products, etc., achieve automatic processing, reduce the degree of manual participation, The effect of improving machining accuracy and machining consistency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

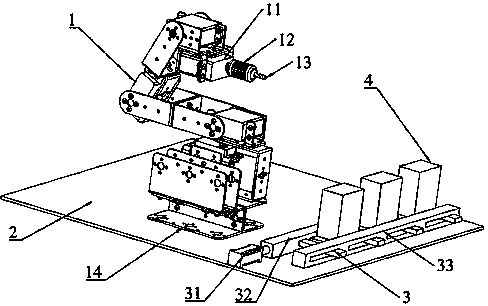

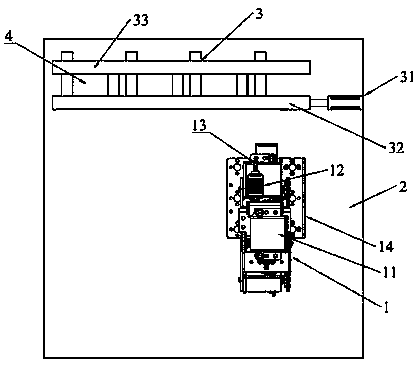

[0031] Such as figure 1 , figure 2 As shown, the plastic window milling process and equipment based on the milling manipulator, its structure includes: manipulator 1, servo motor 11, electric spindle 12, milling cutter 13, bracket 14, base 2, profile fixture 3, cylinder 31, sliding Splint 32, fixed splint 33; the manipulator 1 is fixed on the base 2 through the bracket 14, the manipulator 1 is driven by the servo motor 11, the end of the manipulator 1 is equipped with an electric spindle 12, and the electric spindle 12 drives the milling cutter 13 to rotate, sliding the splint 32 Installed on the base 2 with the fixed splint 33, the side of the sliding splint 32 and the fixed splint 33 are provided with a transverse strip structure, the fixed splint 33 is provided with a square groove along the length direction, and the transverse strip structure on the side of the sliding splint 32 passes through Through the square groove of the fixed splint 33, the cylinder 31 is located a...

Embodiment 2

[0033] The plastic window milling process and equipment based on the milling robot includes the following steps:

[0034] (1) The profile 4 to be processed is placed between the sliding splint 32 and the strip structure on the side of the fixed splint 33 .

[0035] (2) Start the cylinder 31, the front end of the piston rod of the cylinder 31 pushes the sliding splint 32, and the sliding splint 32 moves until the profile 4 is clamped by the strip structure on the side.

[0036] (3) Start the electric spindle 12 of the manipulator 1, and the electric spindle 12 drives the milling cutter 13 to rotate at a preset speed.

[0037] (4) Start the servo motor 11 of the manipulator 1, and the manipulator 1 completes the preset action under the drive of the servo motor 11, and completes the hole machining process on the profile 4 by means of the milling cutter 13.

[0038] (5) After the machining of the upper hole of the profile 4 is completed, the manipulator 1 returns to its position,...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com