A thin plate metallographic thermal embedding method

A technology of hot embedding and thin plate, which is applied in the preparation of test samples, etc., can solve the problems of capillary action, corrosion of metallographic surface, grinding sample corrosion, etc., and achieve the effect of reducing sample preparation cost, improving success rate and efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

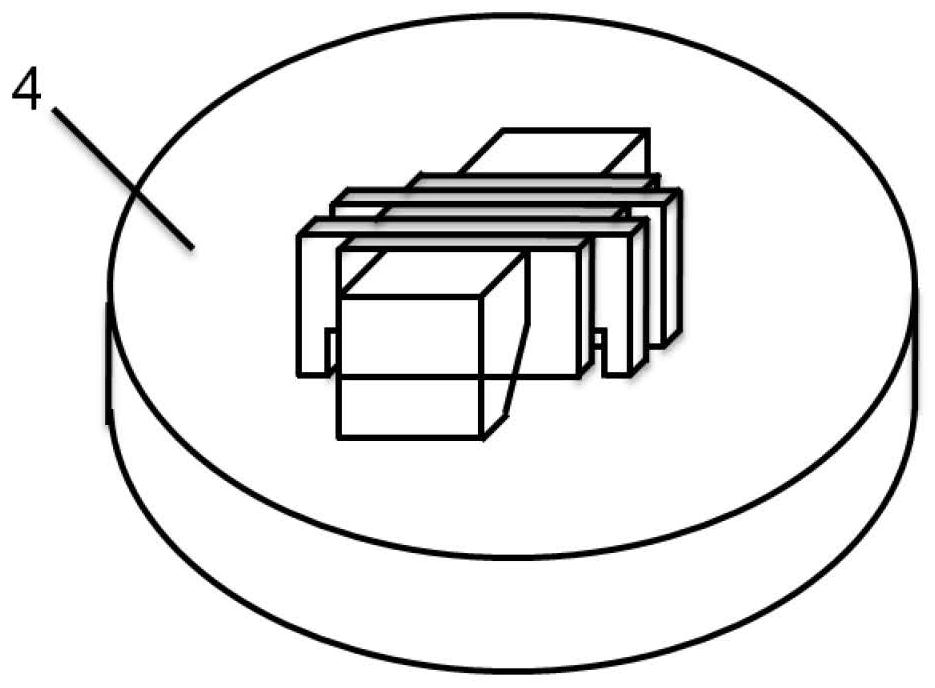

[0028]The single-piece DC04 deep-cut IF steel sheet (0.8 mm) was mounted with a thermal inlaid method, and the size and uniformity of ferrite tissue were mainly observed. With the sheet thermal inlaid method of the sheet in the present invention, it is first used to form a thermosetting resin block (thickness 4.0 mm thick) with a gap, and the sheet is laminated with a cure resin with a gap. Between blocks, overallfigure 2Placed on the macrofaccelock lower platform platform, select the heating temperature of 180 ° C, heat free time of 4 min, pressure 250 bar, select high speed cooling, water cooling time for 4 minutes, and inlaid. The thin plate is flat, and the surface of the surface is no water in the surface of the corrosion, and the metal phase tissue is clean and convenient.

Embodiment 2

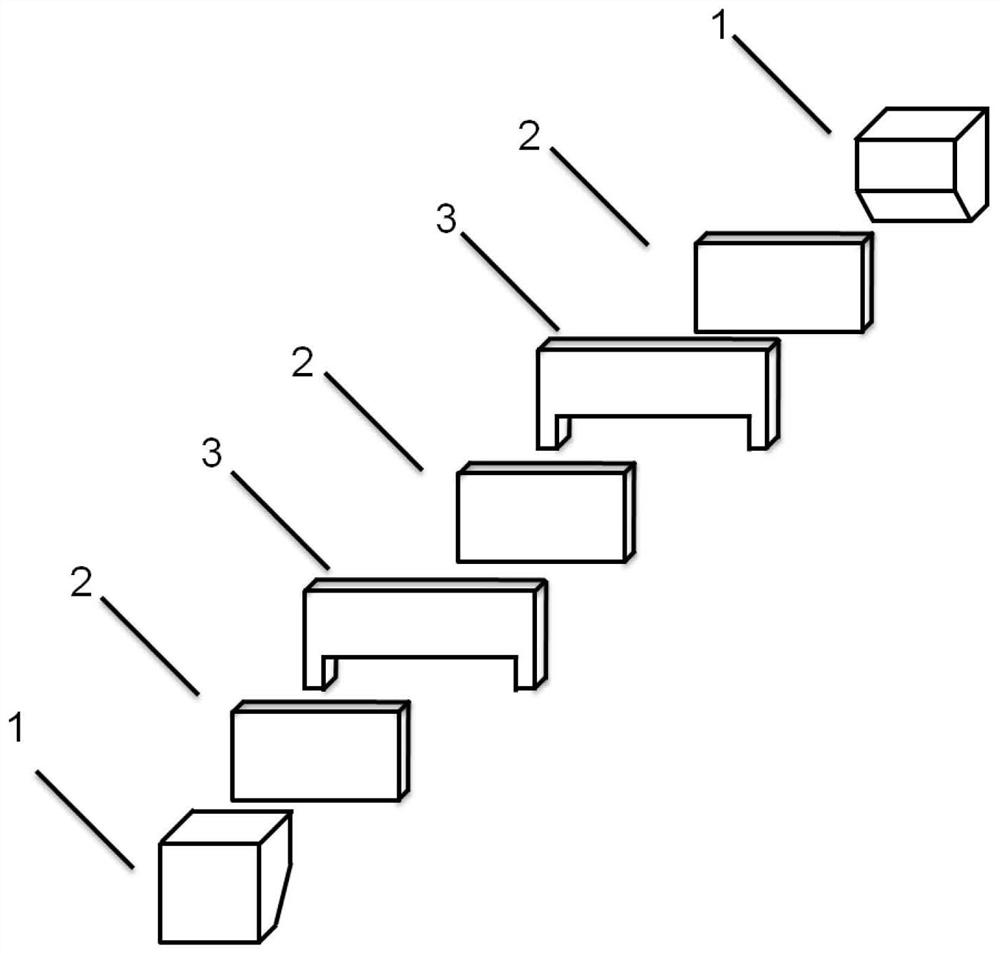

[0030]8-piece number DX53D + Z galvanized sheet (0.5 mm long 6.0 mm, width is 4.0 mm), and the zinc layer tissue is mainly observed in the zinc layer. The thermal inlaid method of the thin plate in the present invention is used, and the inlay structure is first used alone (0.2 mm thickness of 10.0 mm, width of 6.0 mm), and its gap size (length 8.0mm, width is 2.0 mm); processing resin Block (4.0mm), gap edge (2.0 mm). The adjacent sheet samples are separated by a thermosetting resin sheet with a gap, and the two ends are clamped with a cure resin block with a gap.figure 1 Indicated. Overall in the thermal inlaid socket, such asfigure 2As shown, the resin tissue is added, the heating temperature is 190 ° C, the heating time is 6 min, the pressure 280 bar, and the medium speed cooling is selected for 6 min, and the inlay is made. There is no gap between the galvanized sheet cross section, and the surface of the sample is smooth and clean, and the zinc layer is completely retained, whi...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com