Metallographic section sample preparation mold and method for preparing metallographic section sample

A technology for metallographic sectioning and sample preparation molds, which is applied in the preparation, sampling, and measuring devices of test samples, which can solve the problems of artificial randomness in sample preparation numbers and the influence of time on test result reappearance, so as to facilitate review , Improve sample preparation efficiency and avoid confusion

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

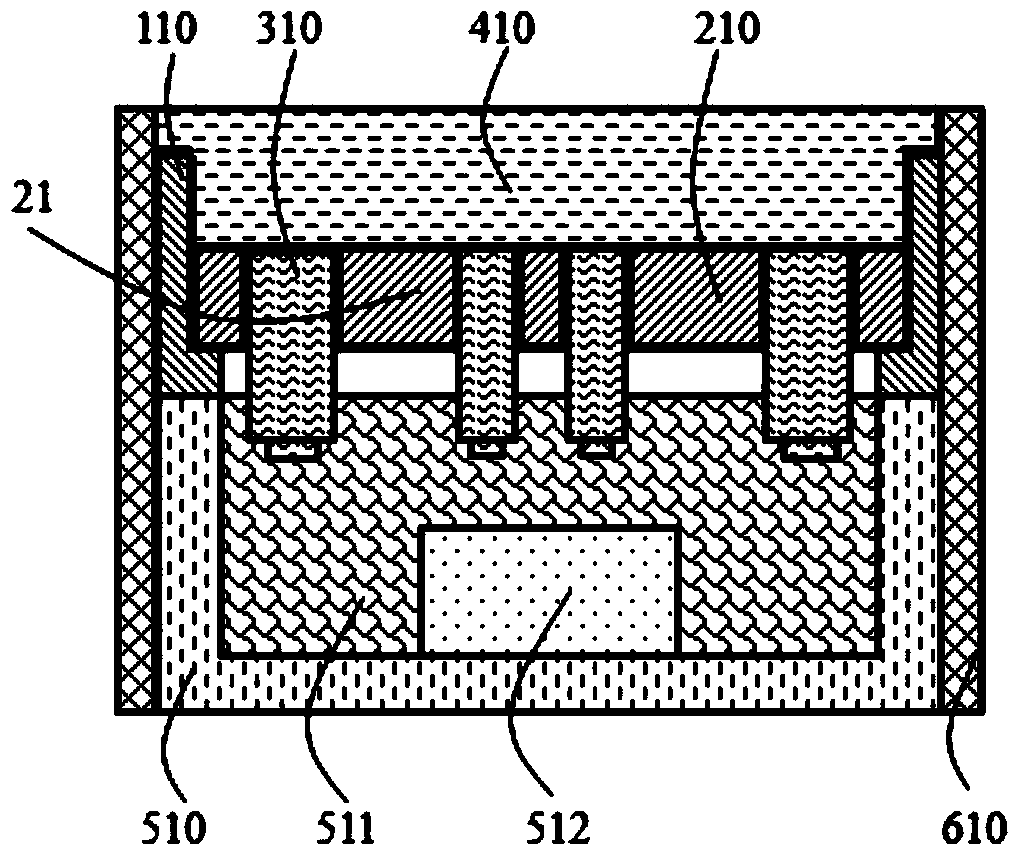

[0047] A metallographic section sample preparation mold, comprising: a rigid overcoat 610, a section glue-filling inner sleeve 510 inside the rigid overcoat 10 and a slice marking inner sleeve 21; the slice marking inner sleeve 21 is located above the section glue-filling inner sleeve 510, comprising The rigid shell 110, the elastic inner pad 210 inside the rigid shell 110 for placing movable type; the elastic inner pad is provided with a positioning hole for fixing the movable type, and the positioning hole is a through hole running through the bottom of the elastic inner pad. The slice marking inner sleeve 510 is used for injecting resin 511 after placing the sample 512, and the slice marking inner sleeve 21 and movable type 310 together form a slice marking assembly.

[0048] The inner diameter of the rigid overcoat is the same as the outer diameter of the slice glue-filled inner sleeve, and the size of the outer wall of the slice marking inner sleeve is consistent with the ...

Embodiment 2

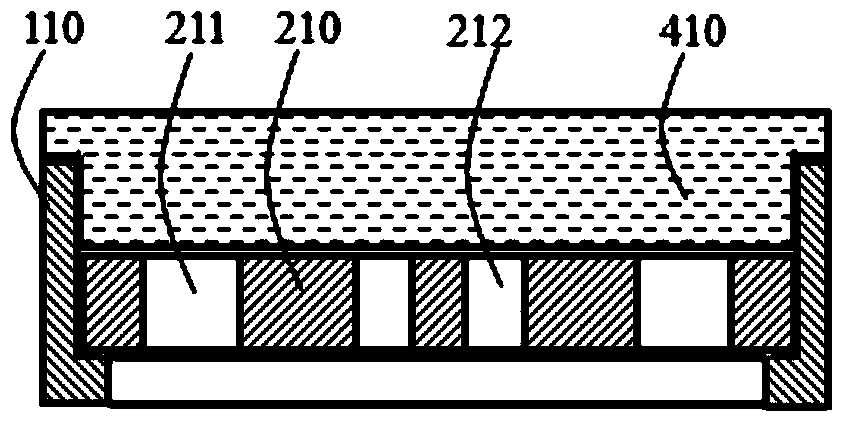

[0060] This embodiment is basically the same as Embodiment 1, the difference is that the date movable type 211 of the elastic inner pad in this embodiment is distributed in a straight line in the center of the elastic inner pad, and the date of the sample main label movable type 212 and sub-label movable type 213 is located in the middle of the elastic inner pad On both sides of the upper and lower sides of the movable type 211, the movable type of the main label and the movable type of the secondary label can flexibly choose one or a combination of numbers and letters.

[0061] Such as Figure 16-18 As shown, the movable type used in this embodiment is suspended on the inner pad of the elastic body through the card position 62 at the top.

Embodiment 3

[0063] This embodiment is basically the same as Embodiment 1, except that the positioning hole is a blind hole extending upward from the bottom of the elastic inner pad. Such as Figure 19 As shown, the blind holes are used to fix the type while keeping the type vertical. Therefore, the slice marker inner sleeve does not need a top cover in this embodiment.

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com