Grinding and polishing clamp and equipment for metallographic sample preparation

A metallographic sample preparation, grinding and polishing technology, which is used in the preparation, sampling, and instrumentation of test samples, and can solve problems such as multiple grinding and polishing planes, good quality of grinding samples, and grinding deviation.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

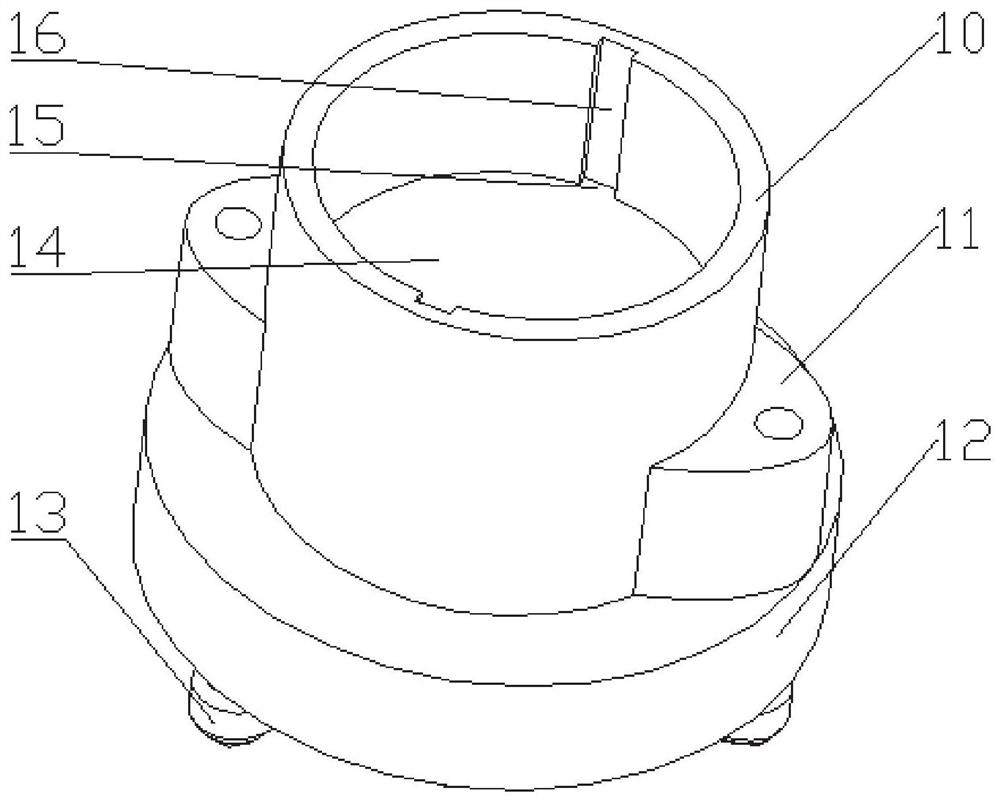

[0042] This embodiment provides a grinding and polishing fixture for metallographic sample preparation, which is suitable for stable working conditions, such as Figure 2-Figure 3 As shown, it includes a sleeve 10 , a fixing ring 12 , several weight blocks 14 and universal balls 13 , and the fixing ring 12 is fixed on the circumferential outside of the sleeve 10 . Several weight blocks 14 are placed inside the sleeve 10 ; the universal balls 13 are arranged along the circumferential direction of the fixing ring 12 .

[0043] Specifically, the sleeve 10 is a hollow cylinder, and the inner wall of the sleeve 10 is provided with several grooves 16 along its axial direction. The outer wall of the sleeve 10 is symmetrically provided with a second boss 11 , and the second boss 11 is located above the fixing ring 12 . A hole for connecting a fixing device is provided on the second boss 11 . In this embodiment, in order to ensure the stable operation of the grinding and polishing ji...

Embodiment 2

[0053] This embodiment provides a grinding and polishing fixture for metallographic sample preparation, which is suitable for unstable working conditions. During the process, the sample will produce rigid axial runout with the shaking of the grinding and polishing disc (2) When the sandpaper is pasted on the grinding and polishing disc due to human reasons, the sandpaper cannot fit the grinding and polishing disc perfectly, resulting in an uneven grinding and polishing plane , and then during the grinding and polishing process, the sample will produce rigid undulating motion with the undulation of the sandpaper.

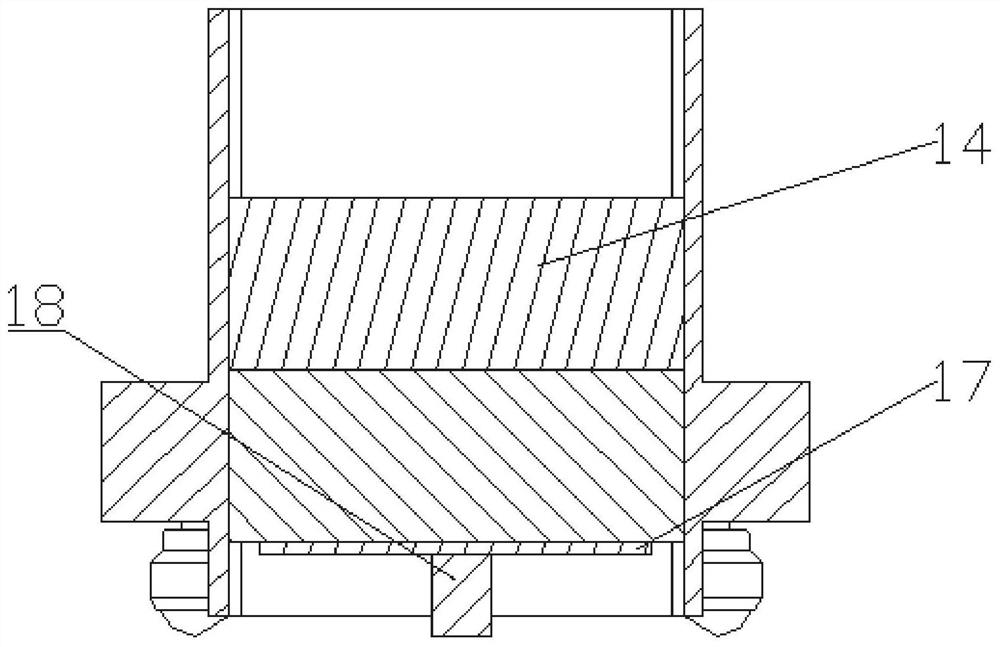

[0054] Such as Figure 4 As shown, this embodiment includes a sleeve 10, a fixed ring 12, a telescopic block 19, several weight blocks 14 and a universal ball 13, the fixed ring 12 is connected with the sleeve 10 as a whole, and the telescopic block is arranged inside the sleeve 10 19, several weight blocks 14 are placed above the telescopic block 19; the universal ...

Embodiment 3

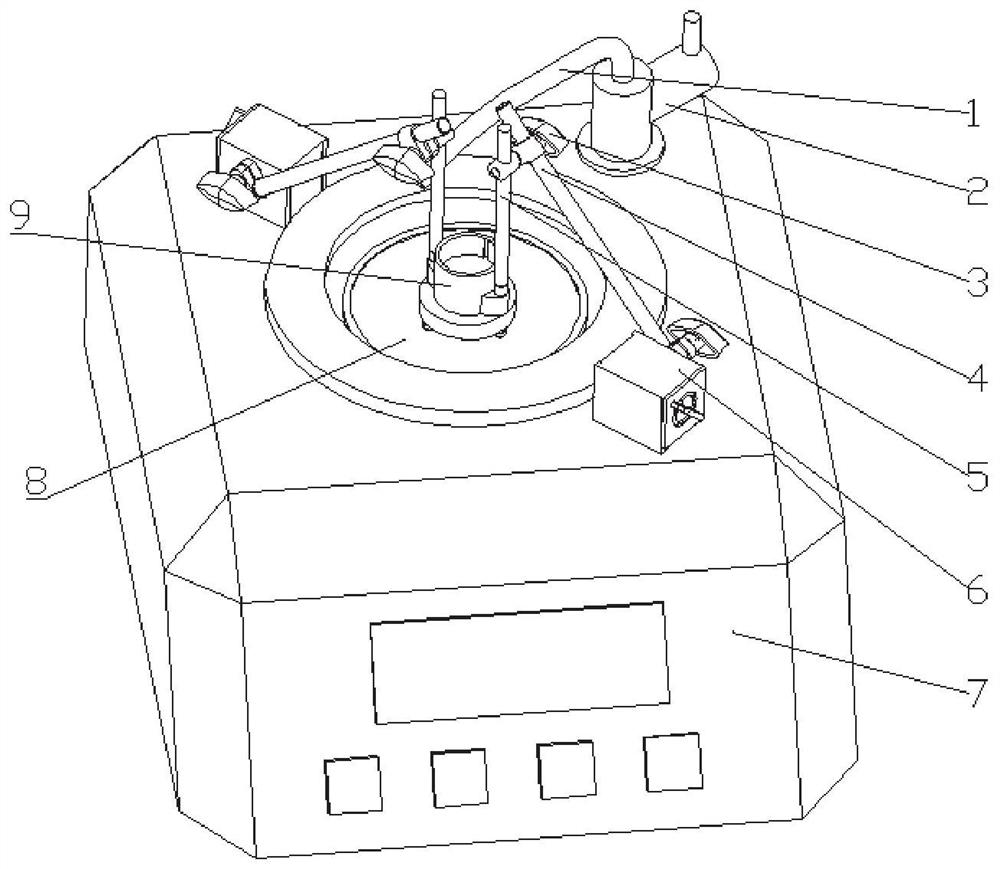

[0062] This embodiment provides a grinding and polishing equipment for metallographic sample preparation, including the grinding and polishing fixture 9 described in Embodiment 1, and also includes a grinding and polishing machine 7 and a fixing device. The grinding and polishing machine 7 is an ordinary grinding and polishing device. machine. Such as figure 1 As shown, a grinding and polishing disc 8 is arranged on the top of the grinding and polishing machine 7, and the grinding and polishing fixture 9 is arranged above the grinding and polishing disc 8 through a fixing device. The top of the grinding and polishing machine 7 is also equipped with a water outlet pipe 1, and the water outlet pipe 1 is equipped with a valve 2, and the water outlet pipe 1 is controlled by the valve 2 to spray water during the grinding process, which plays a cooling role in the grinding and polishing process.

[0063] Such as Figure 5 As shown, the fixing device includes a magnetic base 6, a f...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com