Mechanical arm fixed block for light blockage coating machine

A technology of robotic arms and fixed blocks, which is applied to robotic arms, devices for coating liquid on the surface, coatings, etc., can solve problems such as pipeline breakage, breakage, and impact on chip quality, and reduce the risk of pipeline damage Possibility, reducing the difference in hardness, reducing the effect of short life

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0019] The present invention will be further described below in conjunction with the accompanying drawings.

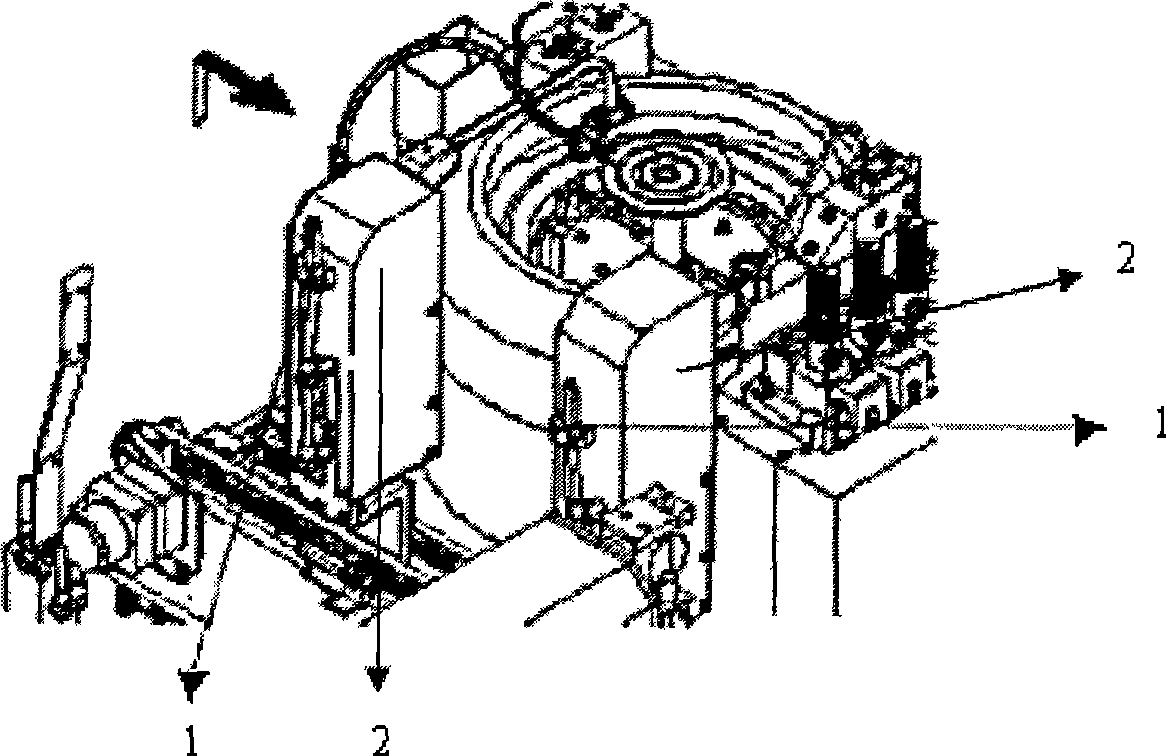

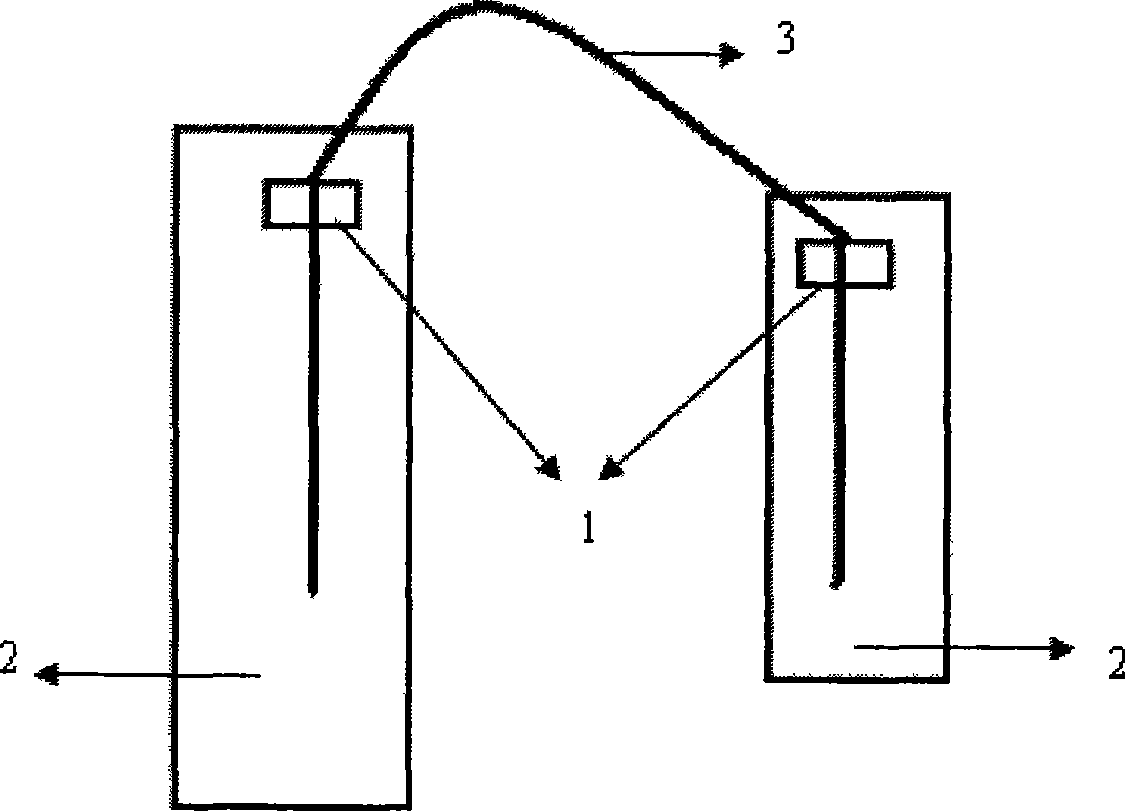

[0020] Such as image 3 As shown, a mechanical arm fixed block 1 for a photoresist coating machine is arranged in the middle of the mechanical arm 2. The outer contour of the fixed block 1 is rectangular in front view, and can also be in any other suitable shape. Here No limitation; the fixed block 1 is arranged at a certain oblique angle relative to the mechanical arm 2, and its longitudinal axis intersects the longitudinal axis of the mechanical arm 2 at an acute angle, so that the fixed block 3 of the pipeline 3 on the two mechanical arms Between the natural bending, not easy to break.

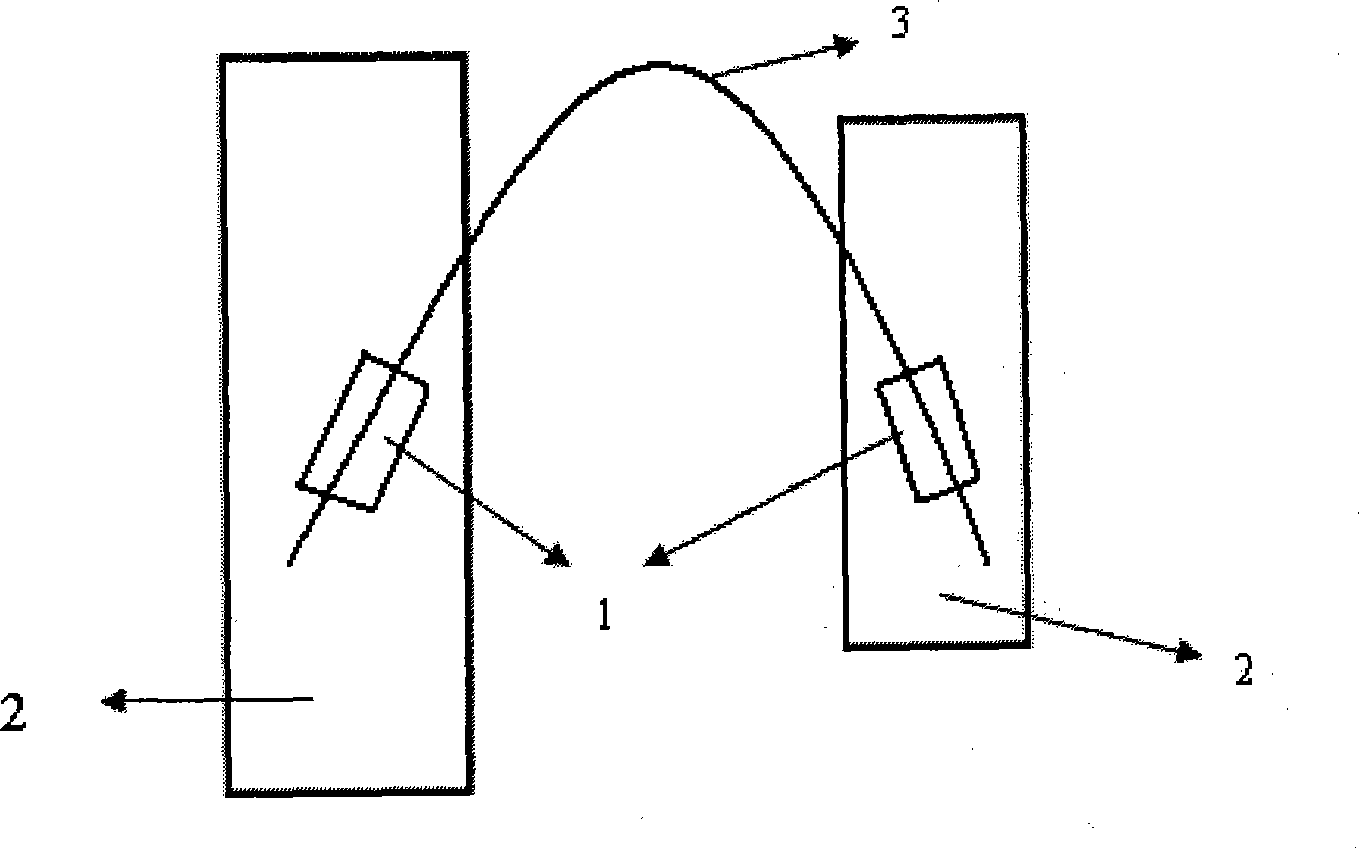

[0021] combine Figure 4 and Figure 5 , the longitudinal and transverse cross-sectional views of a mechanical arm fixing block 1 for a photoresist coating machine of the present invention. The inner wall of the fixed block of the mechanical arm in the present invention is in th...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com