Steel bar bending device and method and application of steel bar bending device

A bending device and steel bar technology, which is applied in the field of steel bar bending devices, can solve the problems of limited protruding length of steel bars at beam ends and narrow bending space of steel bars, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

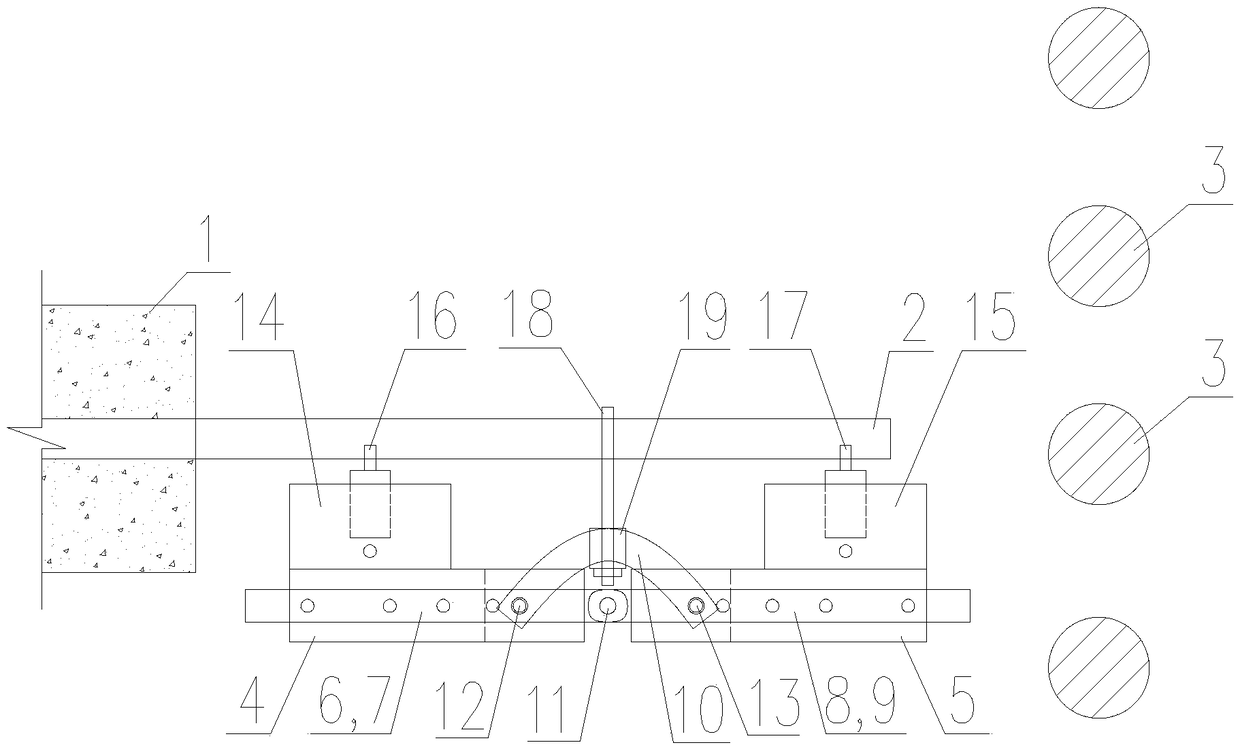

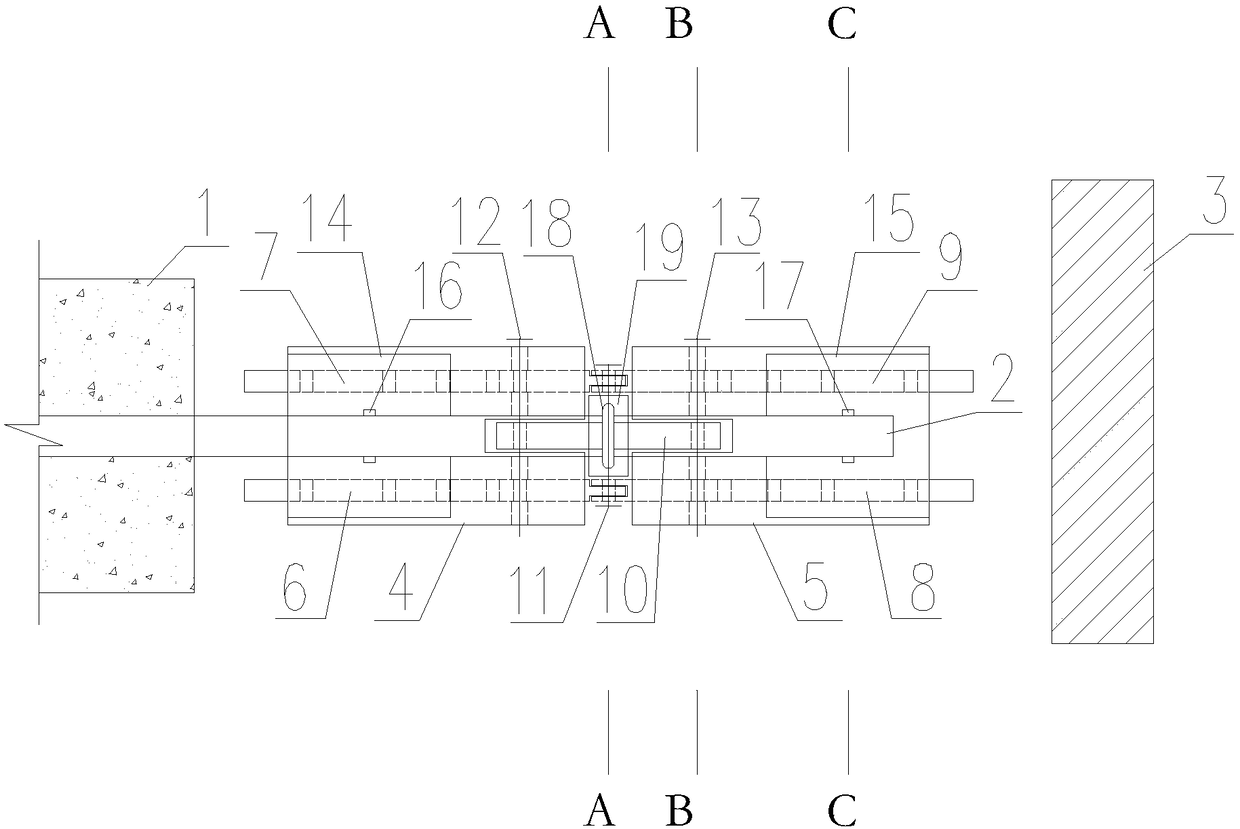

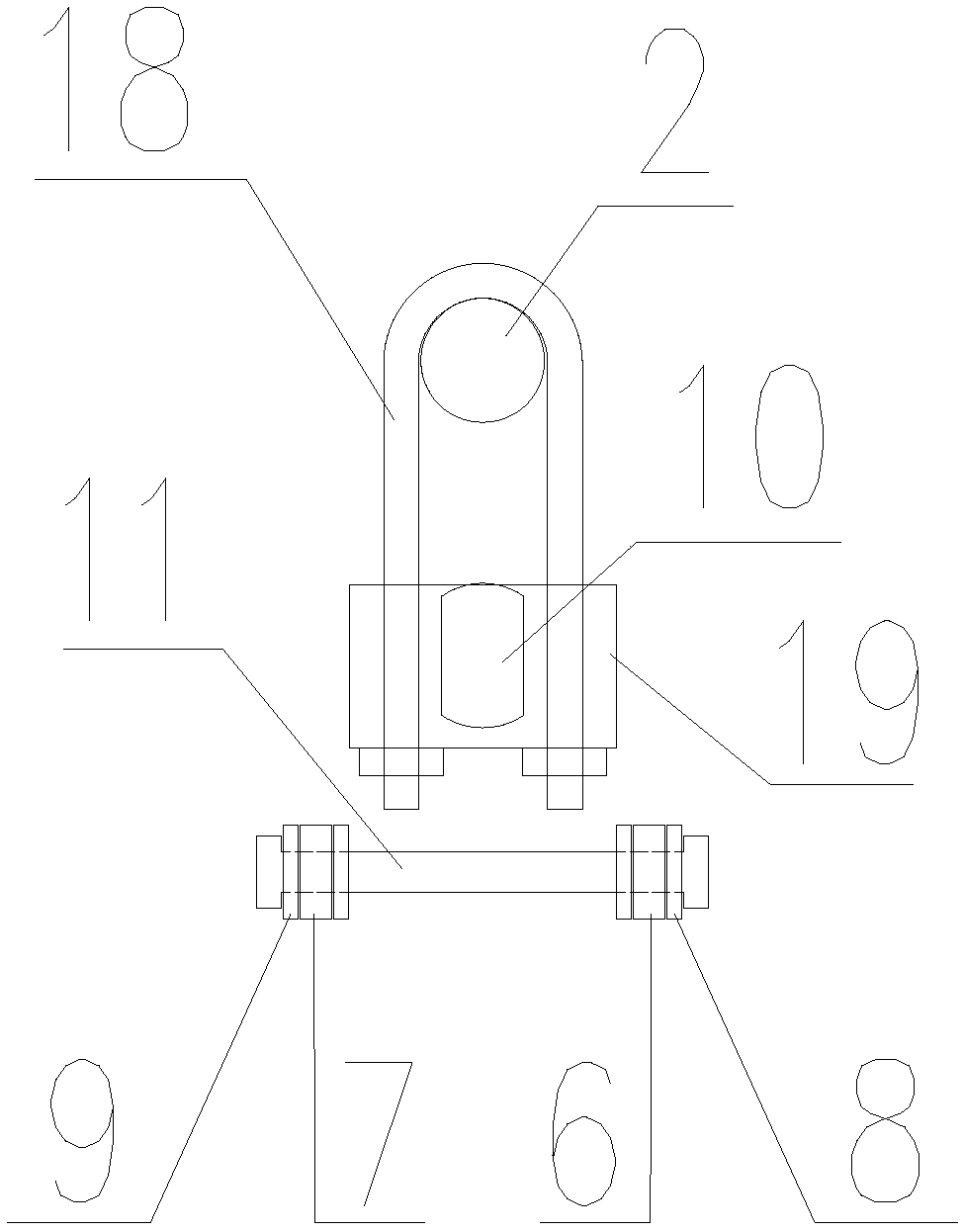

[0033] see Figure 1-Figure 5 , a steel bar bending device, comprising two perforated supports, two sliding chain bars parallel to each other are slidably fitted in the perforations of each perforated support, and the two sliding chain bars on the two perforated supports The opposite ends are hinged by a chain rod rotating shaft. The two perforated supports can rotate mutually through the hinge points of the sliding chain rods, the middle parts of the opposite ends of the two perforated supports are vertically provided with installation gaps, and the two ends of a tensile bending rod are respectively inserted into the two perforated supports. In the installation gap of the seat, the two perforated supports are respectively provided with a socket, the sliding chain rod is provided with a plurality of sockets in the axial direction, and the two ends of the tensile bending rod inserted into the installation gap are respectively provided with There is a socket, and any socket on ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com