Linear drives for template sewing machines

A linear drive and sewing machine technology, applied in the direction of sewing machine control devices, sewing machine components, sewing equipment, etc., can solve problems such as wear and tear, and achieve the effects of beautiful appearance, easy adjustment, and convenient installation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

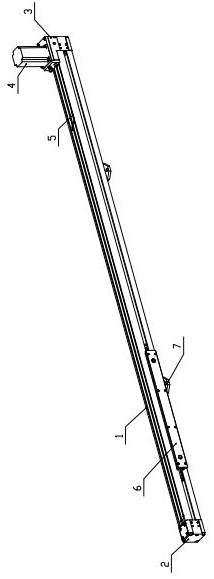

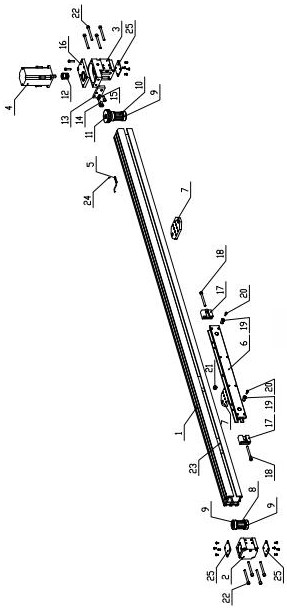

[0050] like figure 1 As shown, the linear drive device of the template sewing machine of the present invention includes a main body 1, and a synchronous belt 26 is arranged in the main body 1. The synchronous belt 26 connects the driving pulley 10 and the driven pulley 8, and the driving pulley 10 passes through the speed change gear pair 11, 12 Connect the stepper motor 4;

[0051] One end of the main body 1 is fixedly connected to the driving pulley seat 3, and the other end of the main body 1 is fixedly connected to the driven pulley seat 2; the driving pulley seat 3 and the driven pulley seat 2 are fixedly connected to the main body 1 through screws 22 respectively;

[0052] like figure 2 As shown, the driving pulley 10 is arranged in the driving pulley seat 3, and both ends of the driving pulley 10 are connected to the driving pulley seat 3 through the bearing 9; one end of the driving pulley 10 is connected to the driven gear 11; The driving gear 12 is meshed, and the...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com