Patents

Literature

30results about How to "There will be no uneven distribution" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

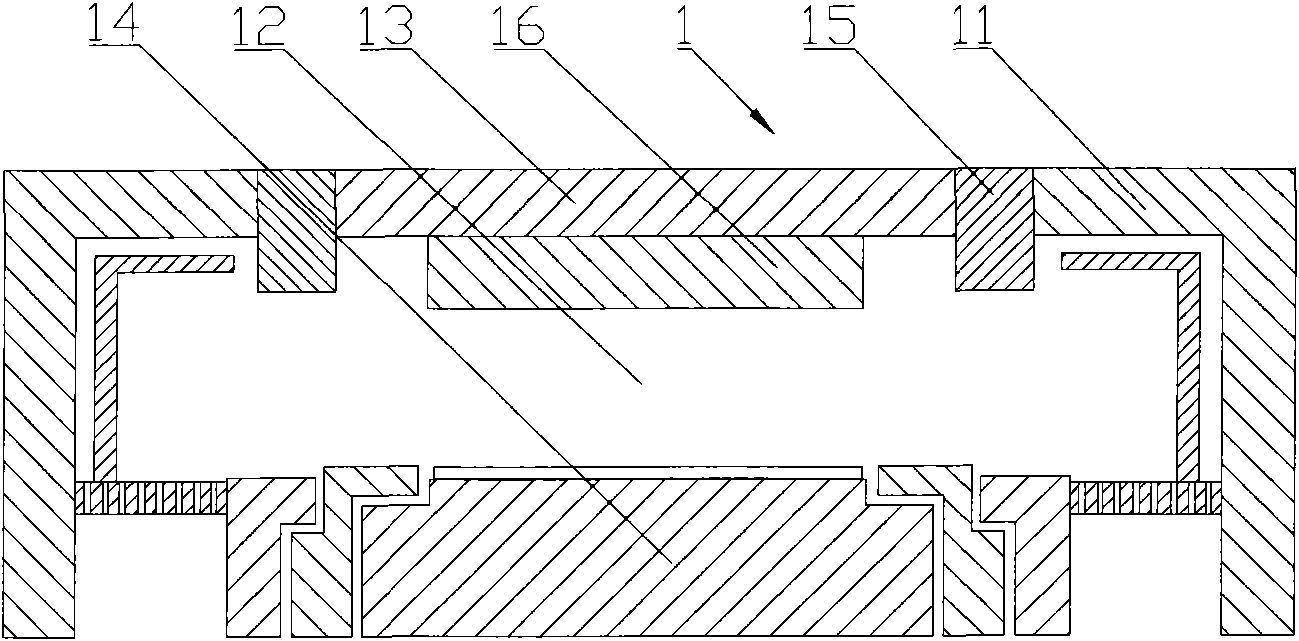

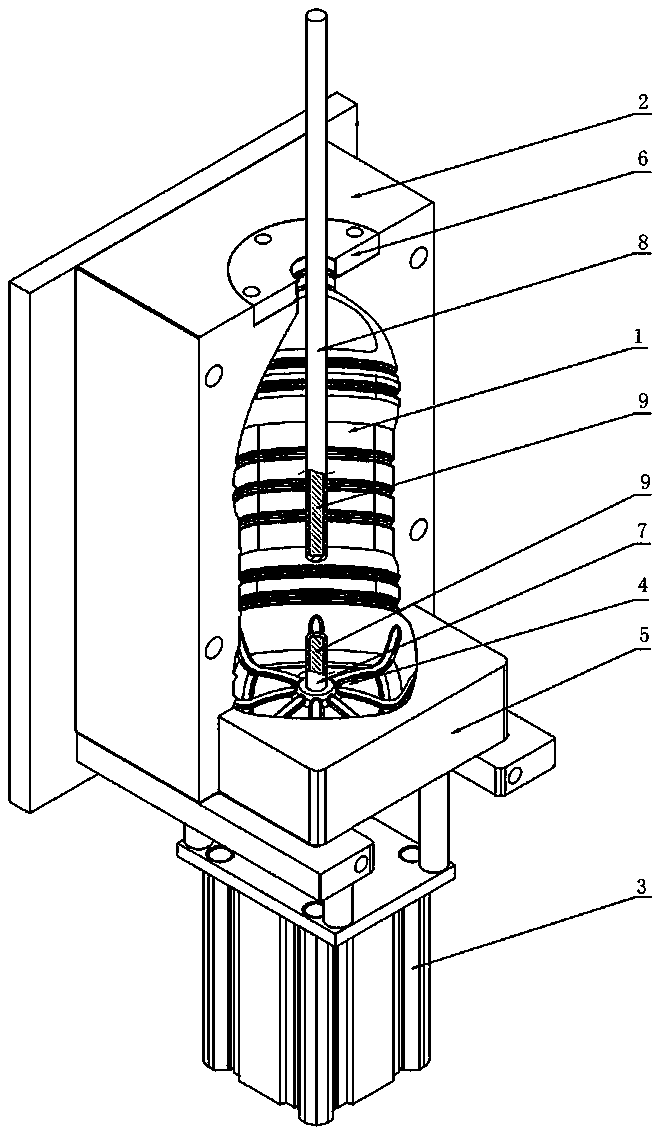

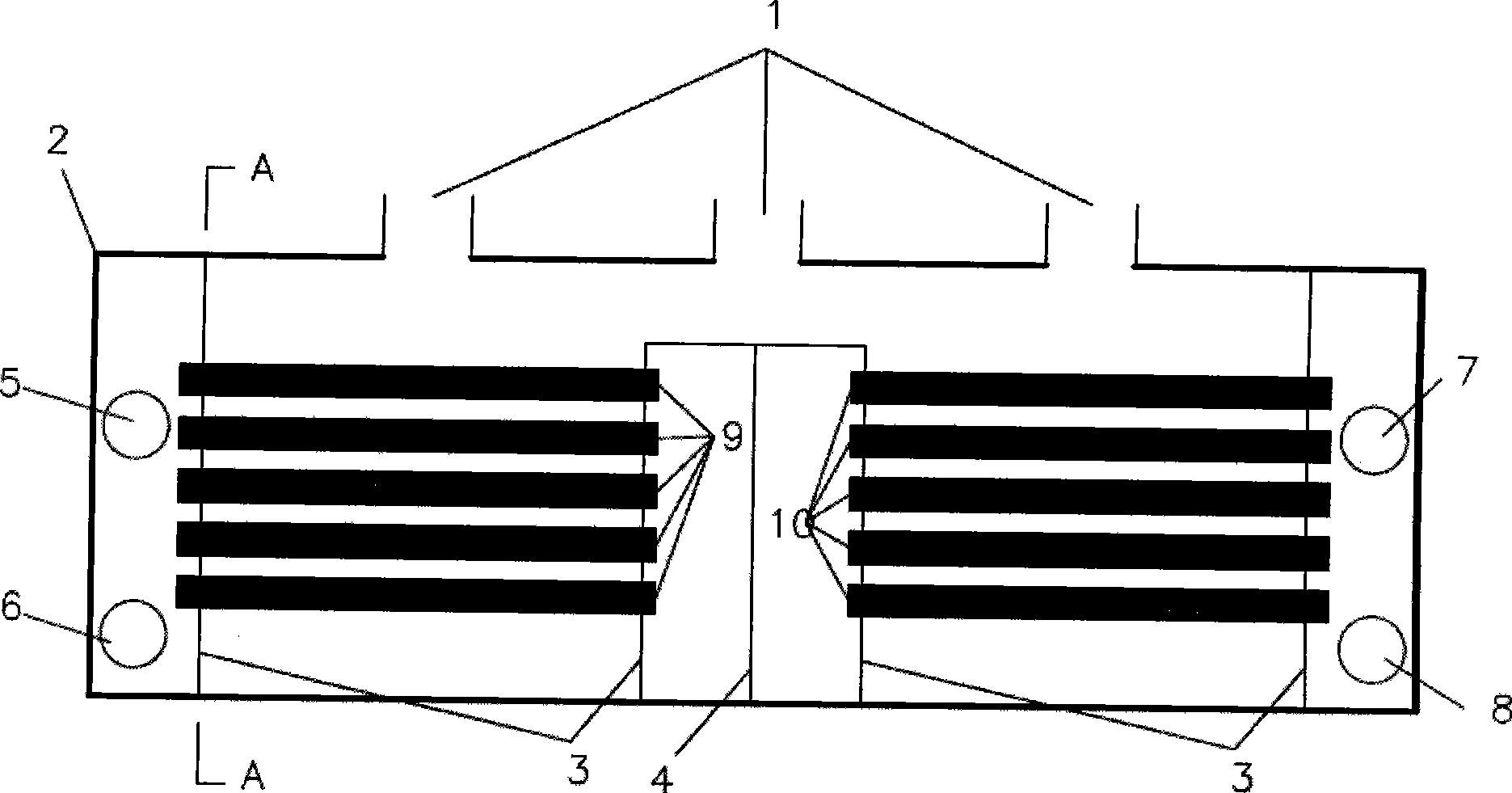

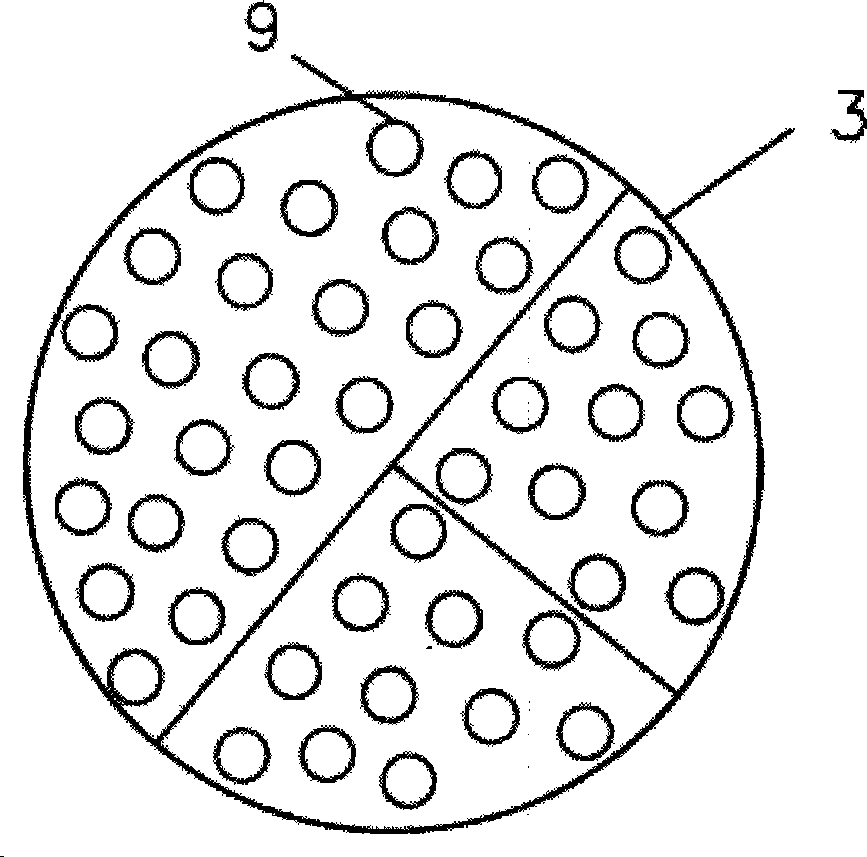

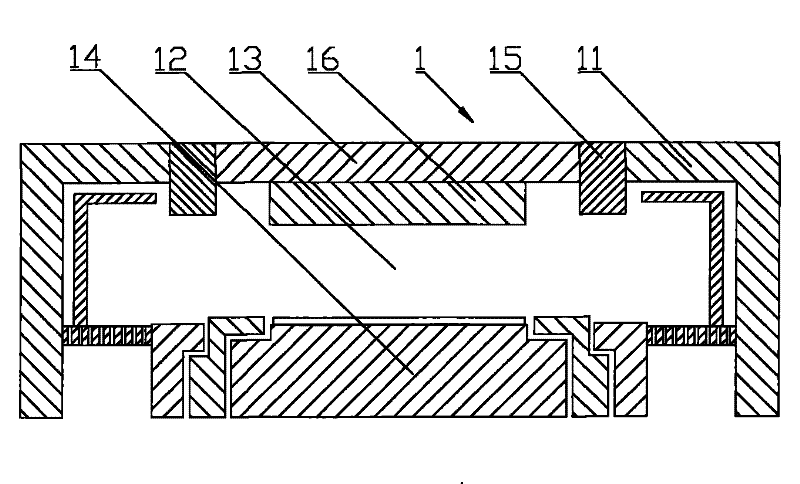

Plasma process equipment and gas distribution device thereof

ActiveCN101770933AImprove uniformityThere will be no uneven distributionElectric discharge tubesSemiconductor/solid-state device manufacturingProcess equipmentProduct gas

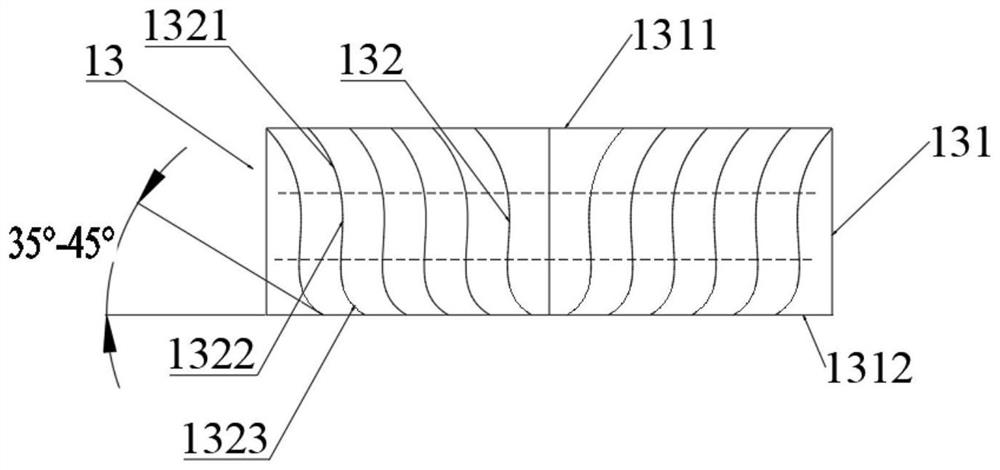

The invention discloses a gas distribution device. A plurality of first and second gas transmission channels are arranged alternately at the top of a gas distribution plate, and the gas flow directions in the first and second gas transmission channels are opposite; a plurality of gas feeding holes are arranged at the bottoms of the first and second gas transmission channels. In the first gas transmission channels, the gasflow flowing out from the gas feeding holes adjacent to the gas inlet end is greater while the gasflow flowing out from the gas feeding holes adjacent to the closed end is smaller; in the second gas transmission channels, the contrary is the case. Because the first and second gas transmission channels are arranged alternately, the total amounts of the gas fed from the plurality of adjacent gas feeding holes are substantially equal, and gas is distributed uniformly in the radial direction of the reaction chamber. The gas distribution device has the advantages of simple structure, convenient machining and low cost and ensures that the gas is distributed uniformly in the radial direction of the reaction chamber.

Owner:BEIJING NAURA MICROELECTRONICS EQUIP CO LTD

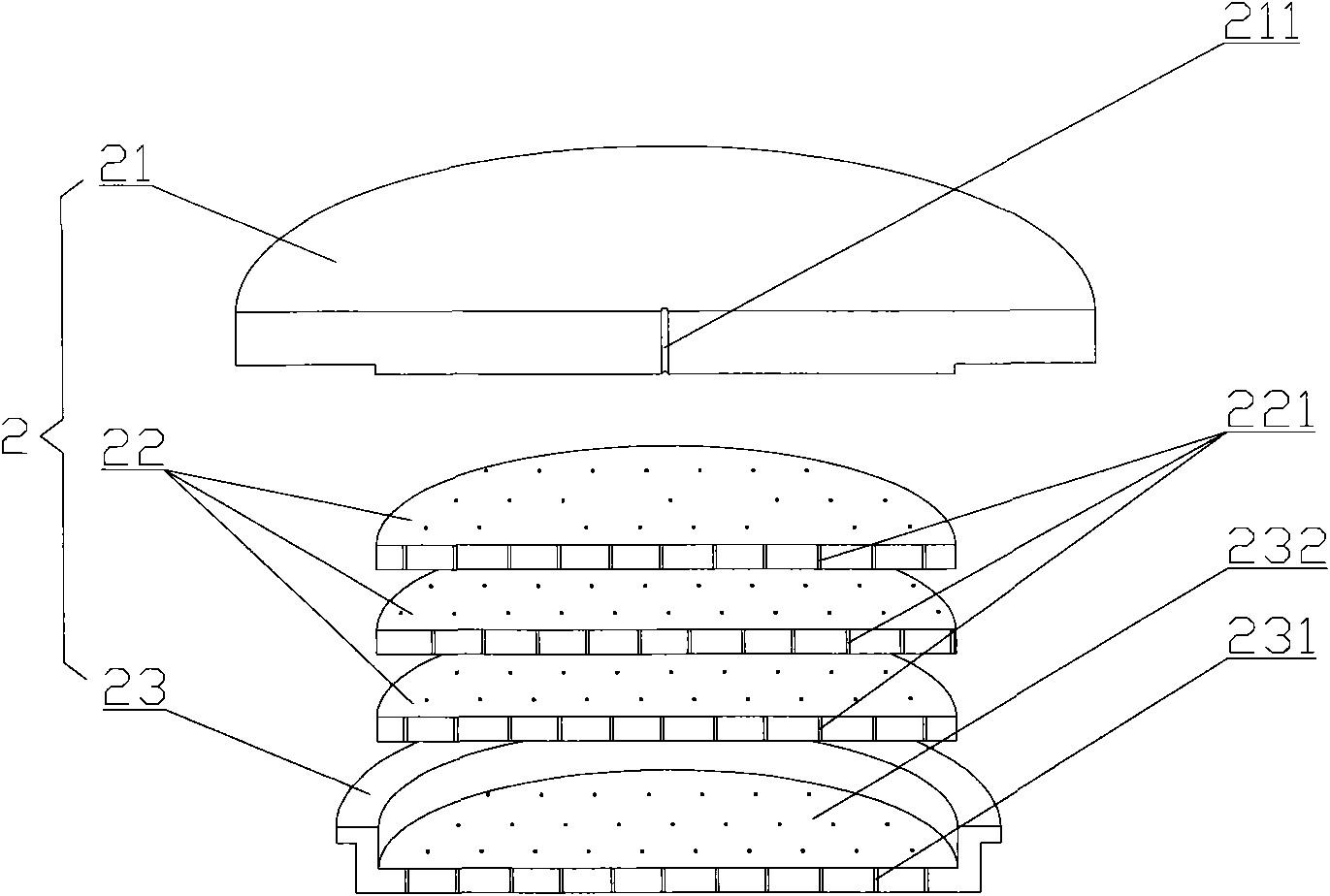

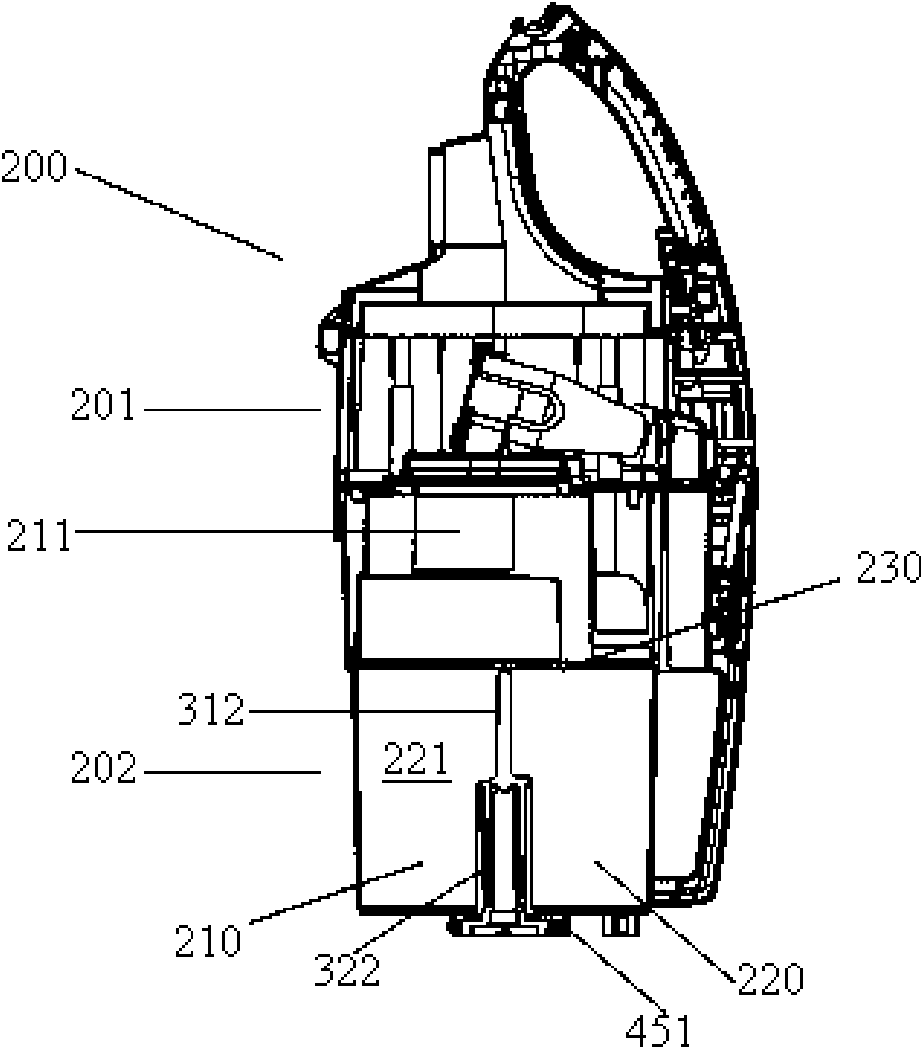

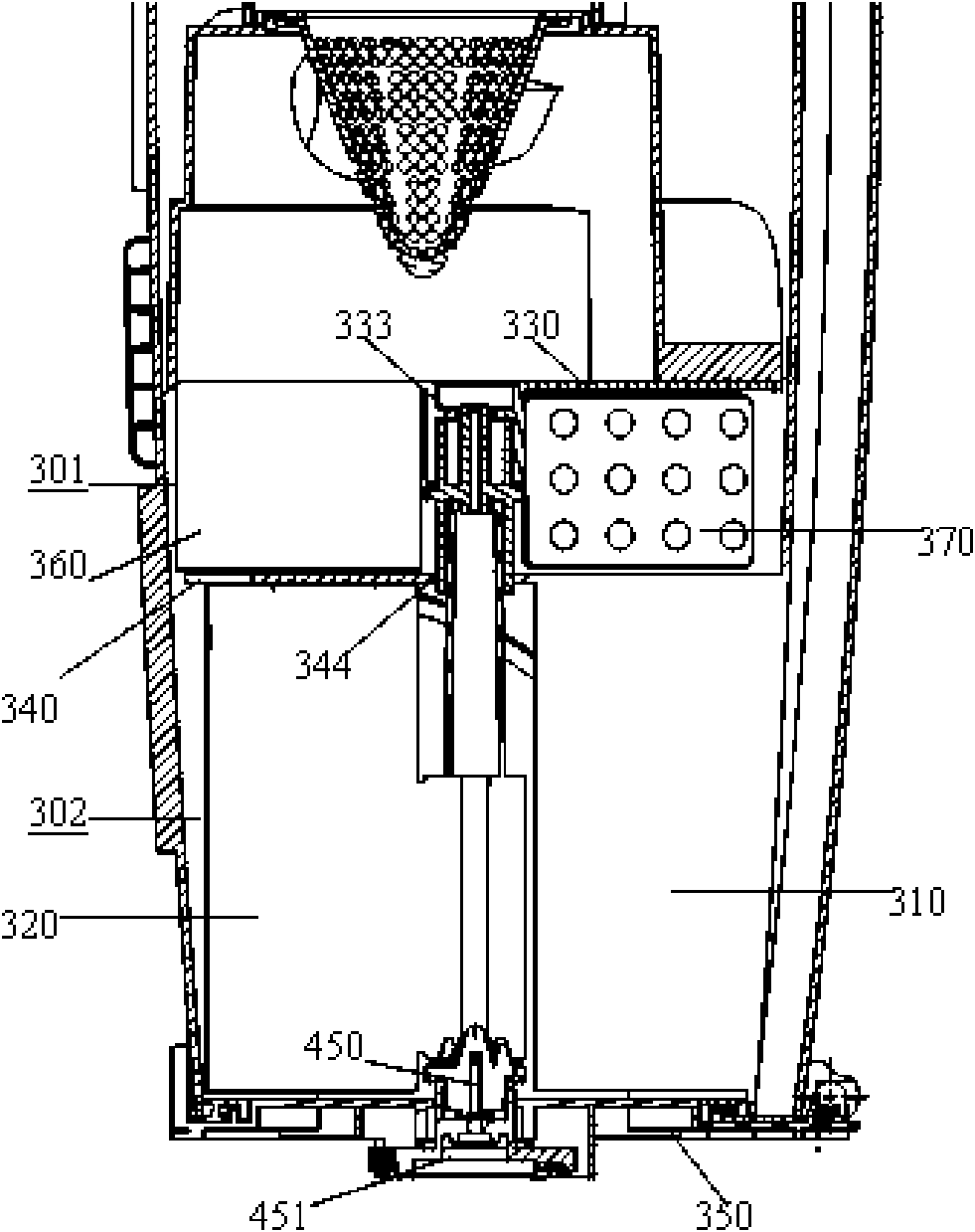

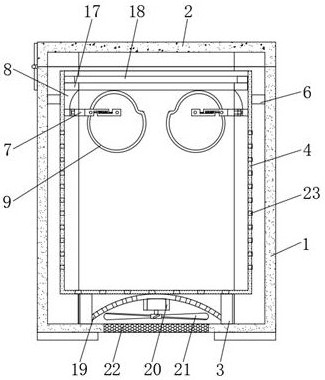

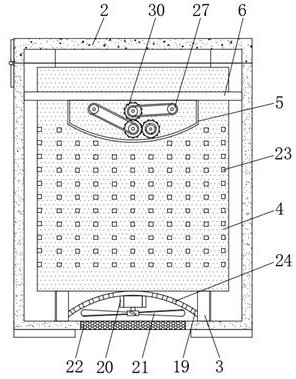

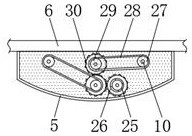

Dust barrel with double dust compressing function

InactiveCN101961227AImprove compression efficiencyThere will be no uneven distributionSuction filtersEngineeringGear wheel

The invention discloses a dust barrel with a double dust compressing function, comprising compression cavities and a bottom cover, wherein the center of the bottom cover is provided with a driven gear wheel and a connecting head, a partition plate is arranged in the dust barrel and used for dividing the dust barrel into an upper-layer compression cavity and a lower-layer compression cavity, an upper movable compression plate and an upper fixed compression plate are arranged in the upper-layer compression cavity, the upper movable compression plate is rotatablely fixed on the upper partition plate, and the upper fixed compression plate is fixedly connected with the upper partition plate; a lower movable compression plate and a lower fixed compression plate are arranged in the lower-layer compression cavity, the upper end of a rotating shaft of the lower movable compression plate is fixedly connected with a rotating shaft of the upper movable compression plate, the lower end of the rotating shaft is engaged with the connecting head, and the lower fixed compression plate is fixedly connected with the partition plate. The dust barrel realizes twice compression of dust and improves compression efficiency.

Owner:LG ELECTRONICS (TIANJIN) APPLIANCES CO LTD

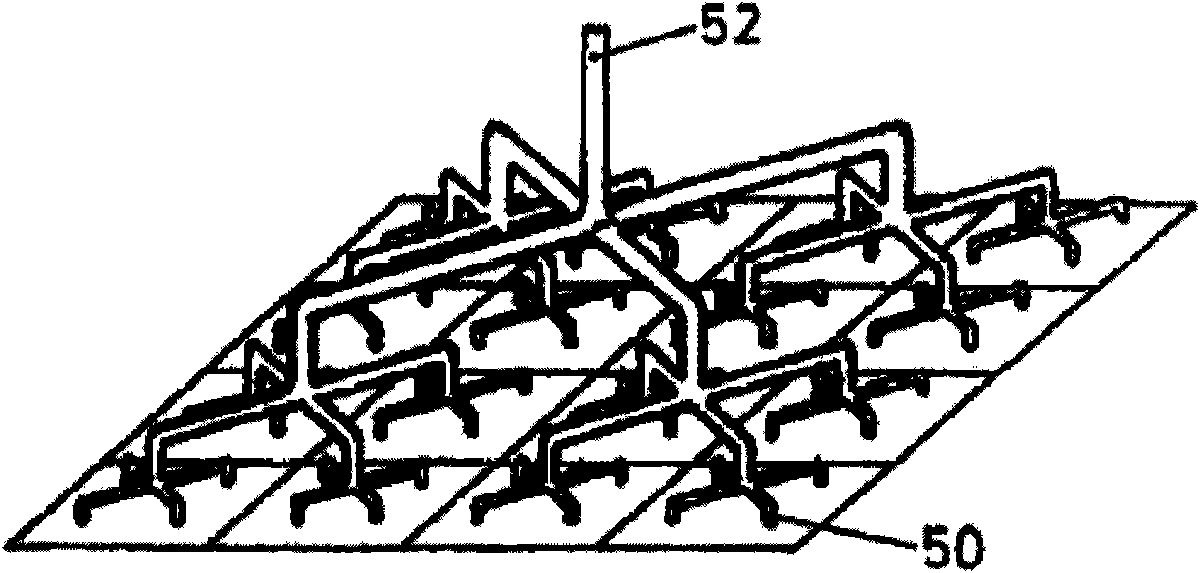

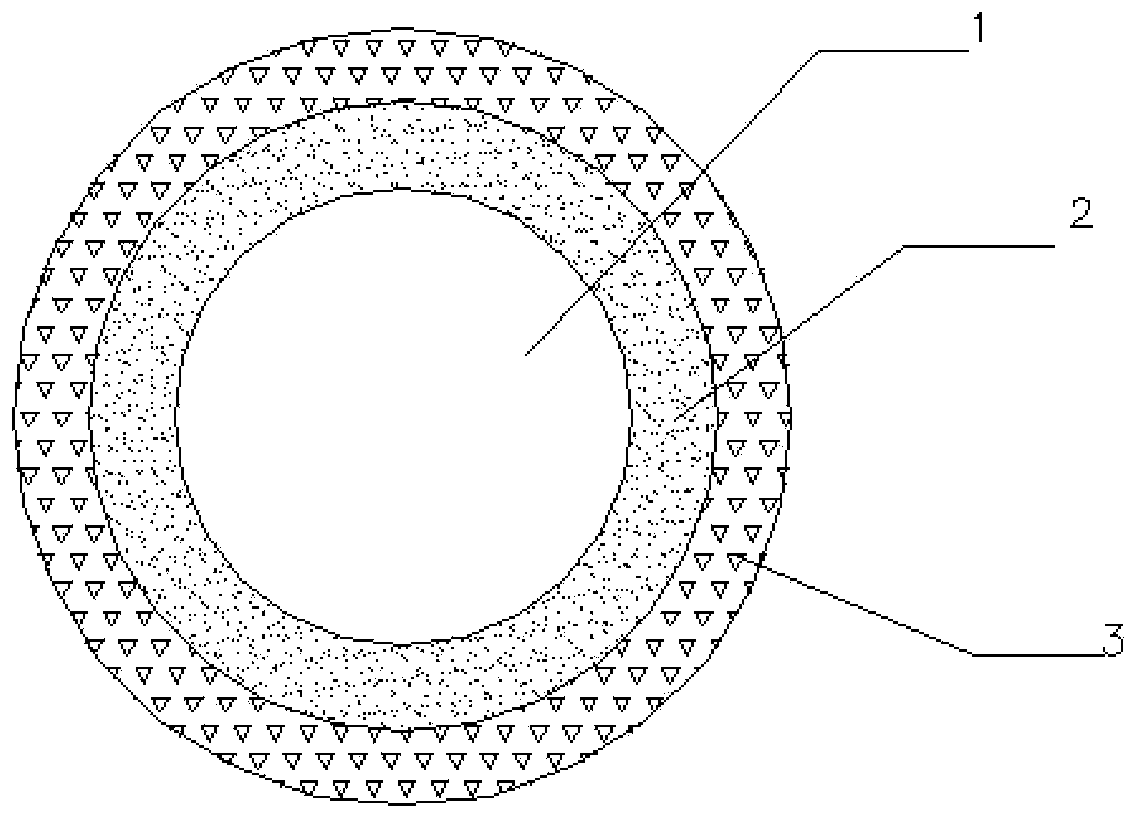

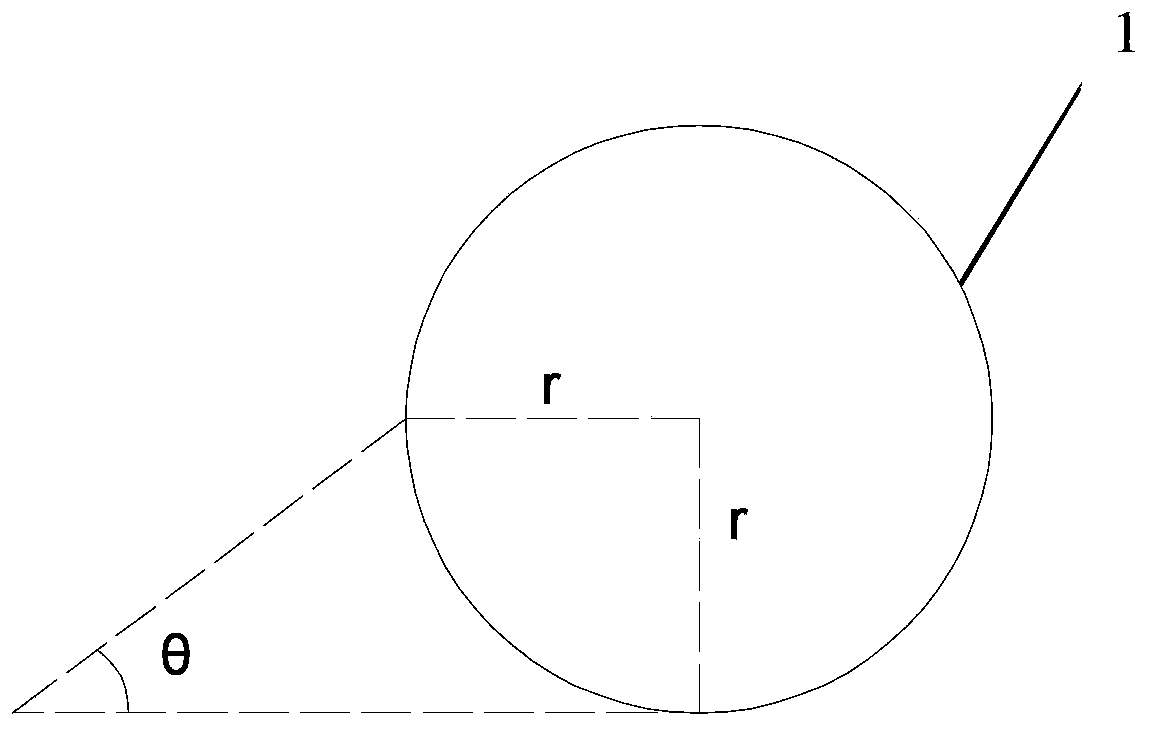

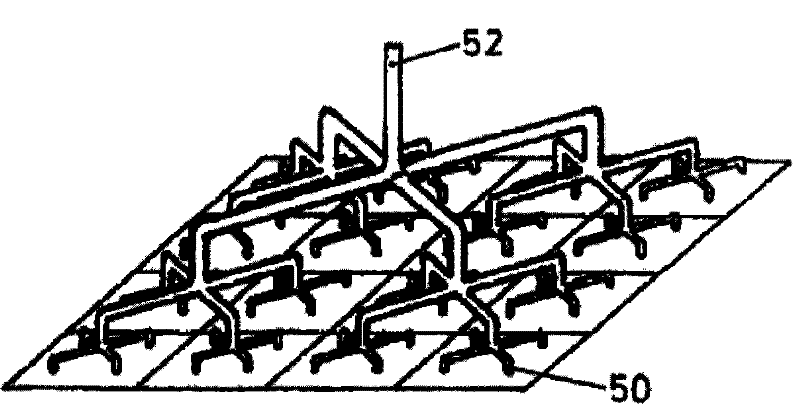

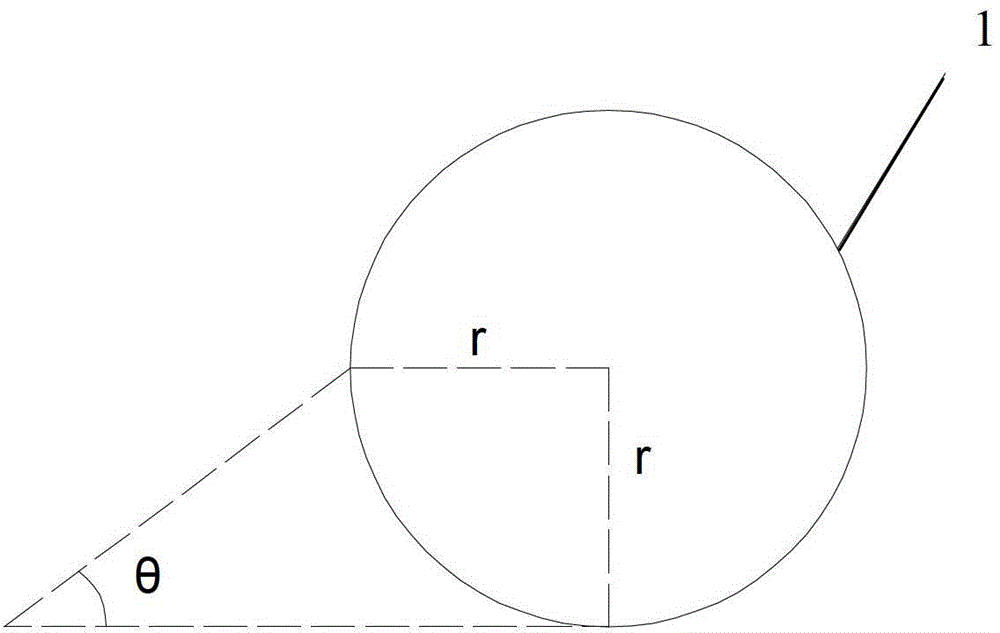

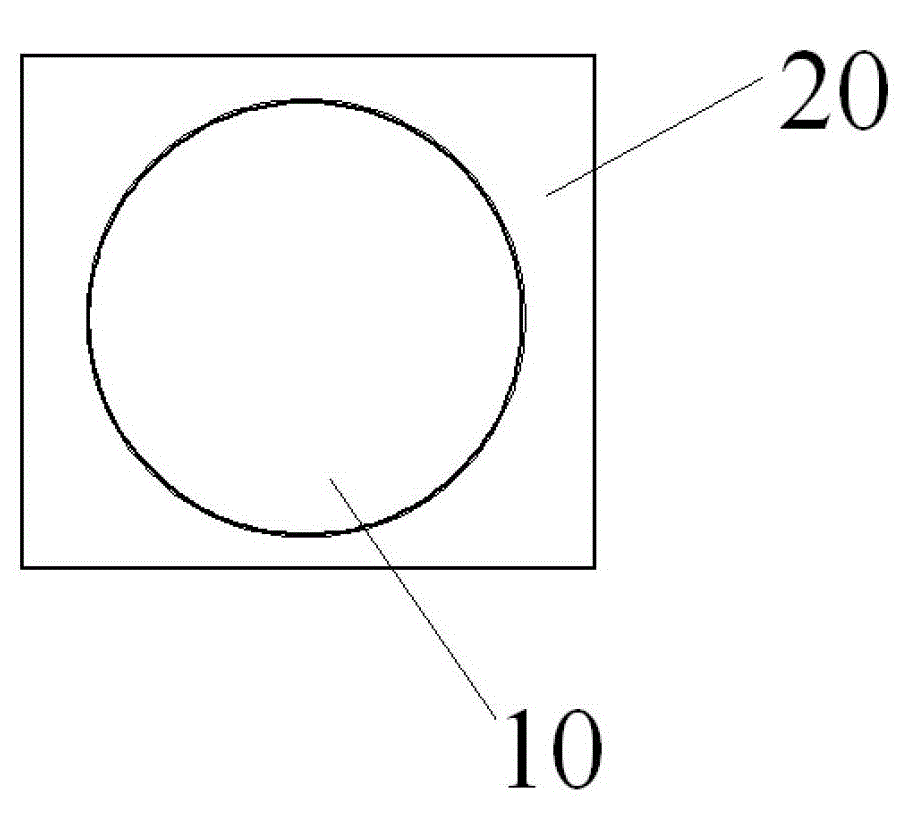

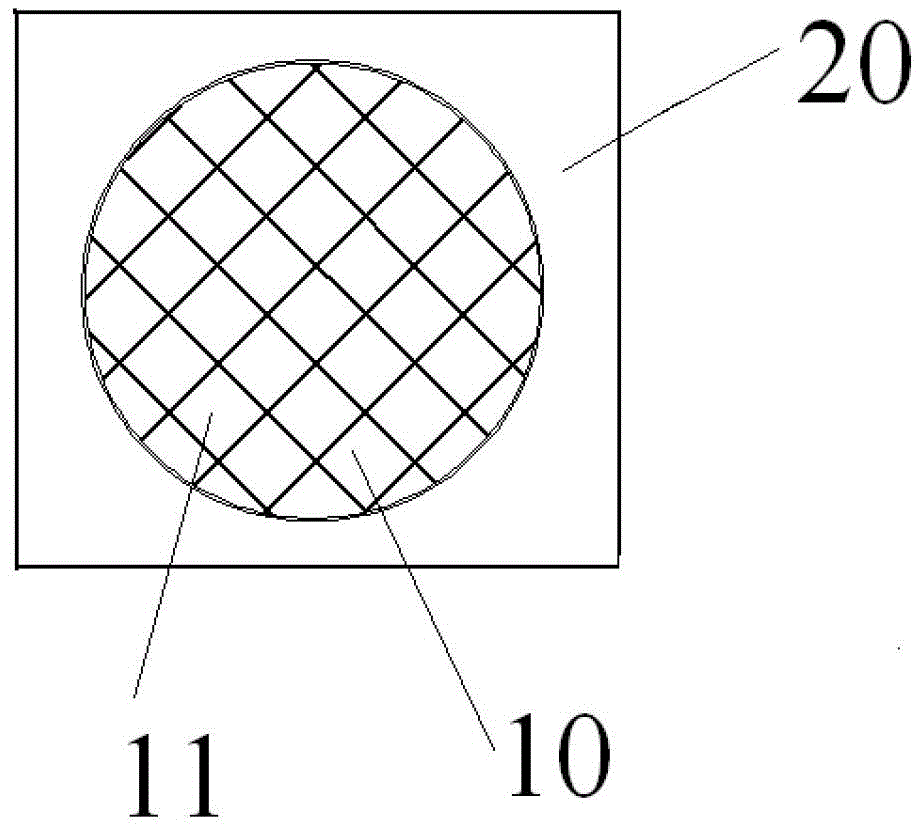

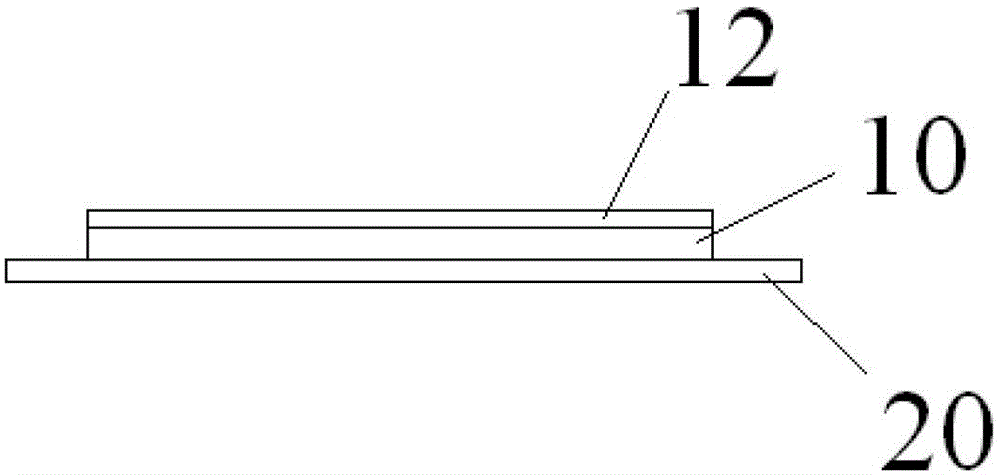

Material distribution technology of one-time forming brazing super-hard material grinding tool

ActiveCN103522206AGood effectSimple and fast operationBonded abrasive wheelsGrinding devicesWear particleMetallurgy

The invention discloses a material distribution technology of a one-time forming brazing super-hard material grinding tool. The material distribution technology includes the following steps that firstly, composite pellets are prepared for standby application, the peripheries of abrasive particles are coated with solder layers to form a composite body, and the periphery of the composite body is coated with a paraffin layer to form composite pellets; secondly, the surface of a base body is cleaned; thirdly, a material distribution area of the surface of the base body is brushed and coated with binding agents; fourthly, the composite pellets are spread in the material distribution area, obtained in the third step, of the surface of the base body, the composite pellets are tightly distributed and stuck to the material distribution area of the surface of the base body so that semi-finished products can be obtained; fifthly, the surfaces of the semi-finished products are cleaned, and the semi-finished products are prepared to be welded. According to the material distribution technology of the one-time forming brazing super-hard material grinding tool, due to the fact that the abrasive particles and solder are matched according to a certain relation and made into the composite body according to a particle preparing technology, a layer of paraffin coats the outer face of the composite body to form the composite pellets, and therefore the material distribution technology is greatly simplified; use of material distribution equipment is combined, stability of the quality of brazing is ensured, and industrial production operation is facilitated. According to the designed scheme, adaptability to workpieces is good, the brazing quality is stable, and the material distribution technology is suitable for industrial production.

Owner:广东省电力线路器材厂有限公司

Composite carex baccans nees soup formula and processing method of composite carex baccans nees soup

InactiveCN104872517AGuaranteed contentThere will be no uneven distributionFood ingredient functionsFood preparationCoixAdditive ingredient

The invention relates to a composite carex baccans nees soup formula and a processing method of the composite carex baccans nees soup. The composite carex baccans nees soup comprises the following raw materials: carex baccans nees, sticky rice, red jujubes, sesames, red beans, Chinese yam, ginkgo, coix seeds and tuckahoe; the composite carex baccans nees soup has the efficacies on replenishing blood, tonifying Qi, tonifying spleen, nourishing stomach, promoting the secretion of saliva or body fluid, benefiting lung, enriching yin, nourishing kidney, eliminating edema and dropsy, strengthening brain, soothing nerves, promoting sleepness, stabilizing blood level, blood fat and blood pressure, maintaining beauty, keeping young, regulating diet balance, promoting human immunity and building body. The composite carex baccans nees soup is of a soup type, can be absorbed and digested easily, and is particularly suitable for being eaten by the aged, women, children and the like; the raw materials are subjected to winnowing and screening, the high-quality raw materials can be selected out, and the quality of the finished product is ensured; and furthermore, the baking step adopts the low-temperature baking process, the whole baking temperature is not more than 90 DEG C, the contents of nutritional ingredients in the raw materials can be ensured under a condition that moisture in the raw material is eliminated.

Owner:ZUNYI JUNHUIYUAN FOOD ENG

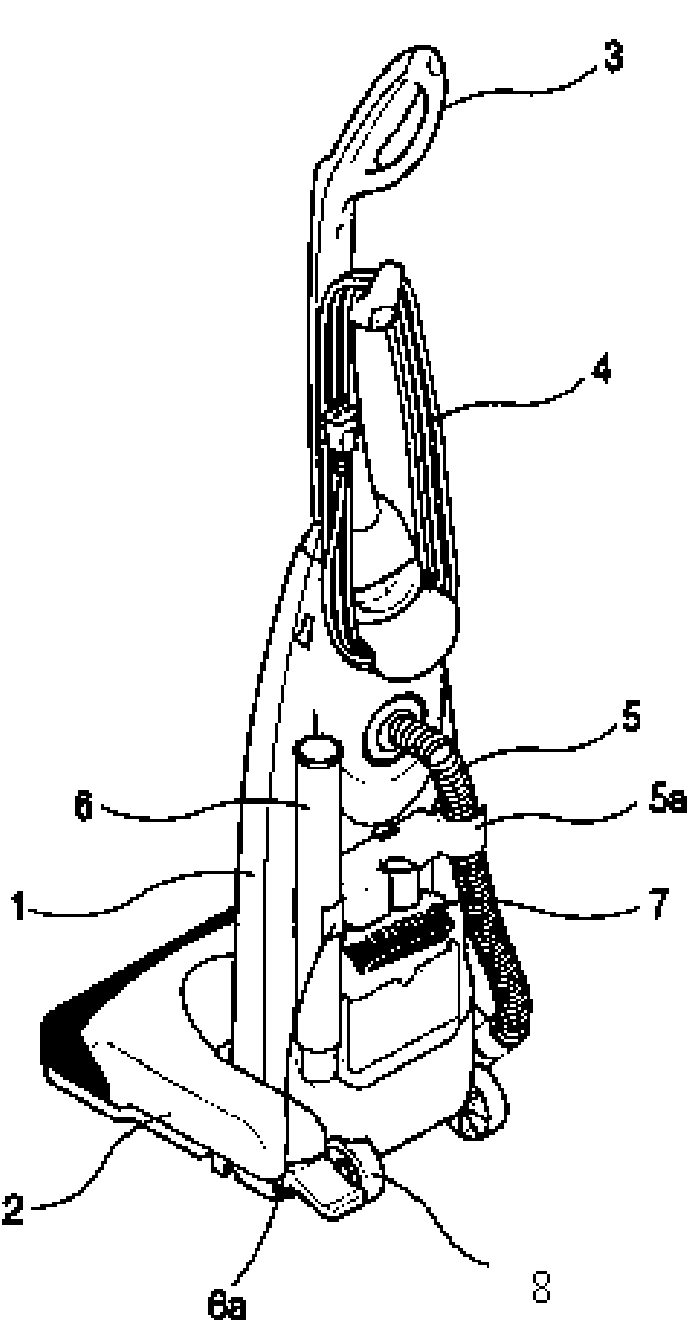

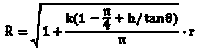

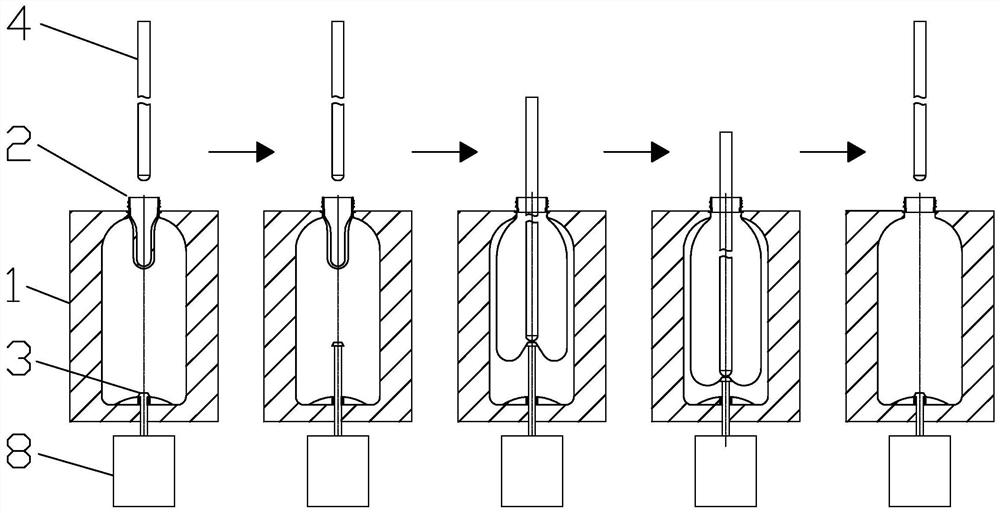

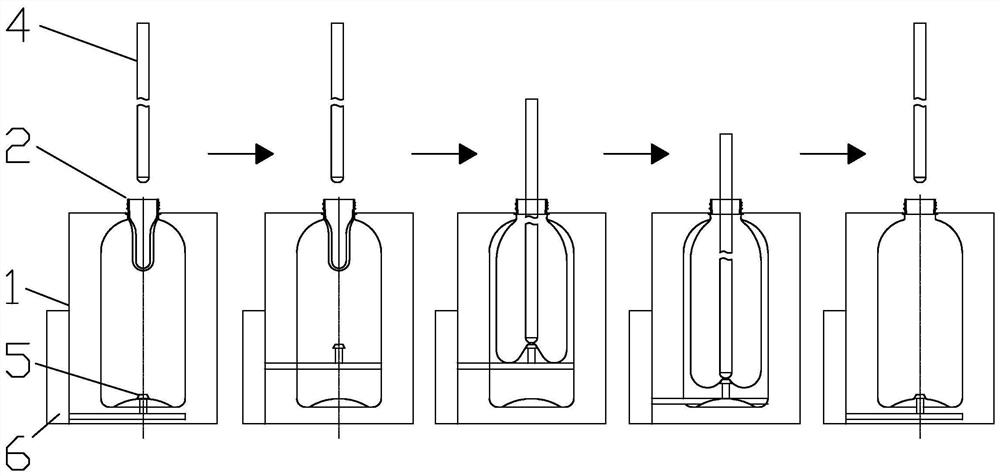

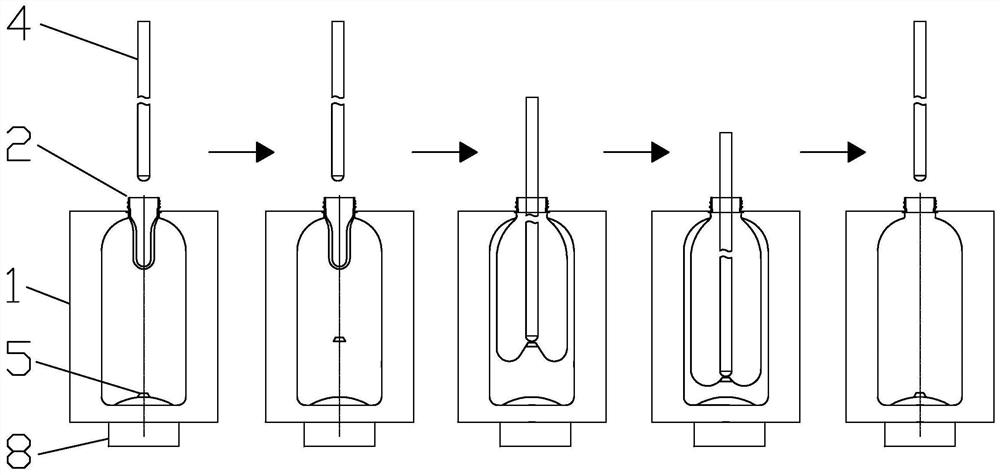

Blow molding mold and method equipped with heating stretching system

PendingCN110303664AFully stretchedUniform wall thicknessBlowing machine gearingsBlow headsBlow moldingBottle

The invention discloses a blow molding mold equipped with a heating stretching system. The blow molding mold equipped with the heating stretching system comprises a front mold and a rear mold which form a mold cavity in an encircling mode, a bottom mold located at the bottom of the mold cavity, a bottom mold plate used for installing the bottom mold and a stretching rod stretched from the top of the mold cavity into the mold cavity, wherein a bearing mechanism is arranged in the mold cavity, the bearing mechanism comprises a bearing rod and a drive mechanism which drives the bearing rod to stretch into the middle of the mold cavity, and heating elements are arranged in the stretching rod and / or the bearing rod. According to the blow molding mold equipped with the heating stretching system,the heating elements are arranged in the stretching rod and / or the bearing rod, and when a bottle is blown, temperature of the stretching rod and the bearing rod is approximate to temperature of a bottle blank, situations of early cooling and the like cannot occur, and materials at the bottom of the bottle blank are fully stretched, uniformly distributed at the bottom of the bottle, and cooled and shaped well. Due to the fact that the materials are fully stretched, not only is inner stress at the bottom of the bottle reduced, but also a bursting probability is reduced.

Owner:GUANG DONG XING LIAN PRECISE MACHINERY

Low temperature multiple-effect seawater last effect evaporator and working method thereof

InactiveCN101503225AReduce the burden onThere will be no uneven distributionGeneral water supply conservationSeawater treatmentDesalinationFresh water

The invention relates to a low temperature multiple effect seawater desalination final-effect condenser, which is characterized in that the condenser comprises a shell, a feeding seawater heat exchange tube, a cooling water heat exchange tube, a tube plate and an intermediate diaphragm; the working procedure thereof is as follows: (1) a final-effect secondary steam enters into the shell pass of the shell of the final-effect condenser from an inlet; (2) feeding sea water enters into the tube pass of the feeding seawater heat exchange tube from a feeding seawater inlet and is discharged from a feeding seawater outlet after being preheated; (4) steam is controlled by quantity of water and water temperature in the two heat exchange tubes and is freely distributed; (5) the feeding seawater in the tube pass of the feeding seawater heat exchange tube and the cooling water in the cooling water heat exchange tube are respectively warmed by the steam of the shell pass, and simultaneously the steam in the shell pass is condensed into the fresh water. The condenser simplifies the equipment layout, pipeline design and reduces the cost.

Owner:滨海环保装备(天津)有限公司

Preparation method of long-acting p-phenylenediamine anti-aging agent

InactiveCN108586811AExcellent long-term protectionShort reaction timeOrganic solventN-phenyl-p-phenylenediamine

The invention discloses a preparation method of a long-acting p-phenylenediamine anti-aging agent. The preparation method comprises the following steps: (1) mixing a silane coupling agent with N-phenyl-p-phenylenediamine according to a ratio of (0.6-1.4):1 to obtain a mixed solution A; (2) mixing the mixed solution A, an organic solvent and a catalyst according to a weight ratio of 1:(5-10):(0.0005-0.005), then carrying out heating to 50-80 DEG C, and carrying out a reaction for 15-60 minutes to obtain a mixed solution B; (3) mixing the mixed solution B with inorganic filler at a high mixing rate according to a weight ratio of (0.1-1):1 to obtain a mixture C; and (4) drying the mixture C to obtain a final product. The long-acting p-phenylenediamine anti-aging agent prepared by the method provided by the invention is connected to inorganic filler through chemical bonds, and the long-term protective effect is excellent; the silane coupling agent exists on the inorganic filler, and unevendistribution is avoided; and the reaction time of the silane coupling agent with the N-phenyl-p-phenylenediamine is short, and is only 15-60 minutes.

Owner:ZHANGJIAGANG OTSUKA CHEM

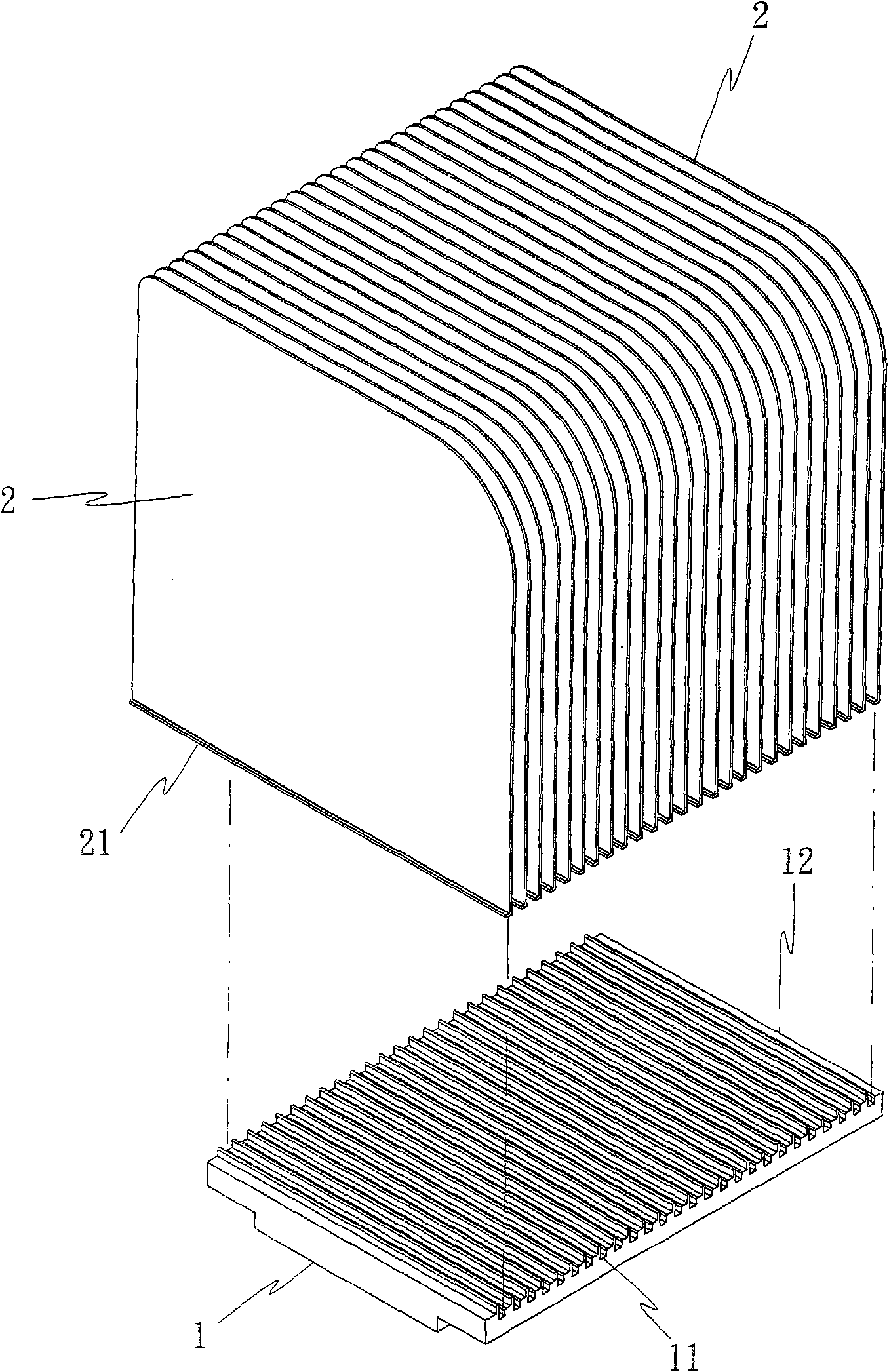

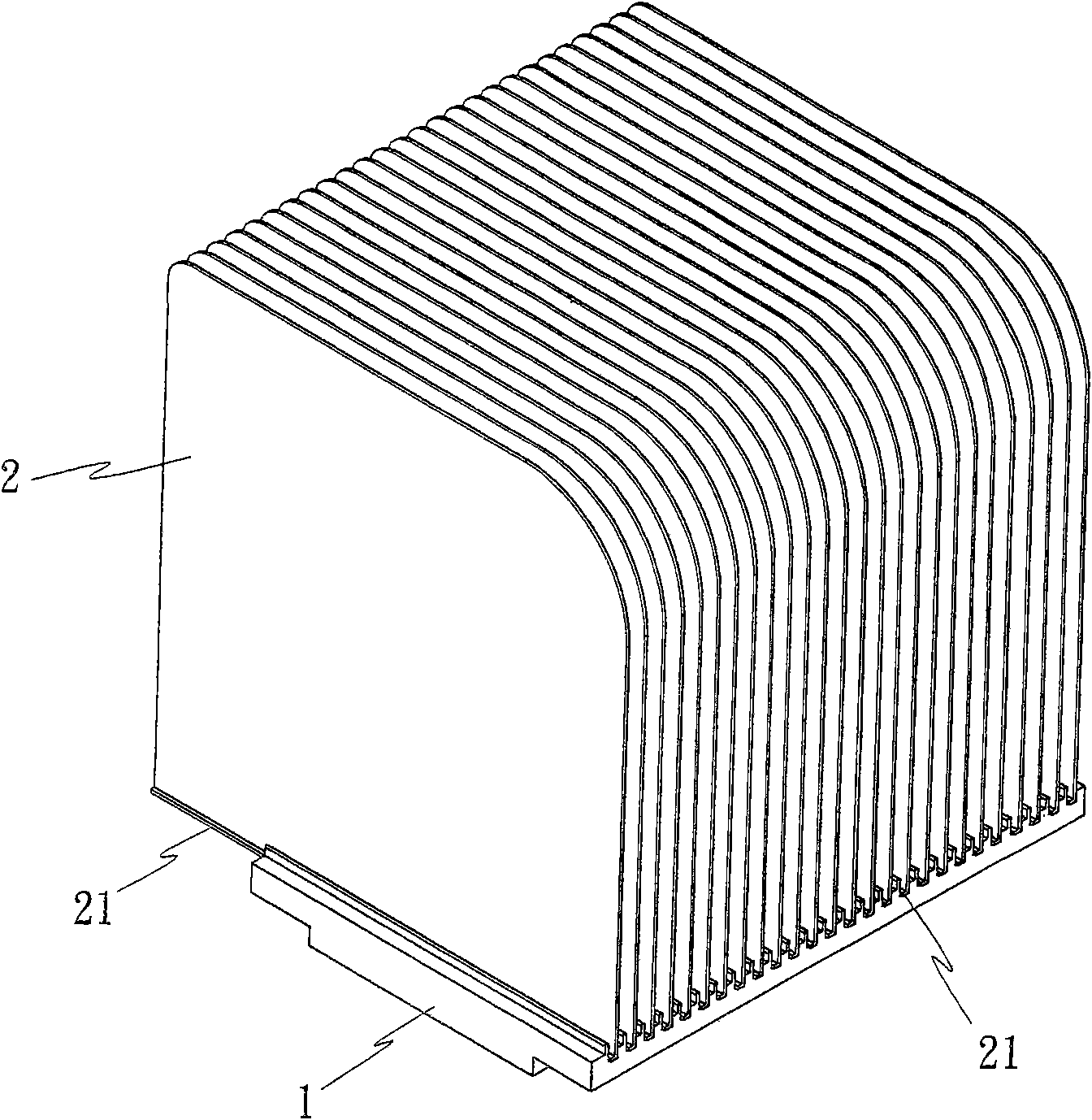

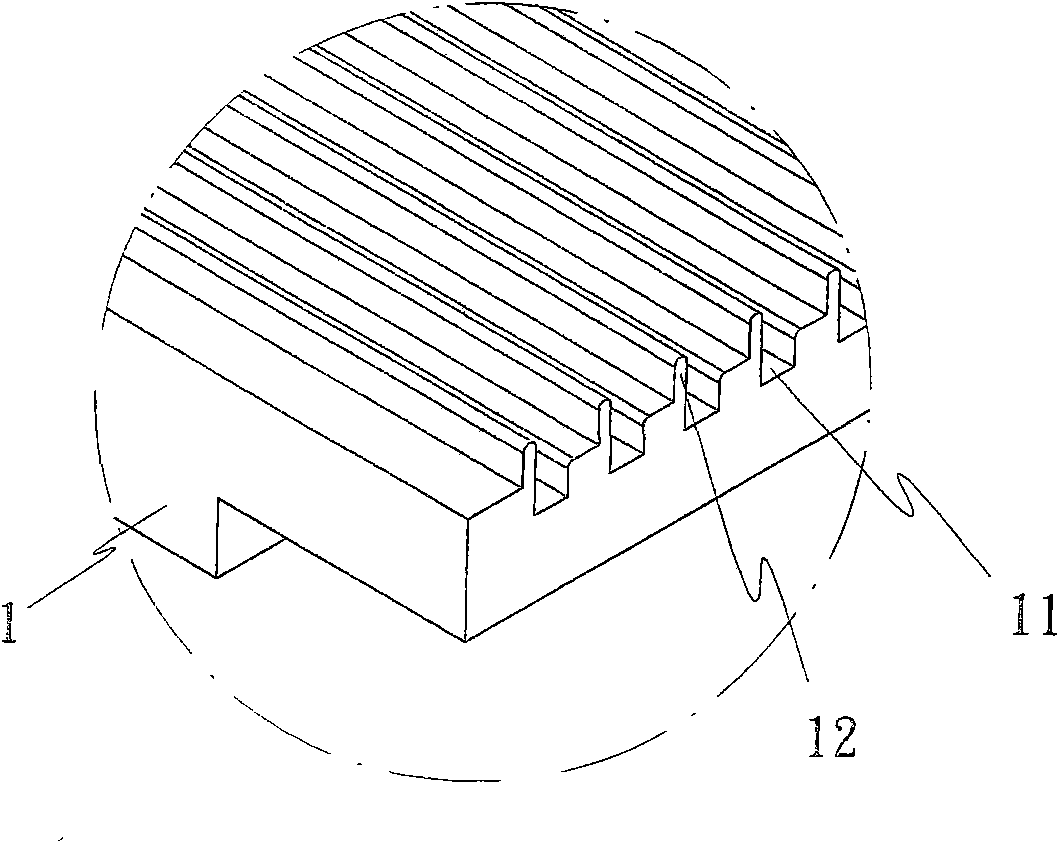

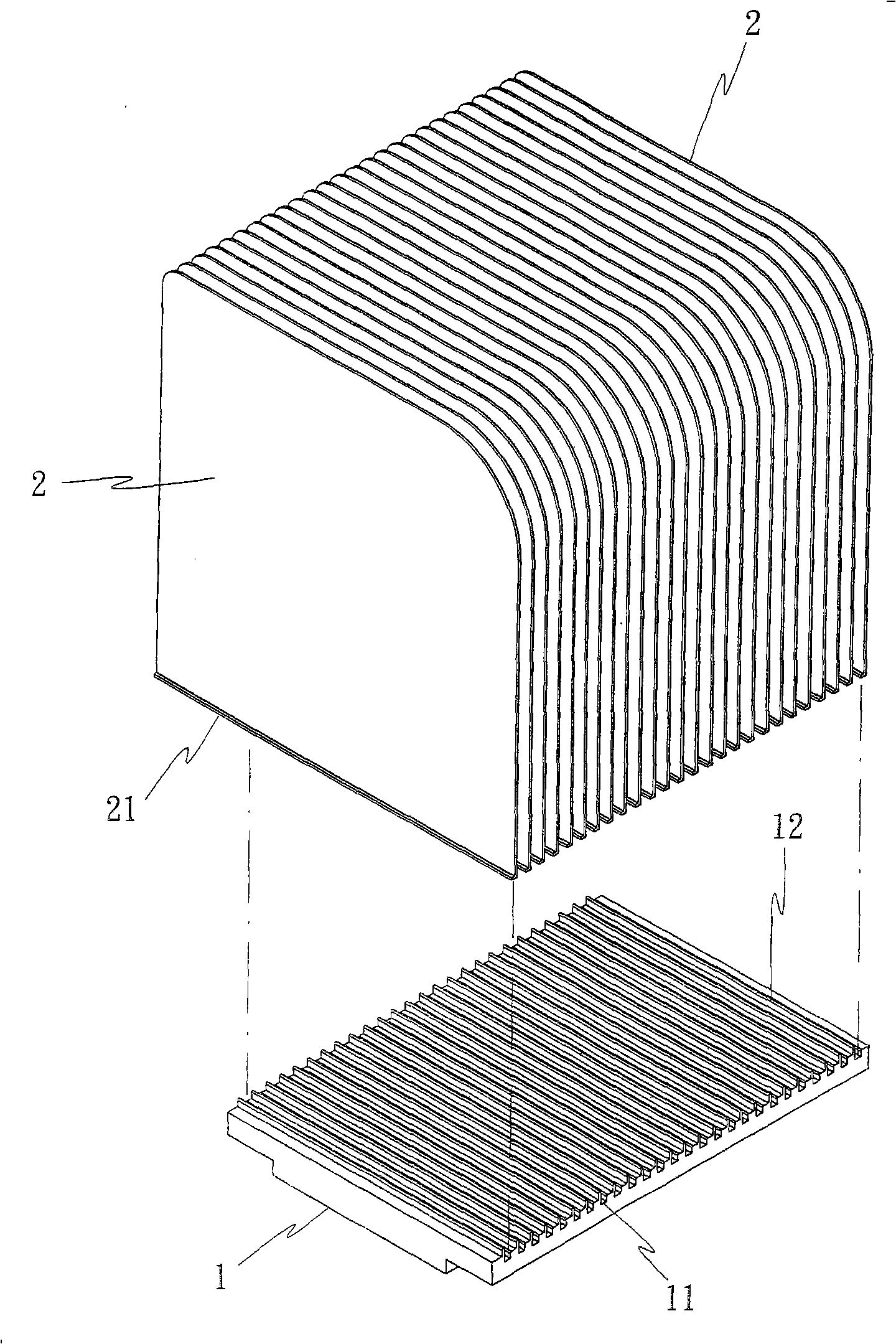

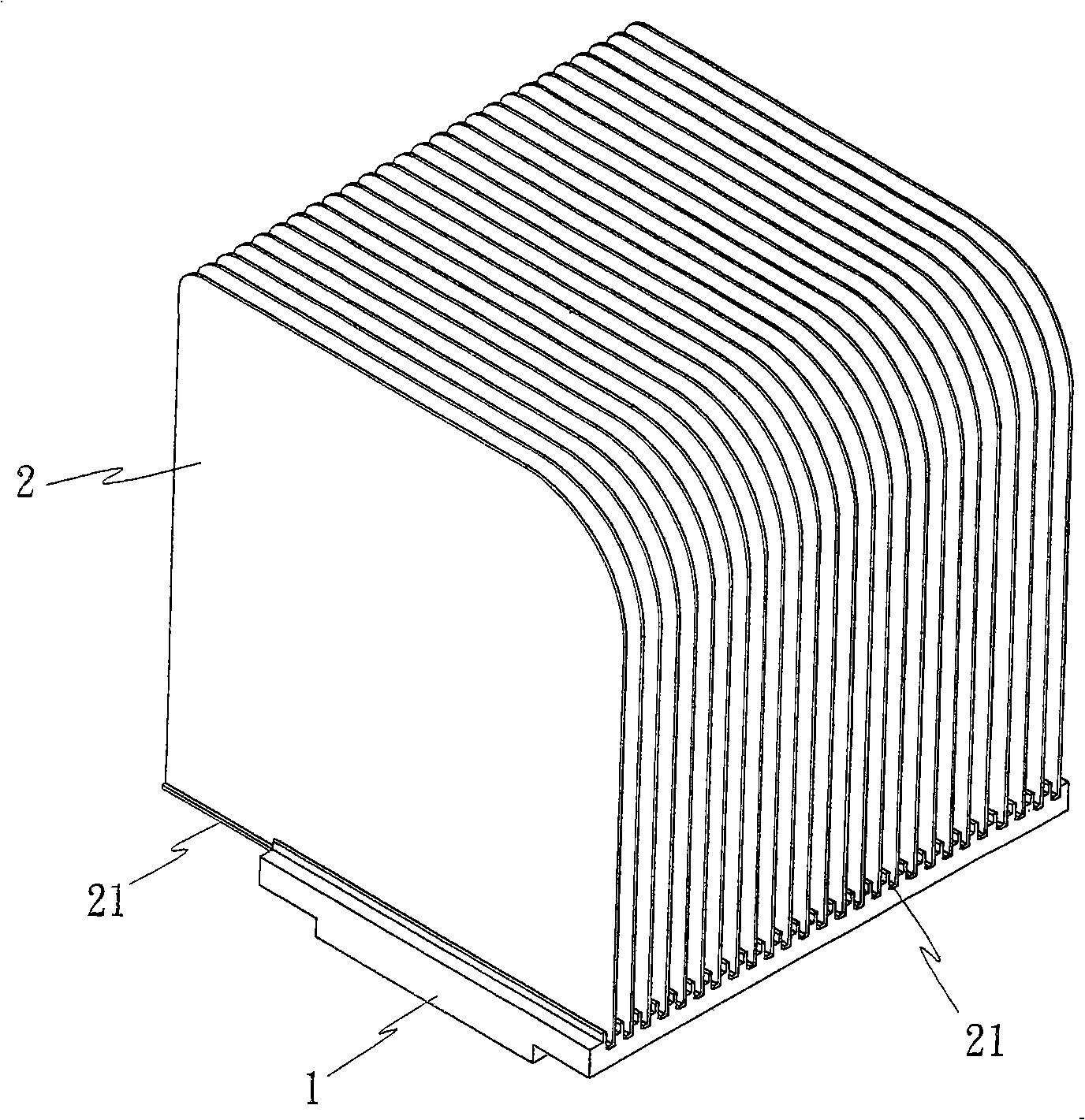

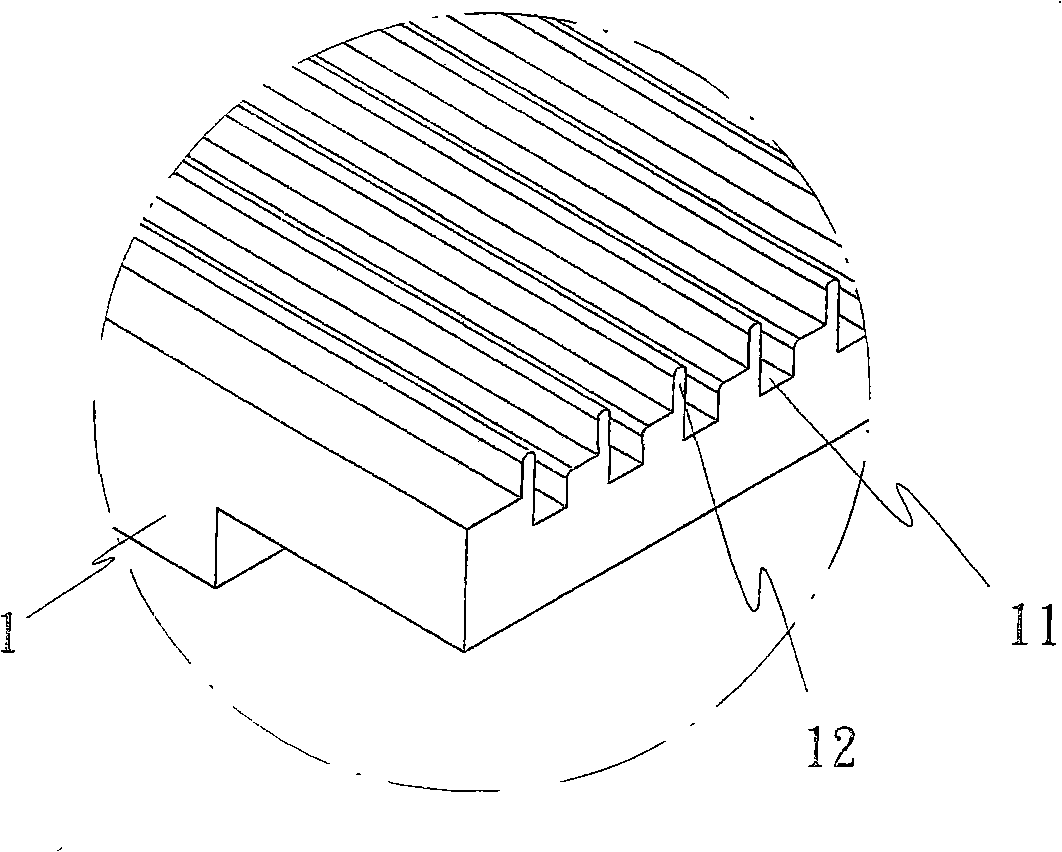

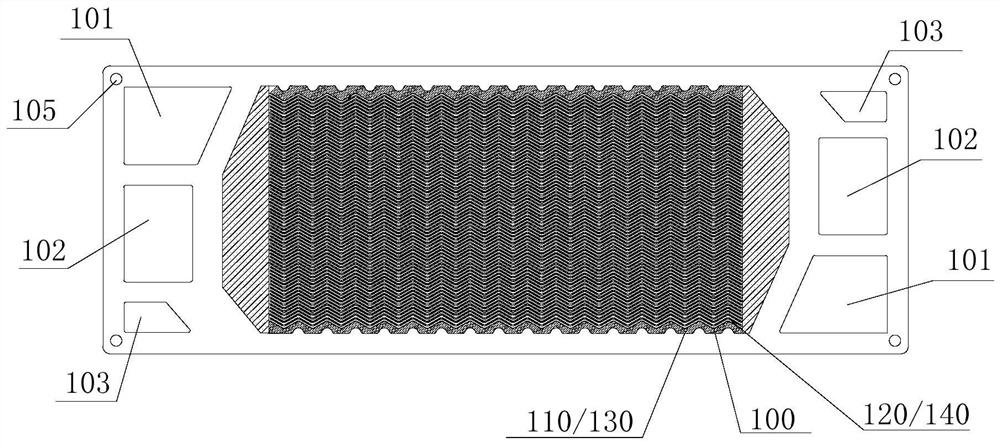

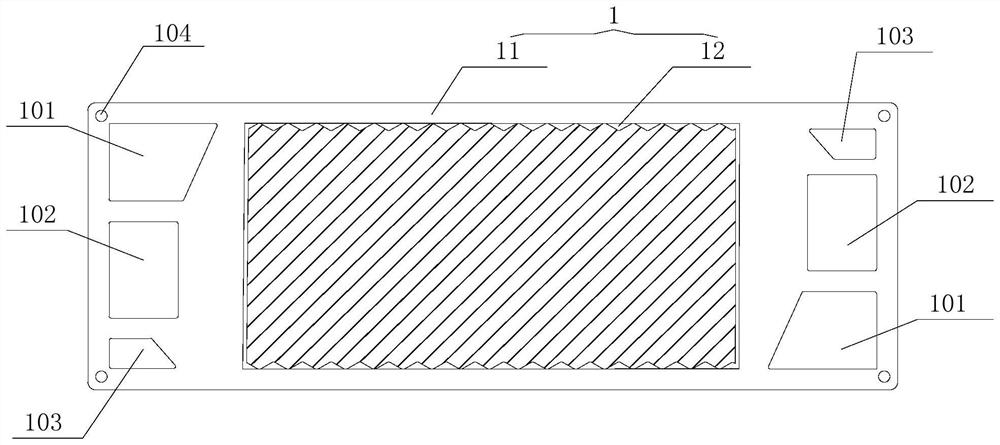

Radiator

ActiveCN101551211AAccurate pressingThere will be no uneven distributionIndirect heat exchangersHeat exchanger casingsEngineeringHeat spreader

The invention relates to a radiator, comprising a plurality of radiating fins and a seat body. The surface of the seat body is provided with a plurality of adjacent grooves; one side of the groove wall of each groove is respectively provided with a first convex part or the other side of the groove wall is also additionally provided with a second convex part; the bottom end of each radiating fin is provided with a bending part; when the radiating fins are matched and implanted into the grooves of the seat body, the stamping die is pressed to force the first convex part to be deformed and further tightly butted against the bending part of the radiating fin, thus forming good pressing combination, leading the radiating fins to be capable of completely being inserted to the bottom and firmly positioned respectively, further ensuring equal height of each radiating fin and having no deformation or unstable combination.

Owner:HUANG TSUNG HSIEN YUAN SHAN HSIANG

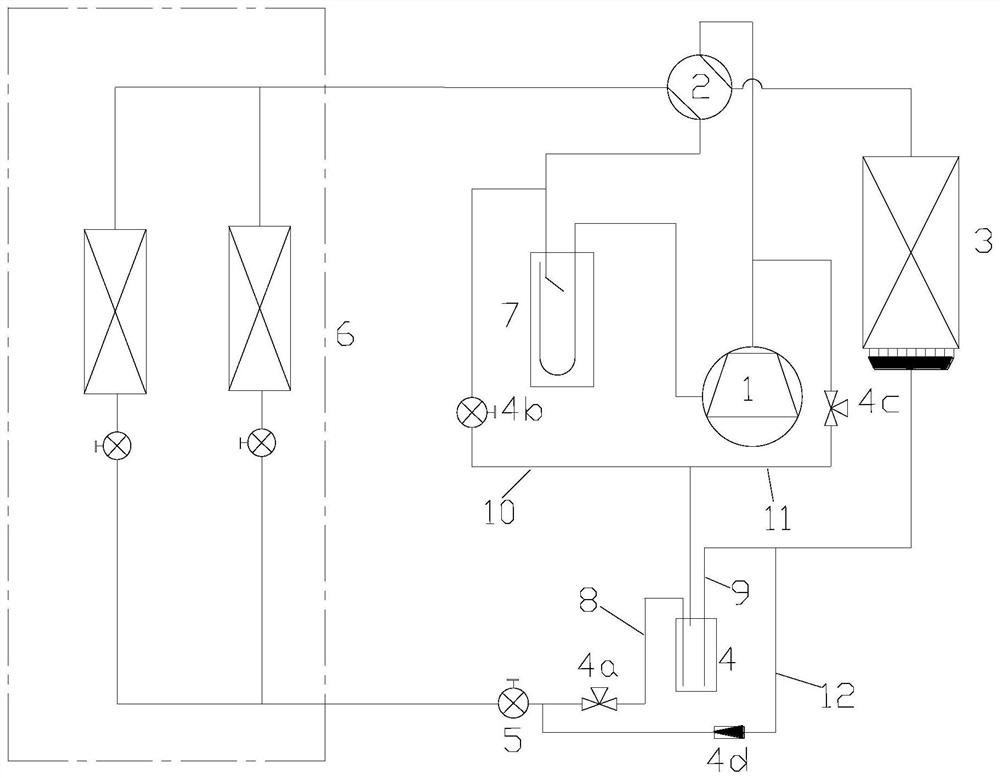

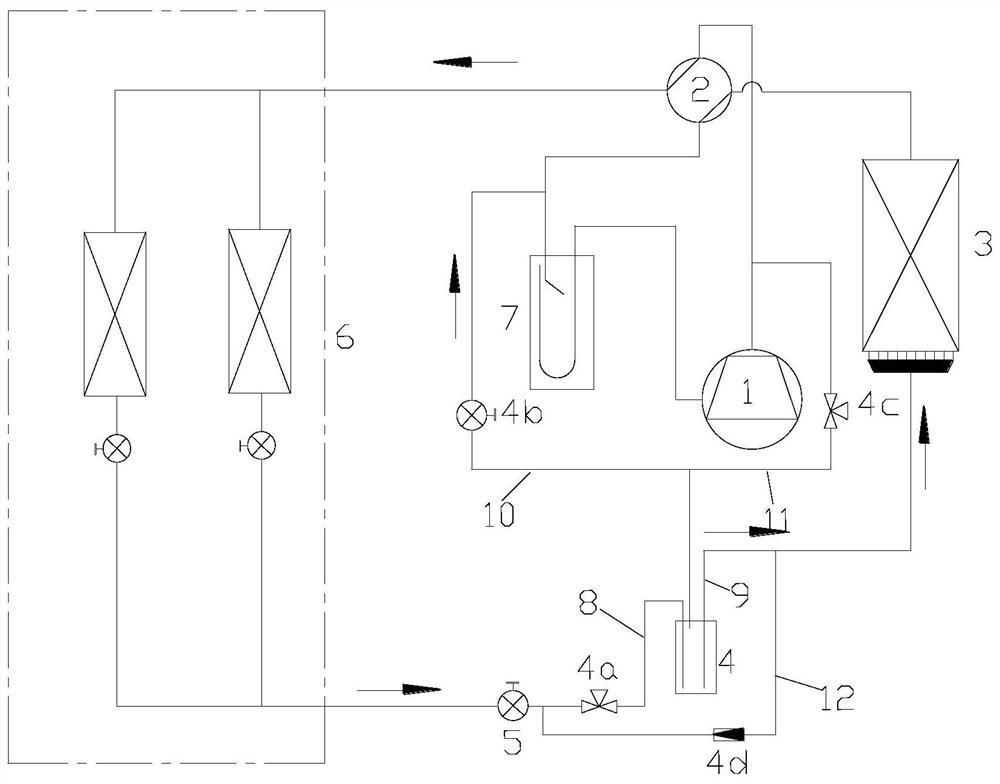

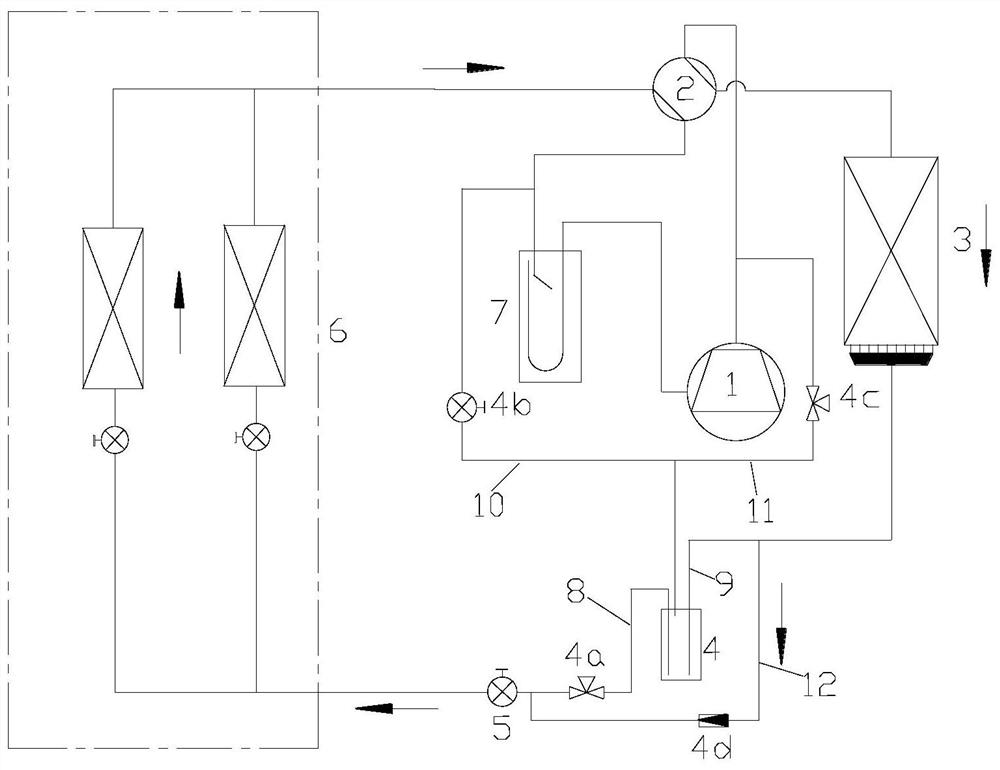

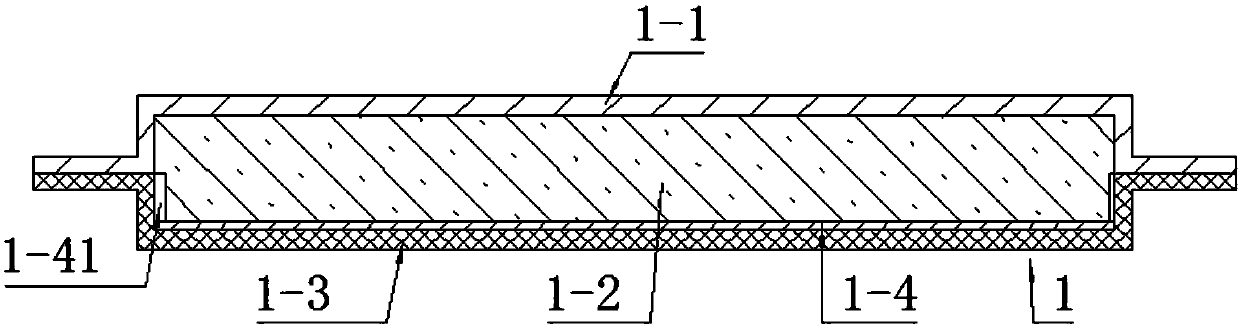

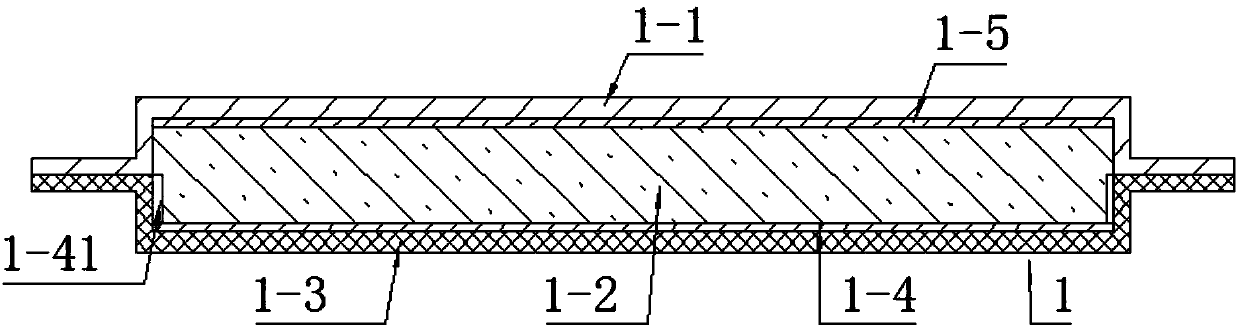

Multi-split system and control method thereof

PendingCN112361669AImprove distribution uniformityImprove heat transfer efficiencyMechanical apparatusEfficient regulation technologiesRefrigerant distributionLiquid storage tank

The invention provides a multi-split system and a control method thereof. The multi-split system comprises a compressor (1), an outdoor heat exchanger, a throttling device (5) and an indoor unit (6),wherein the outdoor heat exchanger comprises a micro-channel heat exchanger (3); the throttling device (5) is located on a pipeline between the micro-channel heat exchanger (3) and the indoor unit (6); a liquid storage tank (4) is arranged on a pipeline between the throttling device (5) and the micro-channel heat exchanger (3); the liquid storage tank (4) is connected to a first liquid pipe (8), asecond liquid pipe (9) and a first air pipe (10); the first air pipe (10) is connected to an air suction port of the compressor (1); the first liquid pipe (8) is connected to the throttling device (5); and the second liquid pipe (9) is connected to the micro-channel heat exchanger (3). According to the multi-split system, the refrigerant distribution uniformity of the micro-channel heat exchangercan be improved, and the heat exchange efficiency of the heat exchanger is improved.

Owner:GREE ELECTRIC APPLIANCES INC

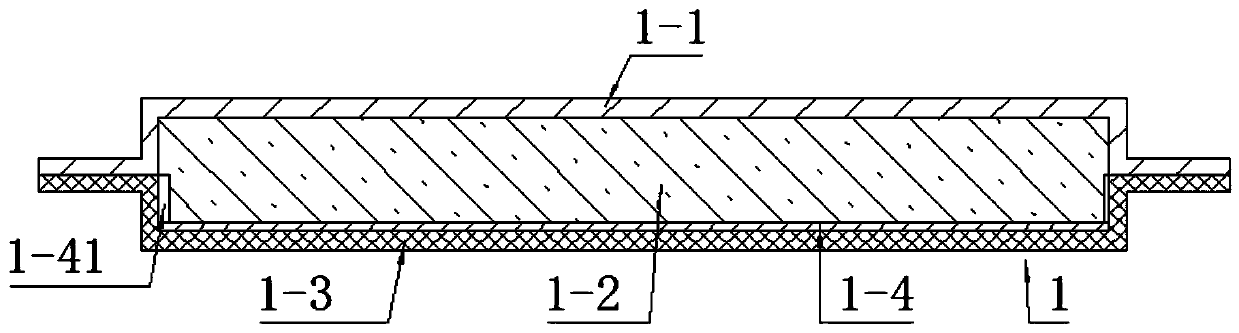

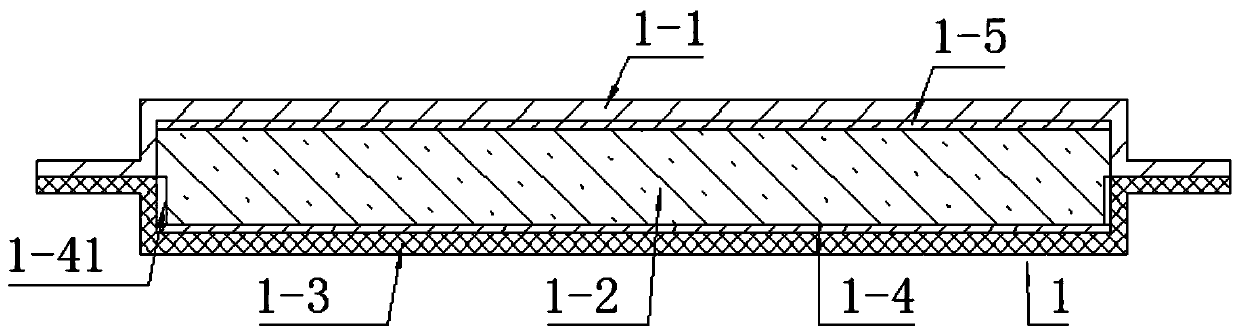

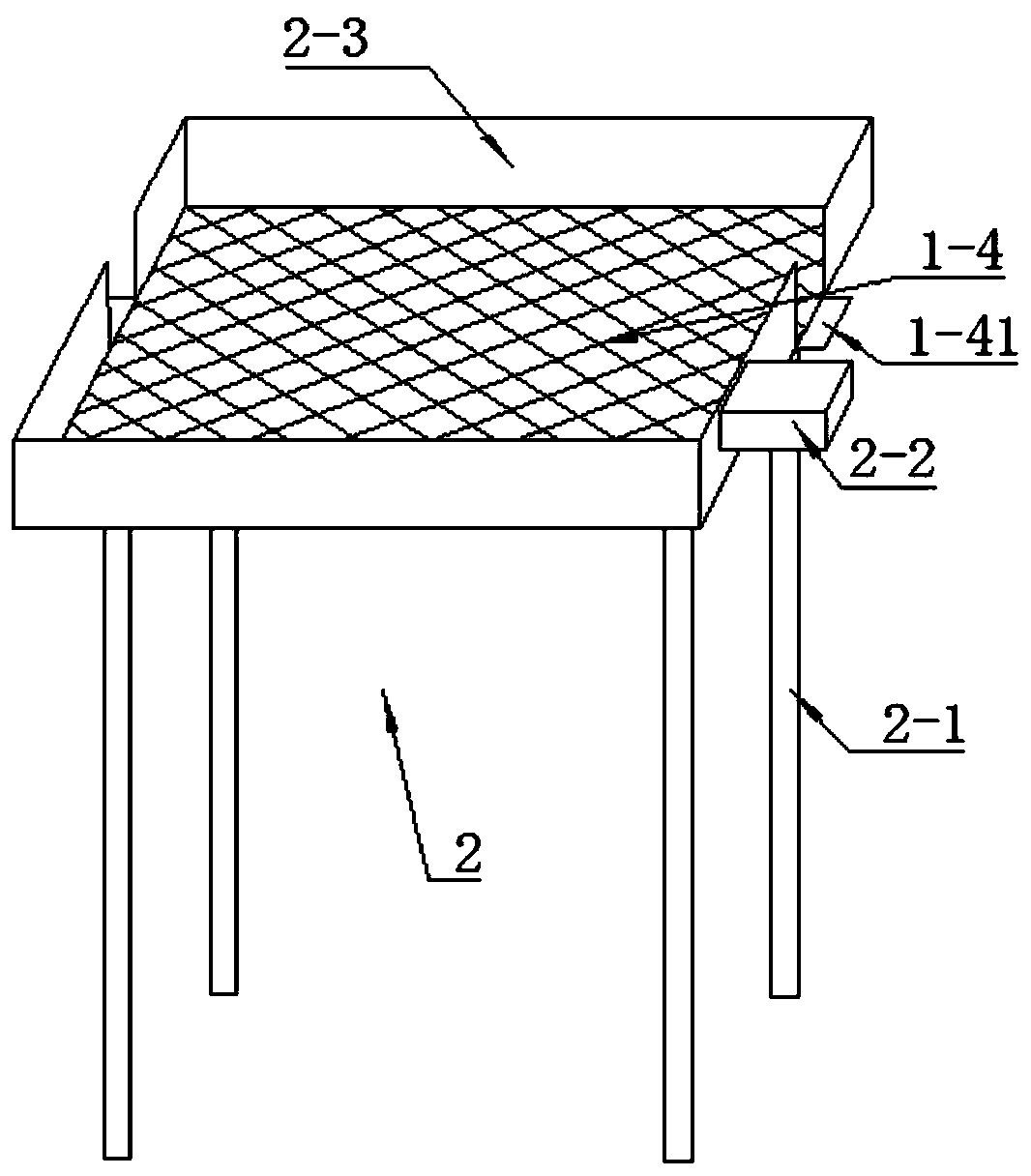

Sponge cement blanket and preparation method thereof

ActiveCN107825784AEasy to makeMake fastUnderground chambersSynthetic resin layered productsFiberYarn

The invention relates to a sponge cement blanket, which comprises an upper-layer fabric, a lower-layer fabric, and a sponge cement layer and a metal wire mesh clamped between the upper-layer fabric and the lower-layer fabric. The sizes of outer contours of the upper-layer fabric and the lower-layer fabric are larger than the sizes of the sponge cement layer and the metal wire mesh; the upper-layerfabric, the sponge cement layer, the metal wire mesh and the lower-layer fabric are sewn together through fiber silk yarns; the metal wire mesh at least comprises a lower-layer metal wire mesh arranged between the lower-layer fabric and the sponge cement layer; the sponge cement layer comprises sponge and cement filling gaps of the sponge, or a mixture of the cement, an accelerator and sodium silicate. The sponge cement blanket is convenient to use, low-cost and high in strength. The invention also relates to a preparation method of the sponge cement blanket, which comprises the steps of firstly preparing materials, then preparing the sponge cement layer on a vibration platform, and finally sewing on a sewing platform, so that the sponge cement blanket is simple and fast to prepare.

Owner:YANTAI ZHIBEN INTPROP OPERATIONS MANAGEMENT CO LTD

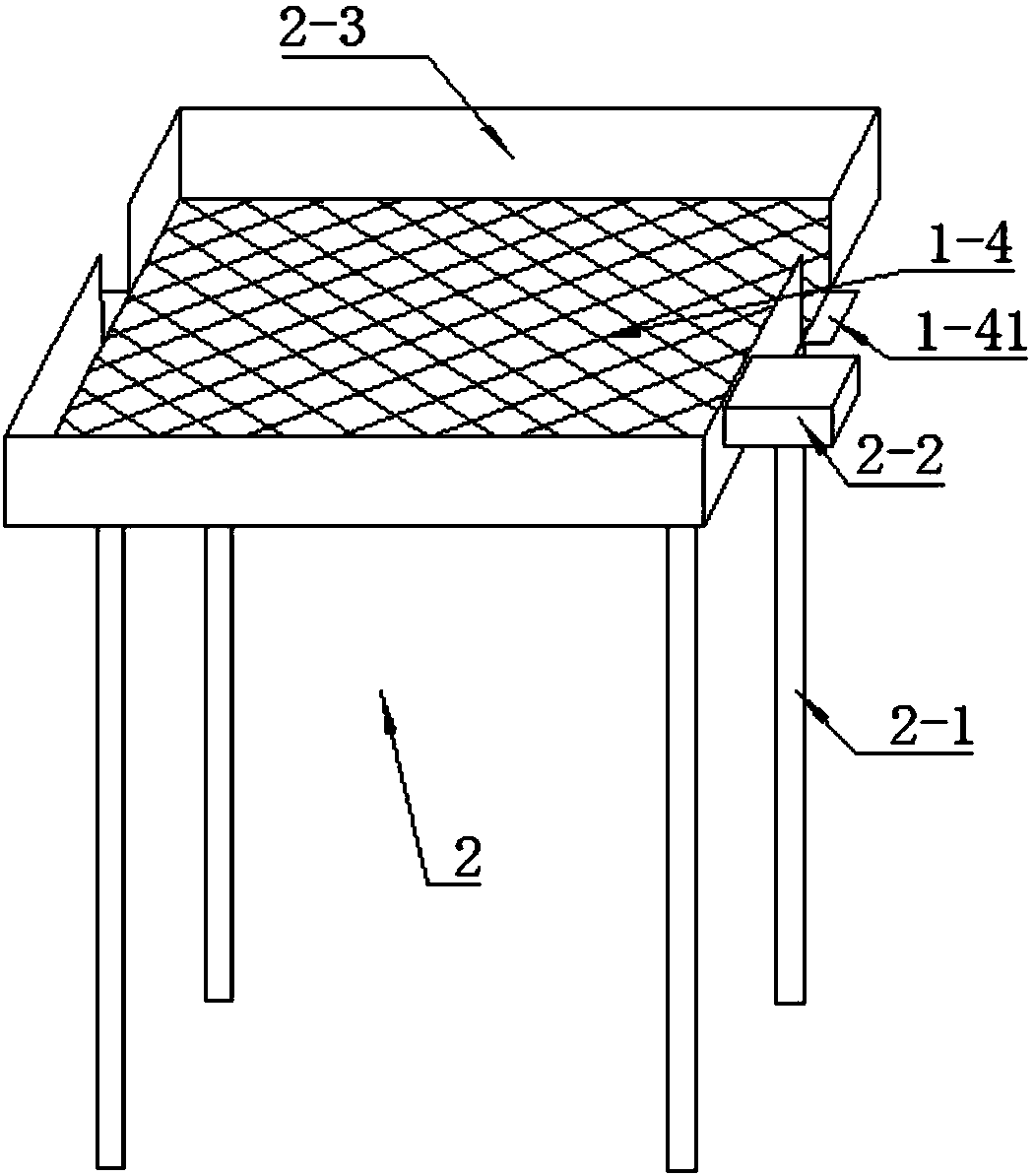

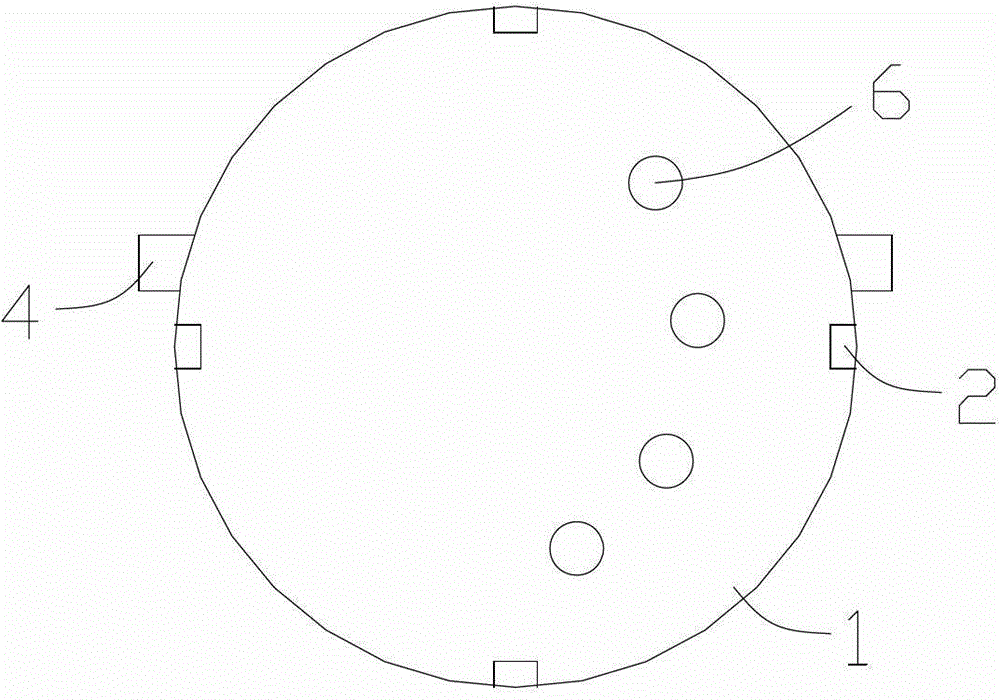

Preparation method of granular primary ore polished section

PendingCN113188861ALow softening pointShort heating timePreparing sample for investigationGrindingGas release

The invention provides a preparation method of a granular primary ore polished section, which comprises the following steps: crushing primary ore into granular ore samples with the granularity of -3mm, uniformly mixing the granular ore samples with a binding agent, uniformly stirring the granular ore samples and the binding agent to form polished section grinding blanks through the operation of a mounting press, and performing coarse grinding, medium grinding and fine grinding on the polished section grinding blanks through a sample grinding machine, subjecting the polished section grinding blanks to polishing solution polishing and water polishing, and finally putting the polished section grinding blanks into an ultrasonic cleaner to be cleaned and dried. Combustion and poisonous and harmful gas release are not prone to occurring in the section preparation process, the environment-friendly and safe effects are achieved, meanwhile, the sample preparation time can be greatly shortened, the situation that coarse and fine particles are not evenly distributed is avoided, and the section grinding efficiency and the section polishing quality are improved.

Owner:JIUQUAN IRON & STEEL GRP

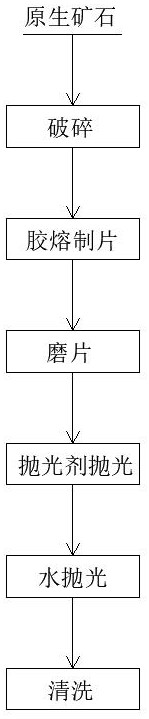

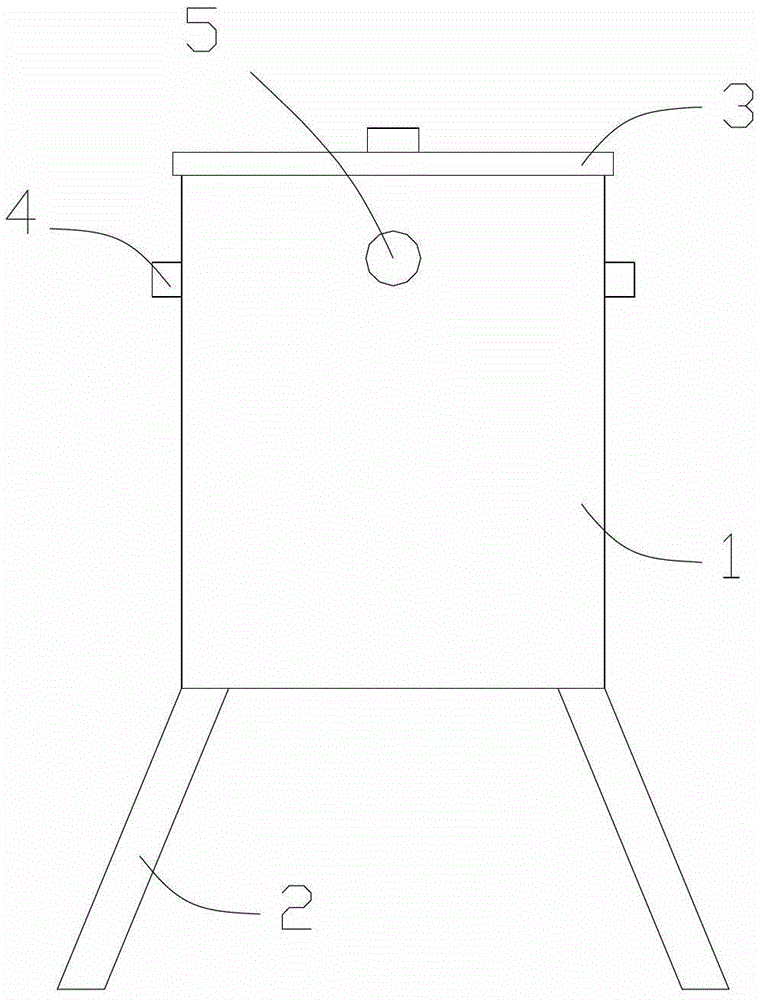

Honey storage tank

The invention discloses a honey storage tank, and belongs to the field of honey production equipment. The honey storage tank comprises a cylindrical tank body and a bracket, and is characterized in that the cylindrical tank body is arranged on the bracket; a tank cover is arranged at the top of the cylindrical tank body; two handles are symmetrically arranged on the cylindrical tank body; a honey inlet is formed in a side wall of the cylindrical tank body; and four honey outlets are formed at the bottom of the cylindrical tank body, and connected with a filling port of a filling machine by four pipelines. The honey storage tank is simple in structure, reasonable in design, convenient to use, low in cost and simple to fabricate; the four honey outlets are directly connected with the filling port of the filling machine, so that honey is distributed uniformly; and the filling quality and filling efficiency are ensured.

Owner:蚌埠市周氏蜂业有限责任公司

Carex baccans nees thick soup recipe and processing method thereof

InactiveCN104921105AGuaranteed contentThere will be no uneven distributionFood dryingFood ingredient functionsDiseaseCooking & baking

The present invention provides a nutritional thick soup recipe using carex baccans nees as main raw materials and a processing method thereof. The recipe is rich in nutrition, has a reasonable matching, can be more comprehensive to meet the needs of various nutrients. Besides, the finished product presents a thick-soup shape after being blended, is easy to digest and absorb, can be consumed by the elderly, children and adults, and can prevent cardiovascular and cerebrovascular diseases in a long-term consumption. The high-quality raw materials are selected by winnowing and screening, and thus the quality of final finished products is guaranteed. Furthermore, in the baking process, a low-temperature baking technology with the entire baking temperature not exceeding 90 DEG C is adopted, and thus the nutrient content of the raw materials can be ensured under the condition that the water content of the raw material is removed.

Owner:ZUNYI JUNHUIYUAN FOOD ENG

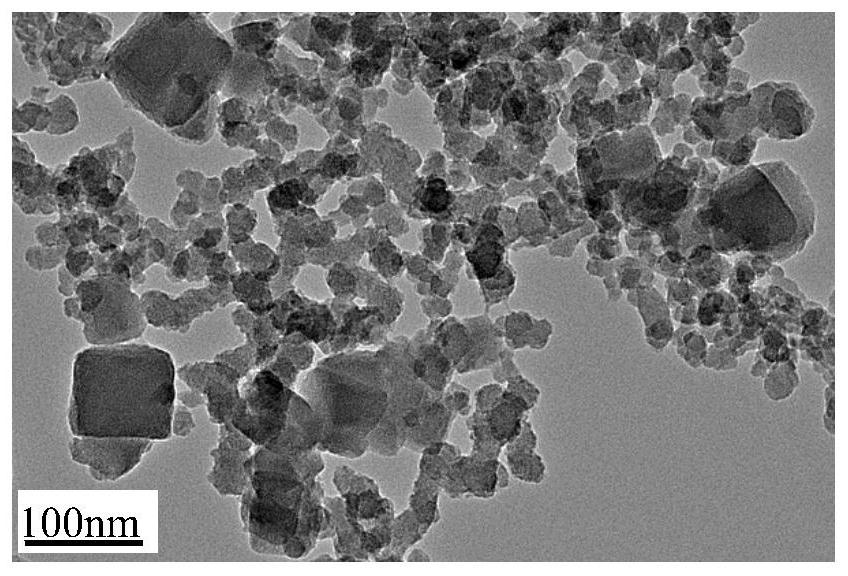

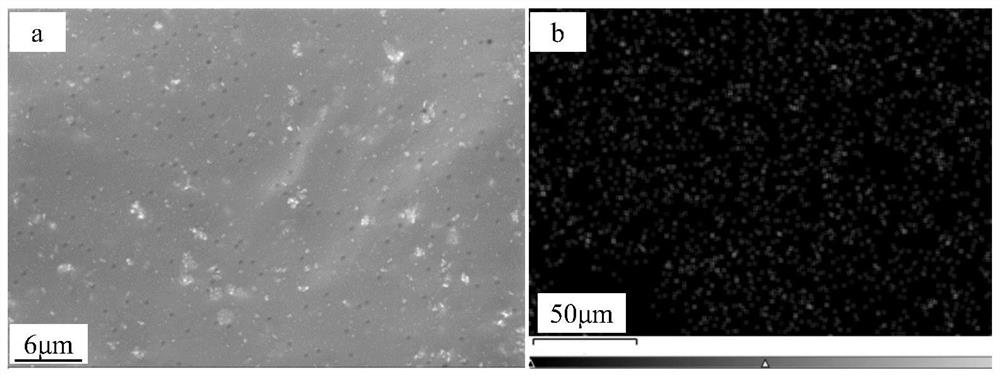

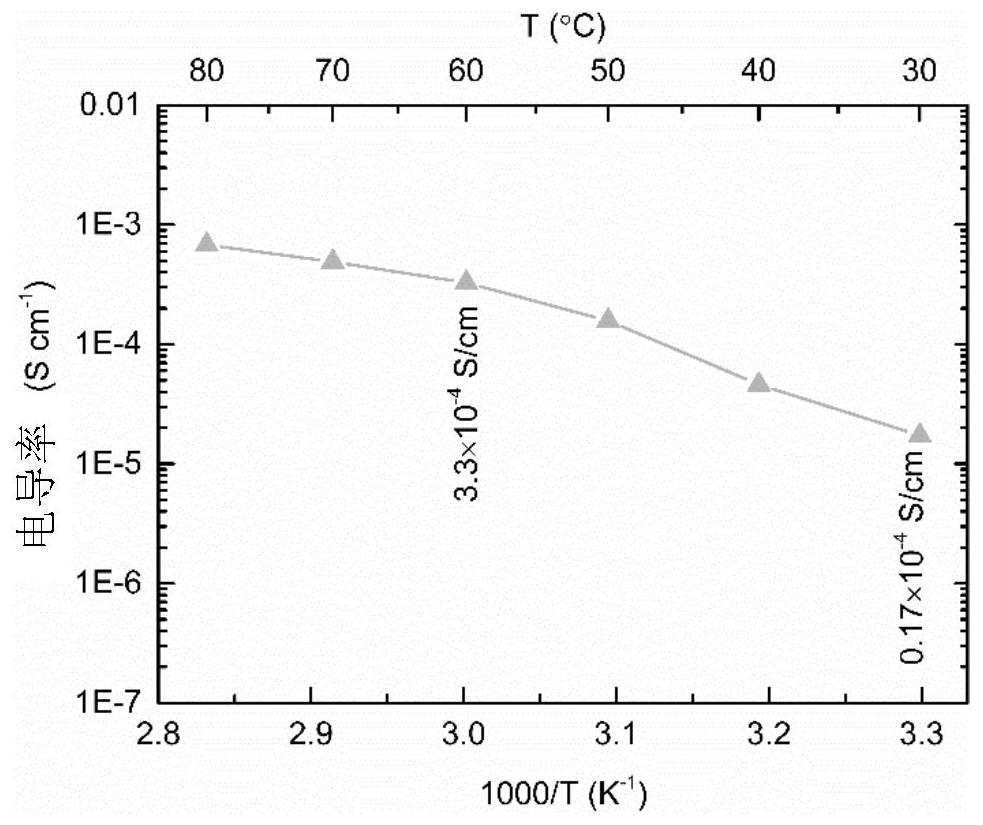

A kind of composite polymer solid electrolyte, solid lithium battery and preparation method thereof

ActiveCN108878970BImprove conductivityThe preparation method is simple and energy-savingSolid electrolytesLi-accumulatorsPhysical chemistryNanostructured metal

The invention belongs to the field of solid-state lithium batteries, and specifically discloses a composite polymer solid electrolyte, a solid-state lithium battery and a preparation method thereof, which uses a novel nanostructured metal-organic framework structure filler to prepare a composite polymer solid based on PEO polymer Electrolyte, and using the composite polymer solid electrolyte to prepare a solid-state lithium battery has the advantages of simple preparation, energy saving, strong applicability, etc. The prepared composite polymer solid electrolyte has high conductivity, and the solid-state lithium battery has excellent electrochemical performance.

Owner:HUAZHONG UNIV OF SCI & TECH

Plasma process equipment and gas distribution device thereof

ActiveCN101770933BImprove uniformityThere will be no uneven distributionElectric discharge tubesSemiconductor/solid-state device manufacturingProcess equipmentMachining

The invention discloses a gas distribution device. A plurality of first and second gas transmission channels are arranged alternately at the top of a gas distribution plate, and the gas flow directions in the first and second gas transmission channels are opposite; a plurality of gas feeding holes are arranged at the bottoms of the first and second gas transmission channels. In the first gas transmission channels, the gasflow flowing out from the gas feeding holes adjacent to the gas inlet end is greater while the gasflow flowing out from the gas feeding holes adjacent to the closed end is smaller; in the second gas transmission channels, the contrary is the case. Because the first and second gas transmission channels are arranged alternately, the total amounts of the gas fed from the plurality of adjacent gas feeding holes are substantially equal, and gas is distributed uniformly in the radial direction of the reaction chamber. The gas distribution device has the advantages of simplestructure, convenient machining and low cost and ensures that the gas is distributed uniformly in the radial direction of the reaction chamber.

Owner:BEIJING NAURA MICROELECTRONICS EQUIP CO LTD

Radiator

ActiveCN101551211BAccurate pressingThere will be no uneven distributionIndirect heat exchangersHeat exchanger casingsEngineeringHeat spreader

The invention relates to a radiator, comprising a plurality of radiating fins and a seat body. The surface of the seat body is provided with a plurality of adjacent grooves; one side of the groove wall of each groove is respectively provided with a first convex part or the other side of the groove wall is also additionally provided with a second convex part; the bottom end of each radiating fin isprovided with a bending part; when the radiating fins are matched and implanted into the grooves of the seat body, the stamping die is pressed to force the first convex part to be deformed and further tightly butted against the bending part of the radiating fin, thus forming good pressing combination, leading the radiating fins to be capable of completely being inserted to the bottom and firmly positioned respectively, further ensuring equal height of each radiating fin and having no deformation or unstable combination.

Owner:HUIZHOU HANXU HARDWARE PLASTIC TECH CO LTD

A kind of sponge cement blanket and preparation method thereof

ActiveCN107825784BEasy to makeMake fastUnderground chambersSynthetic resin layered productsFiberYarn

The invention relates to a sponge cement blanket, which comprises an upper-layer fabric, a lower-layer fabric, and a sponge cement layer and a metal wire mesh clamped between the upper-layer fabric and the lower-layer fabric. The sizes of outer contours of the upper-layer fabric and the lower-layer fabric are larger than the sizes of the sponge cement layer and the metal wire mesh; the upper-layerfabric, the sponge cement layer, the metal wire mesh and the lower-layer fabric are sewn together through fiber silk yarns; the metal wire mesh at least comprises a lower-layer metal wire mesh arranged between the lower-layer fabric and the sponge cement layer; the sponge cement layer comprises sponge and cement filling gaps of the sponge, or a mixture of the cement, an accelerator and sodium silicate. The sponge cement blanket is convenient to use, low-cost and high in strength. The invention also relates to a preparation method of the sponge cement blanket, which comprises the steps of firstly preparing materials, then preparing the sponge cement layer on a vibration platform, and finally sewing on a sewing platform, so that the sponge cement blanket is simple and fast to prepare.

Owner:YANTAI ZHIBEN INTPROP OPERATIONS MANAGEMENT CO LTD

Antibacterial photocureable coating with low surface energy

InactiveCN106380911AEvenly dispersedImprove uniformityAntifouling/underwater paintsPaints with biocidesMechanical propertyOxygen inhibition

The invention discloses an antibacterial photocureable coating with low surface energy. The coating comprises the following ingredients: trimethylolpropane triacrylate, hydroxypropyl methacrylate, 3-mercaptopropylmethyldimethoxysilane, dibutyltin dilaurate, nano-silica, a photoinitiator, polylactic acid and silver nano-particles. There exists no oxygen inhibition during curing, and curing is complete. The coating of the invention has excellent mechanical properties and low surface energy, and has dustproof and antibacterial effects.

Owner:CHENGDU NASHUO TECH

Intelligent garbage can with automatic sealing effect

PendingCN112298850AWith automatic sealing effectKeeping the Automation SealRefuse receptaclesElectric machineryEngineering

Owner:宿迁永泰邦辰知识产权运营管理有限公司

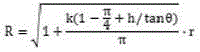

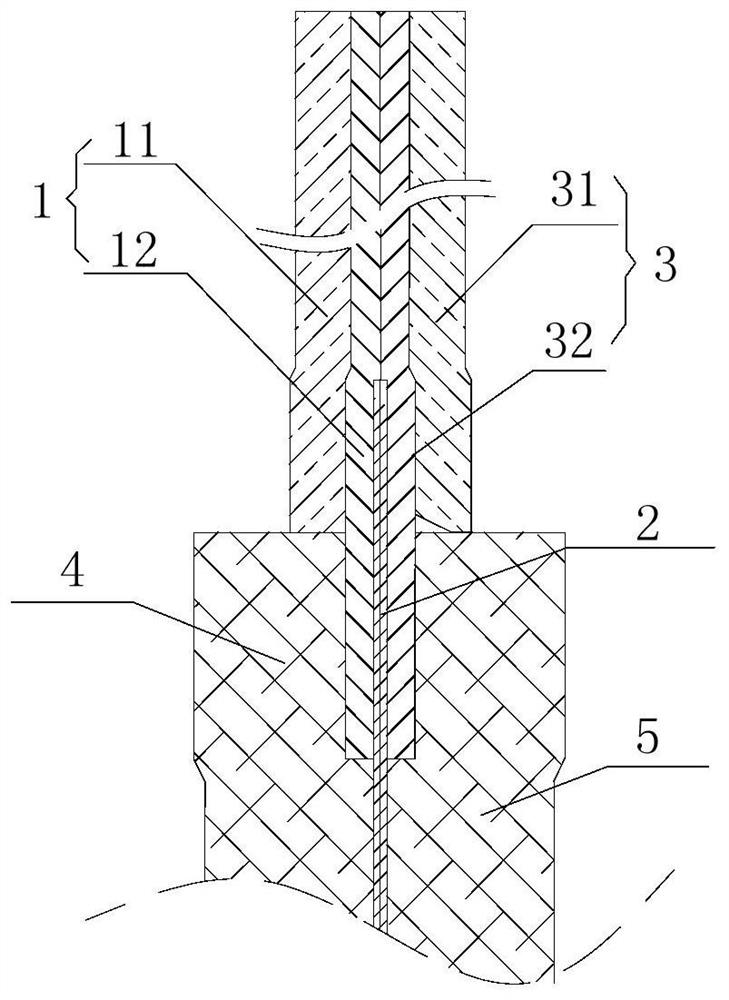

A method for axial and bidirectional orientation stretching hollow blow molding

The invention provides a hollow blow molding method for positioning stretching in both axial and bidirectional directions. A supporting device for briefly supporting the bottom of the bottle blank is provided in the mold cavity. The molding of the blow molding container includes the following steps: step 1, heating the bottle blank To the stretching temperature, pre-blowing while stretching; step 2, when stretching to the position of the supporting device, the supporting device supports the center of the bottom of the preform that has been gradually stretched and expanded, and the bottom of the preform is Slow down the stretching speed or suspend stretching at the position of the supporting point, and the periphery of the supported point will continue to stretch under the action of air pressure and the inertia of its own material; step 3, after the cone bottom is formed in advance, the supporting device retracts or follows the stretching The rod moves, the stretch rod continues to stretch and injects air pressure, then cools to form the blown container. Through the support in step 2, the material at the bottom of the preform is fully stretched and distributed more evenly at the bottom of the bottle, which can achieve better cooling and shaping.

Owner:GUANG DONG XING LIAN PRECISE MACHINERY

Distributing process of one-shot brazing superabrasive tools

ActiveCN103522206BSimple and fast operationImprove cloth efficiencyBonded abrasive wheelsGrinding devicesMetallurgyParaffin oils

The invention discloses a material distribution technology of a one-time forming brazing super-hard material grinding tool. The material distribution technology includes the following steps that firstly, composite pellets are prepared for standby application, the peripheries of abrasive particles are coated with solder layers to form a composite body, and the periphery of the composite body is coated with a paraffin layer to form composite pellets; secondly, the surface of a base body is cleaned; thirdly, a material distribution area of the surface of the base body is brushed and coated with binding agents; fourthly, the composite pellets are spread in the material distribution area, obtained in the third step, of the surface of the base body, the composite pellets are tightly distributed and stuck to the material distribution area of the surface of the base body so that semi-finished products can be obtained; fifthly, the surfaces of the semi-finished products are cleaned, and the semi-finished products are prepared to be welded. According to the material distribution technology of the one-time forming brazing super-hard material grinding tool, due to the fact that the abrasive particles and solder are matched according to a certain relation and made into the composite body according to a particle preparing technology, a layer of paraffin coats the outer face of the composite body to form the composite pellets, and therefore the material distribution technology is greatly simplified; use of material distribution equipment is combined, stability of the quality of brazing is ensured, and industrial production operation is facilitated. According to the designed scheme, adaptability to workpieces is good, the brazing quality is stable, and the material distribution technology is suitable for industrial production.

Owner:广东省电力线路器材厂有限公司

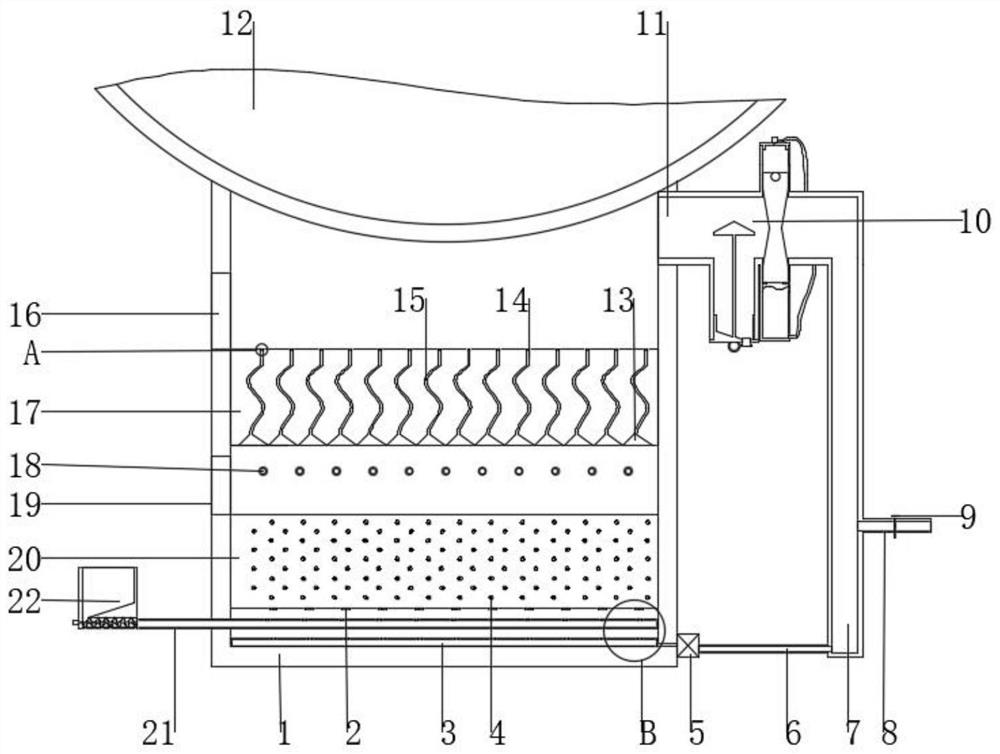

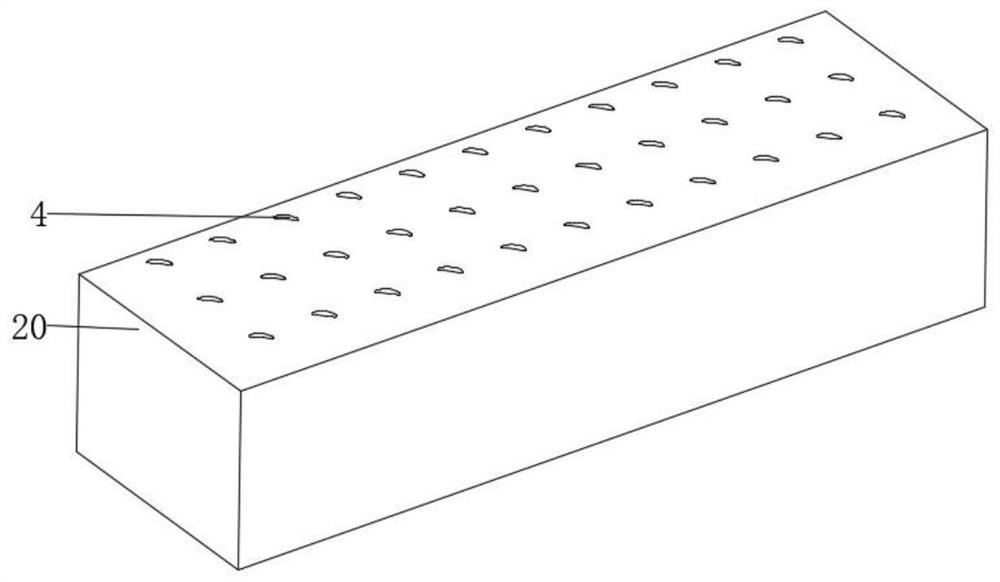

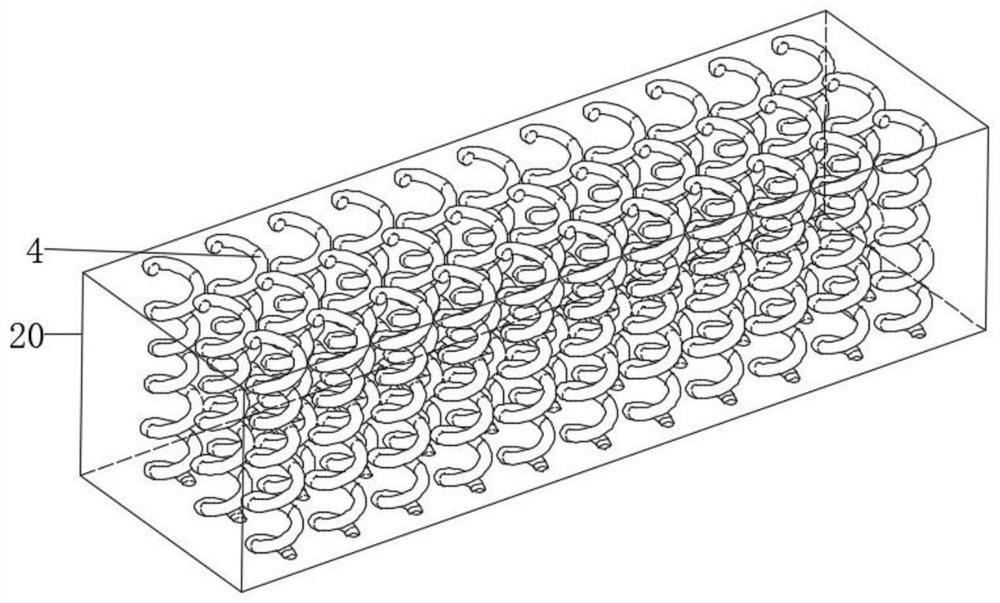

Energy supply mechanism and boiler auxiliary based on mechanism

PendingCN111964041AImprove heating efficiencyEvenly distributedGas treatmentDispersed particle filtrationProcess engineeringEnergy supply

The invention discloses an energy supply mechanism and a boiler auxiliary based on the mechanism. The energy supply mechanism comprises a resource supply unit. The resource supply unit comprises a coal conveying pipeline for conveying coal powder and coal discharging holes which are formed in the coal conveying pipeline and used for conveying the coal powder to the bottom of the coal conveying pipeline, and an air supply pipeline used for blowing and scattering the coal powder conveyed to the bottom of the coal conveying pipeline upwards is arranged at the bottom of the coal conveying pipeline. An evening plate with multiple sets of guide channels is arranged, so that the coal powder can be evenly divided into a plurality of spiral conveying paths and evenly conveyed into a resource ignition unit to be ignited, the action of evenly distributing the coal powder in a shell is achieved, and the phenomenon that coal powder is blown through oriented air, and large eddies are likely to occur, and uneven distribution occurs can be avoided; and besides, flames in the combustion process of the coal powder can pass through leading grooves in a curved mode, the staying time of the flames in the shell can be prolonged, and correspondingly the heat supply efficiency to a boiler can be improved.

Owner:JIESHOU HUASHENG PLASTIC MACHINERY

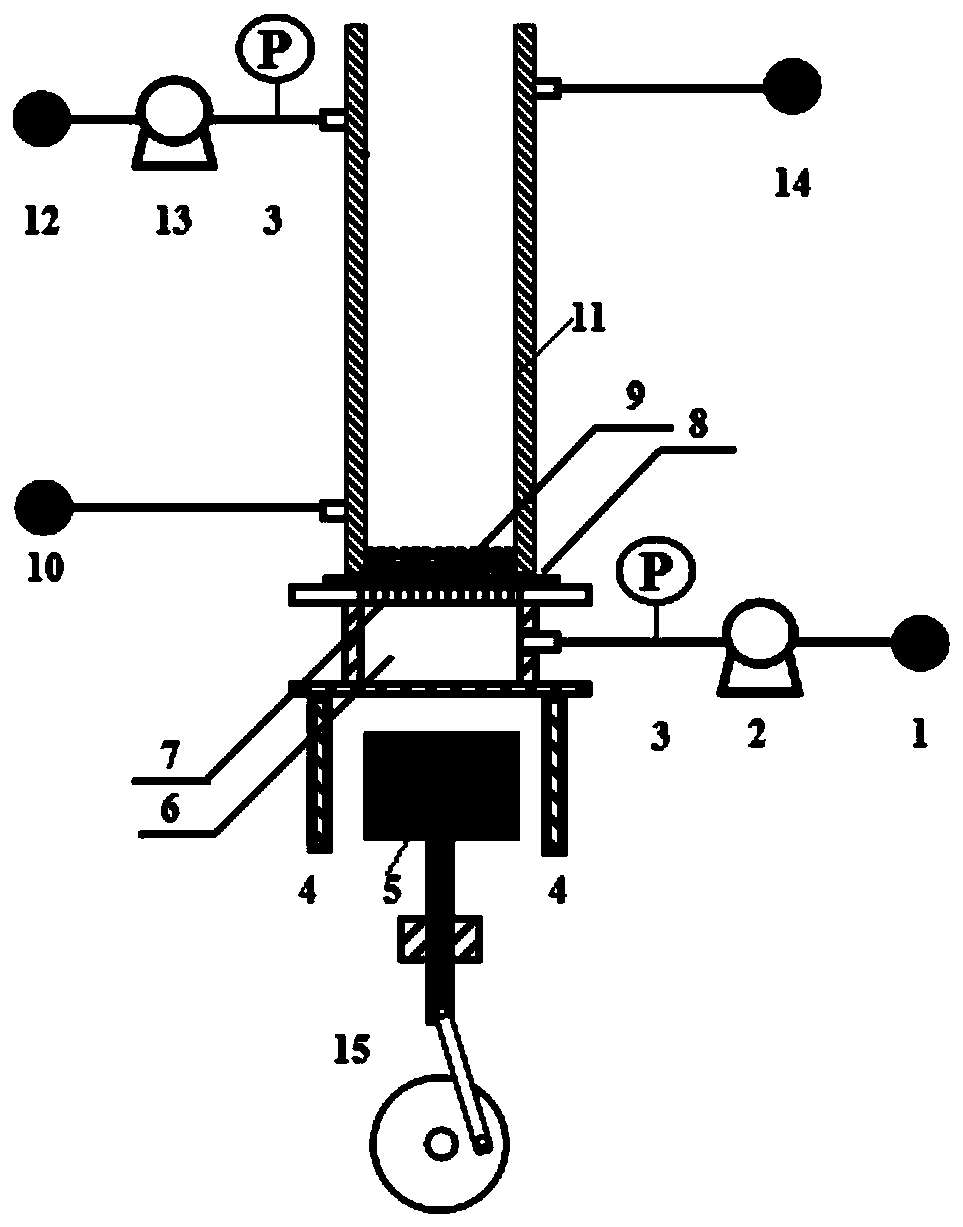

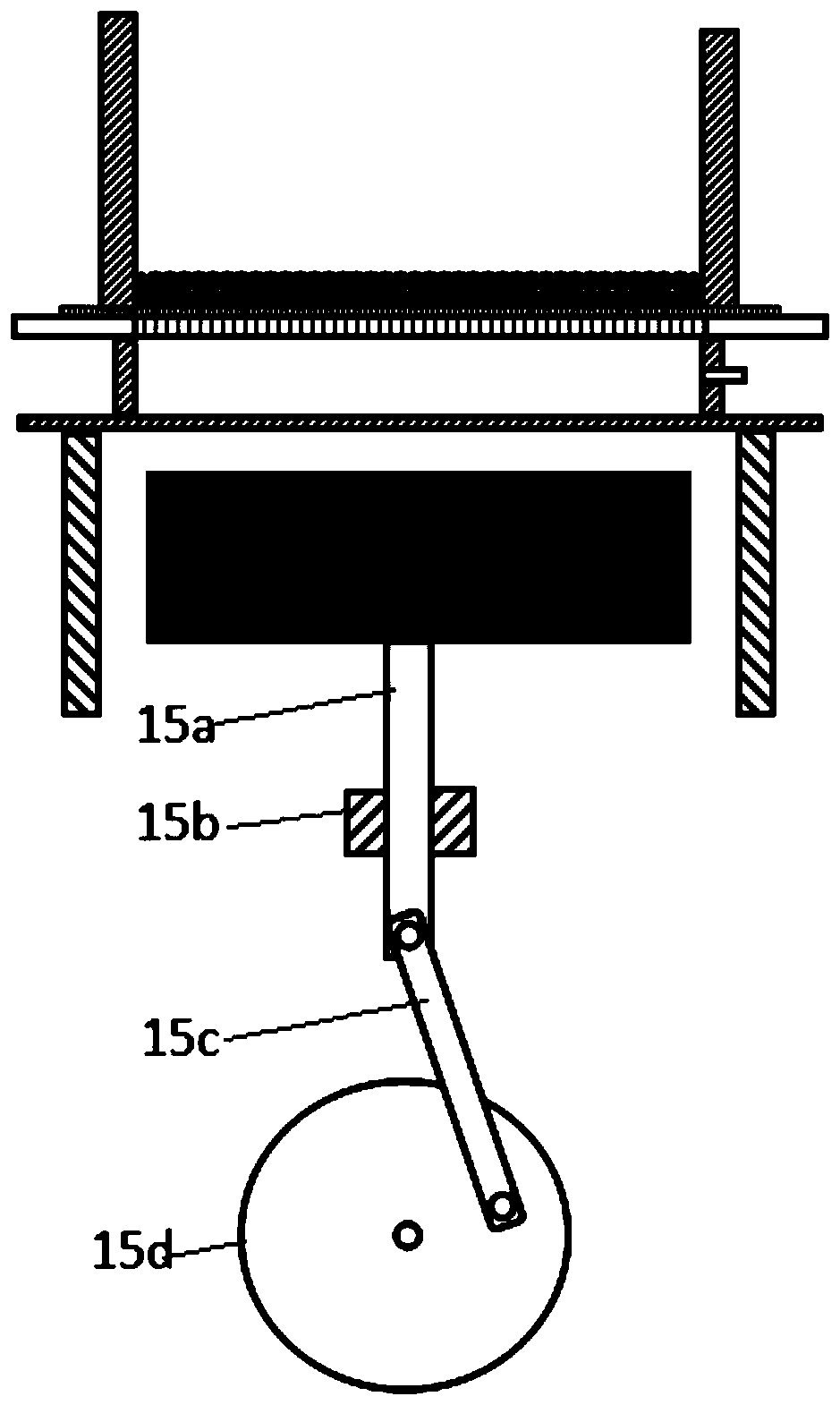

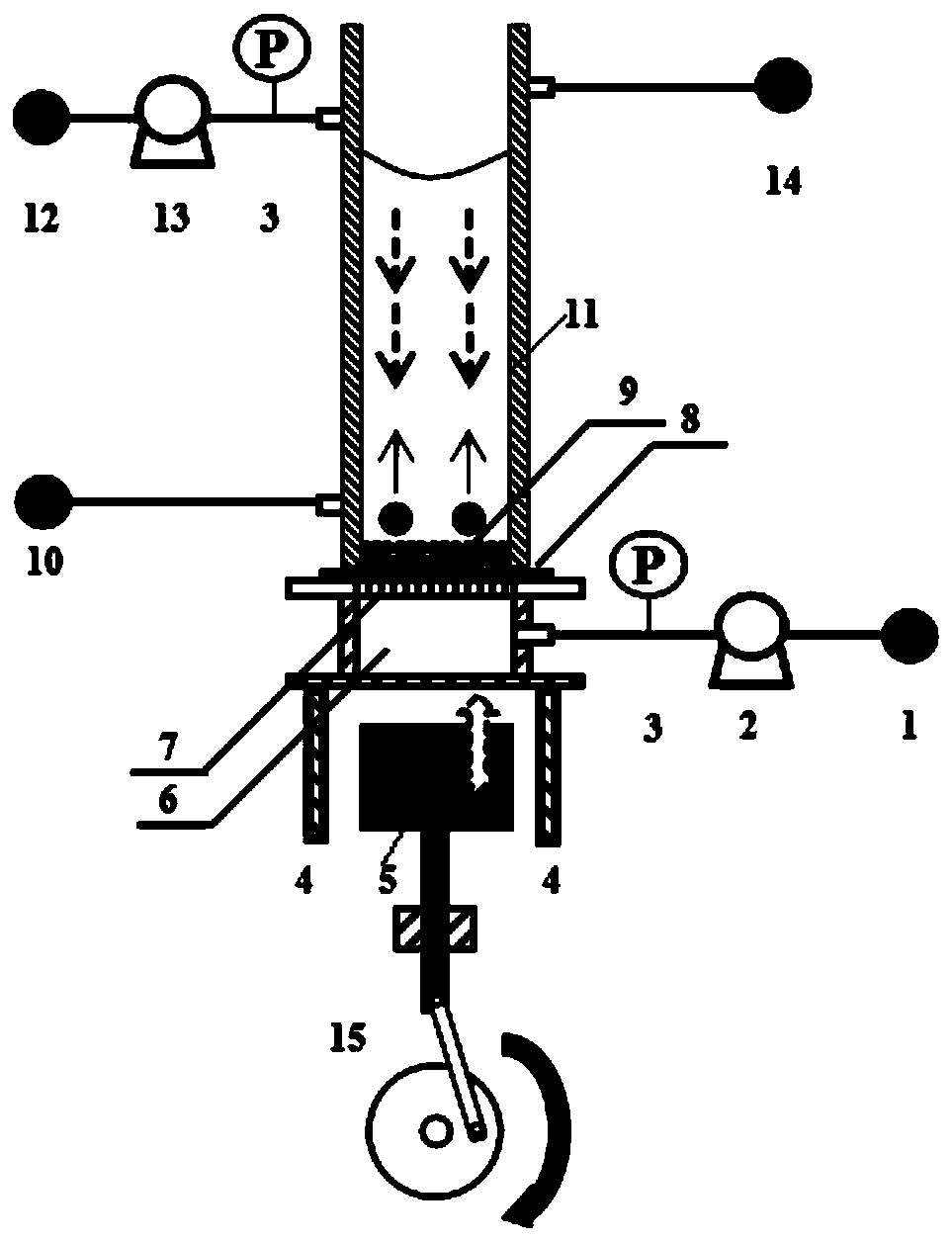

A dynamic magnetic particle combined membrane extraction device and extraction method

ActiveCN107803050BPromote formationPrevent sediment cloggingSemi-permeable membranesLiquid solutions solvent extractionParticulatesEngineering

The invention provides a dynamic magnetic-particle combined membrane extracting device and method. The extracting device comprises a tower body, an extraction phase storage chamber, a porous screen plate, a dynamic magnetic-particle combined membrane, a magnet and a magnet transmission device. The extraction phase storage chamber is located below the tower body, the porous screen plate and the dynamic magnetic-particle combined membrane are sequentially arranged between the extraction phase storage chamber and the tower body from bottom to top, and the magnet and the magnet transmission deviceare arranged below the extraction phase storage chamber. The magnet transmission device of the dynamic magnetic-particle combined membrane extracting device drives the magnet to move vertically, thinmagnetic-particle layers in the dynamic magnetic-particle combined membrane are constantly re-arranged and combined, an extraction phase constantly forms small liquid drops dispersed in a liquid phase, and blockage or ununiform fluid distribution does not occur. Magnetic particles are close to and move towards a magnetic field again to produce the crushing effect on disperse phase liquid drops, formation of small liquid drops is facilitated, meanwhile a channeling phenomenon can be effectively prevented, and the extraction efficiency is improved.

Owner:INST OF PROCESS ENG CHINESE ACAD OF SCI

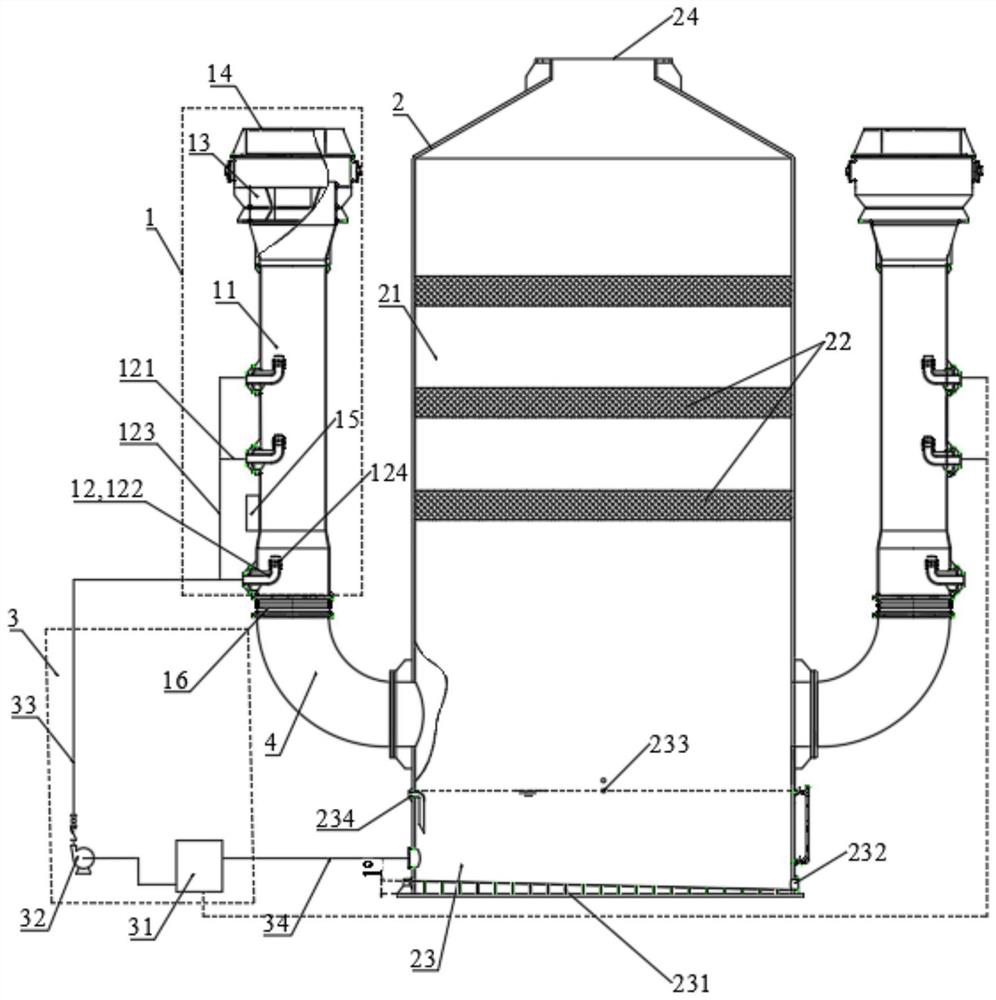

Reverse spraying standing wave dedusting and cooling tower

PendingCN113559642AGood dust removal effectGood cooling effectGas treatmentUsing liquid separation agentFlue gasStress sensors

The invention belongs to the technical field of dust removal towers, and relates to a reverse spraying standing wave dedusting and cooling tower. The dedusting and cooling tower comprises a spraying body and a gas-liquid separation tower, wherein the spraying body comprises a pipe body, wherein a gas inlet is formed in one end of the pipe body, and a flow guide assembly and a spraying assembly are sequentially arranged from the gas inlet to the communicating part of the gas inlet and the gas-liquid separation tower from top to bottom; the spraying assembly is of an L-shaped structure, an opening of the spraying end of the spraying assembly faces upwards, the spraying end of the spraying assembly is provided with a pressure sensor, and the spraying assembly is controlled by a controller arranged outside the spraying assembly to control the flowing speed and the height of sprayed water flow so as to form a standing wave film; the gas-liquid separation tower comprises a tower body, a steam-water separation device and a sedimentation tank; and the communicating part of the spraying body and the tower body is arranged between the steam-water separation device and the sedimentation tank, and the gas outlet is formed in the upper part of the tower body. High-temperature flue gas in the dedusting and cooling tower is in full contact with spraying water which is sprayed from top to bottom to form a standing wave film, the operation is stable, the dedusting effect is good, and the waste heat recovery rate is high.

Owner:常州江南冶金科技有限公司

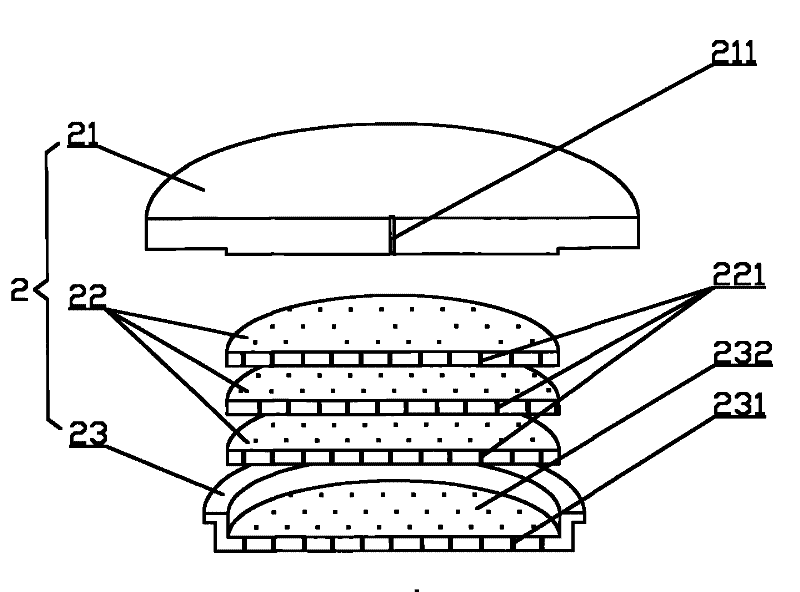

A method of manufacturing an LED package

ActiveCN102931328BThere will be no uneven distributionEasy to operateSemiconductor devicesFluorescenceEngineering

The invention discloses a manufacturing method of an LED (Light-Emitting Diode) packaging body. The preparation method comprises the following steps of: preparing an LED chip provided with a fluorescent powder layer; and then, packaging the LED chip provided with the fluorescent powder layer. With the adoption of the technical scheme, the fluorescent powder layer of the LED chip is arranged before package so that the operation is more convenient and the operation manner is more flexible. A technicist of the field can set the fluorescent powder layer on a whole board LED after an LED wafer is sliced and before the package; the set area is larger so that uniform coating can be carried out; and a phenomenon that the distribution is not uniform, caused by the influence of surface tension, is not caused, so that the technical problem in the prior art that fluorescent powder is not uniformly coated or the use amount of the fluorescent powder is large is effectively avoided.

Owner:北京半导体照明科技促进中心

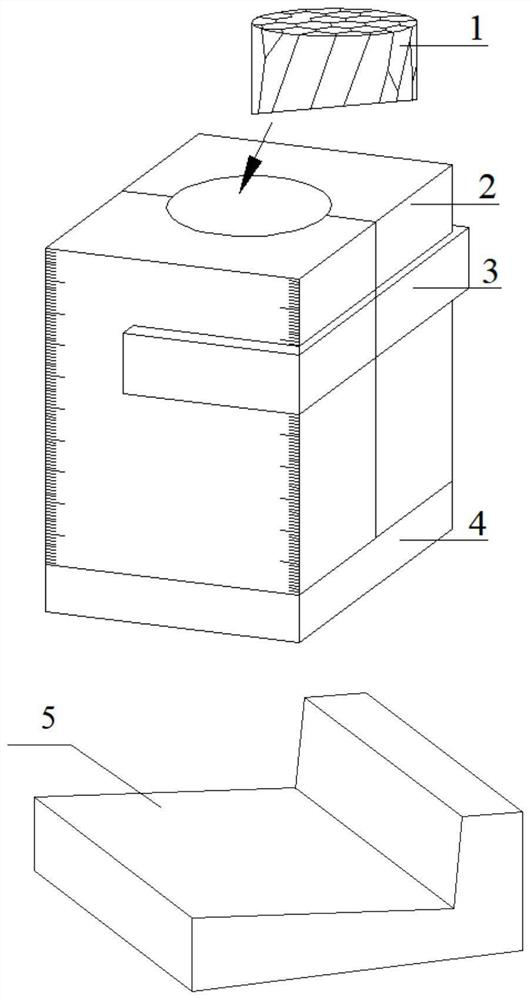

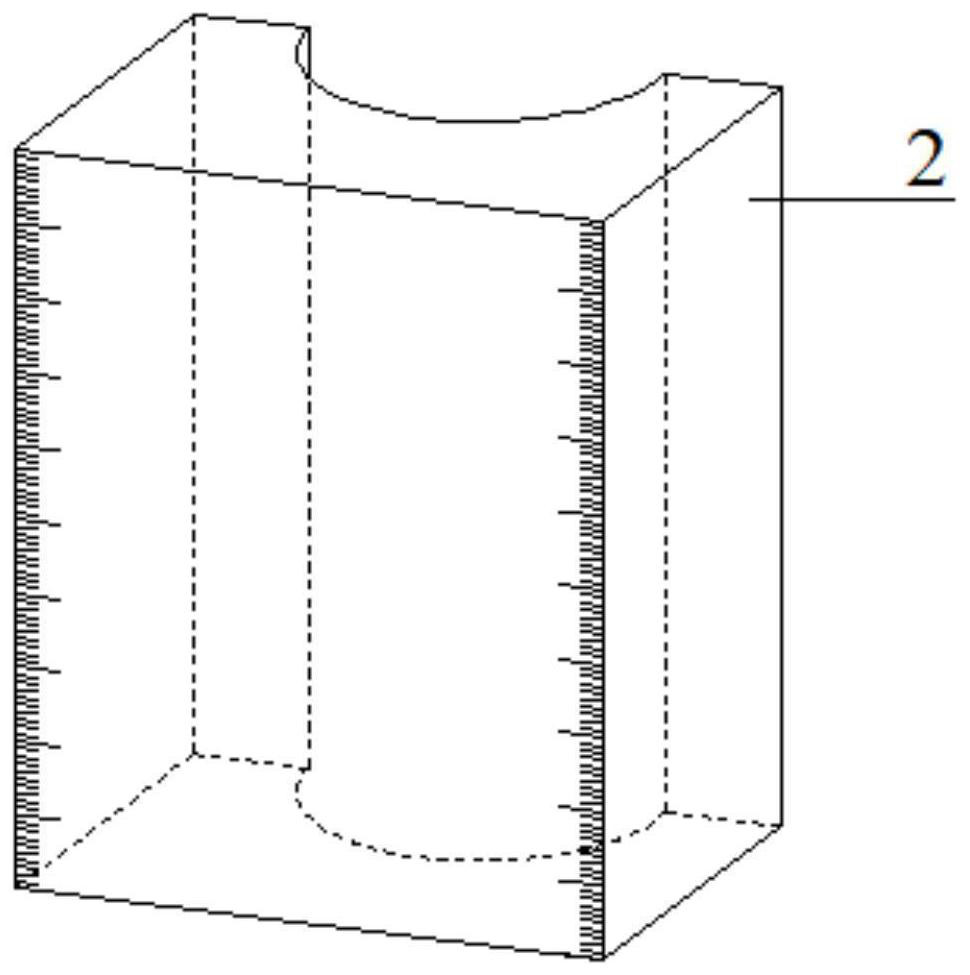

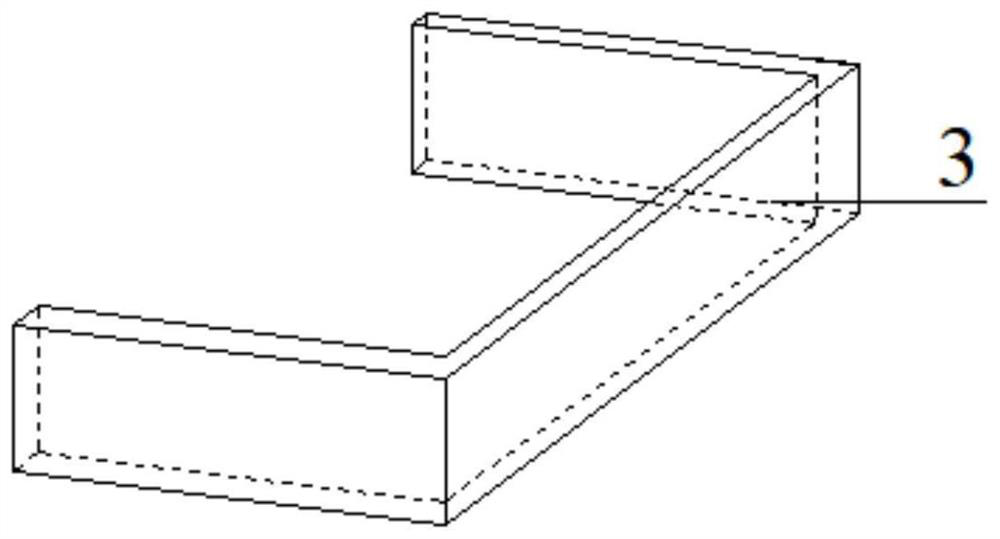

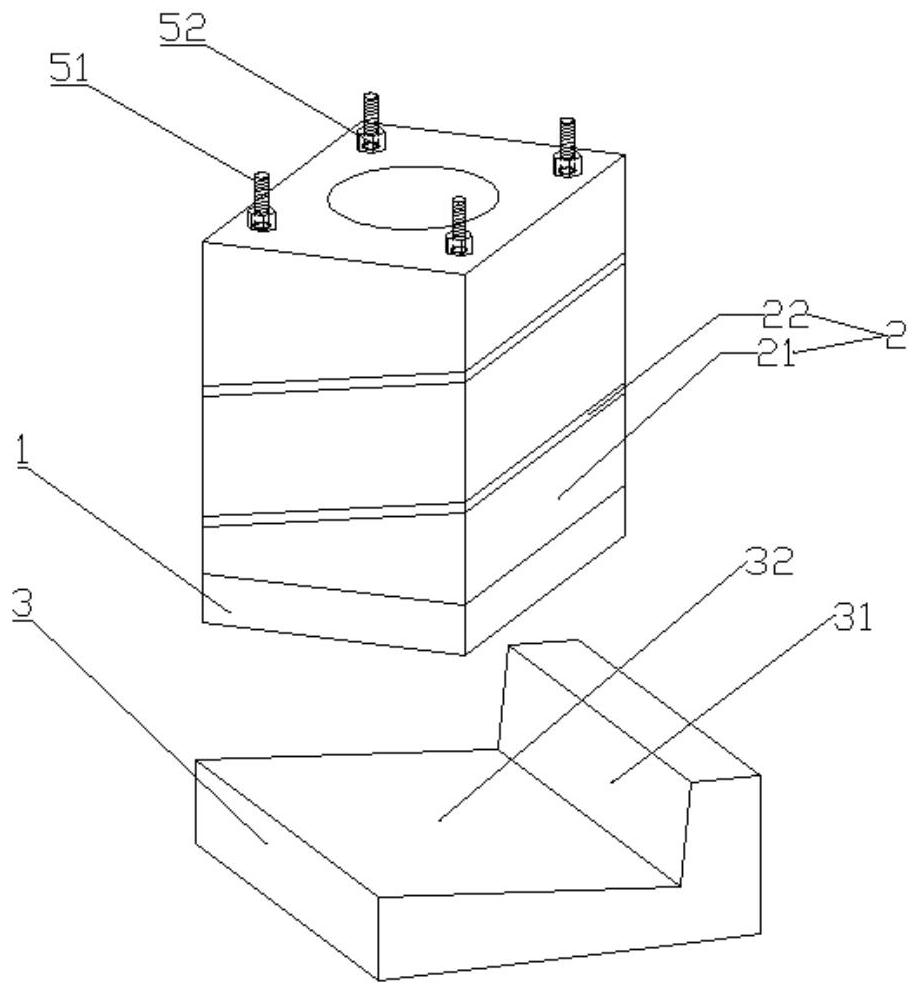

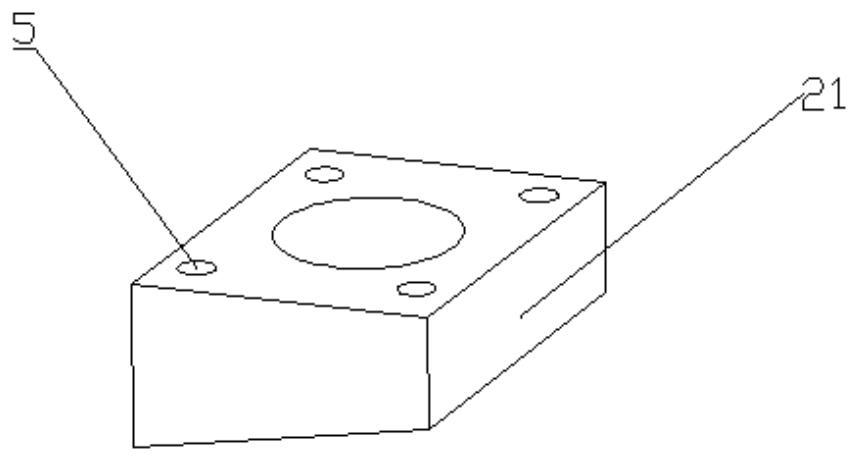

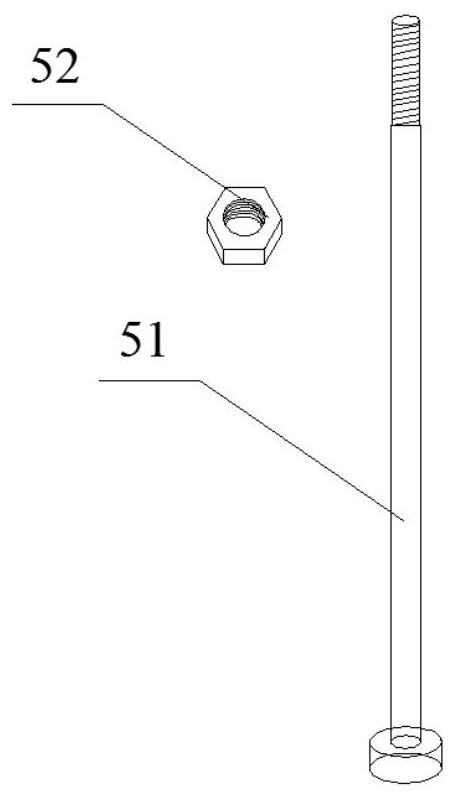

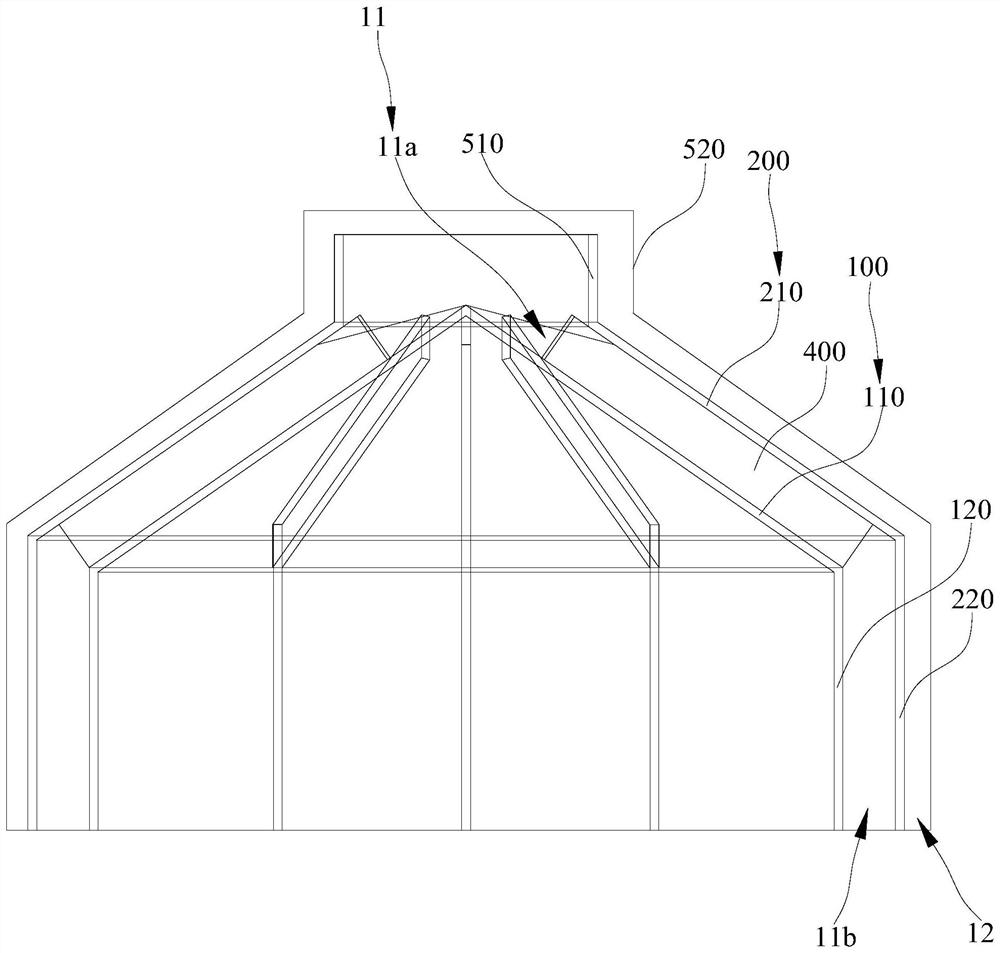

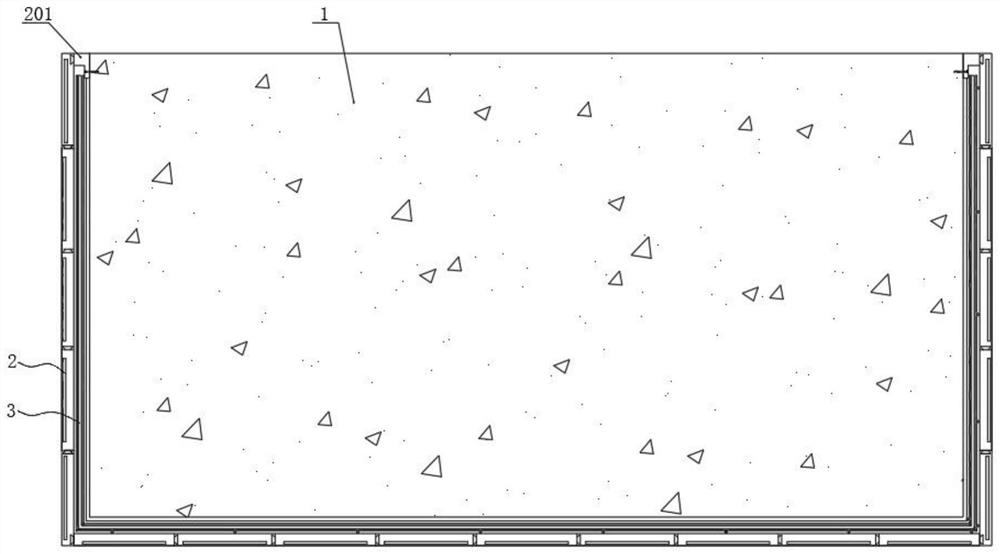

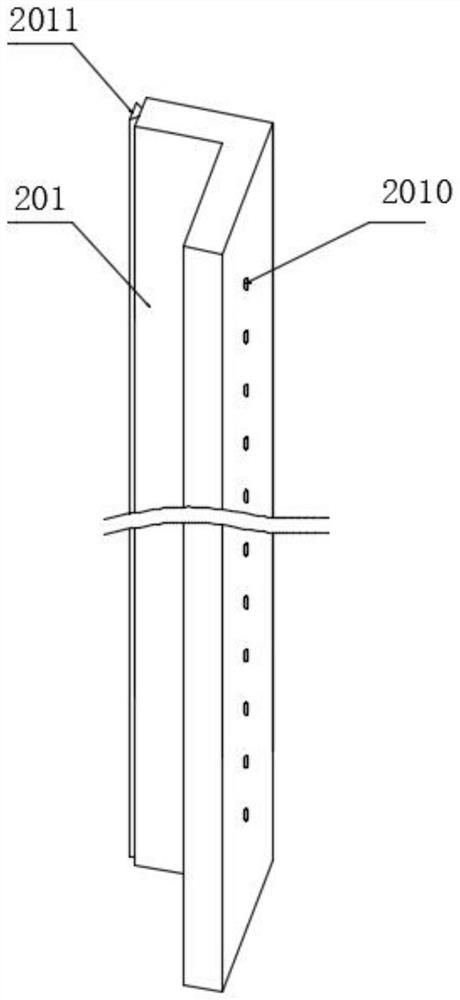

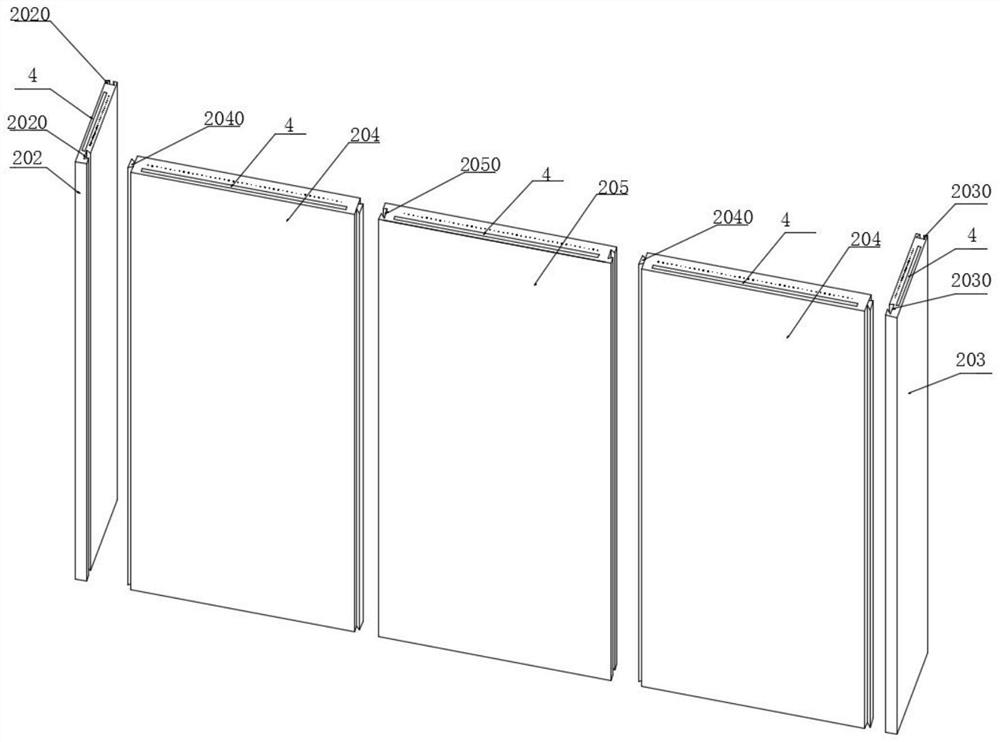

Sample preparation mold and sample preparation method for complex rock mass structure containing multiple interlayer staggered belts and columnar joints

PendingCN114459855AThe method is simple and reliableOvercome the disadvantages of being greatly affected by the environment and poor economyPreparing sample for investigationCrystallographyBedrock

The invention discloses a sample preparation mold and a sample preparation method for a complex rock mass structure containing multiple interlayer staggered belts and columnar joints. The sample preparation mold comprises a restraint plate, a connecting mechanism, a sample preparation base and an inclination angle control mechanism (5); scale marks are arranged on the surface of a restraint plate of the sample preparation mechanism, and simulation positions of a bed rock mass, an interlayer staggered belt and a columnar jointed rock mass can be calibrated through scale setting; the columnar joint structure is realized through a 3D printing technology; the sample preparation mold provided by the invention is simple in structure, can be used for accurately and quickly preparing a simulation sample containing a multi-layer interlayer staggered belt and columnar joint complex rock mass structure, and is beneficial to experimental research on permeation, strength and deformation behaviors of the interlayer staggered belt and columnar joint complex rock mass, so that an accurate and reliable test result is obtained.

Owner:POWERCHINA HUADONG ENG COPORATION LTD

A sample preparation mold and sample preparation method for simulating rock mass with multi-layer interlayer dislocation zone

ActiveCN110057639BThe method is simple and reliableGood repeatabilityPreparing sample for investigationHigh densityVertical plane

The invention discloses a sample preparation mold and a sample preparation method for simulating a rock mass with multi-layer interlayer staggered zones. The sample preparation mold includes an inclination control mechanism for controlling the inclination angle of a sample preparation base and a sample preparation mechanism; The upper surface of the main control cylinder of the mechanism is an inclined surface; the inclination control mechanism is an L-shaped structure including a vertical surface and an inclined horizontal surface; the sample preparation mold provided by the present invention has a simple structure, and can accurately and quickly produce multi-layer interlayer displacement The simulated sample of the rock mass in the belt is beneficial to the experimental research on the strength and deformation behavior of the rock mass in the interlayer dislocation zone, and then obtains accurate and reliable test results. The cylinder is matched for leveling; the sample preparation devices of each layer are prepared separately and then assembled and poured, so that there will be no uneven distribution of test pieces, and the thickness and inclination angle of each layer of samples can be accurately controlled; at the same time, it is avoided to pour layers of the same material for the samples Disadvantages of low density and high density.

Owner:HOHAI UNIV

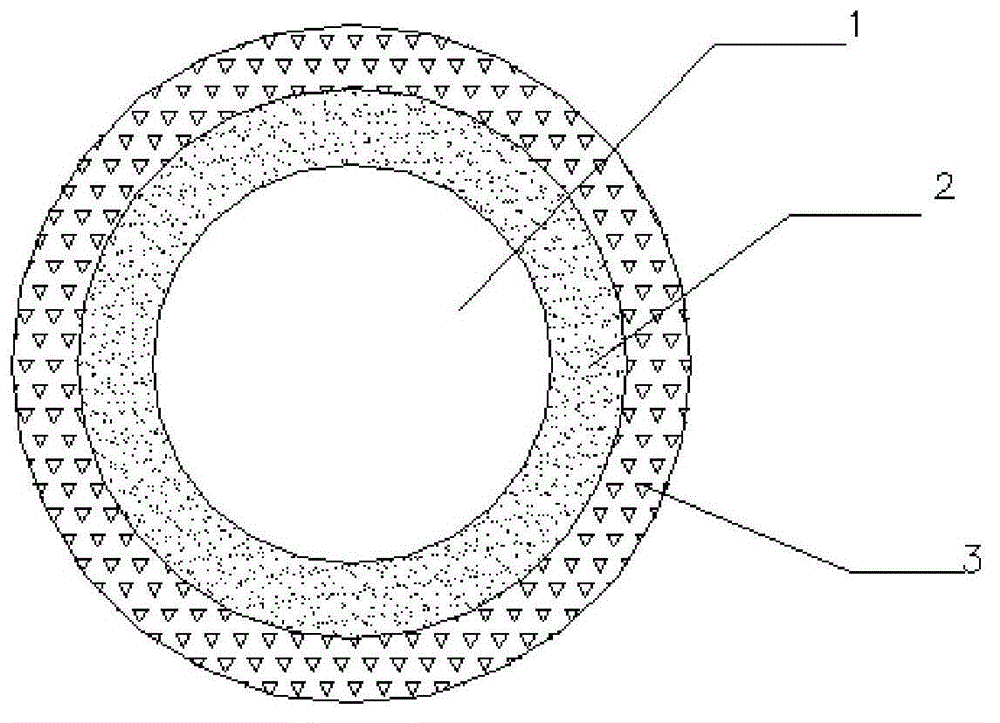

Discharging structure and material distributing system

PendingCN113399622AGood insulation effectLess cleaningMould handling/dressing devicesPhysicsEngineering

The invention discloses a discharging structure and a material distributing system. The discharging structure comprises an inner-layer cover body, a middle-layer cover body and an outer-layer cover body, wherein the inner-layer cover body is used for at least covering a casting opening of a mold, the inner-layer cover body is sleeved with the middle-layer cover body, a first function channel is formed between the middle-layer cover body and the inner-layer cover body, the middle-layer cover body is sleeved with the outer-layer cover body, a second functional channel is formed between the outer-layer cover body and the middle-layer cover body, one of the first functional channel and the second functional channel is a discharging channel, and the other one is a dust collection channel. The inner-layer cover body is sleeved with the middle-layer cover body, and the middle-layer cover body is sleeved with the outer-layer cover body, so that ball sand can be evenly distributed around a mold when entering a heat preservation box, the situation that the ball sand is not evenly distributed is avoided; when one of the first functional channel and the second functional channel serves as the discharging channel for discharging the ball sand, the other one serves as the dust collection channel, so that flying dust generated in the process that the ball sand enters the heat preservation box is pumped away, sweeping work can be greatly reduced, and dust pollution can be reduced.

Owner:广东石井新材料有限公司

Non-dismantling formwork pouring mortar layer heat insulation board and production process of non-dismantling formwork pouring mortar layer heat insulation board

PendingCN114718200AEasy to installShort timePassive housesHeat proofingScreedManufacturing engineering

The invention relates to a non-dismantling formwork pouring mortar layer insulation board and a production process thereof. The non-dismantling formwork pouring mortar layer heat preservation plate comprises an outer formwork mechanism detachably connected to a wall, a pouring shaping mechanism arranged between the outer formwork mechanism and the wall and a mortar heat preservation layer poured among the outer formwork mechanism, the pouring shaping mechanism and the wall. According to the non-dismantling formwork pouring mortar layer heat preservation plate and the production process thereof, the outer formwork mechanism which is more convenient to install is arranged, the time consumed for formwork building can be greatly shortened, the connection relation between the formworks is more stable, the pouring shaping mechanism is additionally arranged between the wall body and the outer formwork mechanism, the poured heat preservation layer can be extruded and shaped, and the heat preservation effect is better. And meanwhile, due to the high sealing performance between the formworks, the formworks can bear expansive force generated when the heat preservation layers are extruded, and the mechanism of the whole heat preservation plate is more precise and stable.

Owner:江苏盈达保温材料有限公司

Membrane electrode assembly and proton exchange membrane fuel cell

PendingCN114695931ANo spreadThere will be no uneven distributionSolid electrolyte fuel cellsPtru catalystChemical physics

The invention provides a membrane electrode assembly and a proton exchange membrane fuel cell, and relates to the technical field of fuel cells, in the membrane electrode assembly, a membrane electrode cathode frame and a membrane electrode anode frame are respectively arranged at two sides of a catalyst coating membrane and in a cathode or anode area, and the frames surround a gas diffusion layer; the shape of the inner side edge of the frame is the same as that of the first winding flow channel at the upper edge of the polar plate, and one of the two ridges on the two sides of the first winding flow channel at the edge of the polar plate, which is close to the edge of the polar plate, is taken as the outer side ridge of the polar plate, and the other ridge is taken as the inner side ridge of the polar plate; and the inner side edge of the frame coincides with the inner side edge of the polar plate outer side ridge. The proton exchange membrane fuel cell comprises the membrane electrode assembly. According to the invention, the technical problems of non-uniform gas distribution and influence on the performance and the service life of the fuel cell due to the fact that the inner edge of the membrane electrode frame is linear and the widths of the inner side ridge and the outer side ridge are different in the bipolar plate fuel cell with a zigzag flow channel in the prior art are solved.

Owner:FTXT ENERGY TECH CO LTD

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com