Flexible piezoelectric fiber thin film with high output and preparation method thereof

A flexible piezoelectric and fiber film technology, applied in fiber processing, fiber chemical characteristics, electrospinning, etc., to achieve the effect of increasing the content of piezoelectric phase, increasing piezoelectric output, and easy concentration of force

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

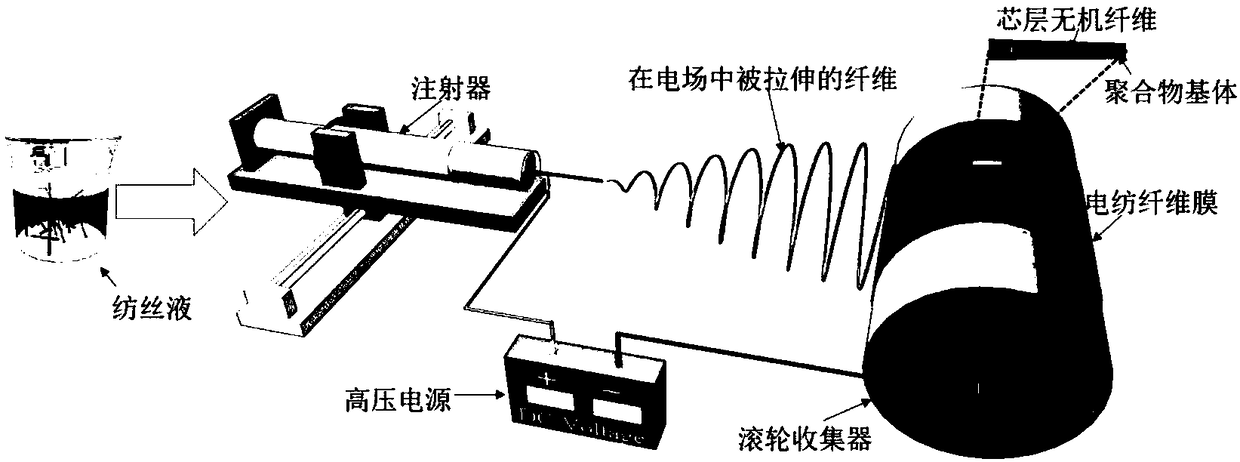

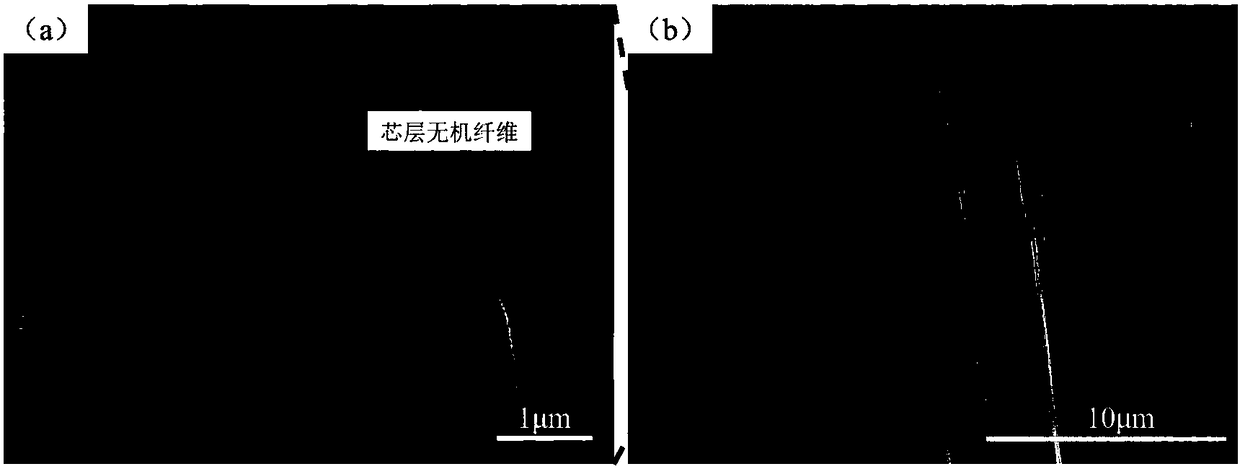

[0027] Weigh 0.159g of surface-modified BT fibers in a beaker, add 3.20g of DMF and 2.13g of acetone, ultrasonically disperse for 1h to form a uniform suspension, slowly add 0.94g of dried P(VDF-TrFE ), heated and stirred at 30°C for 10h until completely dissolved. The obtained spinning solution is placed in a 5mL syringe for electrospinning, and the electrospinning device is as follows: figure 1 As shown, the setting spinning voltage is 15kV, the spinning distance is 15cm, the rotating speed of the roller is 1000rpm, the liquid pushing speed is 0.015ml / min, and a 6# needle is used. After continuous electrospinning for 4 h, the obtained film was dried in a vacuum oven at 40 ° C for 10 h to obtain a BT / P (VDF-TrFE) fiber membrane with a content of 5 vol %. The scanning electron micrograph is shown in figure 2 shown. It can be seen that the fibers obtained by electrospinning are uniform without beads, and the inorganic fibers are completely wrapped in the polymer matrix, form...

Embodiment 2

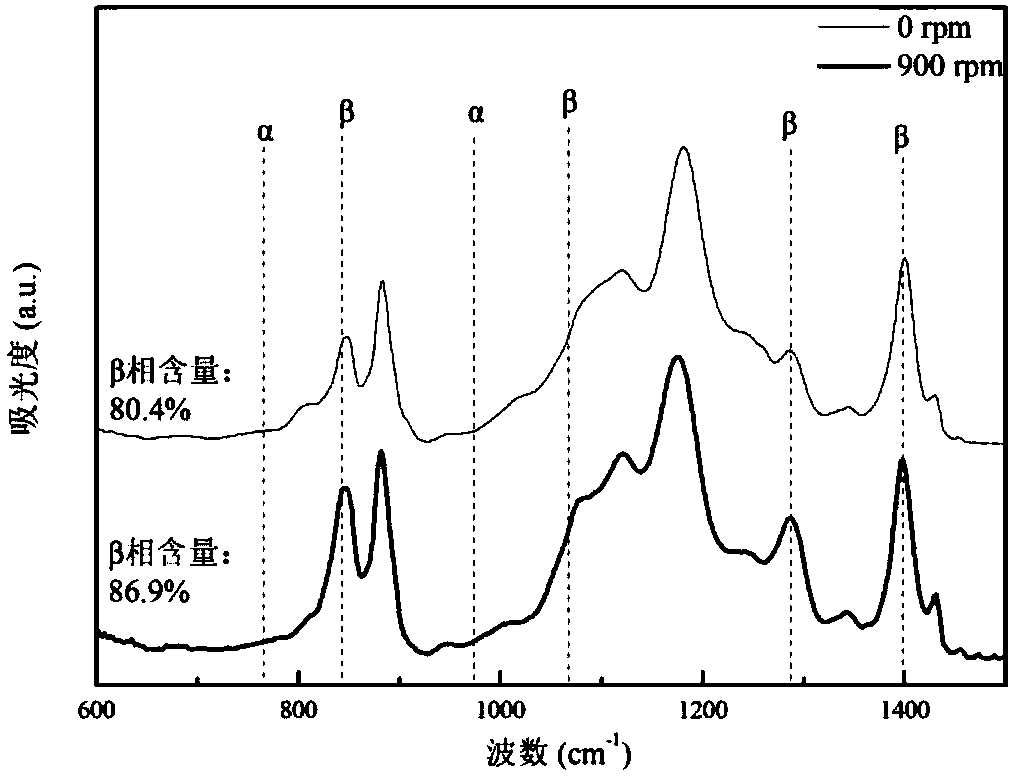

[0029] Weigh 0.318g of surface-modified BT fibers in a beaker, add 6.40g of DMF and 4.26g of acetone, ultrasonically disperse for 1 hour to form a uniform suspension, slowly add 1.88g of dried P(VDF-TrFE ), heated and stirred at 30°C for 10h until completely dissolved. The obtained spinning solution is placed in a 10mL syringe for electrospinning, and the electrospinning device is as follows: figure 1 As shown, the spinning voltage is set to be 15kV, the spinning distance is 15cm, the rotating speed of the roller is 0 and 900rpm respectively, the liquid pushing speed is 0.20ml / min, and a 7# needle is used. After continuous electrospinning for 5 h, the obtained film was dried in a vacuum oven at 40 °C for 20 h to obtain a BT / P (VDF-TrFE) fiber membrane. image 3is the infrared absorption spectrum of the BT / P (VDF-TrFE) fiber membrane when the rotating speed of the roller is 0 and 900 rpm, and the β phase content is 80.4% and 86.9%, respectively. The high rotational speed of t...

Embodiment 3

[0031] Weigh 0.191g of dopamine-modified PZT nanofibers in a beaker, add 3.20g of DMF and 2.13g of acetone, ultrasonically disperse for 1h to become a uniform suspension, add 0.94g of dried P(VDF-TrFE) , heated and stirred at 30°C for 10h until completely dissolved. The obtained spinning solution is placed in a 5mL syringe for electrospinning, and the electrospinning device is as follows: figure 1 As shown, the setting spinning voltage is 12.5kV, the spinning distance is 15cm, the rotating speed of the roller is 1500rpm, the liquid pushing speed is 0.12ml / min, and a 6# needle is used. The film obtained by continuous electrospinning for 4 hours was dried in a vacuum oven at 40°C for 10 hours to obtain a 5vol% PZT / P(VDF-TrFE) fiber film. The obtained film is carried out infrared test, the result is as follows: Figure 4 As shown, the β-phase contents of pure P(VDF-TrFE) and PZT / P(VDF-TrFE) fiber membranes were 86.9% and 91.3%, respectively. The addition of PZT as a nucleatin...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Diameter | aaaaa | aaaaa |

| Total thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com