Device for Measuring Fiber Tension

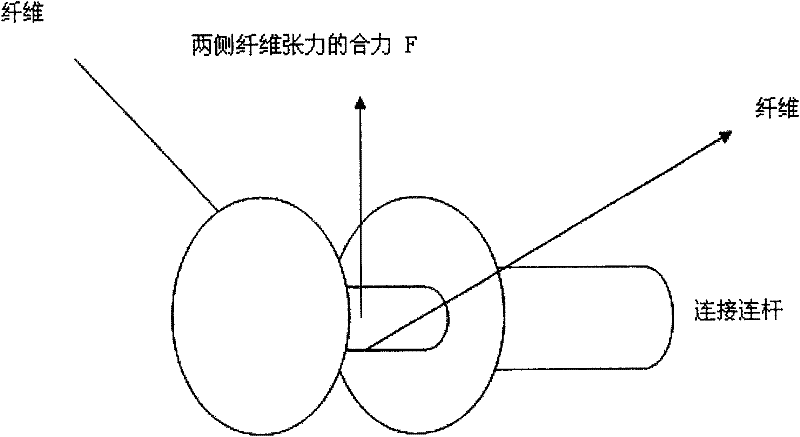

A technology for measuring device and fiber tension, which is applied in the field of force measuring device, can solve problems such as adverse effects on measurement results, large frictional resistance, and limited measurement accuracy, and achieve the effects of amplifying fiber tension, improving measurement accuracy, and satisfying strength

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

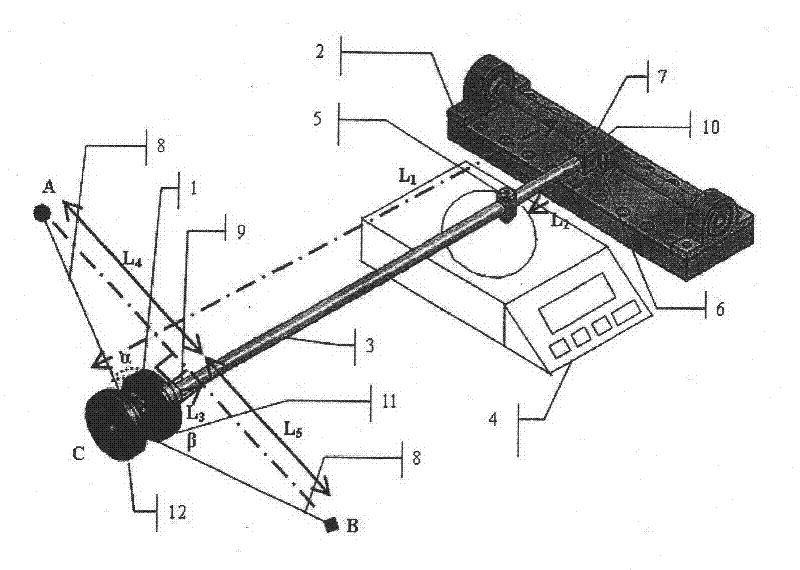

[0091] use as figure 1 The fiber tension measuring device shown measures the tension of polyamide 6 (nylon) fibers. The raw material for melt spinning is Nylon 6 (PA6) chip, the product of Ningbo Hengrun Polymerization Co., Ltd. The spinning temperature is 270°C, the spinneret has a single hole, the diameter of each hole is 1mm, the spinning speed is 0.1g / min / hole, and the winding speed is 100m / min.

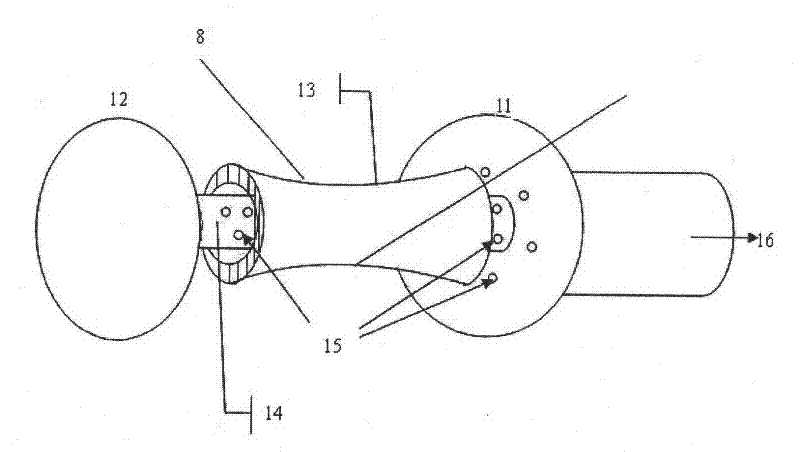

[0092] In this device, the connecting rod is made of aluminum-magnesium alloy, the contact member is made of steel, the air bearing is made of aluminum-magnesium alloy, and the base is made of steel. The mass of the air bearing 1 is 300g, the shaft sleeve 13 is cylindrical, narrowed in the middle, and its outer circumference is 8cm. The connecting rod 3 is hollow tubular, and its length is 40cm. The circumference of the cross section of the connecting rod 3 is about 10cm. The connecting rod 3 is connected with the air bearing 1 in a helical manner. The base 2 supports the c...

Embodiment 2

[0109] use as figure 1 The fiber tension measuring device shown measures the tension of polypropylene (PP) fibers. The raw material for melt spinning is polypropylene (PP), a product of China National Petroleum Corporation Liaoyang Petrochemical Company, grade 70318, weight average molecular weight 2.4*105, polydispersity coefficient 2.8, melting point 165-170°C, spinning grade. The spinning temperature is 280°C, the spinneret has 24 holes, each hole has a diameter of 0.2 mm, the spinning rate is 0.3 g / min / hole, the winding speed is 1000 m / min, and there are 24 fibers per bundle.

[0110] In this device, the mass of the air bearing 1 is 1 kg, the shaft sleeve 13 is cylindrical, slightly convergent in the middle, and its outer circumference is 15 cm. The connecting rod 3 is hollow tubular, and its length is 50cm. The circumference of the cross section of the connecting rod 3 is less than the circumference of the shaft sleeve of the air bearing 1, which is about 10 cm. The c...

PUM

| Property | Measurement | Unit |

|---|---|---|

| length | aaaaa | aaaaa |

| melting point | aaaaa | aaaaa |

| polydispersity index | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com