Pipe bending mold, pipe bending machine and pipe bending method

A pipe bending machine and pipe bending technology, which is applied in the direction of forming tools, manufacturing tools, heat exchange equipment, etc., can solve the problems of waste of materials, low efficiency of pipe bending, time-consuming and laborious, etc., to save time and cost of pipe bending, and save materials , Ease of use

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

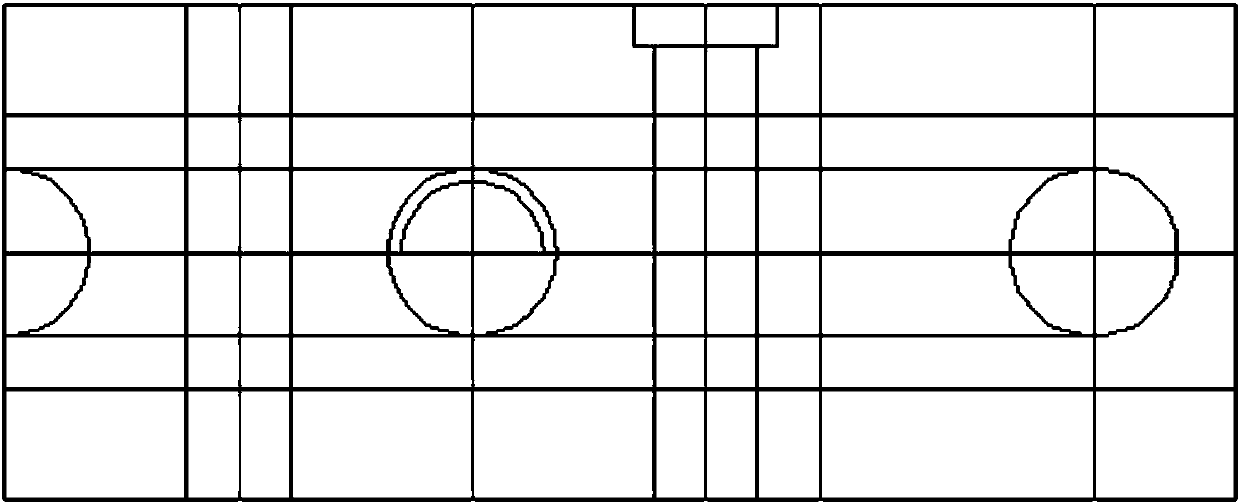

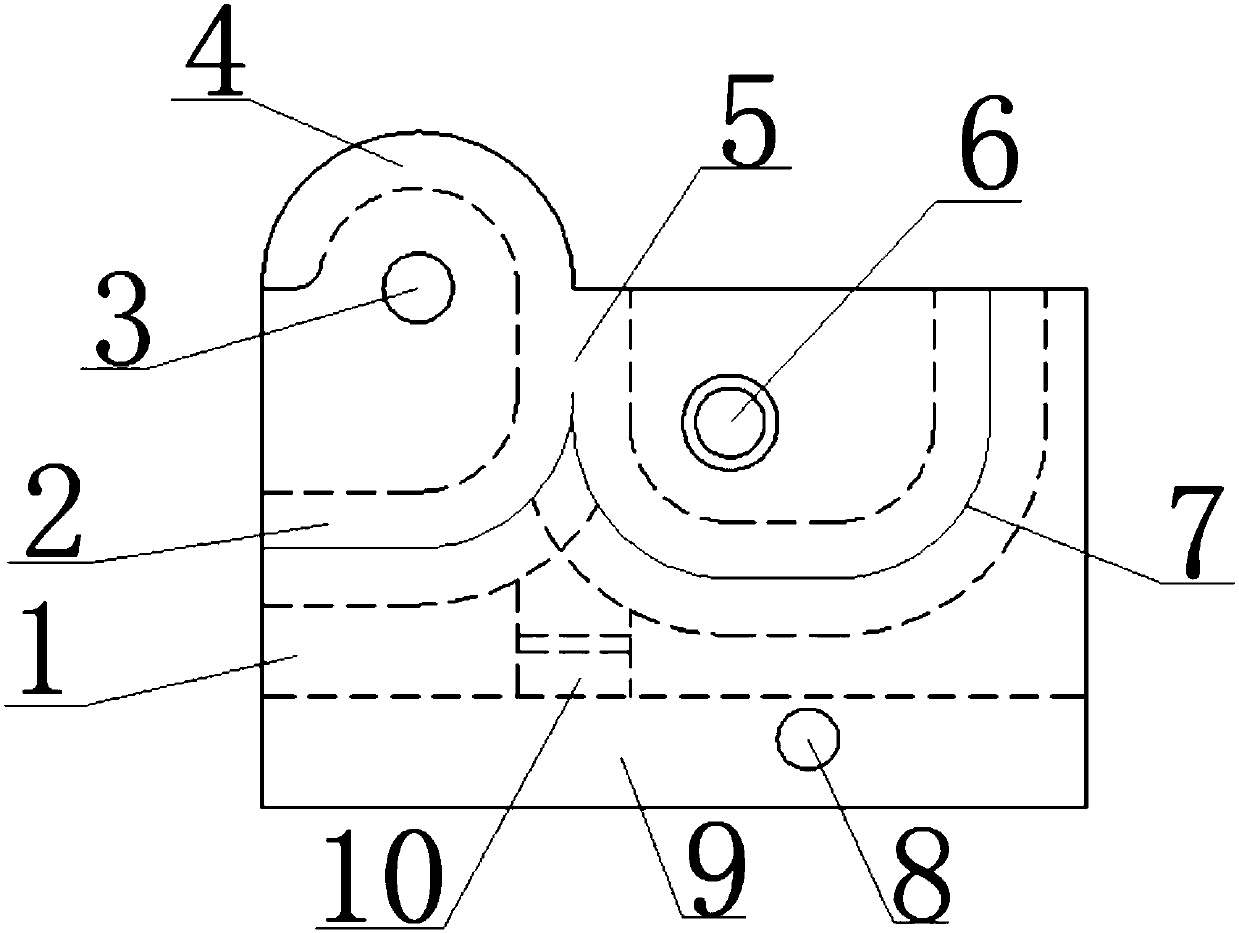

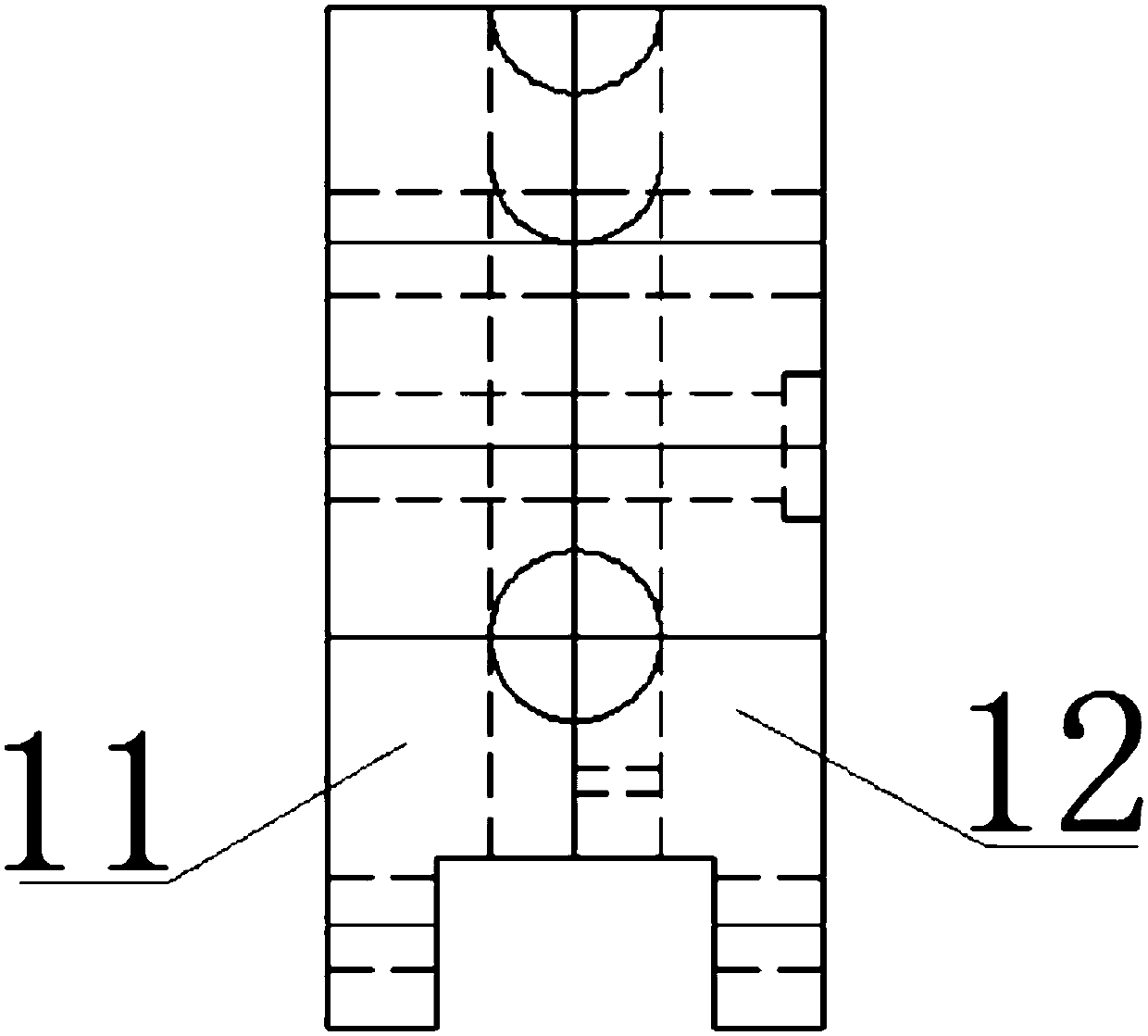

[0040] Such as Figure 1-Figure 3 Shown, a kind of pipe bending mold comprises the upper mold 12 and the lower mold 11 of identical structure and paired up and down;

[0041] The upper mold 12 or the lower mold 11 includes a main body 1, the upper end surface of the main body 1 is concavely formed with an L-shaped elbow cavity 2 and a U-shaped elbow cavity 7, and the bend of the L-shaped elbow cavity 2 and the U-shaped elbow cavity 7 The folds are all arc-shaped, and the L-shaped elbow cavity 2 and the U-shaped elbow cavity 7 are partially overlapped to form a shared elbow cavity 5. The two open ends of the U-shaped elbow cavity 7 are located on the front end of the main body 1. The open end of the shared elbow chamber 5 is any one of the two open ends of the U-shaped elbow chamber 7, one of the open ends of the L-shaped elbow chamber 2 is a shared elbow chamber 5, and the L The other opening end of the curved pipe cavity 2 is located on the left side of the main body 1, and ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com