Preparation method of granular primary ore polished section

A light sheet and ore technology, applied in the field of preparation of granular primary ore light sheet, can solve the problems of unenvironmental protection, potential safety hazards, uneven distribution of precipitation, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0020] The technical solutions of the present invention will be described below in conjunction with the accompanying drawings and implementation methods.

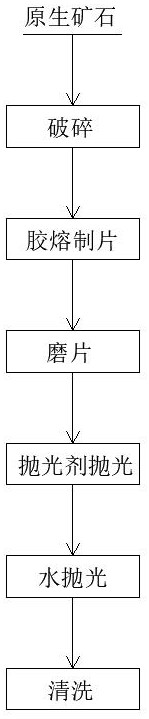

[0021] like figure 1 Shown, a kind of preparation method of granular primary ore light sheet, comprises the following steps:

[0022] a. Crushing: Use a jaw crusher to crush the raw ore to a granular ore sample with a particle size of -3mm, and shrink it to 100g after mixing;

[0023] b. Adhesive melting tablet: Weigh the mineral sample in step a and mix it with the binder in a ratio of 2:1, stir evenly and heat to 80°C, then pour the mixture into the sample mounting machine and pressurize to 2.5MPa and stop About 40s, take out the cured light sheet grinding blank;

[0024] c. Grinding sheet: place the light sheet grinding blank in step b on the sample grinding machine for rough grinding, use 120# water-resistant sandpaper for rough grinding, and rinse it with clean water after grinding for 1 minute;

[0025] Put the rou...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Granularity | aaaaa | aaaaa |

| Granularity | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com