Patents

Literature

35results about How to "Reduce sample preparation costs" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

ELISA kit for detecting clenbuterol and detection method thereof, and animal tissue sample preparing method before detection

ActiveCN1885038AReduce dosageHigh sensitivityColor/spectral properties measurementsSpecial data processing applicationsElisa kitImmune adsorption

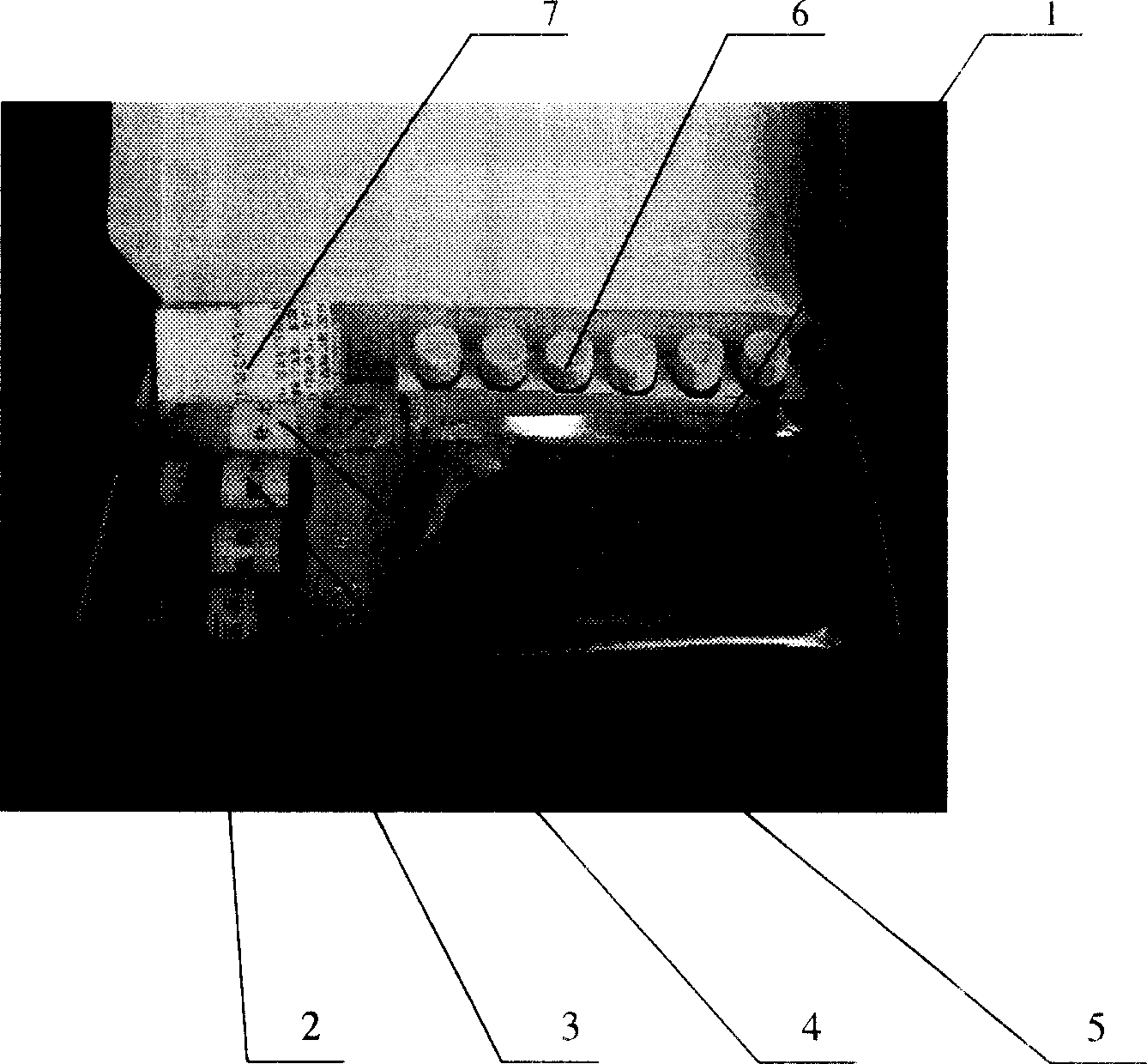

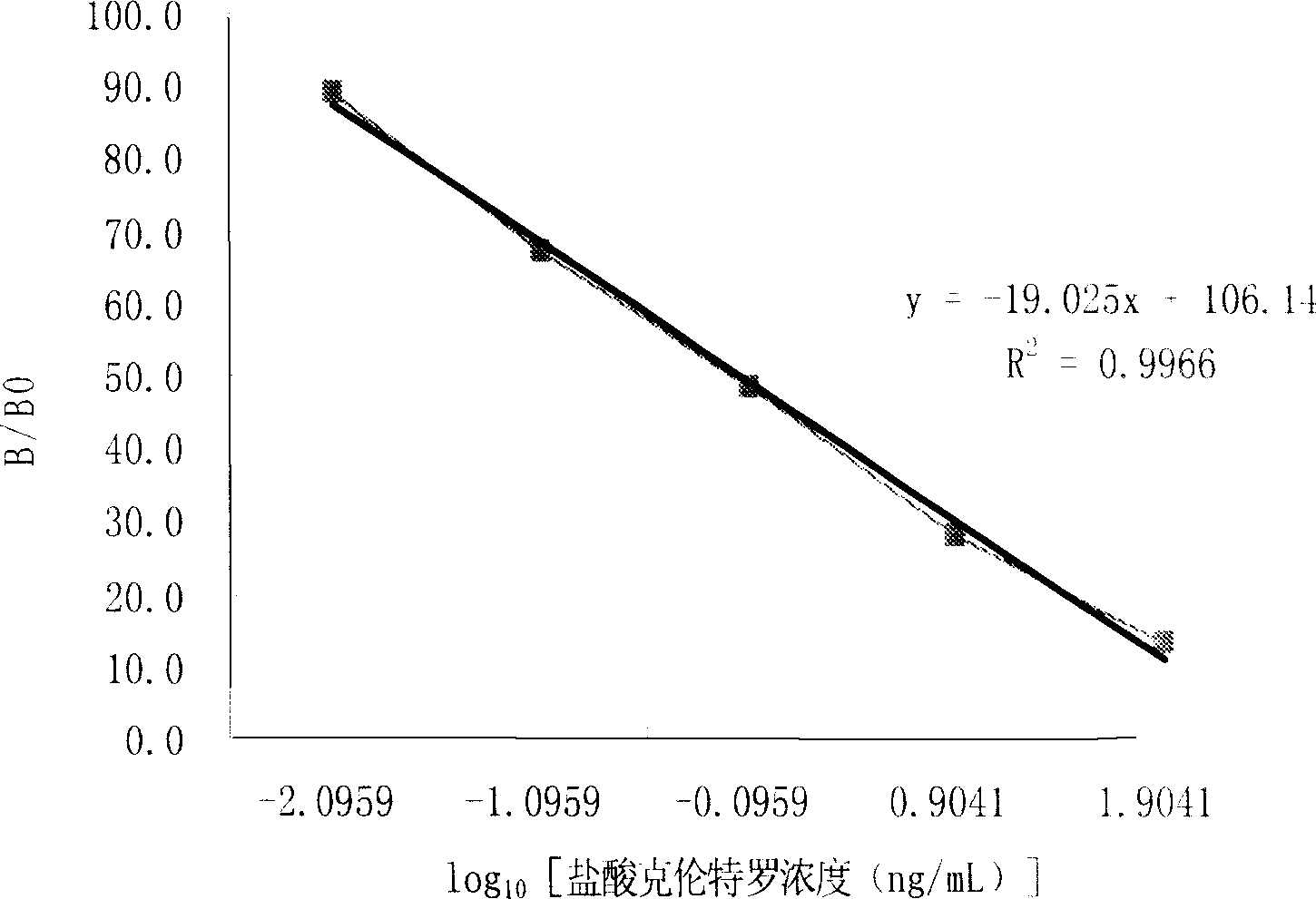

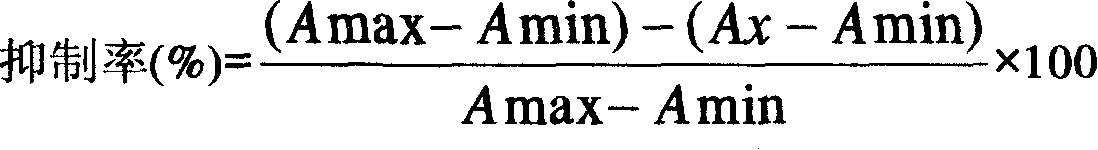

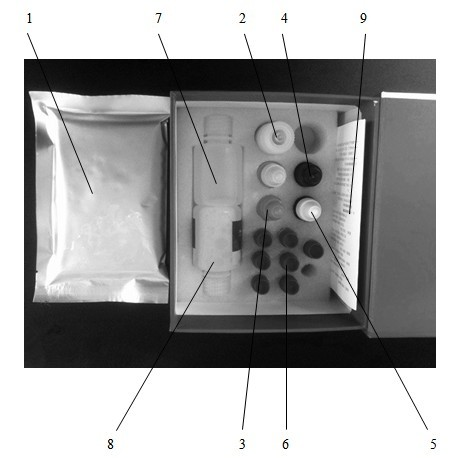

The invention relates to an enzyme couple immune detecting field, especially disclosing a clenobuterol enzyme immune agent box, relative detecting method, and a method for preparing the sample of animal organism, wherein said box comprises a box body, a 96 / 40 porous enzyme mark plate, a horse peroxide enzyme mark antibody, a clenobuterol standard solution, a substrate liquid, a substrate buffer liquid and a reaction ending liquid; the holes of said mark plate packs the packing antibody that combined with the clenobuterol antibody. The invention uses direct competitive enzyme couple immune adsorption analysis technique, to simplify the operation and reaction time, to reduce error. The inventive method has simple operation, low cost, and short time, while the extracted sample can be directly used in enzyme couple immune method and golden mark immune laminated analysis, to be sample of prior analysis.

Owner:SOUTH CHINA AGRI UNIV

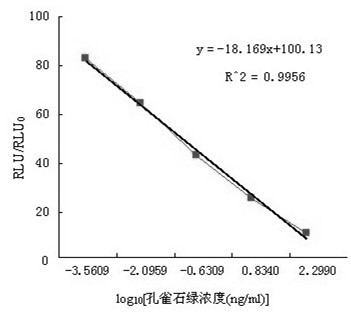

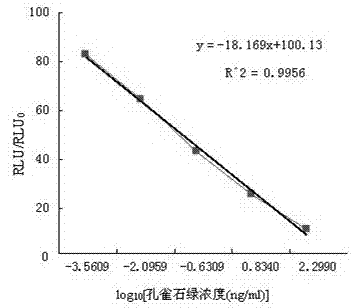

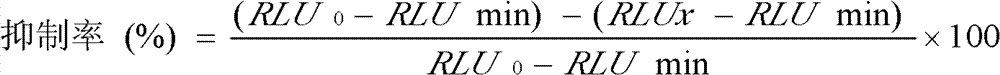

Malachite chemiluminescence ELISA detection method and kit

ActiveCN102661946AIncreased sensitivityStrong specificityChemiluminescene/bioluminescenceELISA unitImmuno detection

The invention discloses a malachite chemiluminescence ELISA detection method and a kit. According to the invention, it is the first time to discuss chemiluminescence ELISA mechanism of malachite, a malachitechemiluminescence ELISA detection system and a detection method are successively established, and perfect combination of high sensitivity and high specificity is realized. The kit provided by the invention has high sensitivity, accuracy, precision and stability, is used to simplify operation steps and reaction time and reduce errors caused by complex operation, is very suitable for trace analysis and batch detection of malachite residues, and is of great practical application significance.

Owner:广州万联生物科技有限公司

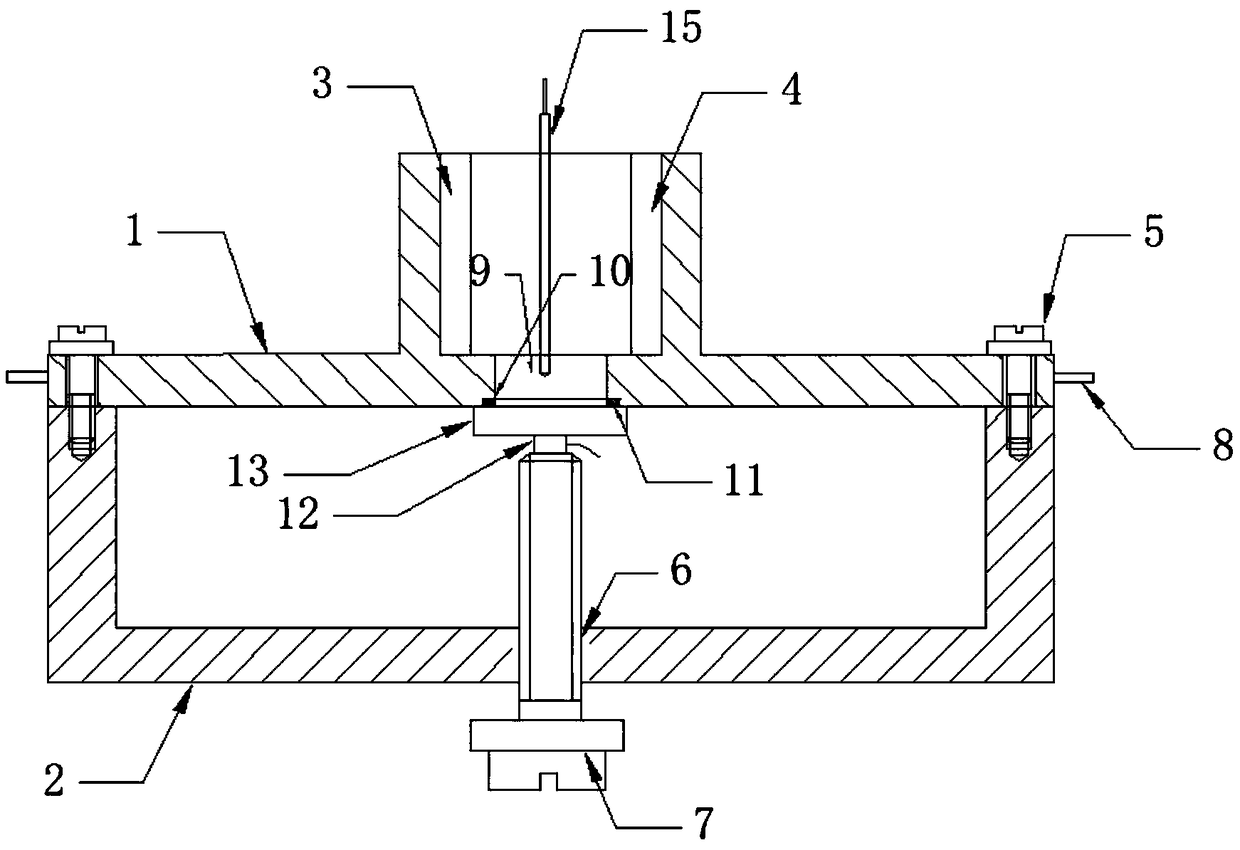

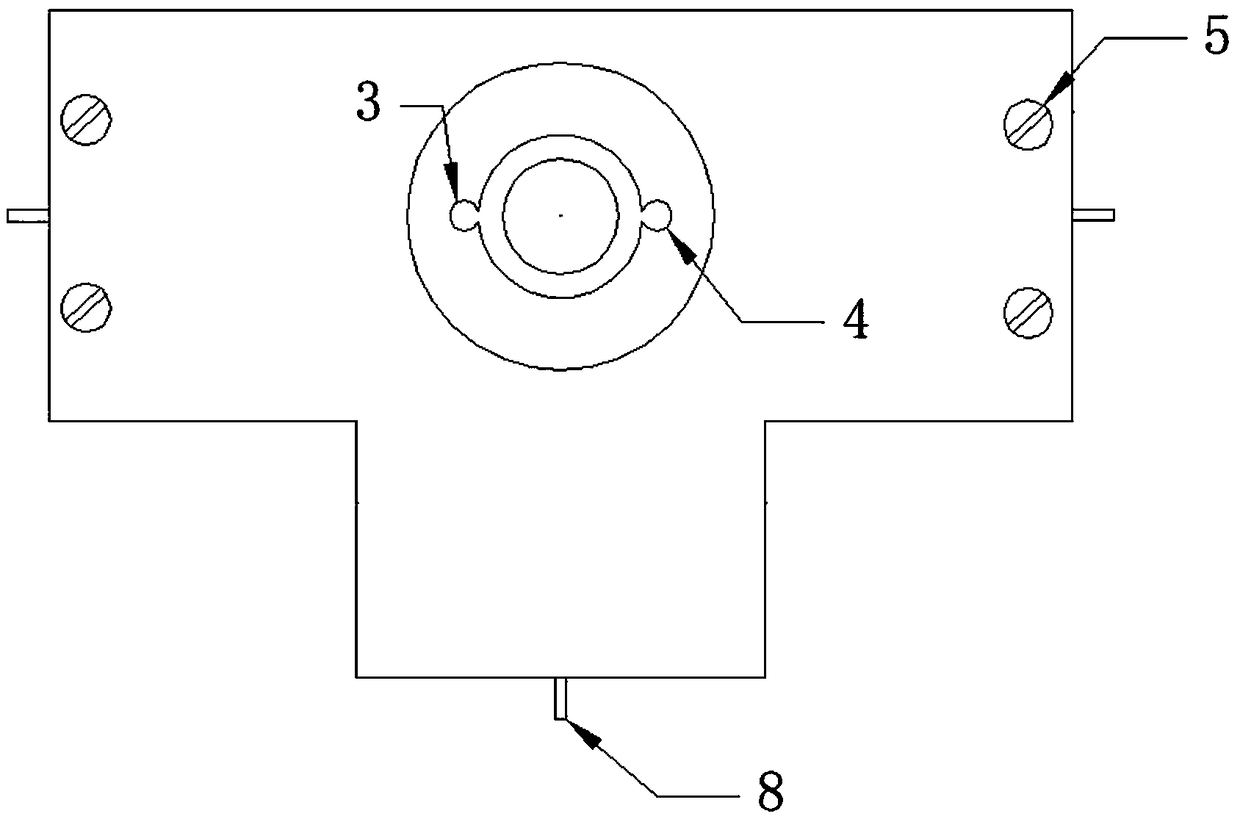

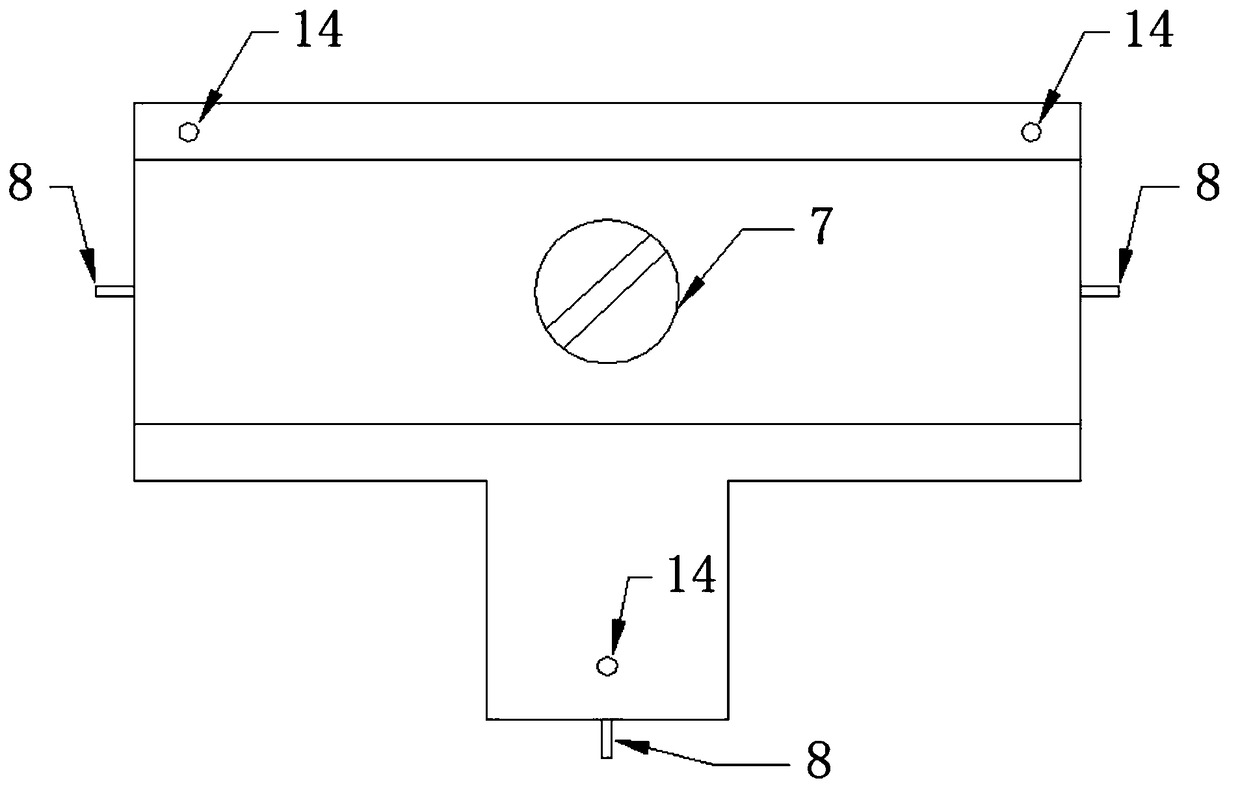

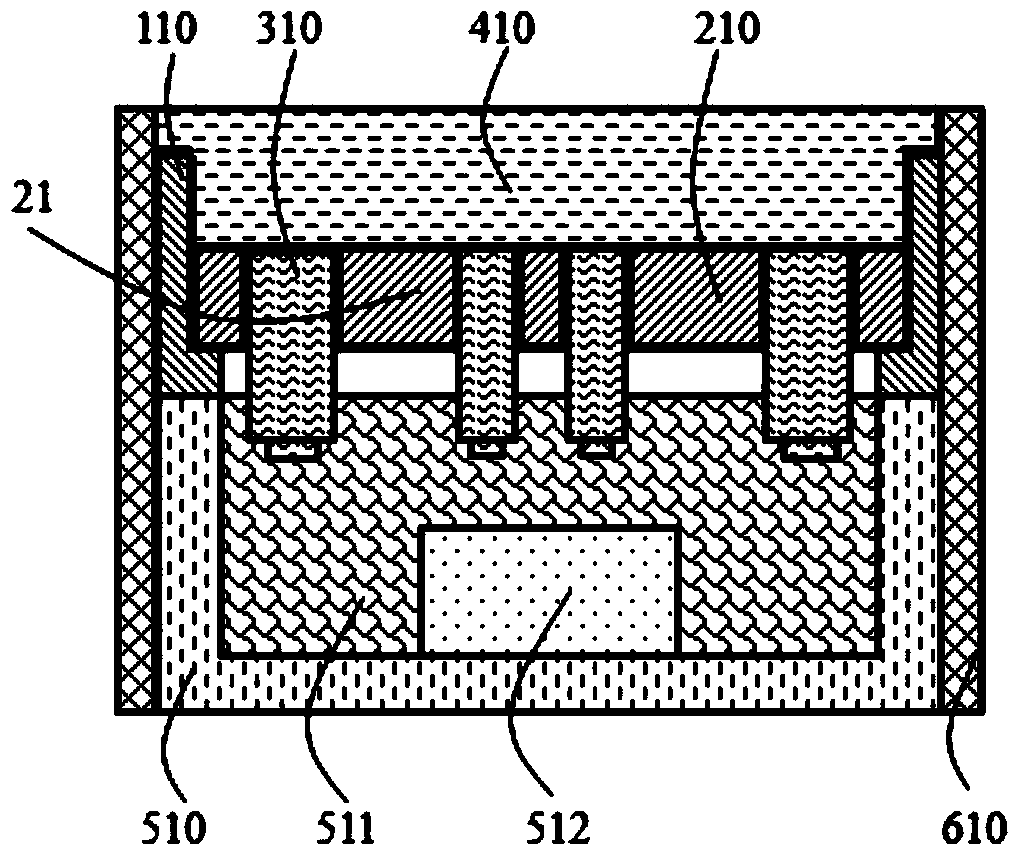

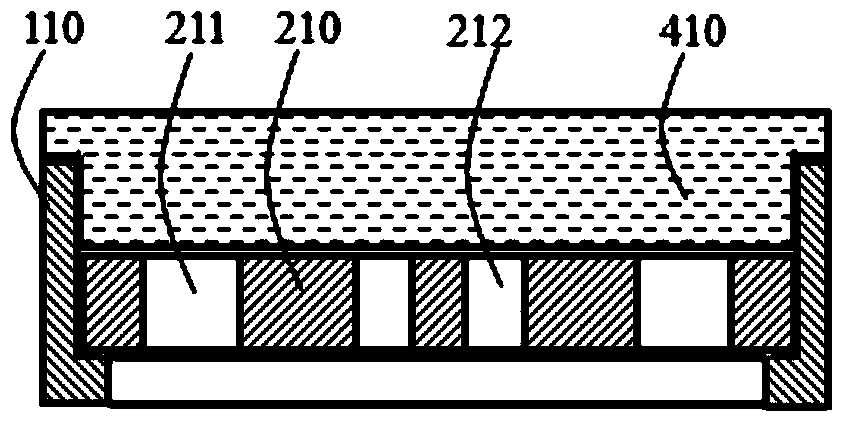

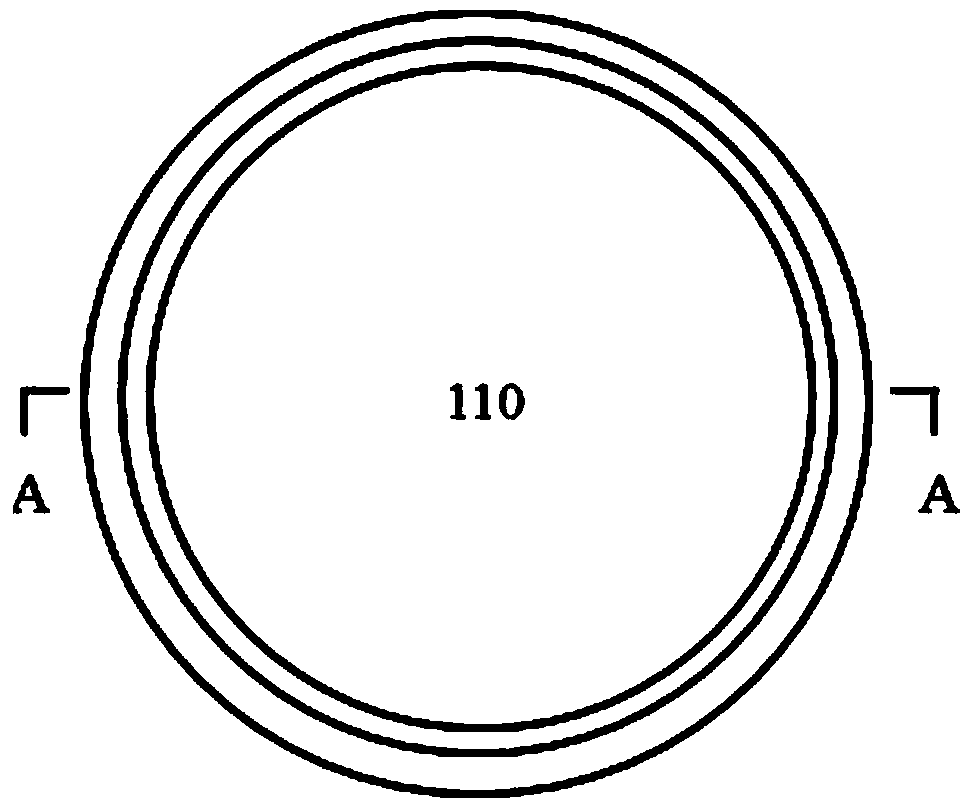

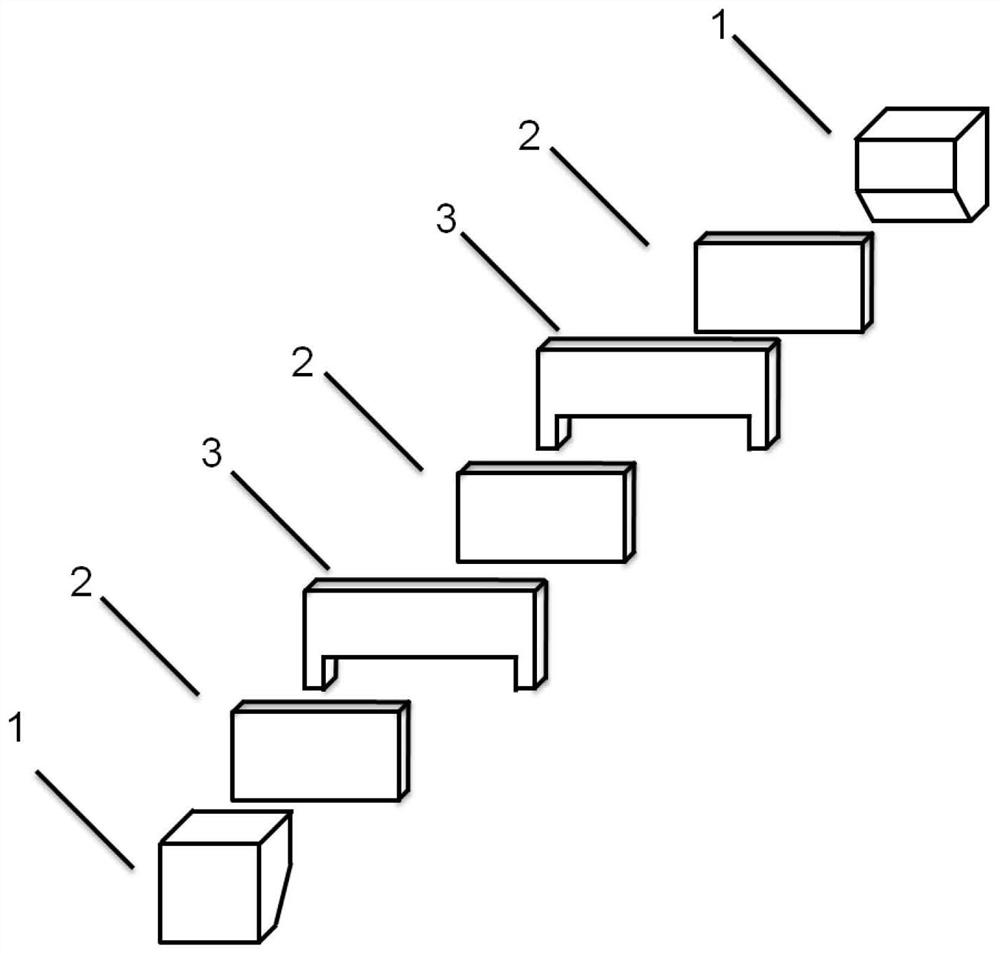

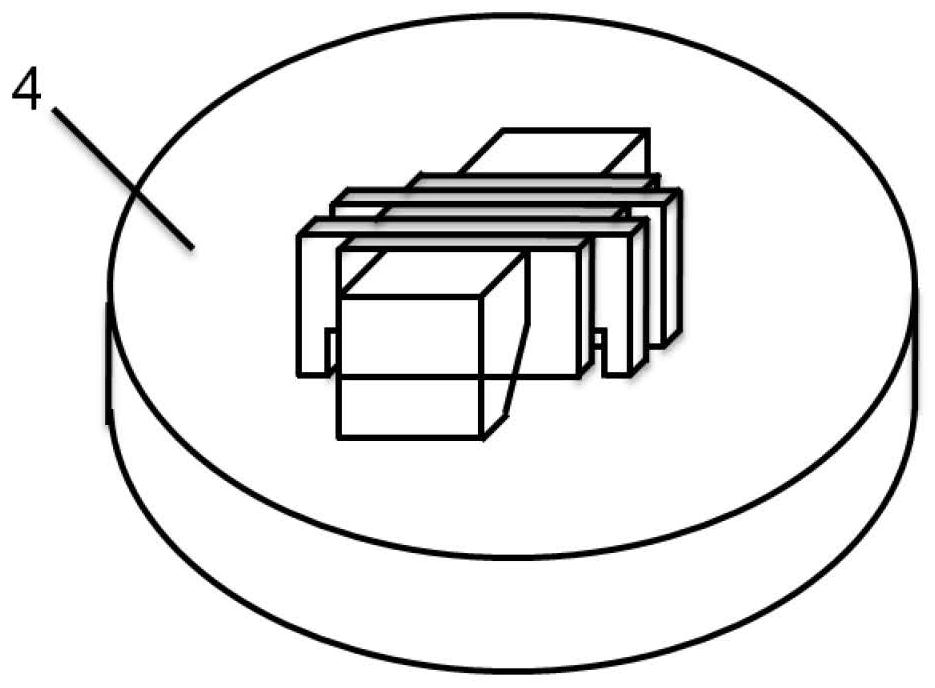

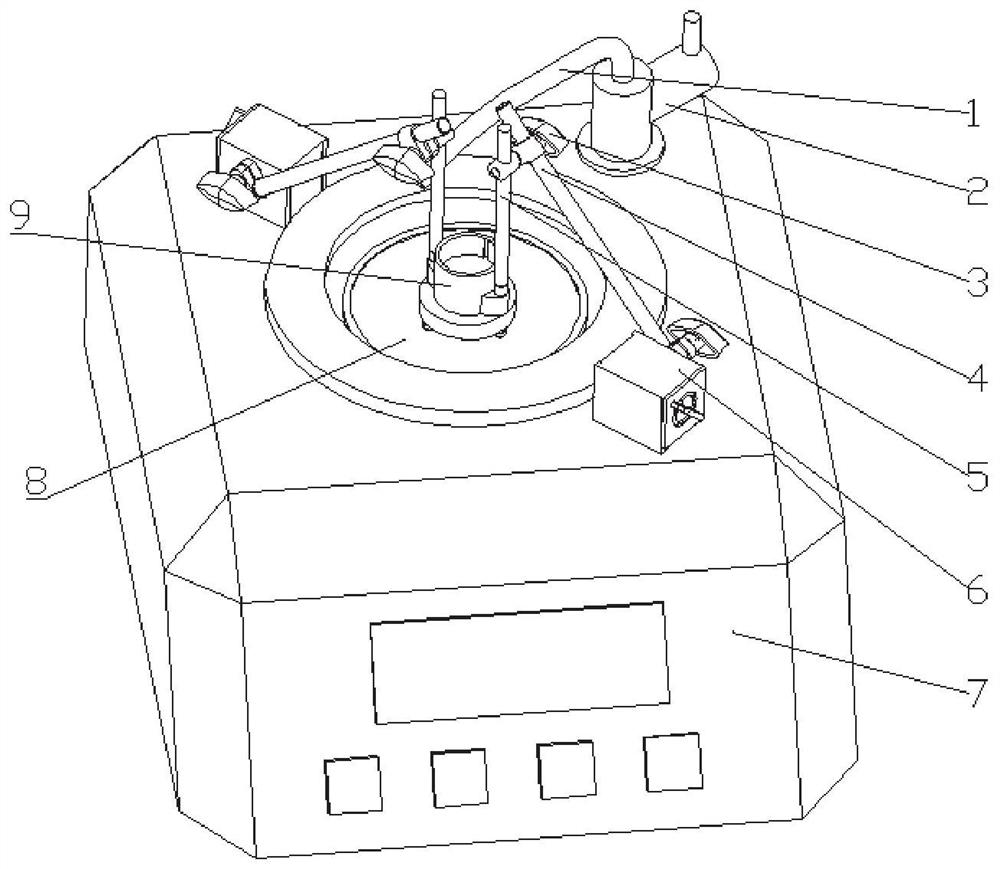

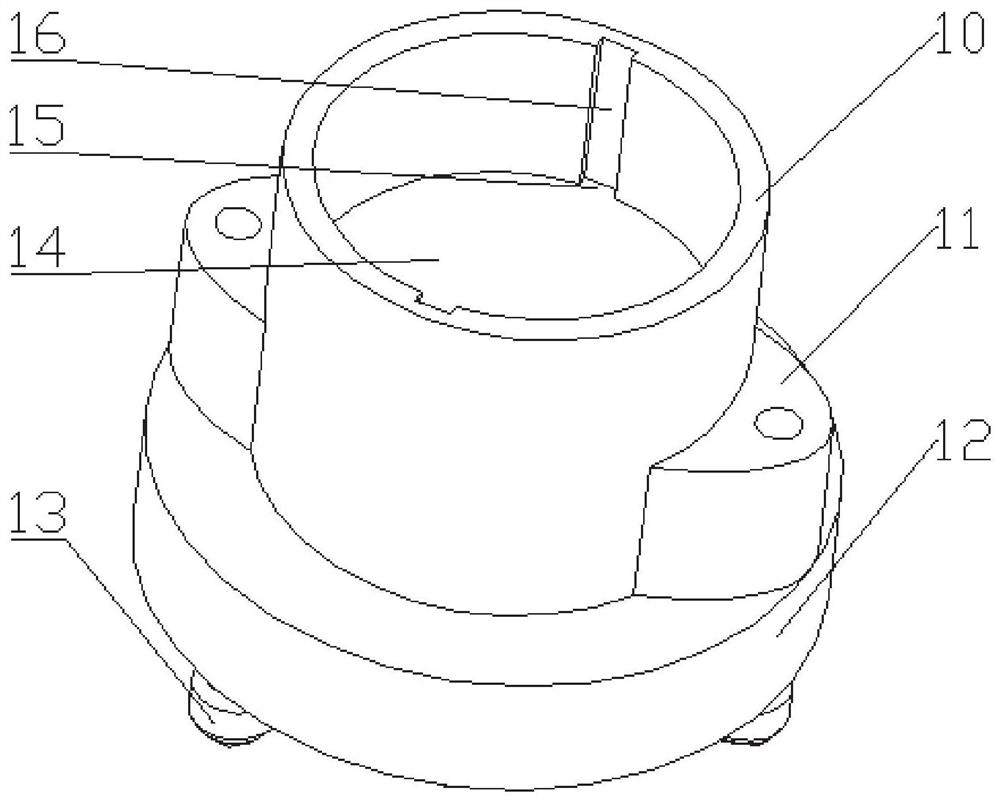

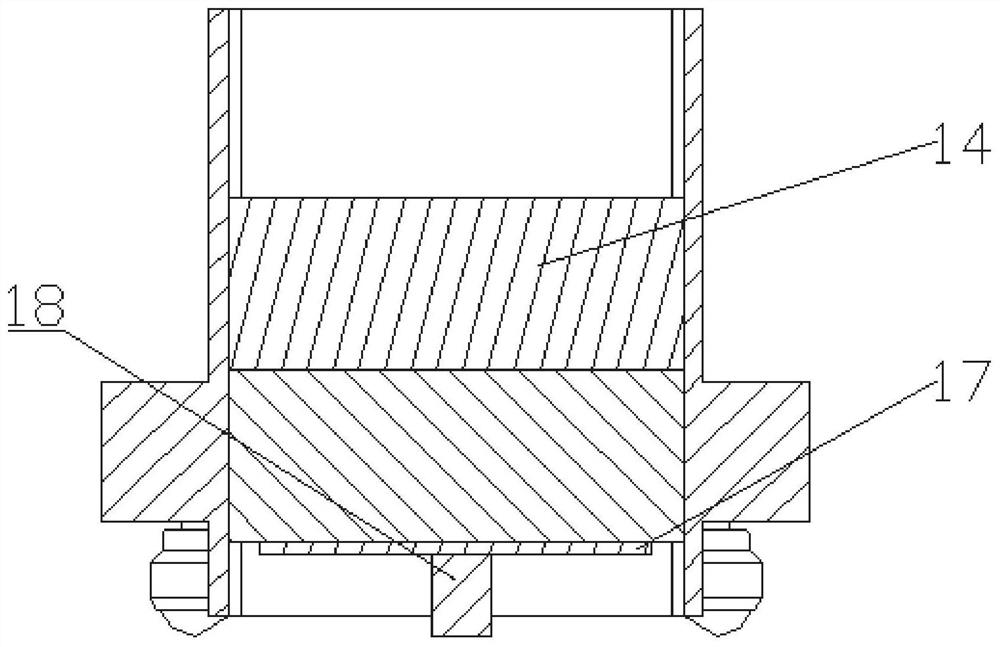

Scanning electrochemical microscope sample stage for testing multi-standard sample strip electrolytic cell

InactiveCN109270137AIntegrity guaranteedWithout causing damageMaterial electrochemical variablesSample integrityTest sample

The invention relates to a scanning electrochemical microscope sample stage for testing a multi-standard sample strip electrolytic cell. The sample stage is formed by a Teflon carrier plate (the electrolytic cell at the upper end) and a U-shaped support. The left end wall and the right end wall of the electrolytic cell are respectively provided with a round hole for placing a counter electrode anda reference electrode respectively. The U-shaped support is fixed by screws with the carrier plate. Cylindrical small rods are riveted into the carrier plate in the positive direction and the negative direction of the X-axis and the positive direction of the Y-axis. The bottom surface is provided with a circular groove, the carrier plate at the center of the electrolytic cell is provided with a circular hole and the circular groove, a rubber gasket is placed in the groove, a test sample is placed on the rubber gasket, and then a metal pressing piece is placed. Bolts on the U-shaped support are adopted for fixation, and a probe is used for scanning the sample at the circular hole. The sample stage is simple and quick in sample preparation, convenient to remove and capable of testing multi-standard samples under the premise that the sample integrity is maintained. The tested sample can be reused for other test analysis, the application field of the SECM is expanded, and the utilizationrate is improved.

Owner:SOUTHWEST PETROLEUM UNIV

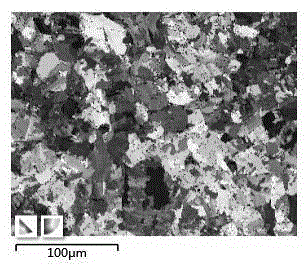

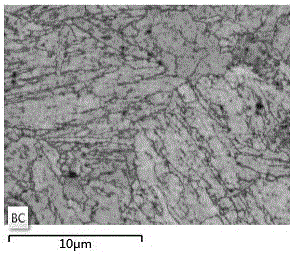

Preparation method of Cr-Mo steel EBSD sample

InactiveCN105241695AMeet analysis requirementsReduce sample preparation costsPreparing sample for investigationAnhydrous ethanolElectrolysis

The invention relates to a preparation method of Cr-Mo steel EBSD samples, which particularly includes the following steps: (a) grinding one surface of a Cr-Mo steel EBSD sample by abrasive paper and grinding a to-be-test surface through silicon carbide waterproof abrasive papers being 280#, 400#, 800#, 1000# and 1500# in meshes; (b) polishing the to-be-test surface with diamond polishing fluids and aluminum oxide polishing fluids in different granularities; (c) reducing the thickness of the mechanically-polished sample to 3 mm through a wire cutting machine; (d) cleaning the sample to remove oil dirt from the sample; (e) continuously polishing the to-be-test surface of the sample with a polishing fluid being 50 nm in granularity for 1-4 min; and (f) cleaning the polished sample in anhydrous ethanol and air-drying the sample to obtain the sample for EBSD analysis. The preparation method is simple, wherein the sample just needs to mechanically polish without any special electrolytic polishing device, so that the method is low in sample making cost and the sample satisfies the requirement in the EBSD analysis.

Owner:HEBEI IRON AND STEEL

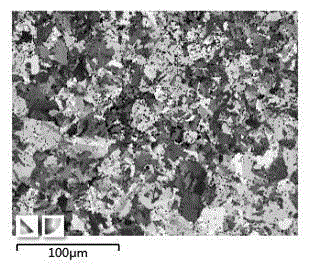

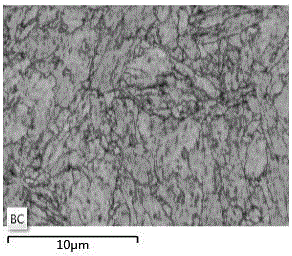

Preparation method of nickel steel-containing sample for EBSD analysis

InactiveCN105928767AImprove resolutionMeet analysis requirementsPreparing sample for investigationMaterials scienceAluminium oxide

The invention discloses a preparation method of a nickel steel-containing sample for an EBSD analysis. The method comprises the following steps: rough machining of the nickel steel-containing sample, fine polishing after polishing and erosion, surface cleaning after fine polishing of the sample, and the sample for the EBSD analysis is obtained; the fine polishing process comprises the following steps: diamond suspension liquid is used for polishing the sample after polishing and erosion, and aluminum oxide suspension liquid is used for polishing the sample. Special sample preparation links are reduced for facilitating implementation; the fine polishing process can relieve stress; compared with the conventional polishing method, the method has the advantages of simplicity, saved time, reduced sample preparation cost, and improved sample preparation efficiency, and the sample has a high desorption rate which can meet the requirements of EBSD analysis. The method has high operability, so that sample preparation is simple and timesaving, and preparation efficiency of the sample is improved. The sample for the EBSD analysis has a high desorption rate and good stability, the calibrate rate of the sample reaches 90% or above, general demands are satisfied, and the effects are good.

Owner:HEBEI IRON AND STEEL

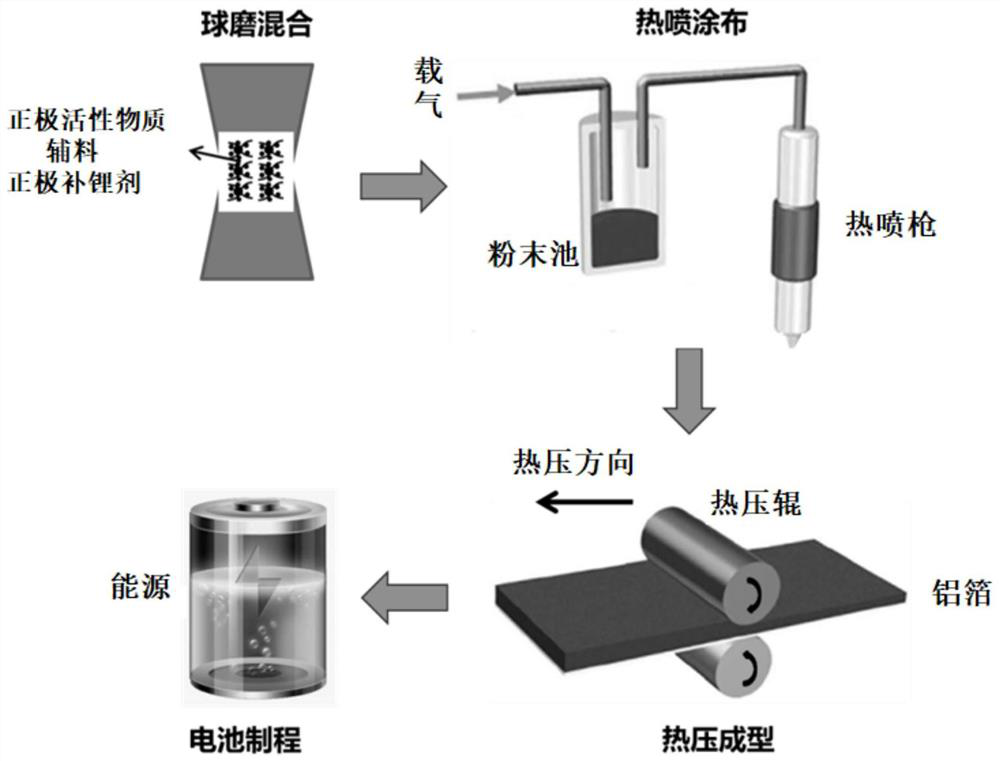

Positive electrode lithium supplementing method of lithium ion battery, product of positive electrode lithium supplementing method and application of product

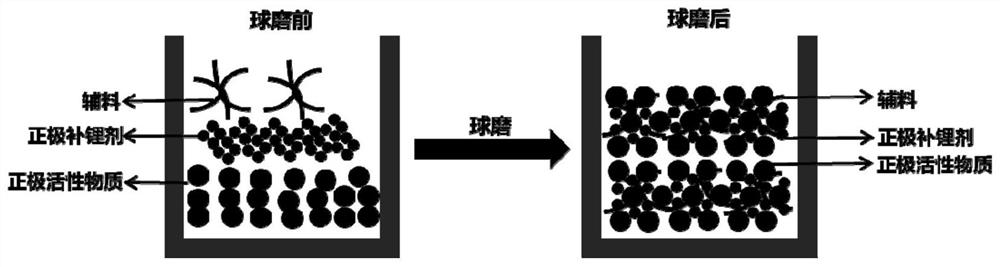

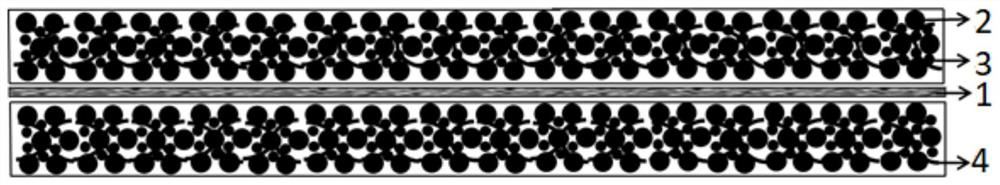

InactiveCN112151765AReduce consumptionEasy to fillSecondary cells charging/dischargingNon-aqueous electrolyte accumulator electrodesPhysical chemistryLithium-ion battery

The invention provides a positive electrode lithium supplementing method of a lithium ion battery, a product of the positive electrode lithium supplementing method and an application of the product. The positive electrode lithium supplementing method comprises the steps that a positive electrode active substance, auxiliary materials and a positive electrode lithium supplementing agent are mixed through a dry method, a mixed powder is obtained, then a lithium supplementing positive electrode pole piece is prepared, and the positive electrode lithium supplementing agent comprises Li3N. Accordingto the method, an operation process is simplified, and consumption of a side reaction between Li3N in the positive electrode lithium supplementing agent and a solvent is avoided by dry mixing so thata lithium supplementing effect is improved, the lithium supplementing positive plate with correspondingly improved porosity is obtained, and a first effect, the energy density, the cycle performanceand the rate capability of a battery cell are improved; and after lithium supplementation, byproduct nitrogen of the positive electrode lithium supplementation agent Li3N is removed by negative pressure in a formation stage so that the structure and the performance of the battery are not influenced. The positive electrode lithium supplementing method has the characteristics of low cost, simplicityand convenience in operation and a good lithium supplementing effect.

Owner:EVE ENERGY CO LTD +1

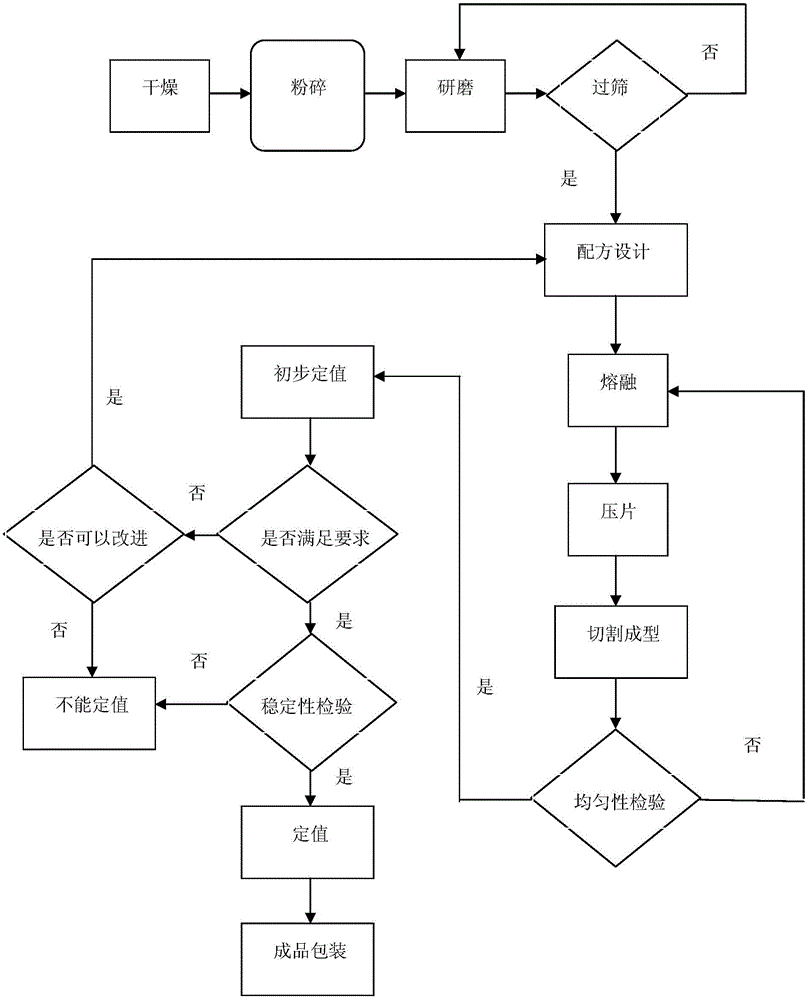

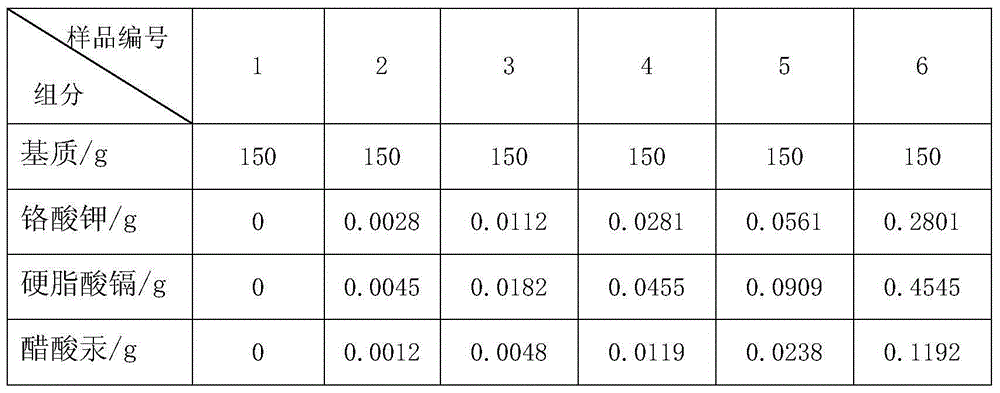

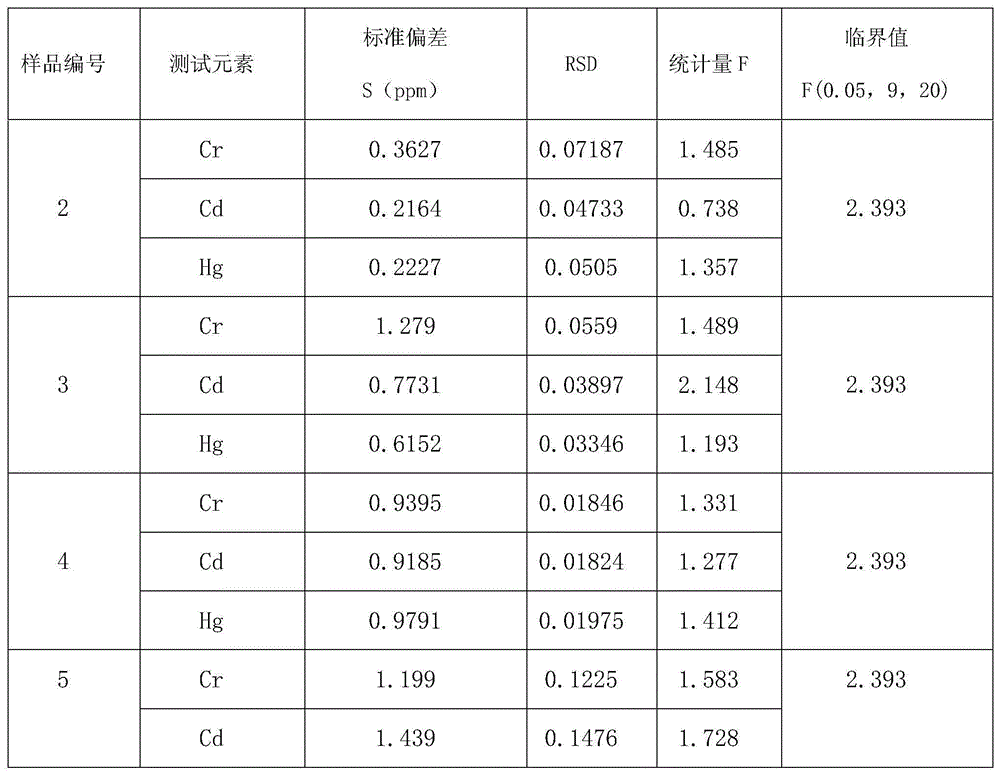

Sample preparation method for uniformly distributing trace components in solid block matrix

InactiveCN103604678AEvenly distributedAvoid problemsPreparing sample for investigationSolid massPrimary standard

The invention discloses a sample preparation method for uniformly distributing trace components in a solid block matrix. The method comprises the following steps: (1) sequentially drying, grinding and screening trace components to be measured; (2) accurately weighing a certain amount of trace components and a plastic matrix according to the formula design, heating to a melting temperature so as to melt the plastic matrix, adding the trace components into the melted plastic matrix under stirring condition, stirring and mixing for 2-3 hours, and thus preparing a molten mixture; (3) introducing the molten mixture in the step (2) into a mold, separating the molten mixture from the mold through diaphragm paper, and pressing for molding under the pressure of 70-120kg / cm<2> and at the melting temperature; (4) cooling and sizing the sample in the step (3) under the pressure of 100-150kg / cm<2> and at temperature which is 10-30 DEG C lower than the melting temperature, and cutting into samples with different sizes and shapes. The sample preparation process is simple, the trace components can be uniformly distributed in the sample, and the uniformity requirement of primary standard substances is met.

Owner:GUANGZHOU CEPREI CALIBRATION & TESTING CENT SERVICE

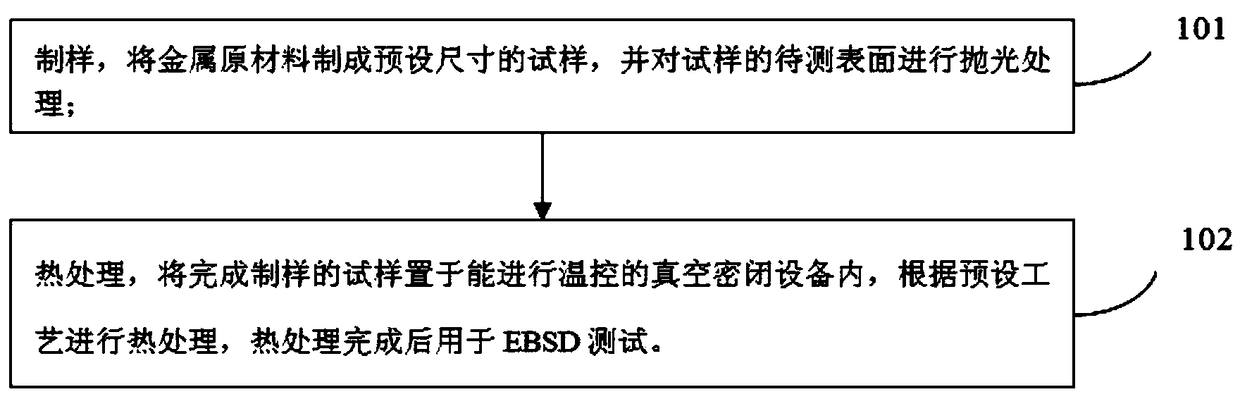

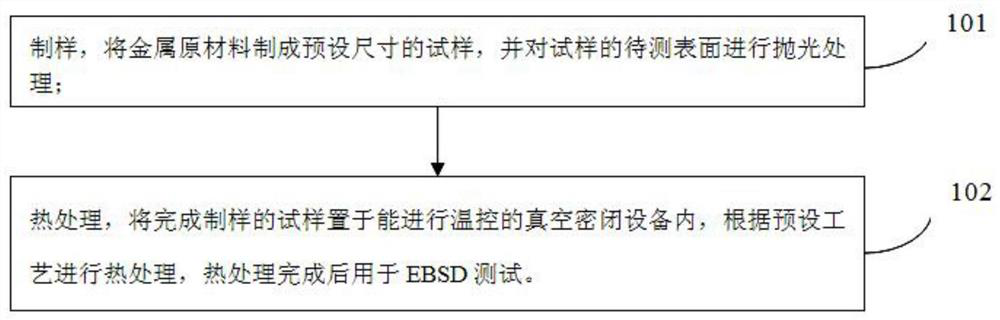

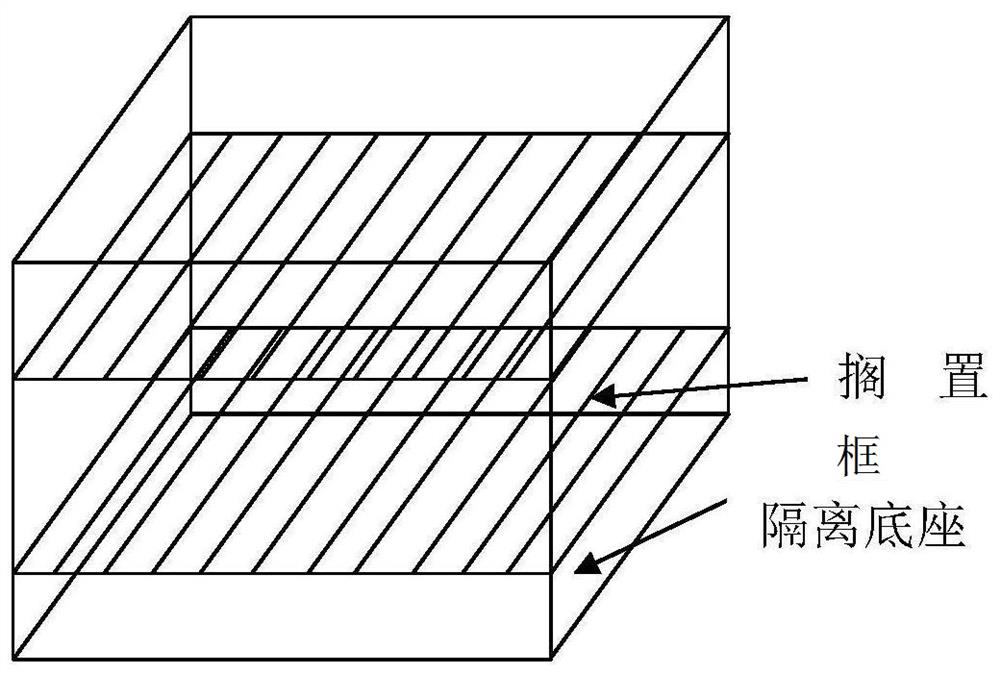

EBSD sample making method

InactiveCN109270096AEliminate surface stressShorten the sample preparation processMaterial analysis using wave/particle radiationTemperature controlTest sample

The invention provides an EBSD sample making method. The method includes: sample making, wherein a preset-size test is made from sample raw-material, and a to-be-tested surface of the test sample is polished; and heat processing, wherein the test sample after sample making completion is placed in vacuum airtight equipment capable of temperature control, heat processing is carried out according topreset technology, and the sample is used for an EBSD test after heat processing completion. Through the method, a sample making process and time can be shortened, sample making costs can be reduced,sample making efficiency can be improved, calibration rates of IPF graphs in EBSD tests can be significantly improved at the same time, and a highest calibration rate can reach 99%.

Owner:CENT IRON & STEEL RES INST

Borate salt solution for cold-rolling plate bonderizing prediction

ActiveCN1854727AShorten evaluation timeSimplify peripheral conditionsMaterial electrochemical variablesBorate saltAnalytical chemistry

Owner:BAOSHAN IRON & STEEL CO LTD

Thin plate metallographical thermal embedding method

ActiveCN109813589AReduce sample preparation costsThickness is not requiredPreparing sample for investigationCapillary actionPolyresin

The invention discloses a thin plate metallographical thermal embedding method. Resin embedding materials are processed into thermocured resin flakes and resin blocks, and gaps are machined in the thermocured resin flakes and resin blocks. When there is one thin plate sample, the thin plate sample is fixed by the thermocured resin blocks with the gaps, and put into a thermal embedding machine as awhole, and the resin embedding materials are added for embedding; when there are many thin plate samples, every two adjacent thin plate samples are separated through the thermocured resin blocks withthe gaps, the two ends of each thin plate sample are clamped and fixed through the thermocured resin blocks with the gaps, the thin plate samples are put into the thermal embedding machine as a whole, and the resin embedding materials are added for embedding. According to the method, the sample preparation cost is low, the thickness of the thin plates is not required, and the thin plate embeddingefficiency can be improved; moreover, the capillary phenomenon cannot occur, and the metallographical shooting success rate is increased.

Owner:INST OF RES OF IRON & STEEL JIANGSU PROVINCE +2

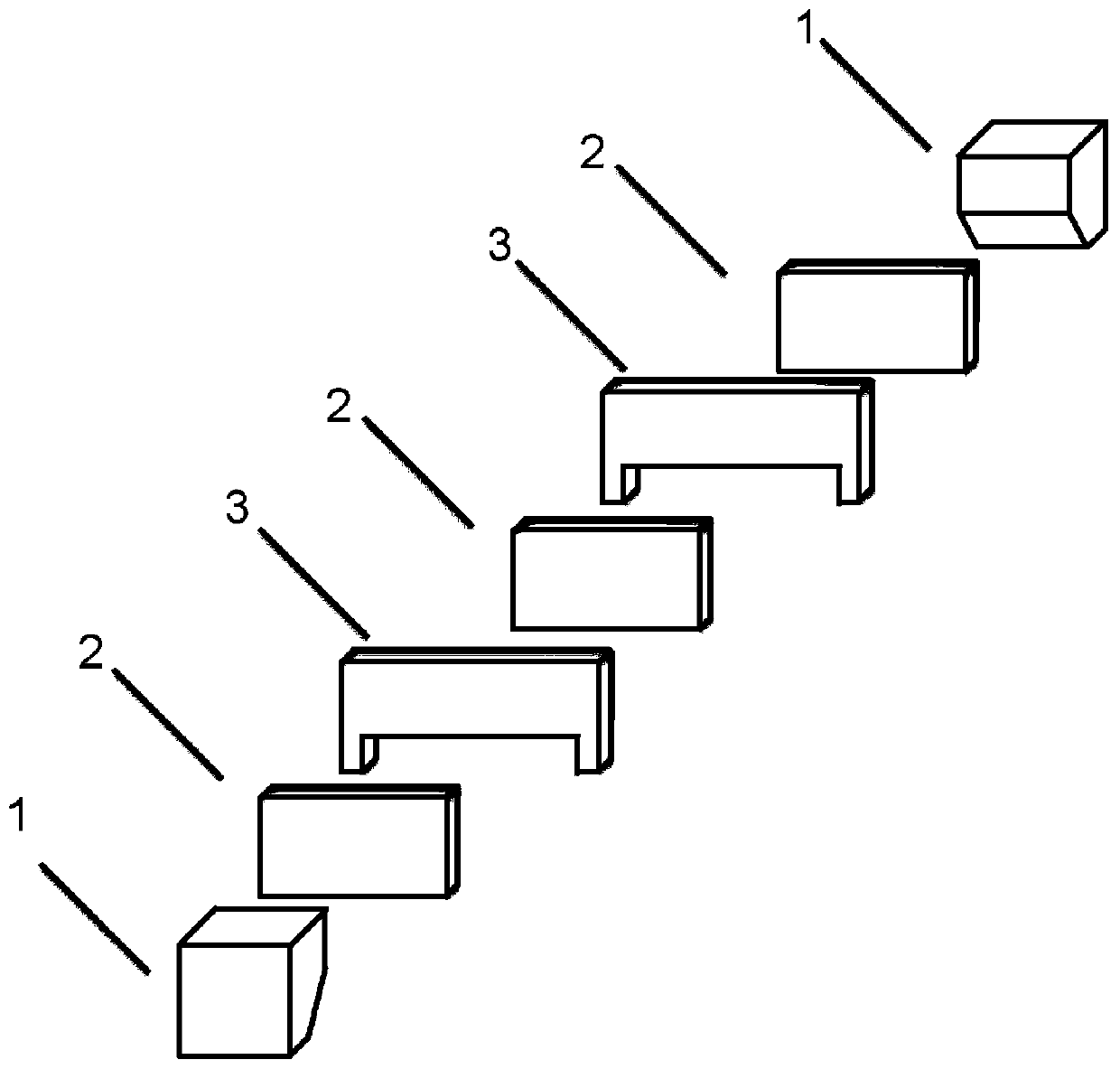

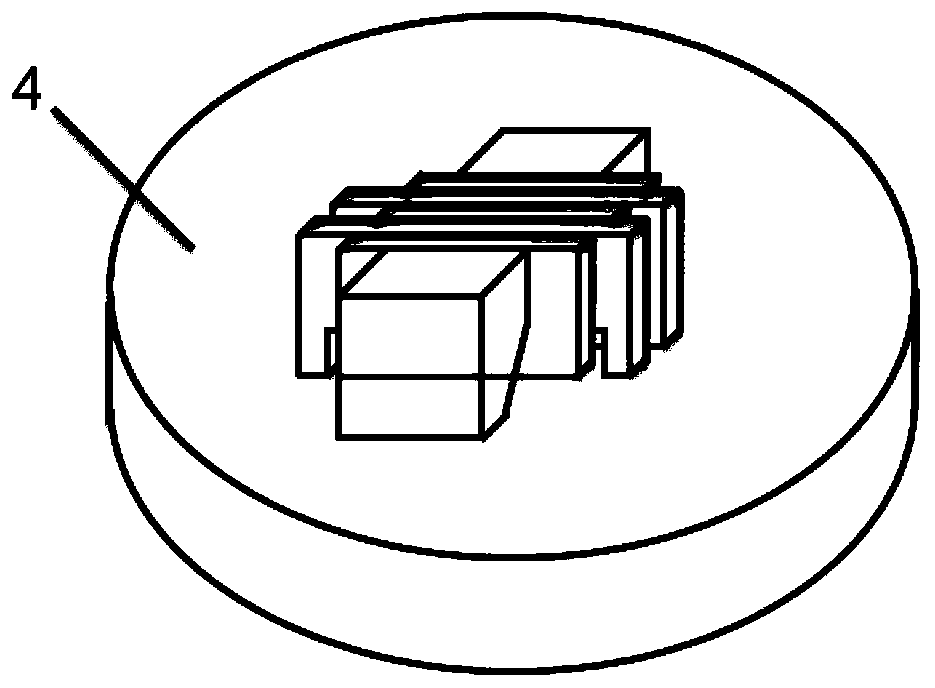

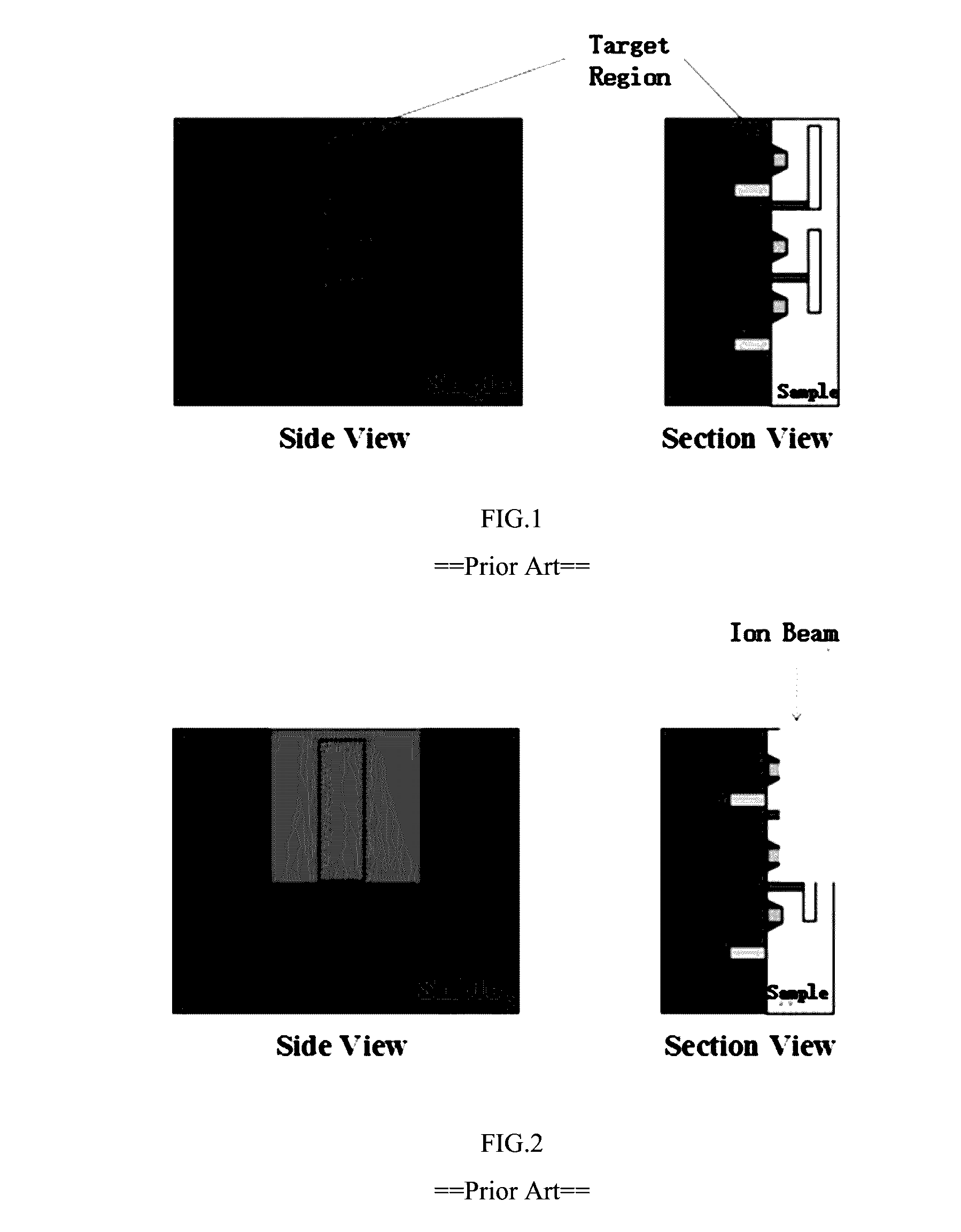

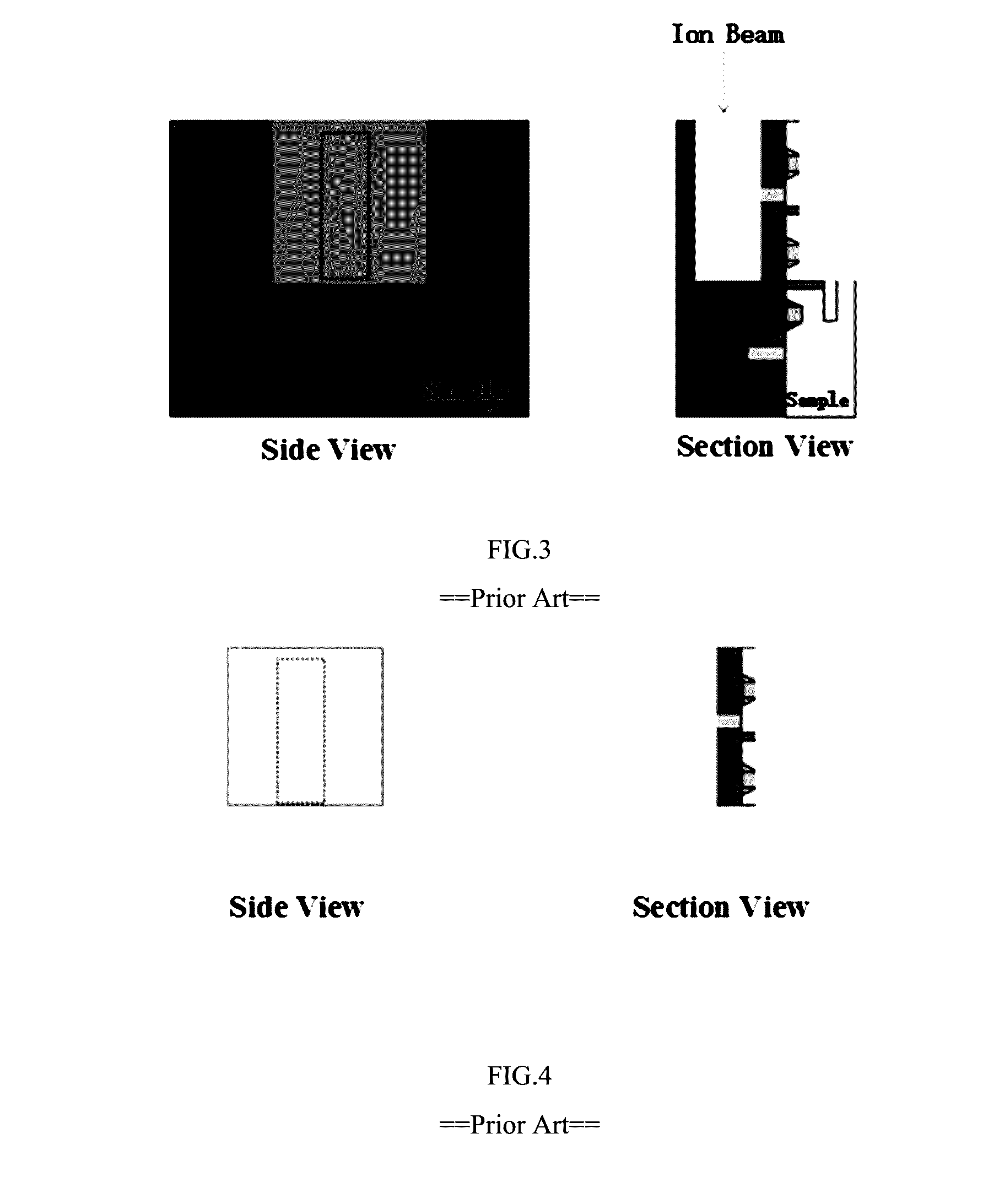

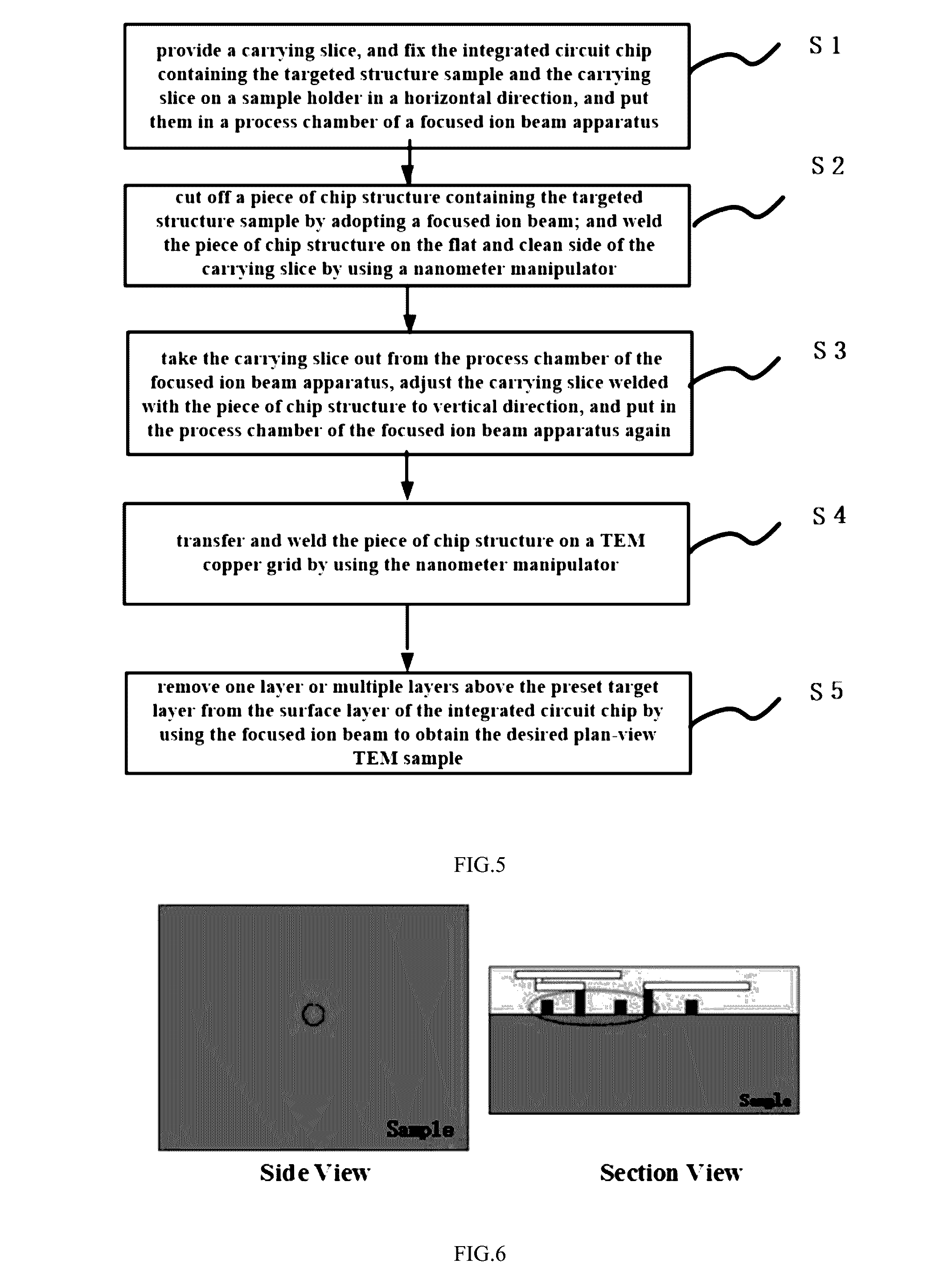

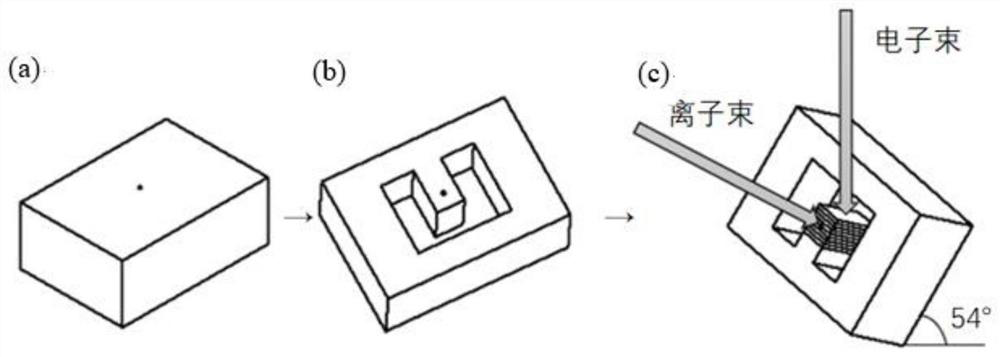

Method of preparing a plan-view transmission electron microscope sample used in an integrated circuit analysis

ActiveUS20170053778A1Reduce analysis costsReduce the difficulty of analysisElectric discharge tubesPreparing sample for investigationNanomanipulatorSurface layer

The present invention discloses a preparation method of plan-view TEM sample used in an integrated circuit analysis. The method comprises the steps of: providing a carrying slice, and fixing a chip containing a targeted structure sample and the carrying slice on a sample holder in a horizontal direction, and putting them in a process chamber of a FIB apparatus; cutting off a piece of chip structure containing a target structure sample by adopting a FIB; and welding the piece of chip structure on the flat and clean side of the carrying slice by using a nano-manipulator; after being taken out from the process chamber of the FIB apparatus, the carrying slice welded with the chip structure is adjusted to vertical direction, and is put in the process chamber of the FIB apparatus again; transferring and welding the chip structure on the TEM copper grid by using the nano-manipulator; and removing one layer or multiple layers above the preset target layer from the surface layer of the chip by using the FIB to obtain the desired plan-view TEM sample.

Owner:SHANGHAI HUALI MICROELECTRONICS CORP

X-luminoscope fusion sample preparation method

InactiveCN103808559AChemically stableNot easy to absorb moistureMaterial analysis using wave/particle radiationPreparing sample for investigationCrucibleFree cooling

The invention discloses an X-luminoscope fusion sample preparation method, comprising the following steps: grinding a solid sample into powder of not less than 200 meshes for later use, wiping a crucible, a stirrer and a medicine spoon to be clean by using alcohol, placing in an oven for drying for 30min and more, taking out and placing on a tray, wiping the inner wall of a die to be clean by using alcohol, naturally withering for later use; weighing a certain mass of PE material to be put into a crucible, heating until the solvent is completely fused; weighing a certain mass of sample powder in S1 to place in a crucible in the S4, turning on the stirrer, stirring while heating, stopping stirring and heating after 30min; fetching melt at the upper layer in the crucible in S5 with a medicine spoon in a die in the S3, wherein the melt is about 2 / 3 of the height of the die, naturally cooling to completely solidify to obtain the sample sheet. The borate flux is replaced by the PE material, the manufactured sample sheet is hard to break, crack and pollute, easy to de-mold and store, the sample preparation time is effectively shortened, and the sample preparation cost is greatly reduced.

Owner:南京大展机电技术研究所

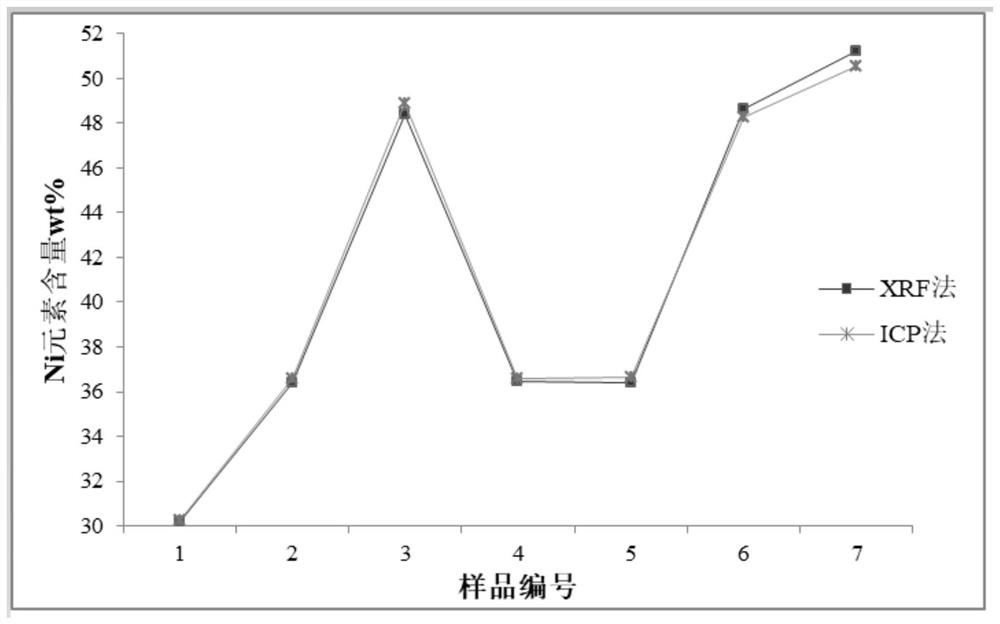

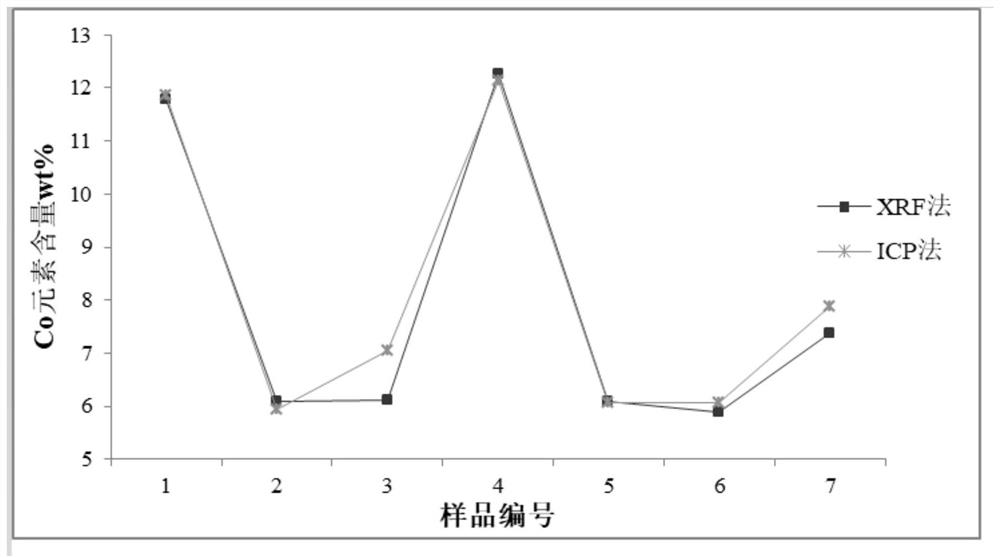

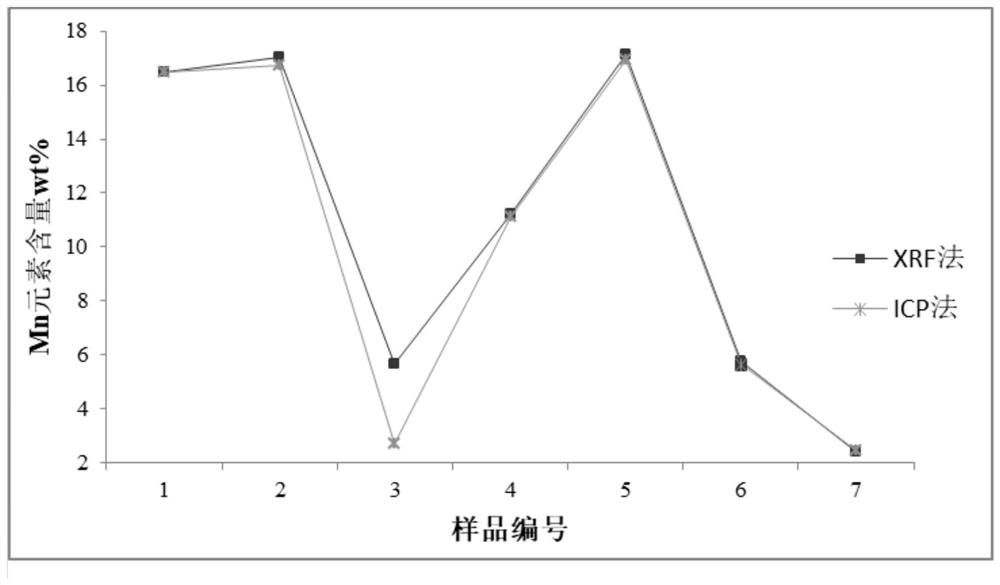

Method for analyzing content of main elements in nickel cobalt lithium manganate positive electrode material

PendingCN113311015AAvoid damageReduce the number of exposures to hazardsMaterial analysis using wave/particle radiationOptical spectrometerManganate

The invention provides a method for analyzing the content of main elements in a nickel cobalt lithium manganate positive electrode material. The analyzing method comprises the following steps: (1) carrying out tabletting treatment on a standard sample, then testing the tableted sample by adopting an X-ray fluorescence spectrometer, selecting a model calibration curve spectrogram, preprocessing the curve spectrogram, and establishing a corresponding standard curve; and (2) carrying out tabletting treatment on a to-be-detected sample, then testing the tableted sample by adopting the X-ray fluorescence spectrometer, and obtaining the content of the main elements in the to-be-detected sample according to the corresponding standard curve in the step (1). According to the method, the X-ray fluorescence spectrophotometer is adopted to analyze multiple elements such as Ni, Co and Mn in NCM at a time, and the method is easy to operate, high in analysis speed, safe, rapid, low in cost, high in accuracy, good in stability, high in detection efficiency, high in practicability and suitable for actual production.

Owner:HUBEI JINQUAN NEW MATERIALS CO LTD

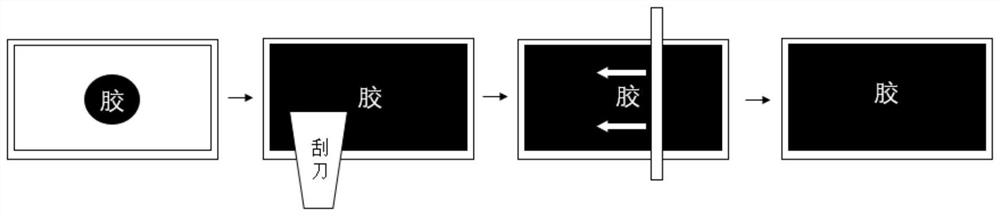

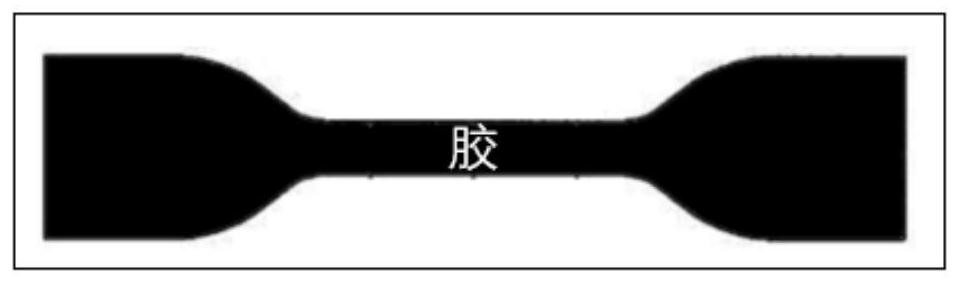

Sample preparation method for factory inspection of elastic adhesive

PendingCN112485097AQuality improvementImprove accuracyPreparing sample for investigationTest sampleRubber sheet

The invention discloses a sample preparation method for factory inspection of an elastic adhesive. The method comprises the following steps of: extruding an adhesive sample at one end of a rectangularmold groove, and filling the whole mold groove with the adhesive along the same direction by using a metal scraper; pushing out the redundant adhesive along one end of the mold by using a glass rod to form an adhesive layer with a horizontal surface; curing the prepared mold at room temperature for a certain period of time, and performing direct demolding; and cutting a rubber sheet into test sample strips by using a cutting knife with a specified model after performing demolding. The sample preparation method disclosed by the invention is simple and convenient to operate, low in sample preparation cost and high in efficiency; the rubber sheet prepared by the method has few defects such as flat surface, bubbles and flashes; different test sample strips can be prepared by using with different cutters on the basis of the method; the defect positions can be selectively avoided, the quality of the sample strips is greatly improved, a good premise is provided for adhesive performance detection, the accuracy of detection data is improved, batch detection is realized, and the detection efficiency is greatly improved.

Owner:李人哲

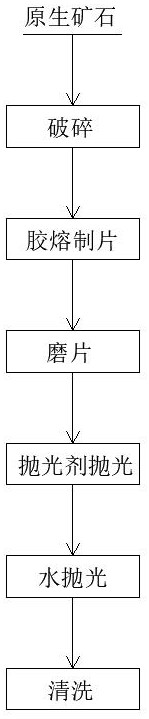

Preparation method of granular primary ore polished section

PendingCN113188861ALow softening pointShort heating timePreparing sample for investigationGrindingGas release

The invention provides a preparation method of a granular primary ore polished section, which comprises the following steps: crushing primary ore into granular ore samples with the granularity of -3mm, uniformly mixing the granular ore samples with a binding agent, uniformly stirring the granular ore samples and the binding agent to form polished section grinding blanks through the operation of a mounting press, and performing coarse grinding, medium grinding and fine grinding on the polished section grinding blanks through a sample grinding machine, subjecting the polished section grinding blanks to polishing solution polishing and water polishing, and finally putting the polished section grinding blanks into an ultrasonic cleaner to be cleaned and dried. Combustion and poisonous and harmful gas release are not prone to occurring in the section preparation process, the environment-friendly and safe effects are achieved, meanwhile, the sample preparation time can be greatly shortened, the situation that coarse and fine particles are not evenly distributed is avoided, and the section grinding efficiency and the section polishing quality are improved.

Owner:JIUQUAN IRON & STEEL GRP

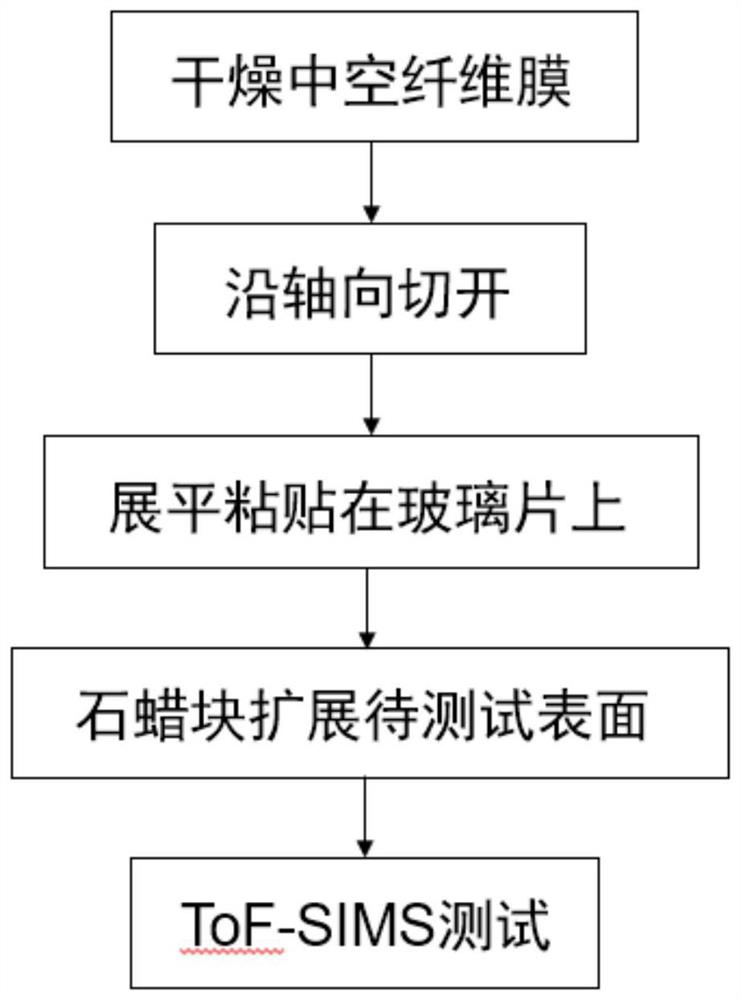

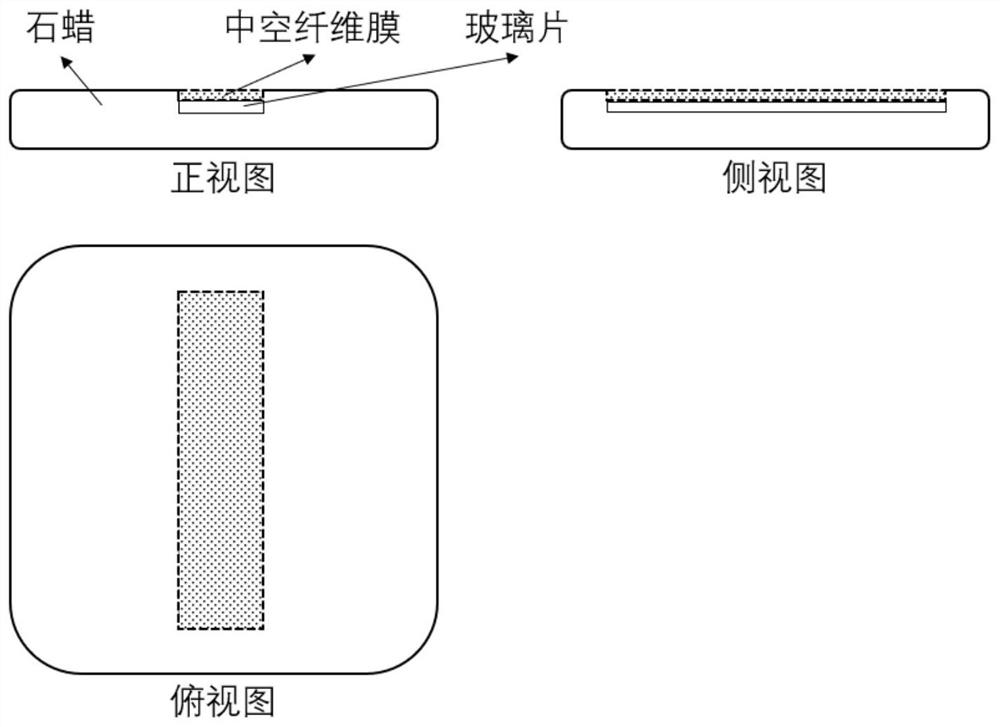

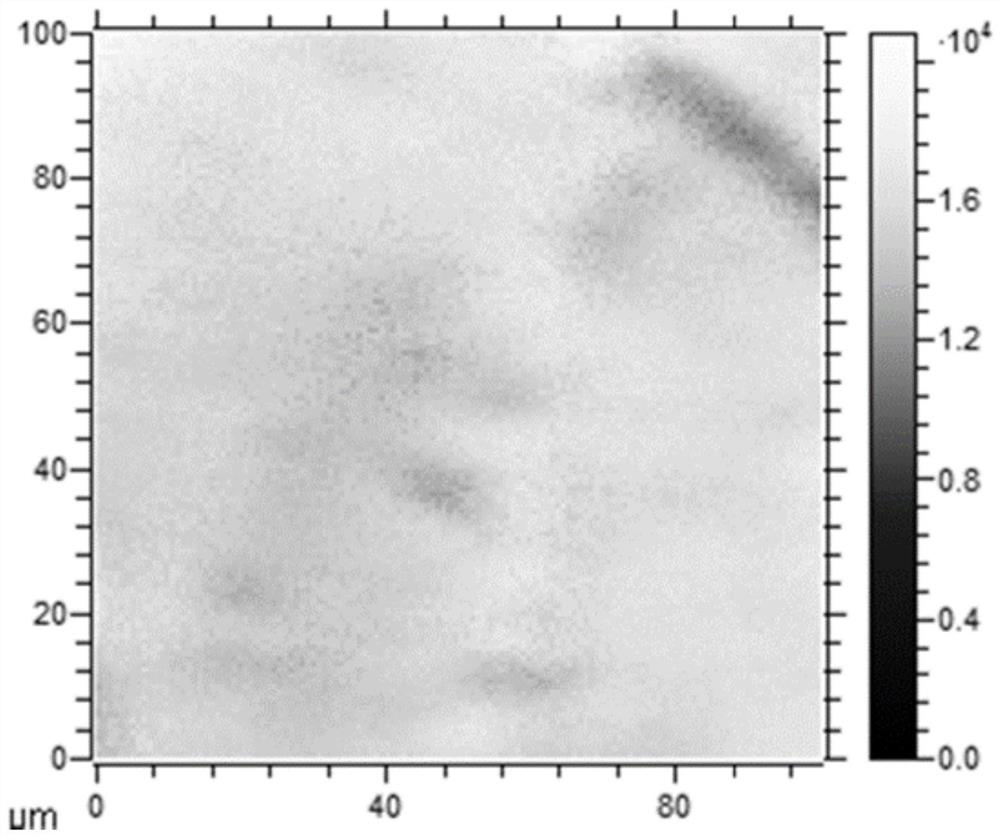

Sample preparation method for ToF-SIMS test of hollow fiber membrane

InactiveCN112505081AImplement analysis testsDoes not affect the compositionMaterial analysis using wave/particle radiationGlass chipComposition analysis

The invention provides a sample preparation method for ToF-SIMS test of a hollow fiber membrane, and belongs to the technical field of ToF-SIMS test. The method comprises the following steps: cuttinga hollow fiber membrane along the axial direction, flattening and pasting the hollow fiber membrane on a glass sheet, and expanding a to-be-tested surface by adopting a paraffin block. According to the method, the problem that the result is not credible due to the fact that the diameter of the hollow fiber membrane is too small, ToFSIMS cannot be effectively focused and the test signal is too pooris solved, the accurate and credible ToFSIMS test of the hollow fiber membrane is successfully achieved, the good test signal is obtained, operation is easy, and the method can be used for hollow fiber membrane surface filter cake layer composition analysis, membrane material composition analysis and the like.

Owner:RES CENT FOR ECO ENVIRONMENTAL SCI THE CHINESE ACAD OF SCI

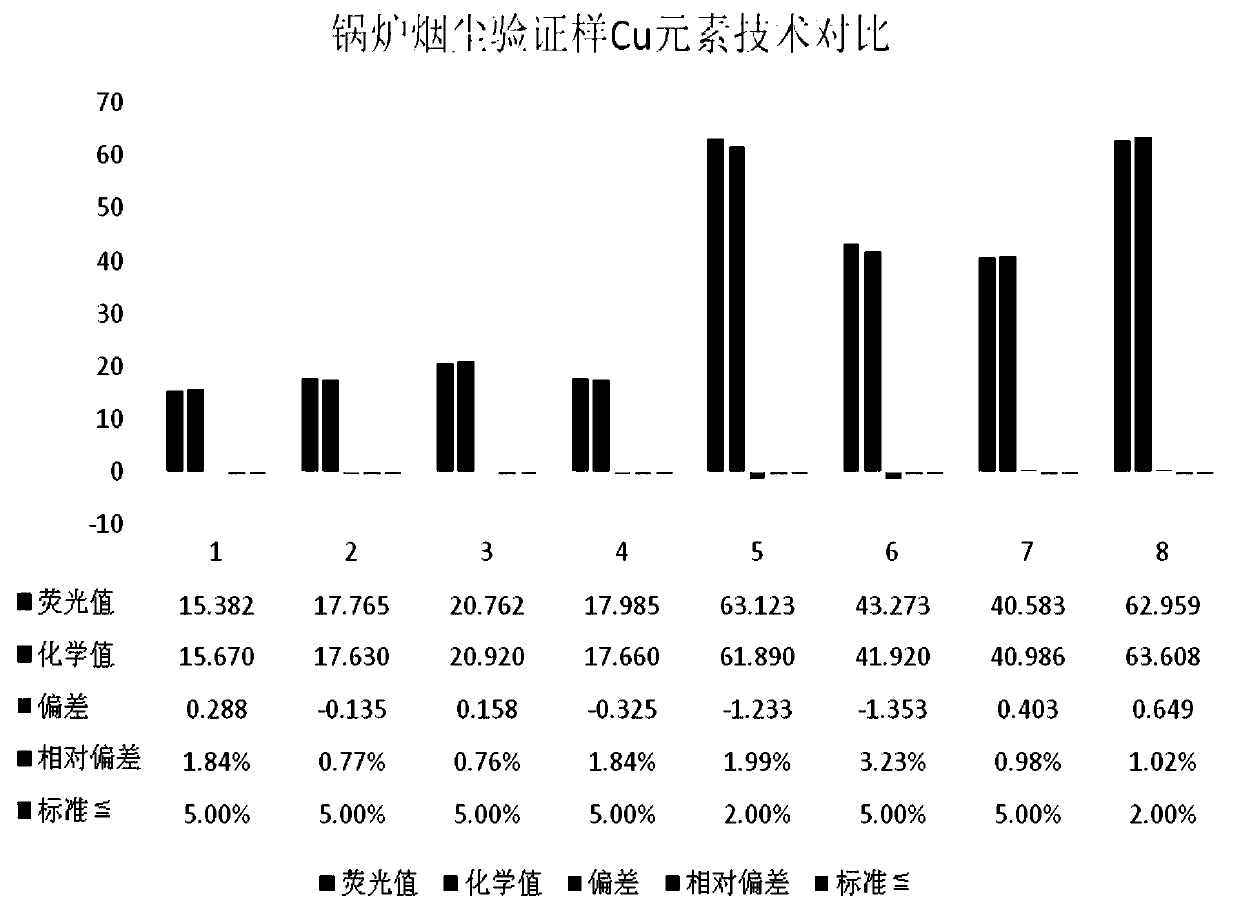

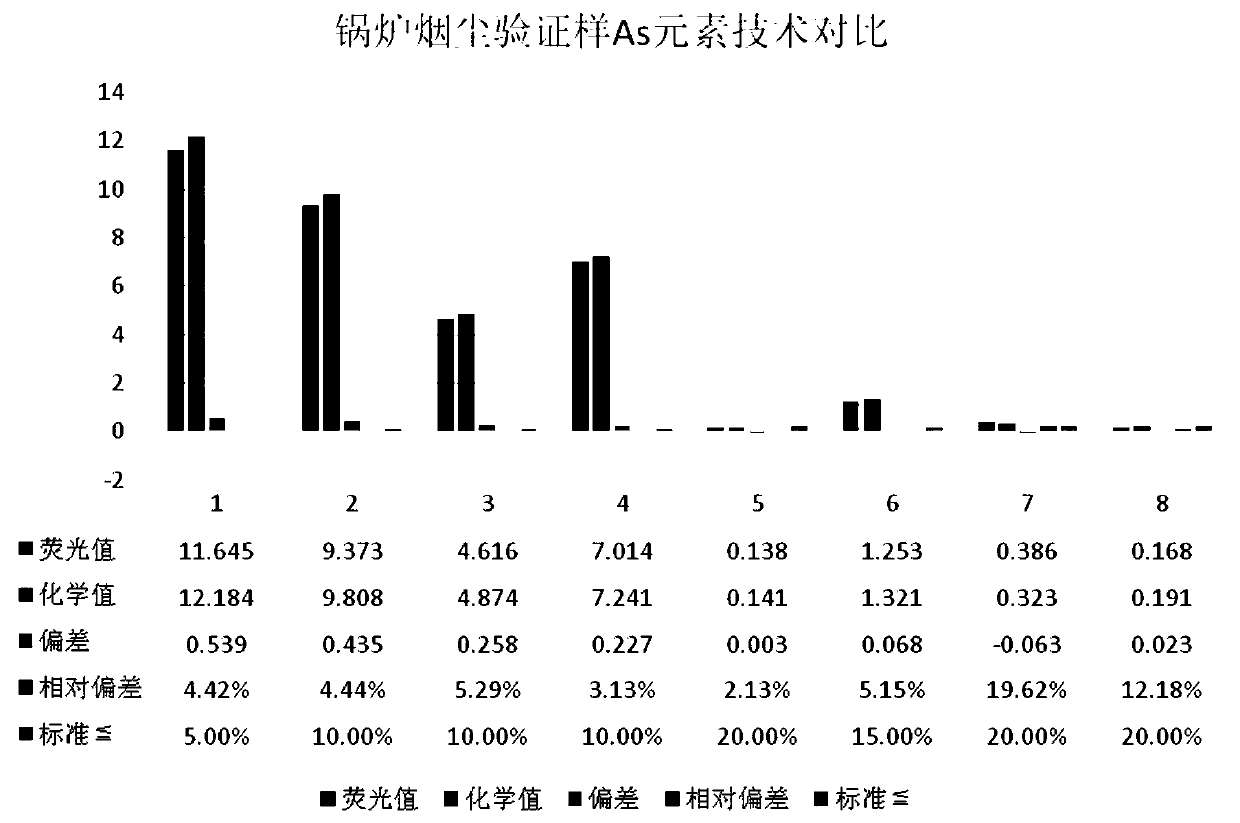

Method for analyzing Cu, As, Pb and Zn elements in boiler smoke by X-ray fluorescence spectroscopy

InactiveCN110376230AGuaranteed smoothnessGuaranteed tightnessMaterial analysis using wave/particle radiationAdhesiveEngineering

The invention discloses a method for analyzing Cu, As, Pb and Zn elements in boiler smoke by X-ray fluorescence spectroscopy. A direct compression method is used in a sample preparation process, a module group does not need to be specially produced, and adhesive does not need to be added in addition so that a sample for analysis and detection can be obtained. Preparation cost is greatly reduced, and safety during an operation process is improved. After the prepared sample is detected by the detection method of the invention, high accuracy, good stability and high detection efficiency are possessed, and the sample is highly practical, and is worth promoting.

Owner:LIANGSHAN MINING CO LTD

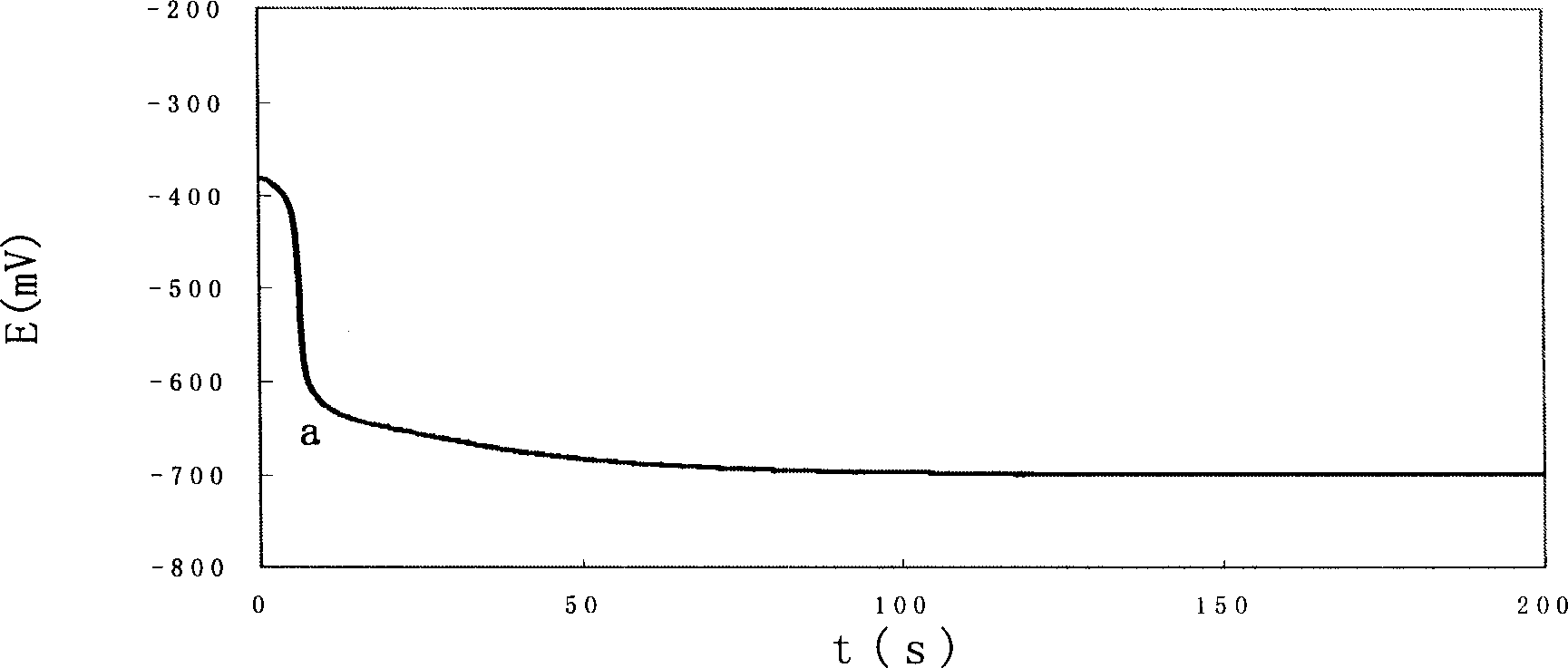

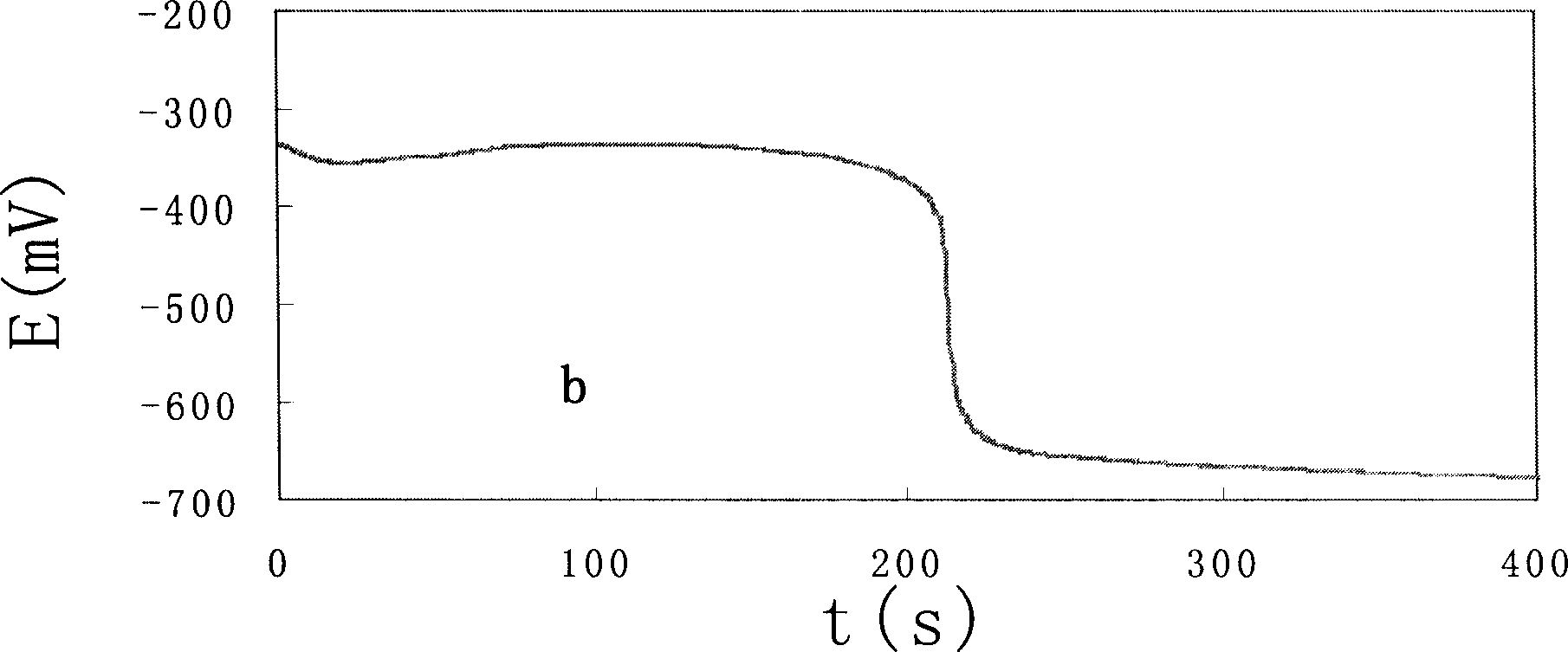

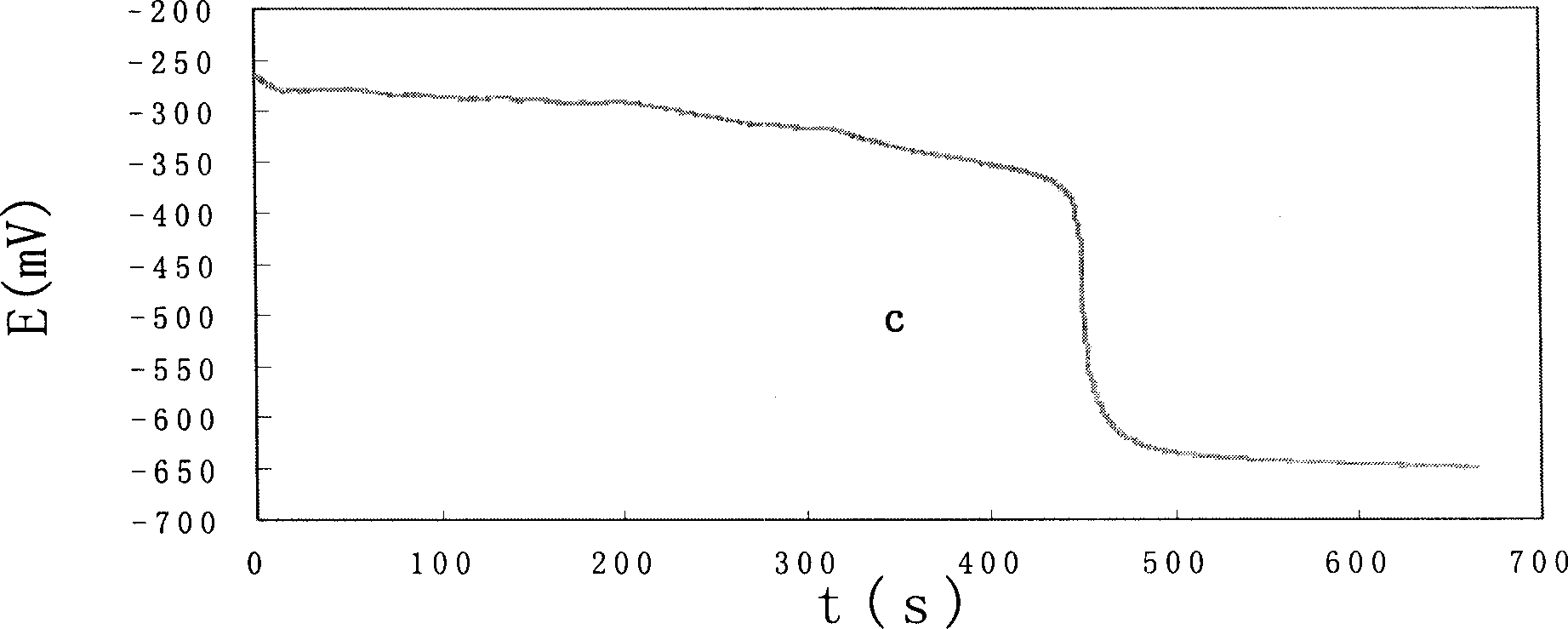

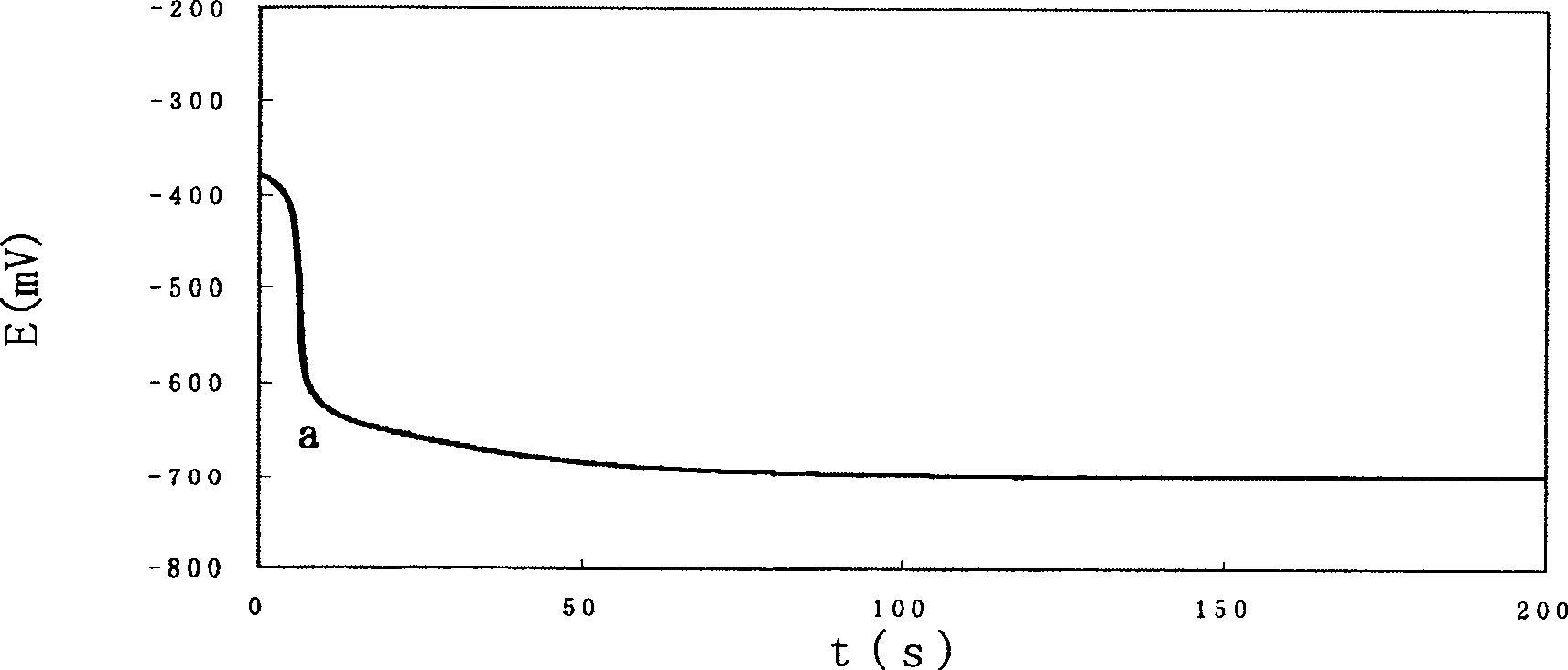

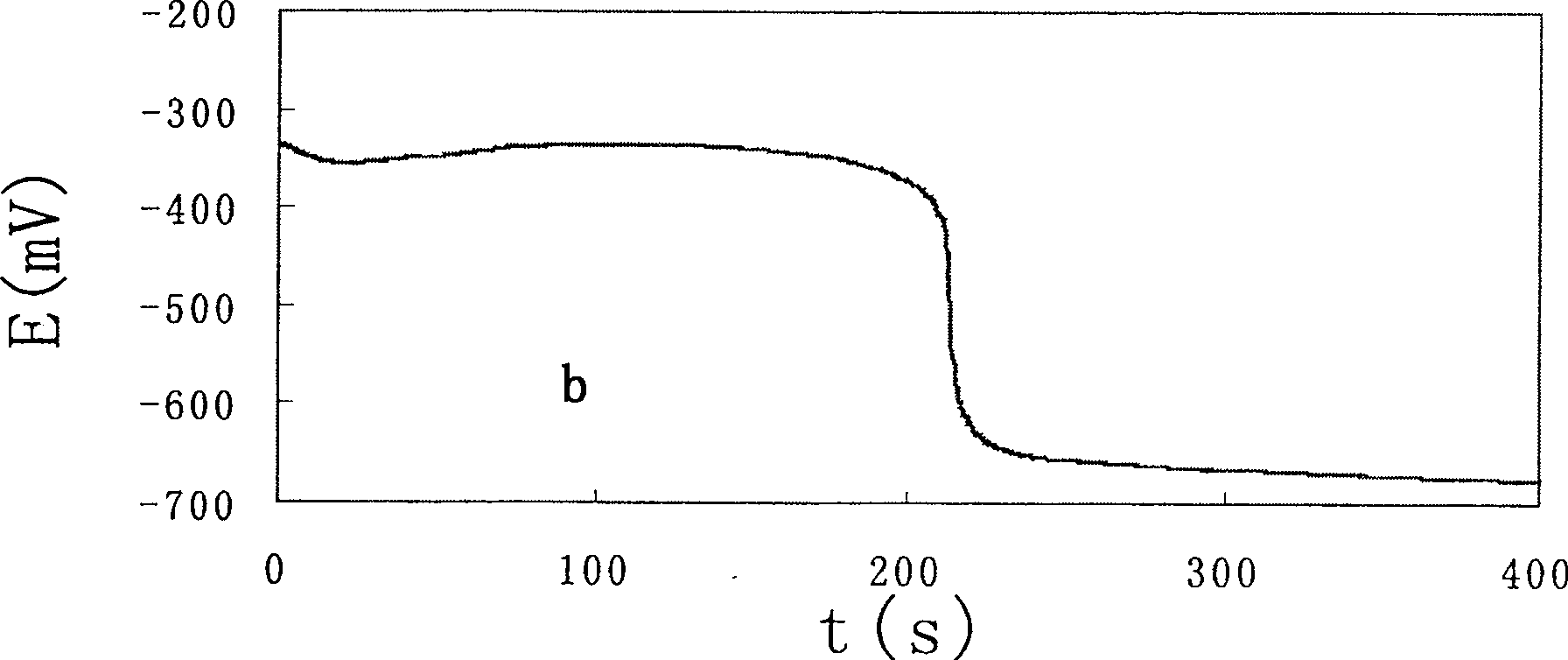

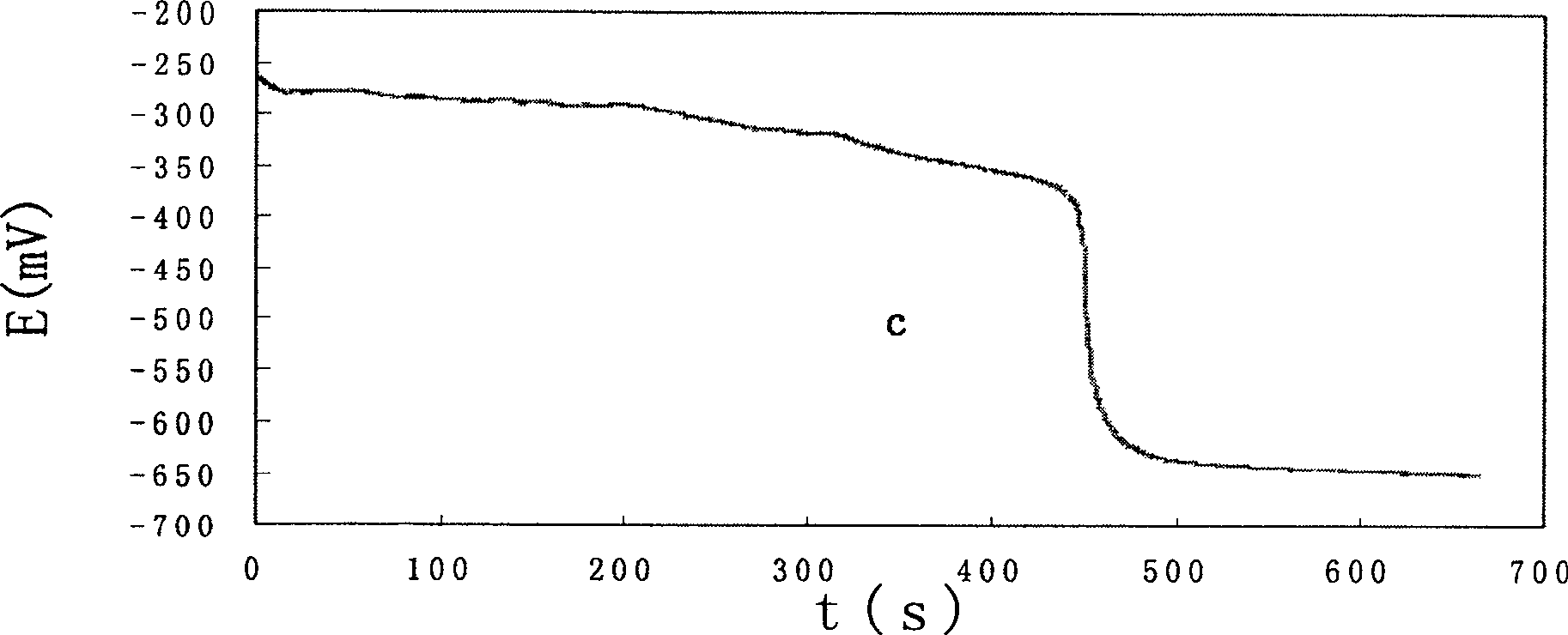

Quick evaluation method of old-rolling plate phosphating property

ActiveCN100520386CShorten evaluation timeSimplify peripheral conditionsMaterial electrochemical variablesPhosphatePotentiostat

The invention discloses a method for quickly evaluating the phosphability of cold-rolled sheets. The steps are as follows: Step 1. Prepare a sodium tetraborate solution, and then adjust the pH value of the solution with hydrochloric acid at a concentration of 1:1, and the adjusted sodium tetraborate solution The solute concentration is 0.05 mol / liter, and the pH value of the solution at 25°C is between 5.5 and 6.9; step 2, place the cold-rolled sheet to be tested in the above-mentioned sodium tetraborate solution; step 3, use a potentiostat to record the cold The dynamic change process of the potential value of the rolling plate after entering the above solution, when an obvious inflection point appears, the test is terminated, and the potential-time record chart is obtained on the potentiostat; Steps 4 and 5, according to the abscissa of the inflection point on the potential-time record chart Value, that is, the time value of the inflection point, to judge the phosphating sensitivity of the cold-rolled sheet, and analyze and predict the phosphating film quality of the cold-rolled sheet after phosphating. The invention can quickly and accurately evaluate the phosphating characteristics of the cold-rolled sheet, predict the coating quality of the cold-rolled sheet, and has wide applicability.

Owner:BAOSHAN IRON & STEEL CO LTD

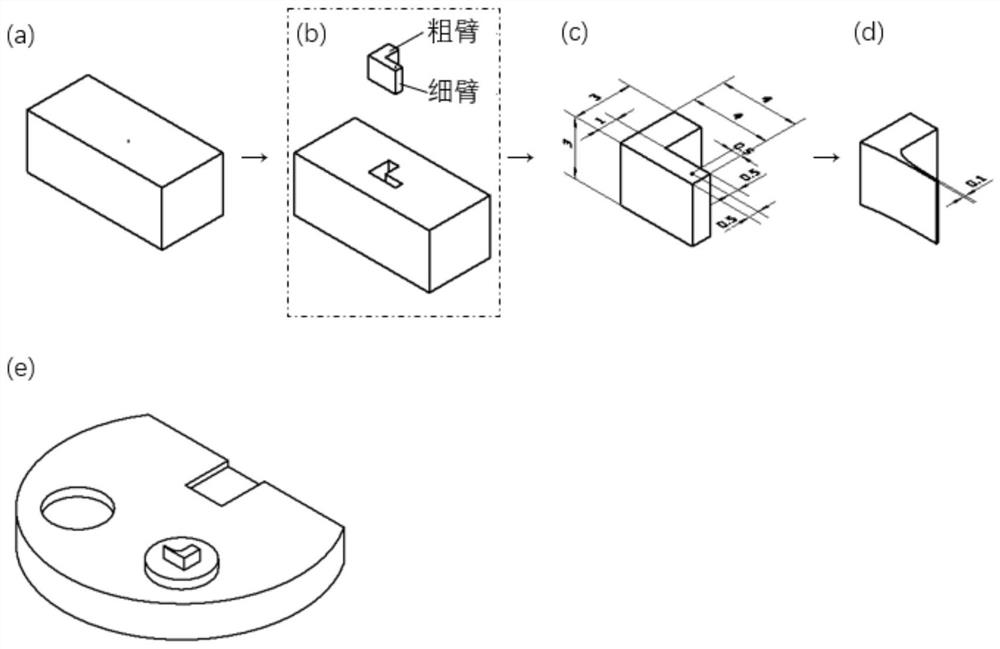

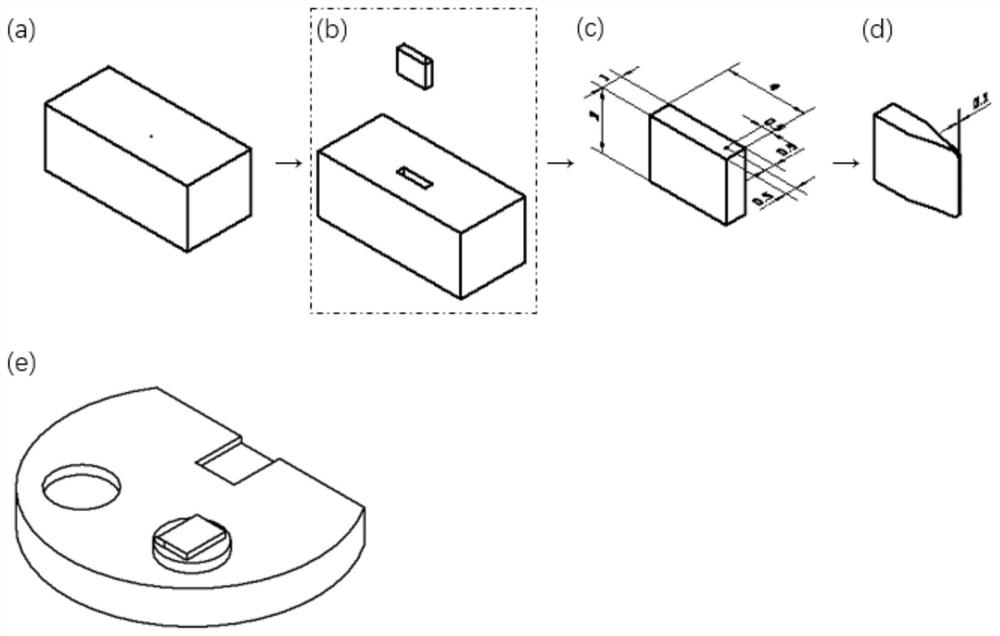

A method of preparing "nose tip" specimen for fib three-dimensional reconstruction

ActiveCN109540947BReduce usage timeReduce sample preparation costsMaterial analysis using wave/particle radiationNoseNasal tip

Owner:UNIV OF SCI & TECH BEIJING

Metallographic section sample preparation mold and method for preparing metallographic section sample

InactiveCN105628469BRealize the mergerMark flexiblePreparing sample for investigationPermanent markerMovable type

The invention provides a metallographic section sample preparation mold and a method for preparing a metallographic section sample by using the mold. The mold includes: a rigid outer casing, a section glue filling inner casing and a section marking inner casing; the section marking inner casing includes a rigid shell, The elastic inner pad inside the rigid body shell is used to place movable type; the elastic inner pad is provided with a positioning hole, and the inner sleeve of the slice is used to place the sample and then inject resin, and the inner sleeve of the slice mark and the movable type together form a slice mark assembly; preparation The method includes the steps of: sampling, glue filling, placing a slice marking assembly, post-processing and detection; the invention realizes the combination of sample making and marking process, improves sample preparation efficiency and reduces sample preparation cost; uses movable type to mark slices , can flexibly mark the sample production date and sample label, form a unified and standardized experimental sample marking method, avoid confusion between multiple metallographic sections, and permanent marking is conducive to the observation record of the later section and the review of the test results.

Owner:UNIV OF ELECTRONICS SCI & TECH OF CHINA

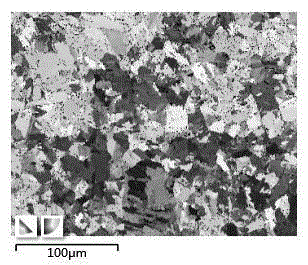

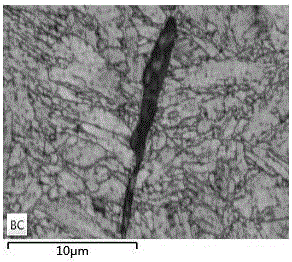

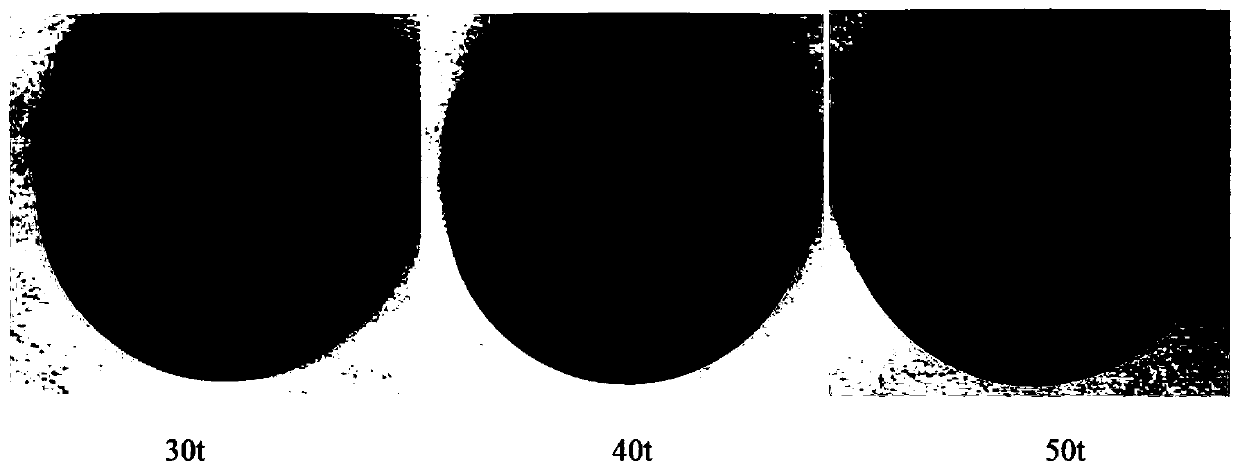

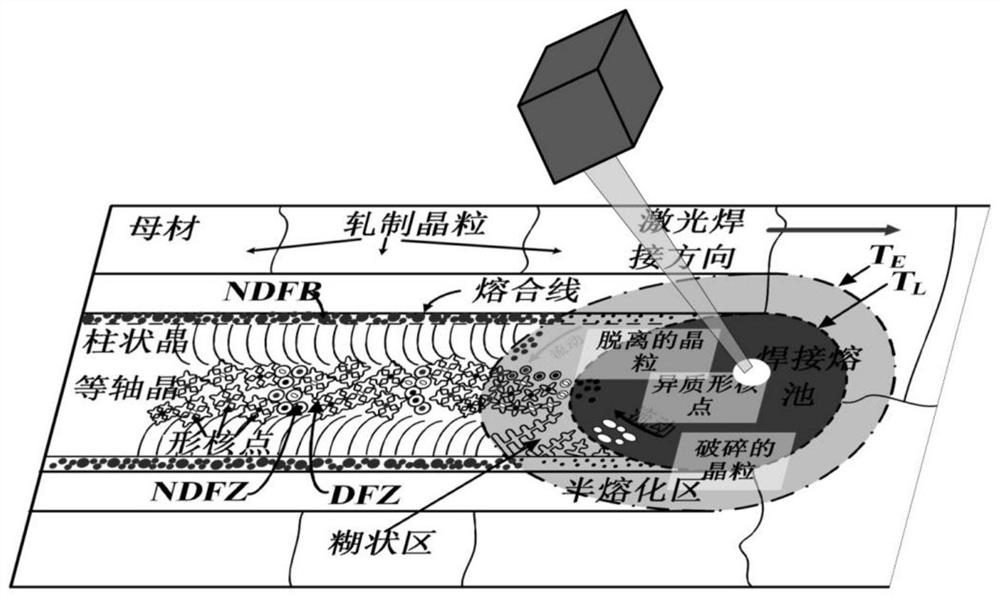

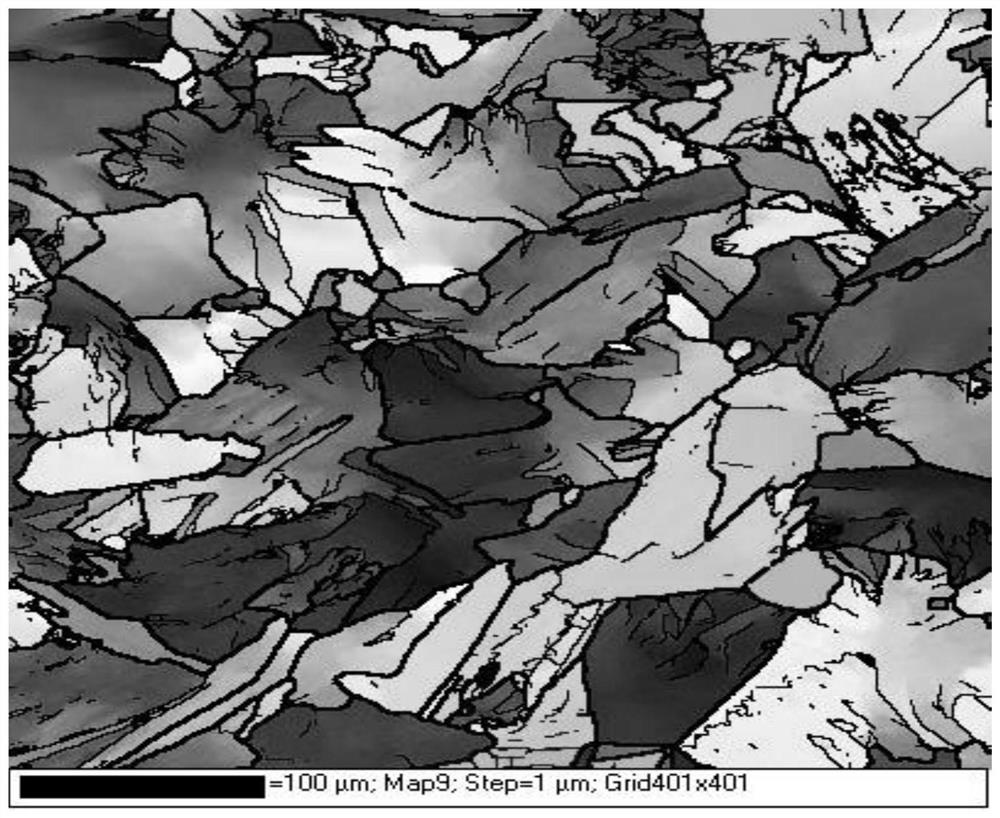

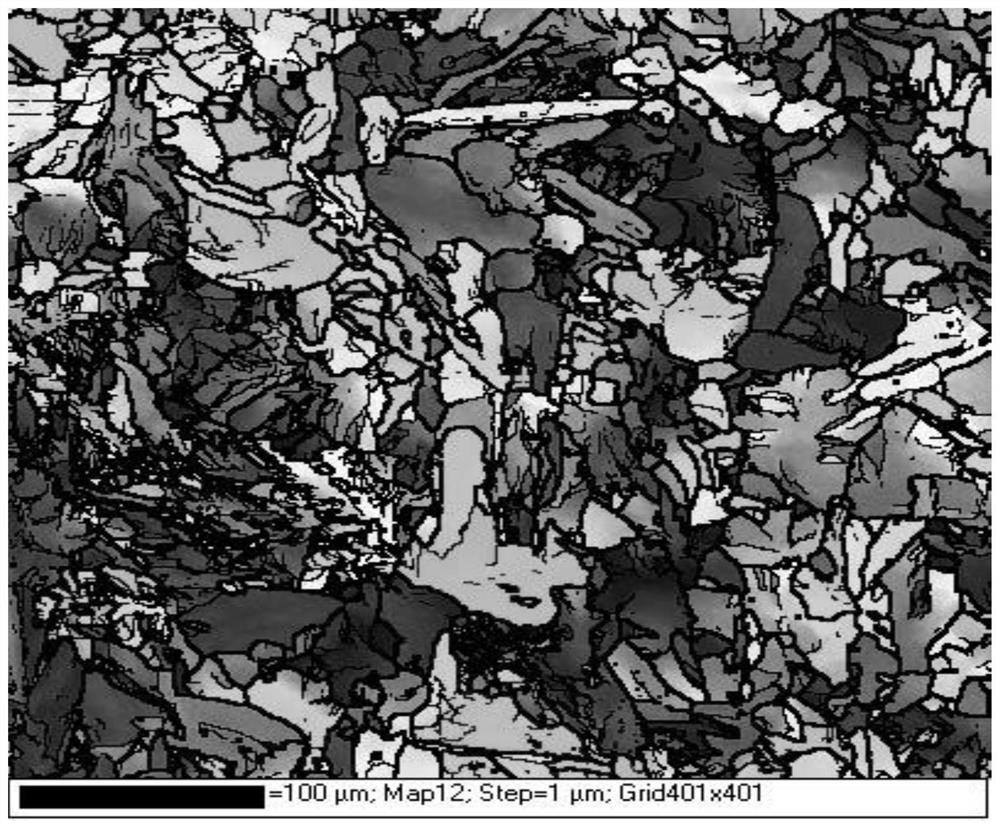

A Method for Analyzing the Nucleation Mechanism of Laser Weld Microstructure

ActiveCN111982618BGood repeatabilityImprove accuracyPreparing sample for investigationTesting metal structuresEngineeringMaterials science

The invention belongs to the technical field related to laser welding, and discloses a method for analyzing the microstructure nucleation mechanism of a laser welding seam. The method includes the following steps: (1) performing laser welding on sample 1, that is, test welding, and Analyze the microstructure and distribution of the laser welded seam; at the same time, TIG welding is used to perform 1 pre-welding and n-pass pre-welding on sample 2-1 and sample 2-2, respectively, and then the welds formed by pre-welding respectively Perform test welding on the above, and carry out metallographic characterization on the obtained overlapping welds; wherein, the material of sample 1, sample 2-1 and sample 2-2 are the same; n is a positive integer greater than or equal to 3; (2) Compare the number and distribution of equiaxed grains in the laser weld and overlapping weld area of sample 1, and pre-identify the nucleation mechanism of the weld according to the comparison results; (3) Confirm according to the pre-identification results to analyze get the nucleation mechanism. The invention improves the accuracy and repeatability of identifying the nucleation mechanism.

Owner:HUAZHONG UNIV OF SCI & TECH

A thin plate metallographic thermal embedding method

ActiveCN109813589BReduce sample preparation costsThickness is not requiredPreparing sample for investigationThin slabCapillary action

The invention discloses a thin-plate metallographic heat embedding method. The heat-cured resin flake and the resin block are processed by processing the resin inlay material, and the heat-cured flake and the resin block are both processed to form gaps. When the thin plate sample is single, fix it with a heat-cured resin block with a gap, put the whole into a thermal mounting machine, add resin inserts for mounting; when there are multiple thin plate samples, use gaps between adjacent thin plate samples The heat-cured resin sheets are separated, and the two ends are clamped and fixed with a heat-cured resin block with a gap. The whole is put into a heat-mounting machine, and resin inserts are added for mounting. The invention has low sample preparation cost and no requirement on the thickness of the thin plate, can improve the inlay efficiency of the thin plate, does not generate capillarity, and improves the success rate of metallographic photography.

Owner:INST OF RES OF IRON & STEEL JIANGSU PROVINCE +2

Nano-film transmission electron microscope in-situ heating chip sample preparation method

InactiveCN110926899AAchieve precise titrationReduce sample preparation costsPreparing sample for investigationMaterial analysis by transmitting radiationCopper wireThin membrane

The invention discloses a nano-film transmission electron microscope in-situ heating chip sample preparation method. The method comprises the following steps: (1) selecting a liquid injection device;(2) cleaning and fixing the liquid injection device; (3) bending one end of a copper wire into a copper ring; (4) moving the copper ring to a position near the thin film sample, and fishing up the thin film sample to the copper ring; (5) extruding a liquid drop from the liquid in the microsyringe; (6) moving the copper ring to a position near the liquid drop at the tip of the microsyringe, so thatthe film sample is adsorbed on the liquid drop; (7) accurately adsorbing the liquid drops in a sample observation area, and then moving away the microsyringe; (8) naturally drying the chip; and (9) heating and baking the naturally dried chip. Accurate titration of the nano-film in the Si3N4 film observation area in the transmission electron microscope in-situ heating chip can be realized, hydrophilic treatment on the Si substrate is not needed, the cost is reduced, the influence of surface tension on the film is avoided, the sample preparation success rate is improved, and the risk of damageto a chip electrode is reduced.

Owner:GUANGXI UNIV

A kind of ebsd sample preparation method

InactiveCN109270096BEliminate surface stressShorten the timeMaterial analysis using wave/particle radiationTemperature controlTest sample

The invention provides an EBSD sample making method. The method includes: sample making, wherein a preset-size test is made from sample raw-material, and a to-be-tested surface of the test sample is polished; and heat processing, wherein the test sample after sample making completion is placed in vacuum airtight equipment capable of temperature control, heat processing is carried out according topreset technology, and the sample is used for an EBSD test after heat processing completion. Through the method, a sample making process and time can be shortened, sample making costs can be reduced,sample making efficiency can be improved, calibration rates of IPF graphs in EBSD tests can be significantly improved at the same time, and a highest calibration rate can reach 99%.

Owner:CENT IRON & STEEL RES INST

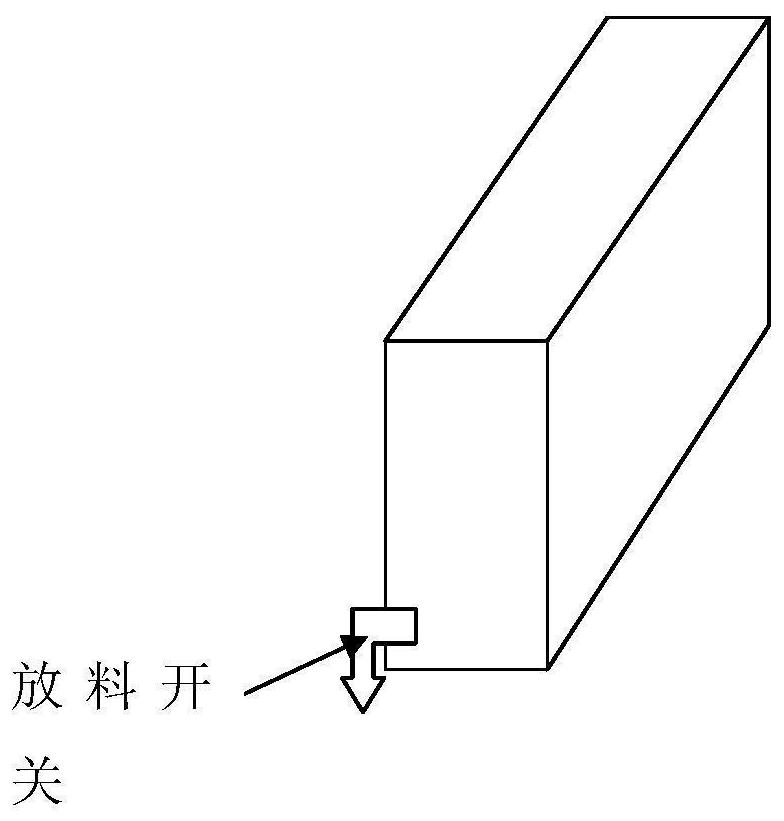

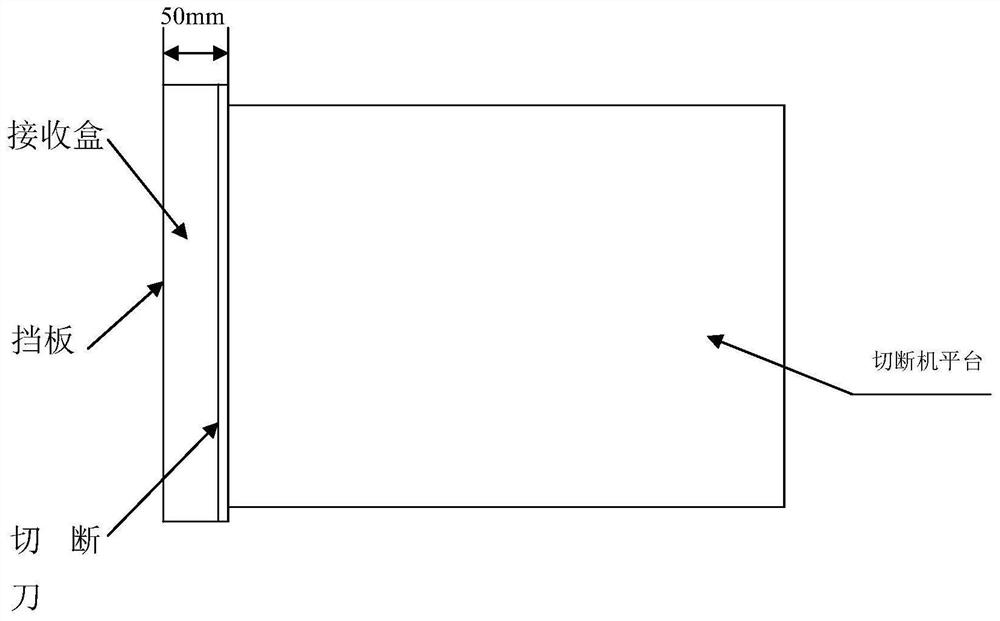

Equipment and method for preparing reinforcing sheets in batches

PendingCN114441248AReduce sample preparation costsTake advantage ofPreparing sample for investigationFiberCarbon fibers

The invention discloses equipment and a method for preparing reinforcing sheets in batches, and the equipment comprises a gum dipping tank, a rest stand and a cut-off machine, and is suitable for preparing reinforcing sheets required by a large-K-number carbon fiber multifilament test sample. The method can be used for preparing reinforcing sheets suitable for tensile property samples of large-K-number carbon fiber multifilaments in batches, and meets the requirements of large-K-number carbon fiber multifilament tensile property test work in large-scale industrialization.

Owner:CHINA PETROLEUM & CHEM CORP +1

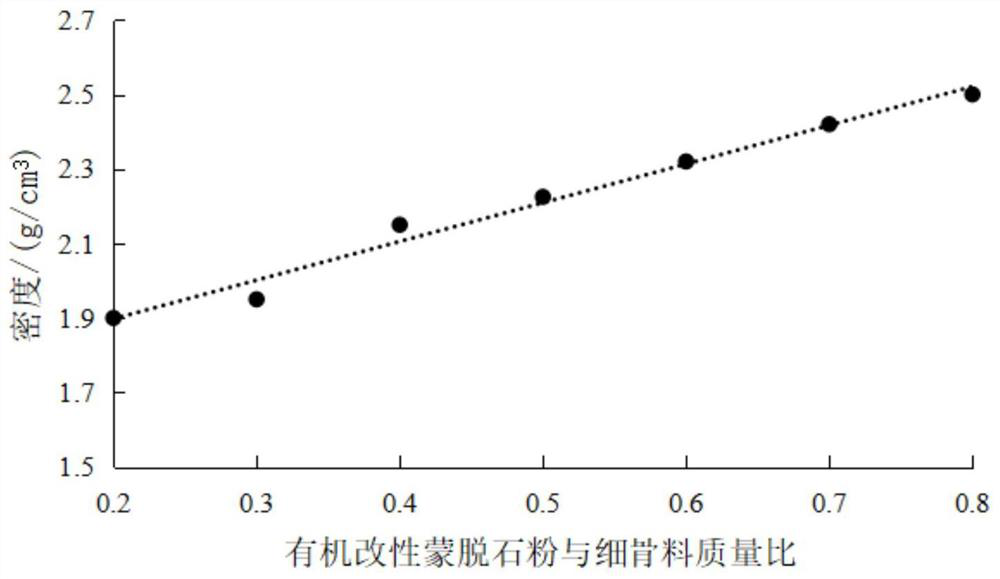

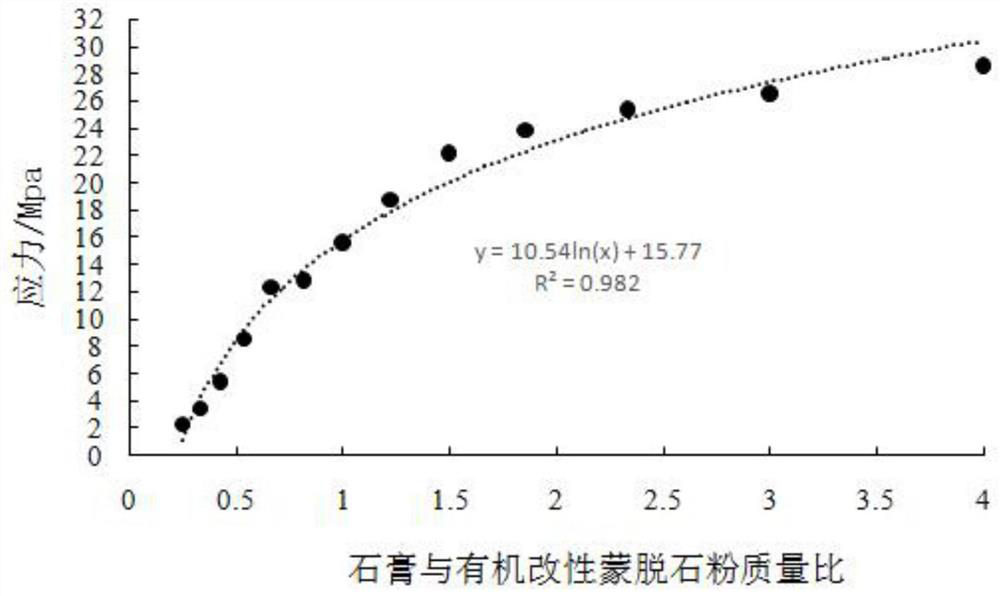

Silty mudstone similar material and preparation method thereof

Owner:CHANGSHA UNIVERSITY OF SCIENCE AND TECHNOLOGY

Malachite chemiluminescence ELISA detection method and kit

ActiveCN102661946BIncreased sensitivityStrong specificityChemiluminescene/bioluminescenceMalachite greenImmuno detection

The invention discloses a malachite chemiluminescence ELISA detection method and a kit. According to the invention, it is the first time to discuss chemiluminescence ELISA mechanism of malachite, a malachitechemiluminescence ELISA detection system and a detection method are successively established, and perfect combination of high sensitivity and high specificity is realized. The kit provided by the invention has high sensitivity, accuracy, precision and stability, is used to simplify operation steps and reaction time and reduce errors caused by complex operation, is very suitable for trace analysis and batch detection of malachite residues, and is of great practical application significance.

Owner:广州万联生物科技有限公司

Grinding and polishing clamp and equipment for metallographic sample preparation

InactiveCN111829853AAvoid adverse phenomena such as grinding deviationAvoid rolling frictionPreparing sample for investigationPolishingStructural engineering

The invention relates to a grinding and polishing clamp and equipment for metallographic sample preparation. The clamp comprises a sleeve, wherein a fixing ring is fixed to the sleeve in the circumferential direction, a plurality of grooves are formed in an inner wall of the sleeve, a plurality of universal balls are arranged on an end surface of the fixing ring, a weight block and a telescopic block are further included, and first bosses matched with the grooves are arranged on a side face of the weight block and a side face of a first supporting plate and a side face of a second supporting plate of the telescopic block. The clamp is advantaged in that problems of grinding deviation, multiple grinding and polishing planes and the like easily generated in the manual grinding and polishingprocess are solved, grinding and polishing efficiency is high, and the sample grinding quality is good.

Owner:SHANDONG UNIV

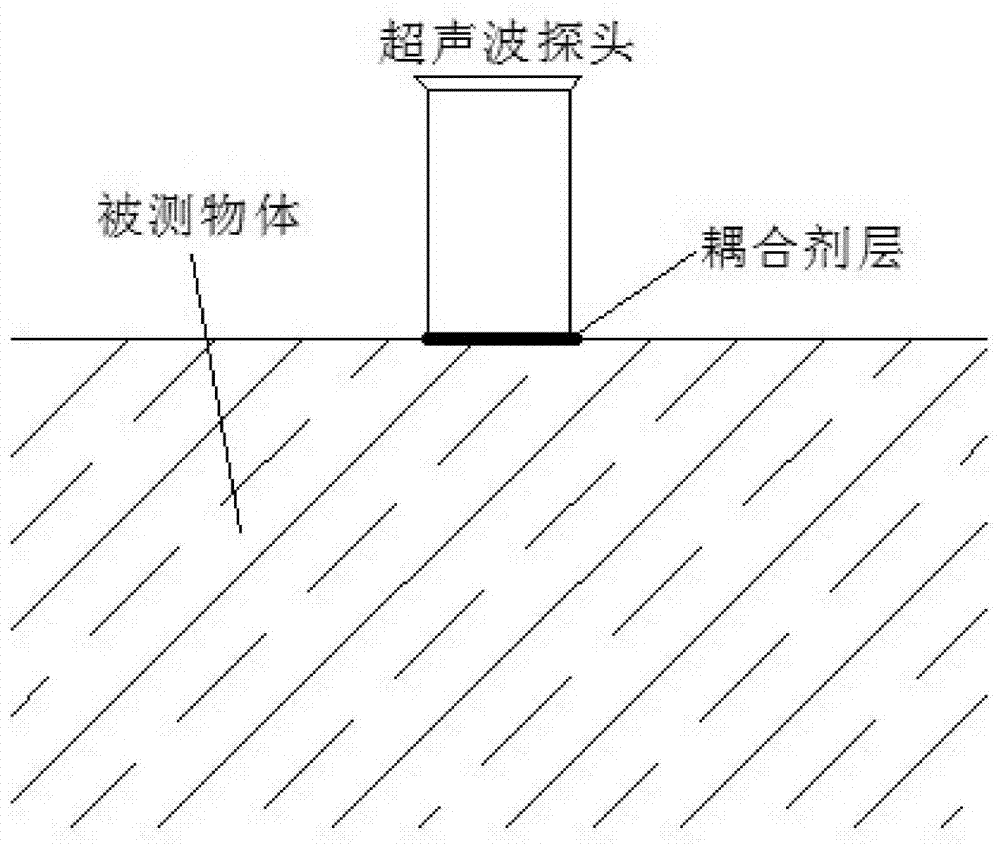

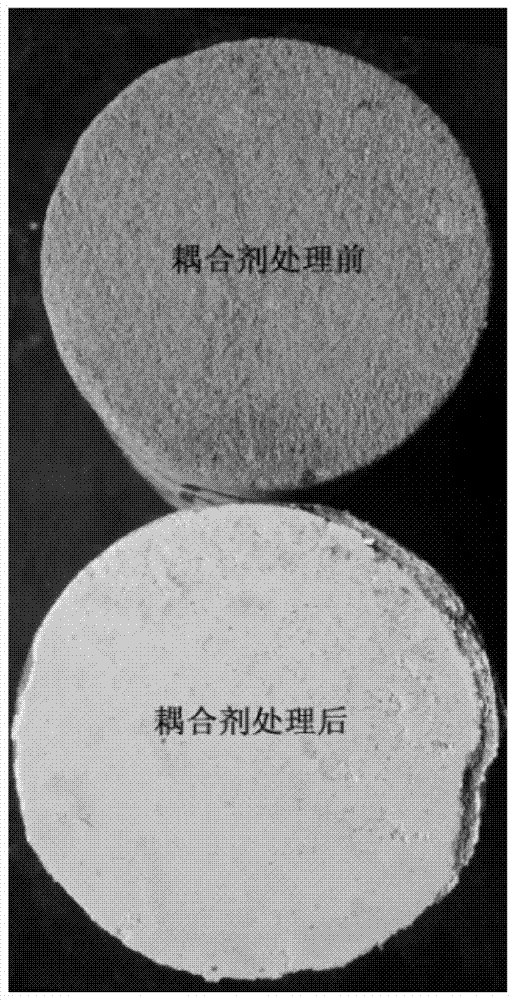

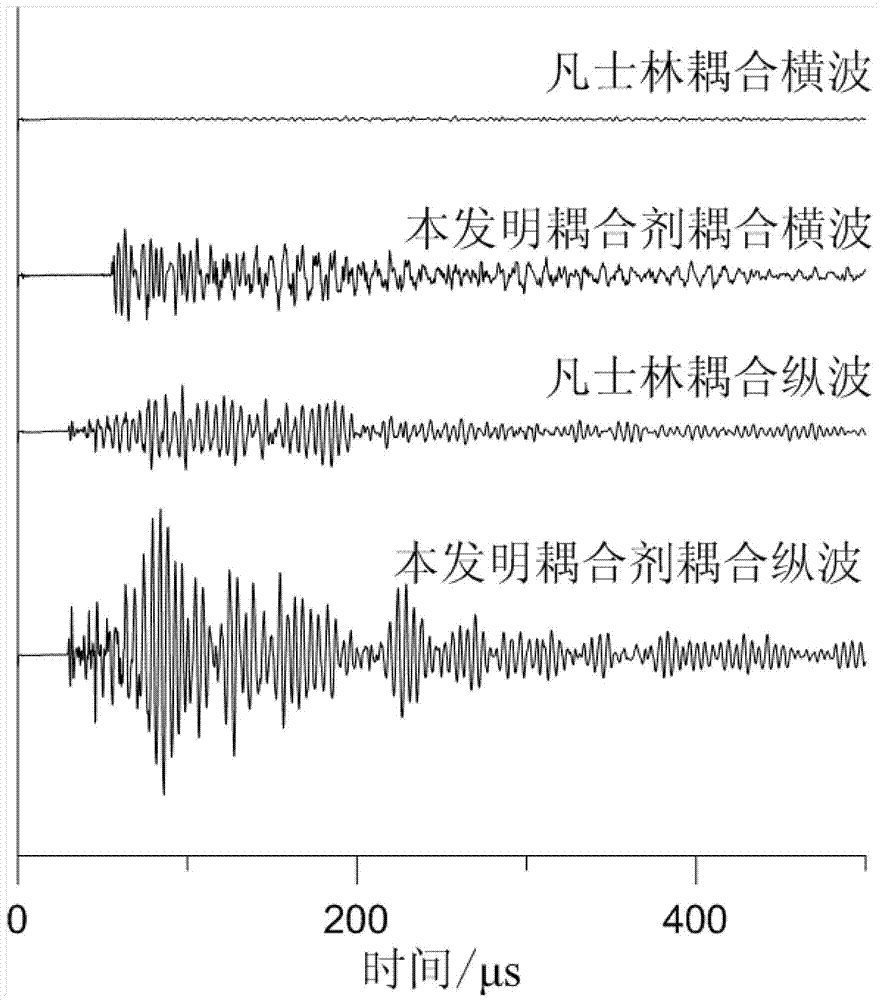

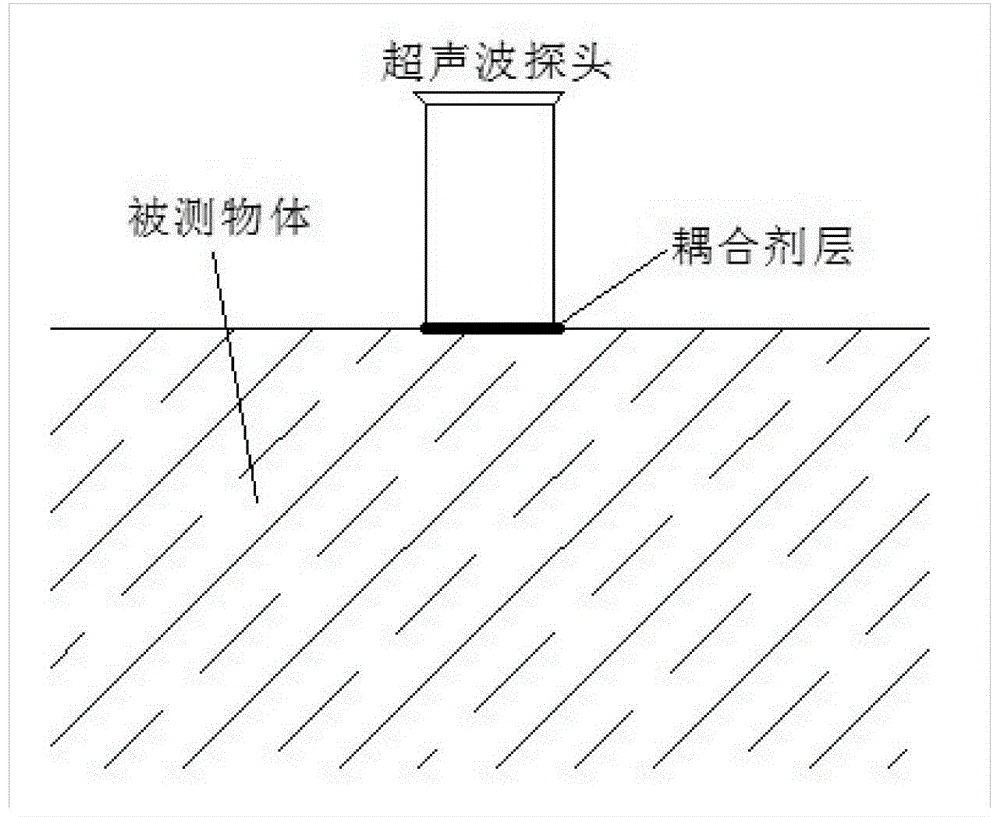

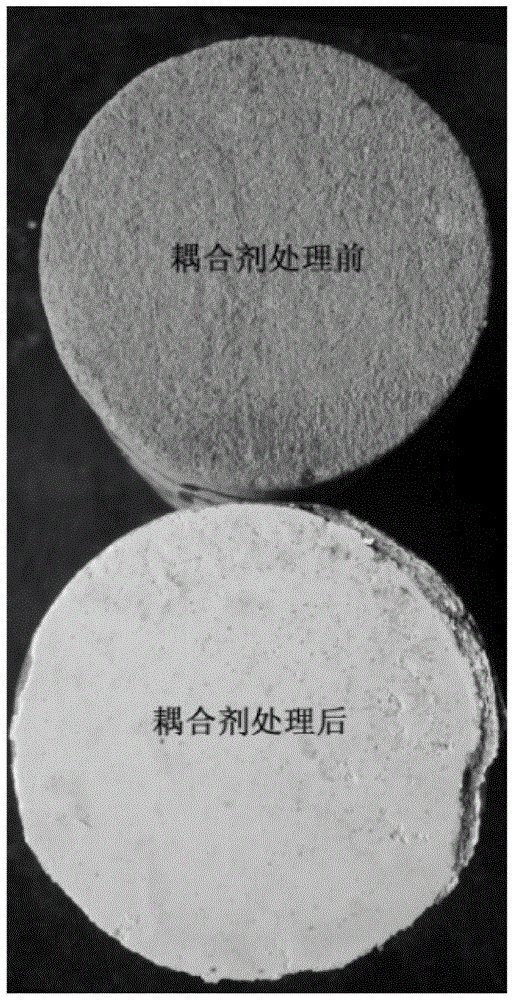

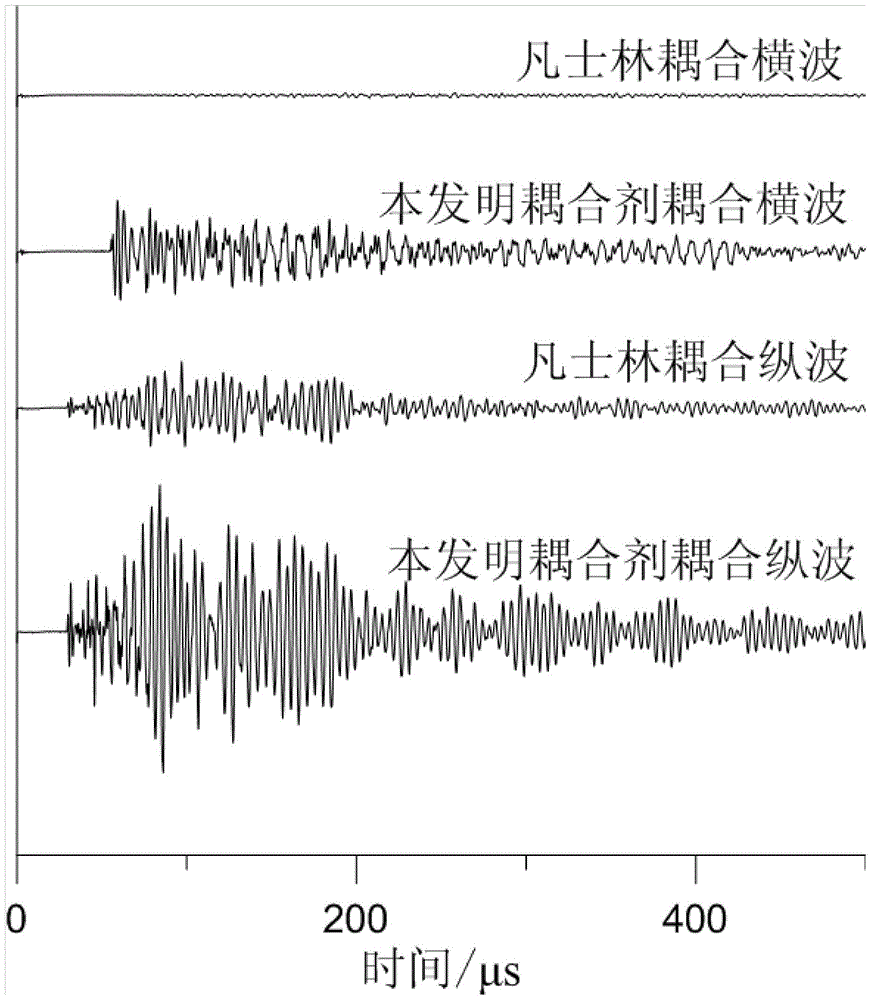

Slow-speed couplant that eliminates the effect of end surface roughness and improves the test effect of longitudinal and transverse waves

InactiveCN103983701BReduce processingSolidifiedMaterial analysis using sonic/ultrasonic/infrasonic wavesChemical reactionPolyvinyl alcohol

A slow-speed couplant that eliminates the effect of end surface roughness and improves the test effect of longitudinal and shear waves. The coupling agent is made of cheap and easy-to-obtain materials such as gypsum, plaster of paris, polyvinyl alcohol, white latex, sodium hexaphosphate, calcium oxide and magnesium chloride according to a certain process, and is stored in a sealed bag for use. , mix with water when used, apply it on the surface of the object to be tested after fully stirring and install the ultrasonic probe, and then the ultrasonic test can be carried out. The couplant is in a flow-plastic state during the pretreatment stage of the ultrasonic test, which can fully fill the gap between the probe and the end face of the object to be measured, and eliminate the influence of the end face roughness on the ultrasonic test. It is in a hard plastic state during the ultrasonic test, and has an appropriate bonding strength to bond the ultrasonic probe and the object under test as a whole, so that better longitudinal and transverse wave test results can be obtained. At the same time, the present invention calculates the reaction quality of each material through the chemical reaction equation, makes the coupling agent close to neutral, and reduces the corrosion to the measured object and the probe.

Owner:LANZHOU UNIVERSITY

Quick couplant that eliminates the effect of end surface roughness and improves the test effect of longitudinal and transverse waves

InactiveCN103995058BDensely filled voidsModerate bond strengthMaterial analysis using sonic/ultrasonic/infrasonic wavesChemical reactionPolyvinyl alcohol

The invention discloses a rapid coupling agent for eliminating end surface roughness influence and improving testing effects of vertical and horizontal waves. The coupling agent is prepared into a powder material from materials such as gypsum, calcined gypsum, polyvinyl alcohol, white emulsion, potassium sulfate, sodium chloride, calcium oxide and magnesium chloride according to certain procedures, the powder material is stored in a sealing bag for later use, when being used, the powder material is mixed with water, the surface of a tested article is coated with the sufficiently mixed powder material, and an ultrasonic probe is also mounted for ultrasonic testing. The coupling agent is in a flowing molding state in an ultrasonic testing pretreatment procedure, a gap between the probe and the end surface of the tested article can be sufficiently filled, and the influence on the ultrasonic testing caused by the roughness of the end surface is eliminated. In ultrasonic wave testing, the coupling agent is in a hard molding state and has appropriate adhesion strength, so that the ultrasonic probe can be integrally adhered to the tested article, and then a relatively good vertical and horizontal wave testing effect can be obtained. In addition, the reaction mass of the materials can be calculated through chemical reaction equations, the coupling agent can be approximately neutral, and the corrosion of the tested article to the probe is alleviated.

Owner:GANSU ELECTRIC POWER DESIGN INST +1

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com