Full-biodegradable high-barrier PLA/PBAT composite packaging film

A composite packaging film, high-barrier technology, applied in the field of packaging materials, can solve problems such as poor barrier properties, and achieve the effects of improving the performance of blocking oxygen, reducing the permeation area, and promoting the performance of blocking water vapor.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

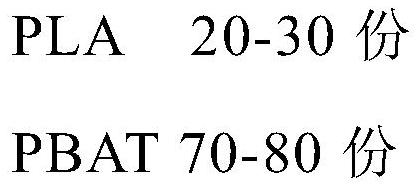

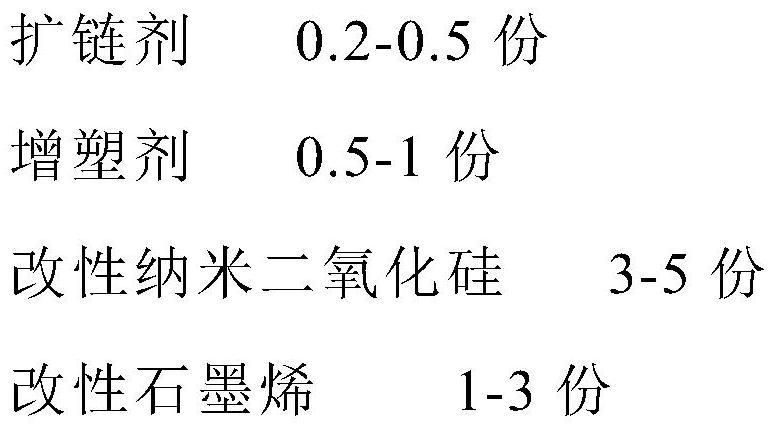

[0047]Nanoparticle-modified high-barrier PLA / PBAT composite packaging film, in parts by mass, includes the following components:

[0048] PLA 20 parts

[0049] 80 copies of PBAT

[0050] Chain extender 0.2 parts

[0051] Plasticizer 0.5 parts

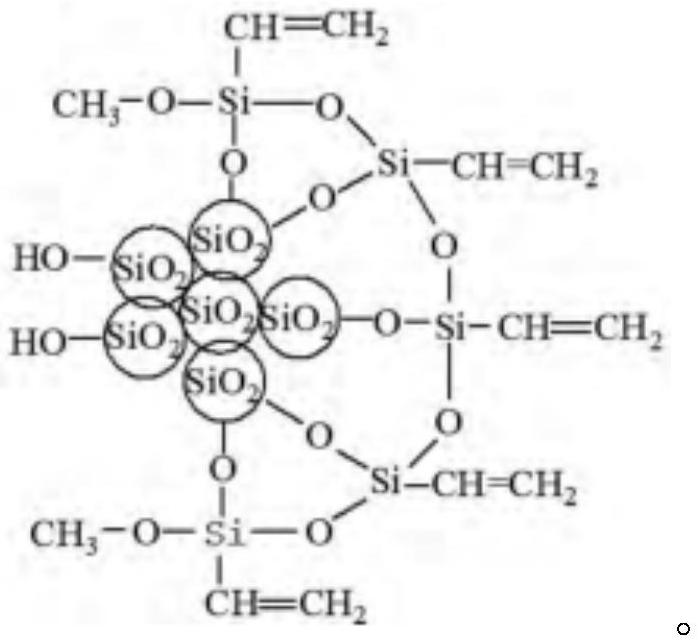

[0052] Modified nano silicon dioxide 3 parts

[0053] Modified graphene 1 part

Embodiment 2

[0055] Nanoparticle-modified high-barrier PLA / PBAT composite packaging film, in parts by mass, includes the following components:

[0056] PLA 30 parts

[0057] PBAT 70 copies

[0058] Chain extender 0.5 parts

[0059] 1 part plasticizer

[0060] Modified nano silicon dioxide 5 parts

[0061] Modified graphene 3 parts

Embodiment 3

[0063] Nanoparticle-modified high-barrier PLA / PBAT composite packaging film, in parts by mass, includes the following components:

[0064] PLA 25 parts

[0065] PBAT 75 copies

[0066] Chain extender 0.3 parts

[0067] 1 part plasticizer

[0068] Modified nano silicon dioxide 4 parts

[0069] Modified graphene 2 parts

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle diameter | aaaaa | aaaaa |

| particle diameter | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com