Solar energy cell silk-screen two-in-one production line

A technology of solar cells and production lines, applied in circuits, photovoltaic power generation, electrical components, etc., can solve the problems of reducing production efficiency, increasing production costs, and long-term equipment, so as to improve production efficiency, improve utilization rate, and reduce equipment costs. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0044] The present invention will be further described below in conjunction with the accompanying drawings and embodiments.

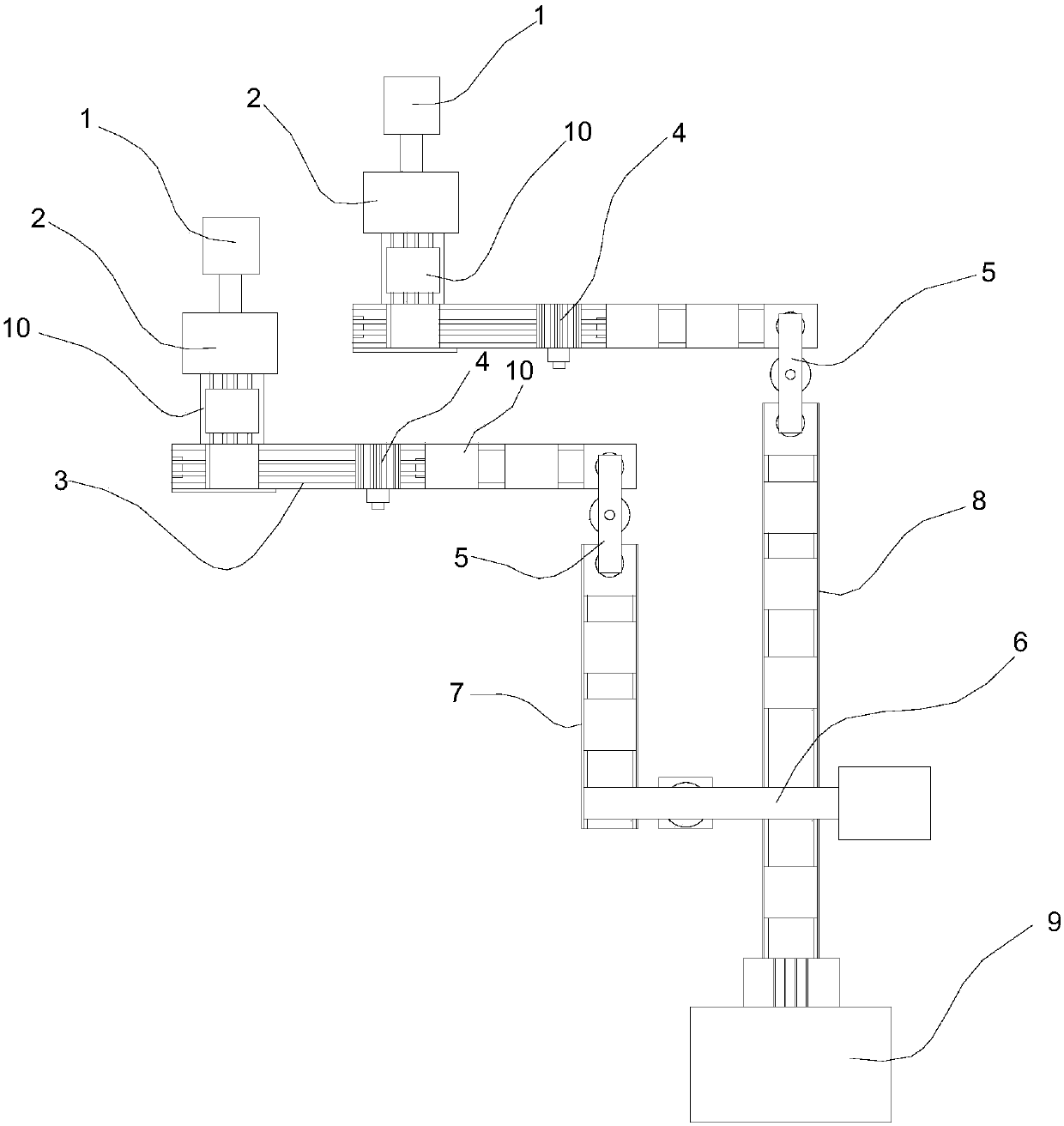

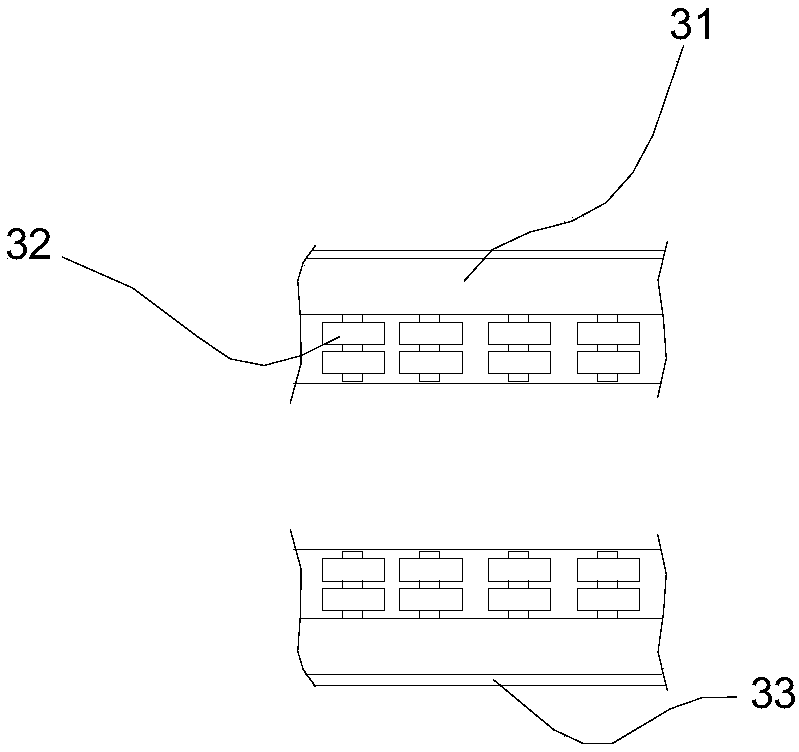

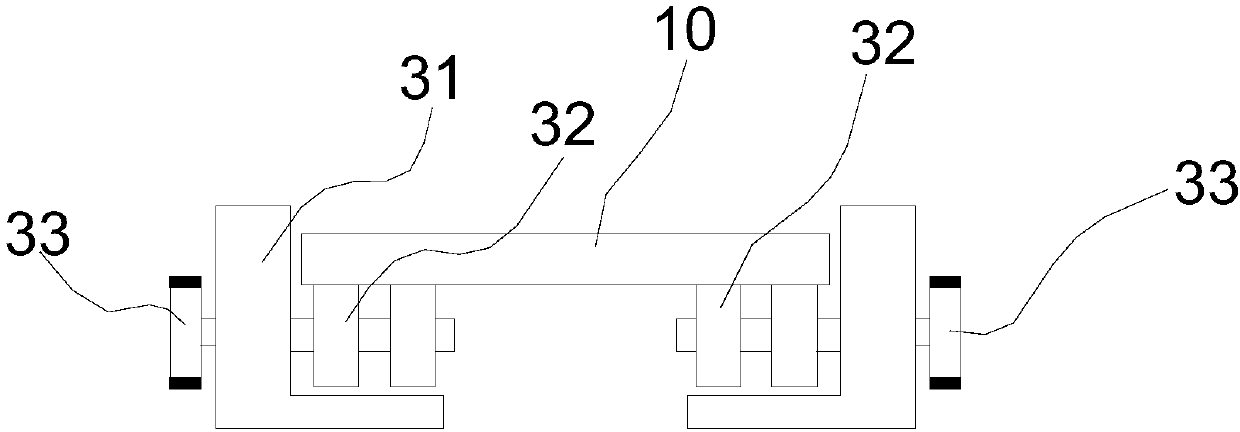

[0045] Such as Figure 1 to Figure 7 As shown, the two-in-one solar cell screen printing production line of the present invention includes a first cell conveyor belt 7, a second cell conveyor belt 8, and two screen printing production lines. The silk screen printing production line includes a first screen printing machine 1, a first oven 2. Conveyor track 3, cell turning device 4 and cell transfer device 5;

[0046] Between the first screen printing machine 1 and the first oven 2, a first battery sheet conveying device for transferring the battery sheet from the first screen printing machine 1 to the first oven 2 is arranged;

[0047] Between the first oven 2 and the conveying track 3, there is a second battery conveying device for transporting the cells from the first oven 2 to the conveying track 3; superior;

[0048] The cell transfer device 5 of ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com