Roller type refrigerator liner double-short-side corner line step-by-step riveting mechanism

A technology of freezer liner and corner line, which is applied in the field of automatic production line of freezer liner, which can solve the problems of low yield rate and achieve the effect of sufficient bending and improved yield rate

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0026] The present invention will be described in further detail below in conjunction with the accompanying drawings.

[0027] Such as Figure 11 shown. Figure 11 It is an upside-down freezer liner, wherein 5991 is a Z-shaped bottom plate, 5992 is a U-shaped large enclosure, and 5993 is a U-shaped small enclosure. U-shaped large coaming plate 5992 and U-shaped small coaming plate 5993 are mutually riveted to form a mouth-shaped coaming plate, and then the mouth-shaped coaming plate is riveted with a Z-shaped bottom plate 5991 to become a refrigerator liner. The step-by-step riveting mechanism for the double short side corners of the inner container of the roller type refrigerator in this embodiment is used for riveting the short side corners 5997 between the Z-shaped bottom plate 5991 and the U-shaped small surrounding board 5993 . There are two short side corner lines 5997.

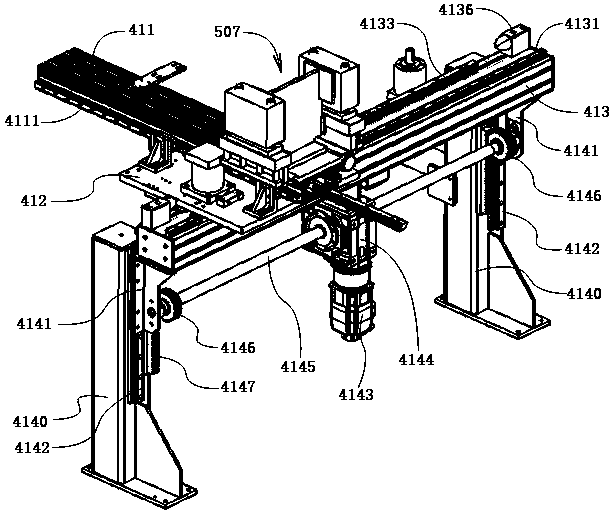

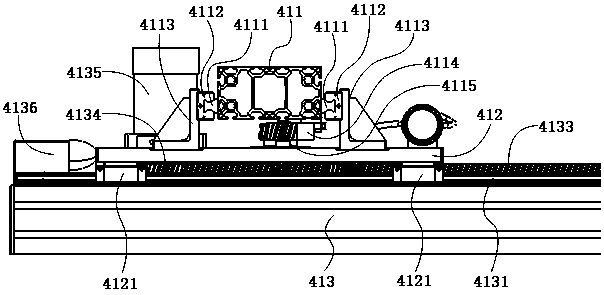

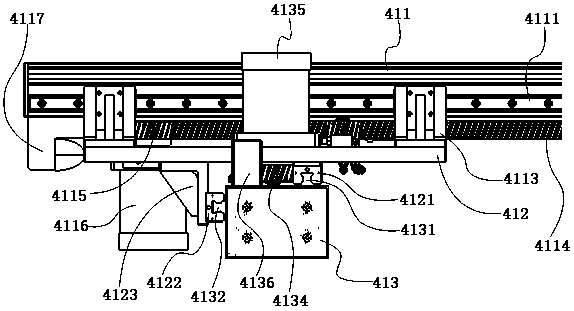

[0028] A step-by-step riveting mechanism for double short side corner lines of a roller-type free...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com