Method for preparing flexible linear cutting cable

A cutting cable and line type technology, applied in the field of explosive cutting, can solve the problems of weak cutting ability, easy gasification, affecting cutting ability, etc., and achieve the effect of strong cutting ability and good flexibility

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0028] Weigh 9g RTV-2, add dropwise 0.60g tetraethyl orthosilicate, 0.326g acetyl tributyl citrate, stir evenly, continue to dropwise add 0.074g dibutyltin dilaurate, stir and mix evenly to form a viscous mixture .

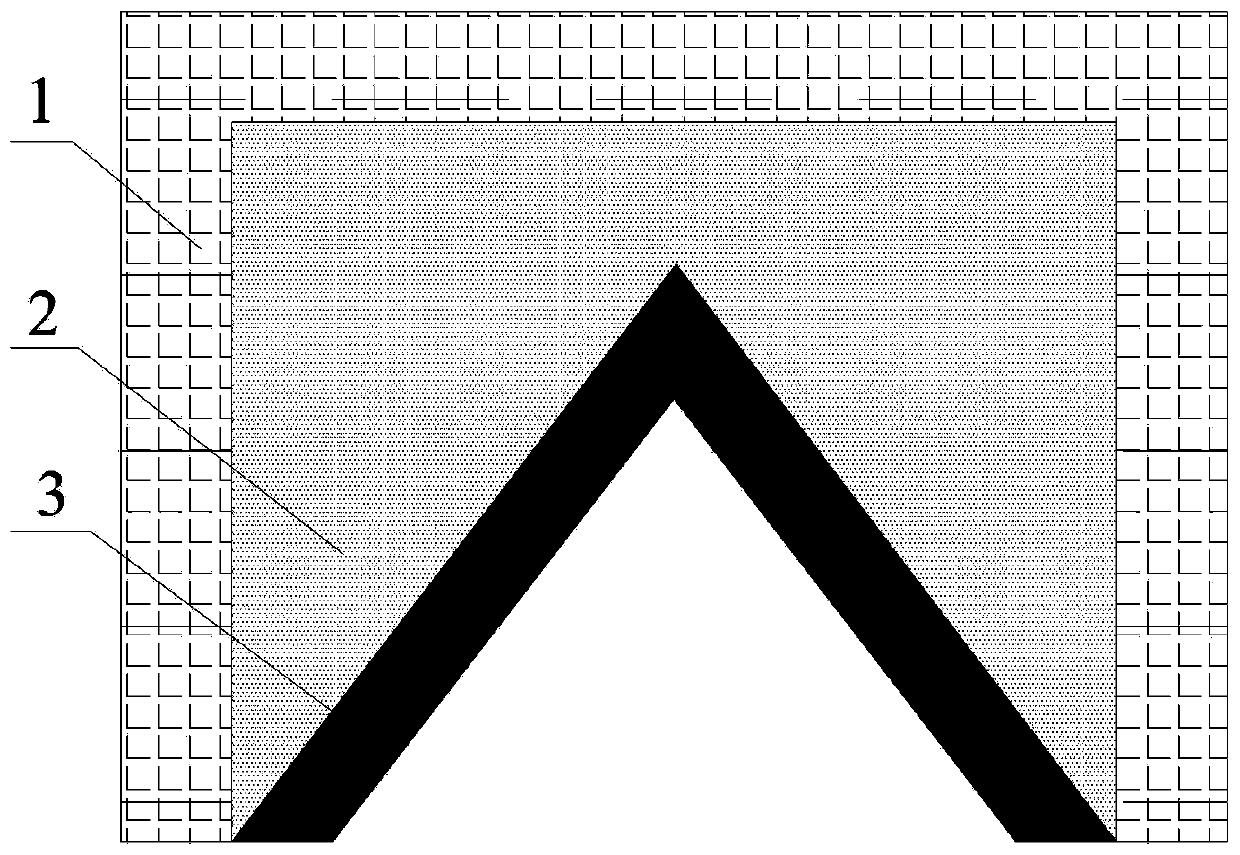

[0029] Pour the formed viscous mixture into a steel mold with a length of 100 mm, a width of 10 mm, and a depth of 13 mm, press it into an "凵" shape, and cure it at room temperature for 1 hour to obtain a cutting cable shell with a "凵" structure.

[0030] Weigh 15g of dynamite RDX, 3.375g of RTV-2, mix well, add dropwise 0.225g ethyl orthosilicate, 0.117g acetyl tributyl citrate, stir well, continue to add dropwise 0.027g dibutyltin dilaurate, stir and mix Uniformly form a viscous mixture.

[0031] Pour the formed viscous mixture into the solidified cutting cable shell, and press it with a pressing plate with a V-shaped protrusion at a cone angle of 60°, so that the surface of the viscous mixture forms a V-shaped energy-gathering The grooves are cured at room te...

Embodiment 2

[0036] Weigh 12g RTV-2, add dropwise 0.65g ethyl orthosilicate, 0.387g acetyl tributyl citrate, stir evenly, continue to dropwise add 0.086g dibutyltin dilaurate, stir and mix evenly to form a viscous mixture .

[0037] Pour the formed viscous mixture into a steel mold with a length of 100 mm, a width of 10 mm, and a depth of 13 mm, press it into an "凵" shape, and cure it at room temperature for 1 hour to obtain a cutting cable shell with a "凵" structure.

[0038] Weigh 17g of dynamite RDX, 3.385g of RTV-2, mix well, add dropwise 0.233g ethyl orthosilicate, 0.132g acetyl tributyl citrate, stir well, continue to add dropwise 0.032g dibutyltin dilaurate, stir and mix Uniformly form a viscous mixture.

[0039] Pour the formed viscous mixture into the solidified cutting cable shell, and press it with a pressing plate with a V-shaped protrusion at a cone angle of 60°, so that the surface of the viscous mixture forms a V-shaped energy-gathering The grooves are cured at room temper...

Embodiment 3

[0044]Weigh 49.50g RTV-2, add dropwise 3.264g ethyl orthosilicate, 1.637g acetyl tributyl citrate, stir evenly, continue to add dropwise 0.374g dibutyltin dilaurate, stir and mix evenly to form a viscous mixture body.

[0045] Pour the formed viscous mixture into a steel mold with a length of 500 mm, a width of 15 mm, and a depth of 23 mm, press it into an "凵" shape, and solidify it at room temperature for 1 hour to obtain a cutting cable shell with a "凵" structure.

[0046] Weigh 160g of dynamite RDX, 49.568g of RTV-2, mix well, add dropwise 2.254g ethyl orthosilicate, 1.873g acetyl tributyl citrate, stir well, continue to add dropwise 0.427g dibutyltin dilaurate, stir and mix Uniformly form a viscous mixture.

[0047] Pour the formed viscous mixture into the solidified cutting cable shell, and press it with a pressing plate with a V-shaped protrusion at a cone angle of 60°, so that the surface of the viscous mixture forms a V-shaped energy-gathering The grooves are cured a...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Particle size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com