Patents

Literature

41results about How to "Solidified" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

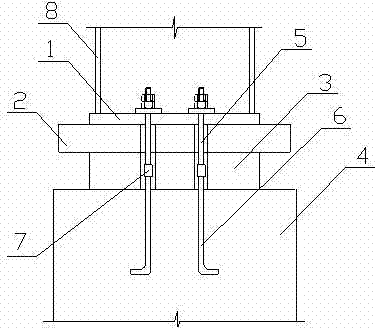

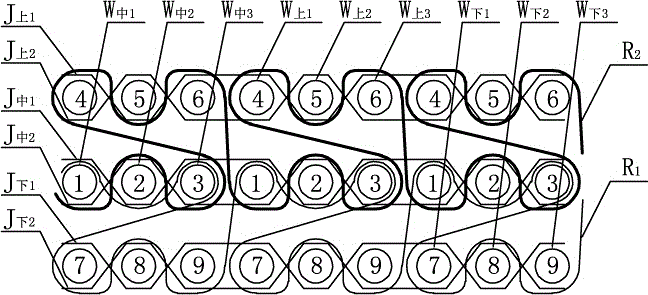

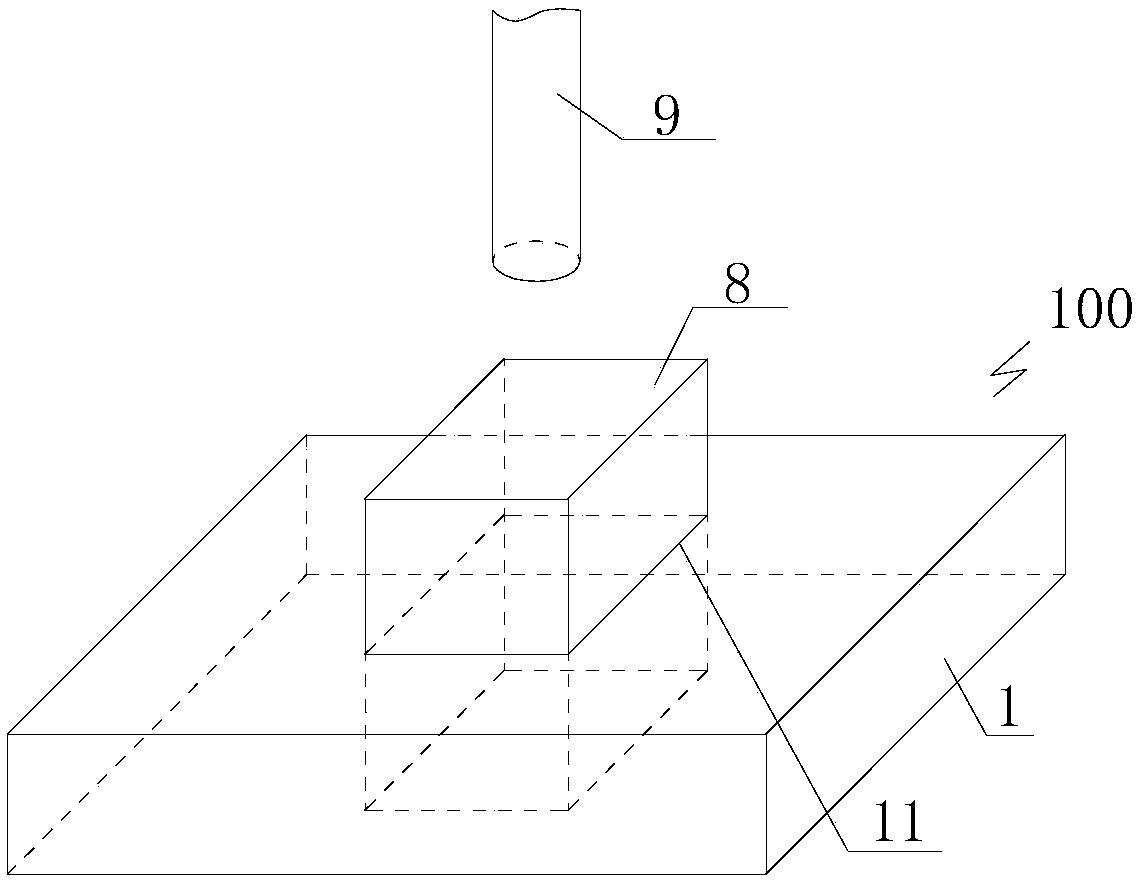

Light steel factory post foundation suitable for sedimentation of filled-in ground and construction method

InactiveCN102864795AHeight adjustableReasonable structureFoundation engineeringArchitectural engineeringEconomic benefits

The invention discloses a light steel factory post foundation suitable for sedimentation of filled-in ground and a construction method. The post foundation comprises a connecting rebar, a post bottom plate, a steel base plate, a precast cushion block and an independent under-post foundation; wherein the post bottom plate, the steel base plate, the precast cushion block and the independent under-post foundation are arranged from top to bottom in sequence; the connecting rebar comprises a top screw rod rebar, a middle screw rod rebar and a bottom drift bolt screw rod rebar; when the filled-in ground sediments, the top screw rod rebar and the middle screw rod rebar can be dismantled; the post bottom plate is jacked and restored to an original design elevation by a jack through the steel base plate, and a gap between the post bottom plate and the independent under-post foundation is filled by the precast cushion block. The light steel factory post foundation is reasonable in structure, convenient to construct, safe and reliable; height of a post bottom can be freely adjusted according to the requirement; adverse effects on construction of the conventional light steel factory post foundation and normal use of a structure caused by foundation sedimentation can be effectively solved, and the light steel factory post foundation has a good economic benefit and a time benefit in engineering construction.

Owner:CHONGQING UNIV

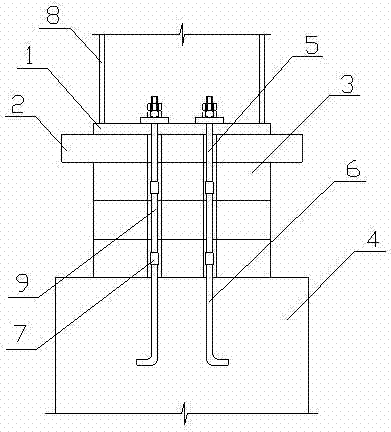

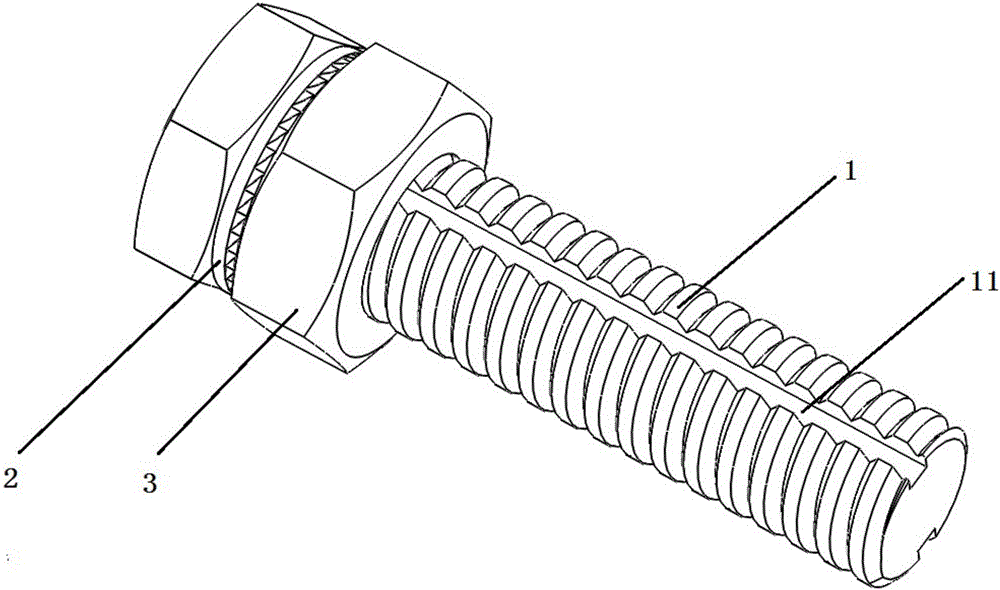

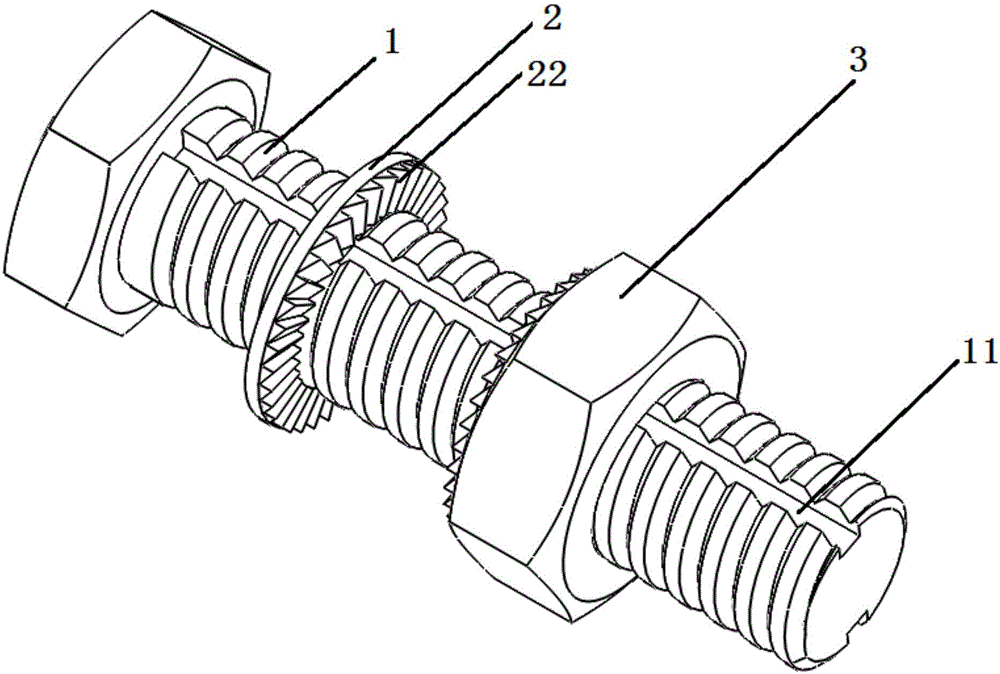

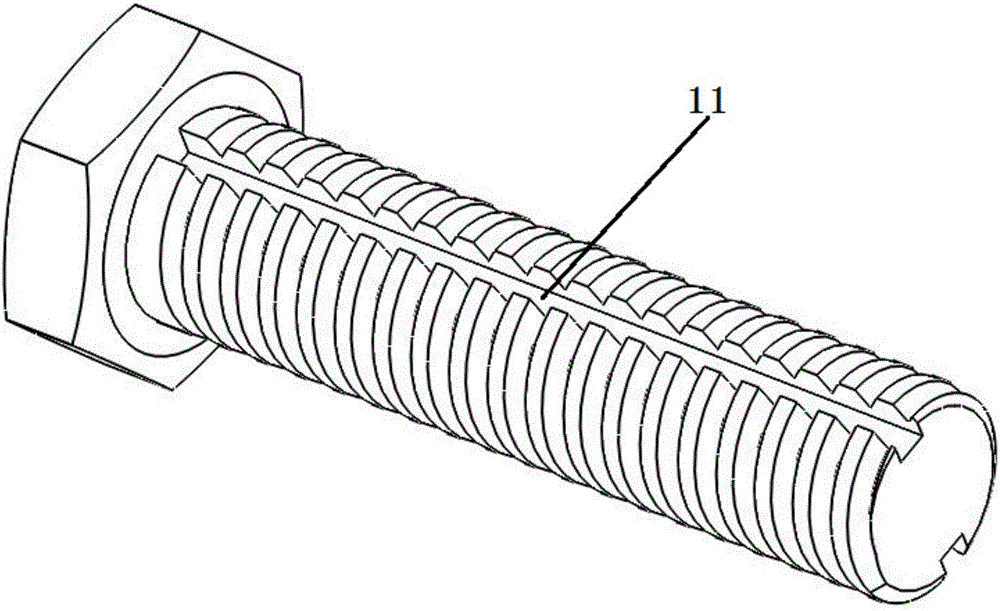

Looseness-preventing and disassembling-preventing bolt

The invention discloses a looseness-preventing and disassembling-preventing bolt. The looseness-preventing and disassembling-preventing bolt comprises a screw, a gasket and a nut, wherein the gasket and the nut are arranged on the screw in a sleeving manner. Grooves extending in the axis direction of the screw are formed in the screw and matched with bosses arranged on the gasket, so that the gasket can only move in the axis direction of the screw and can not rotate around the axis of the screw. The gasket can be in contact with the nut, helical teeth are arranged on the contact faces of the gasket and the nut respectively, and the helical teeth on the gasket are meshed with the helical teeth on the nut, so that when the nut is screwed to the portion where the nut is meshed with the gasket, the nut is locked, looseness caused by vibration and the like can be avoided, and disassembling is also difficult.

Owner:王景东

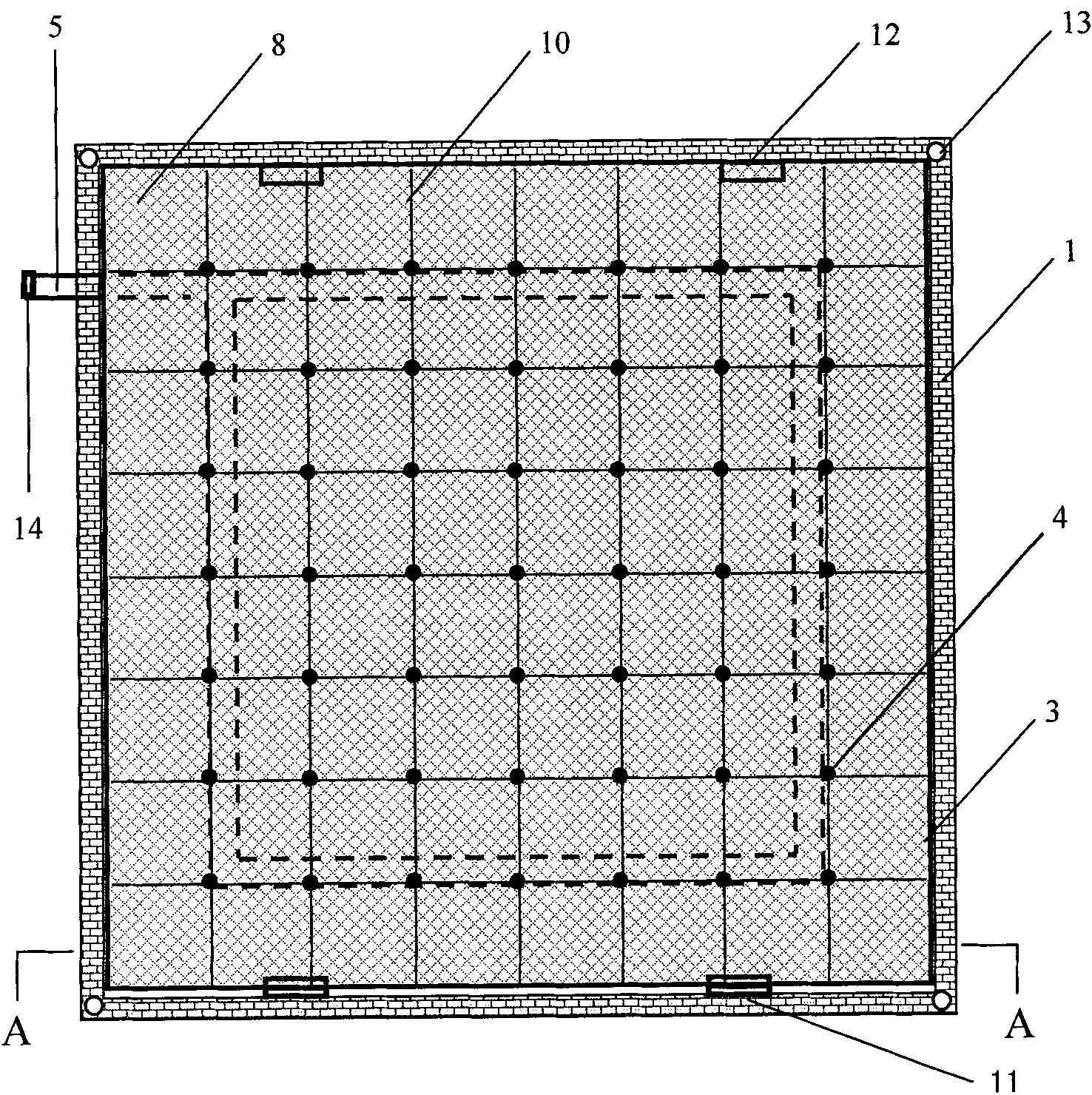

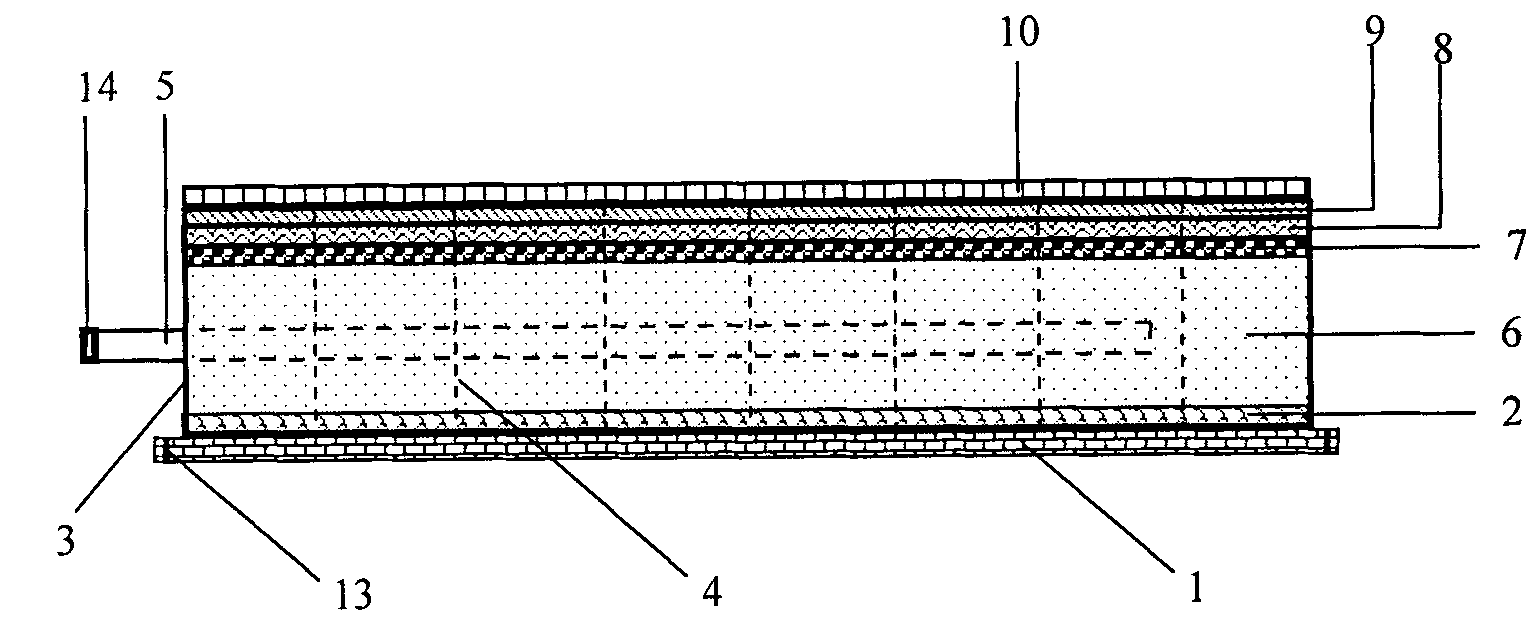

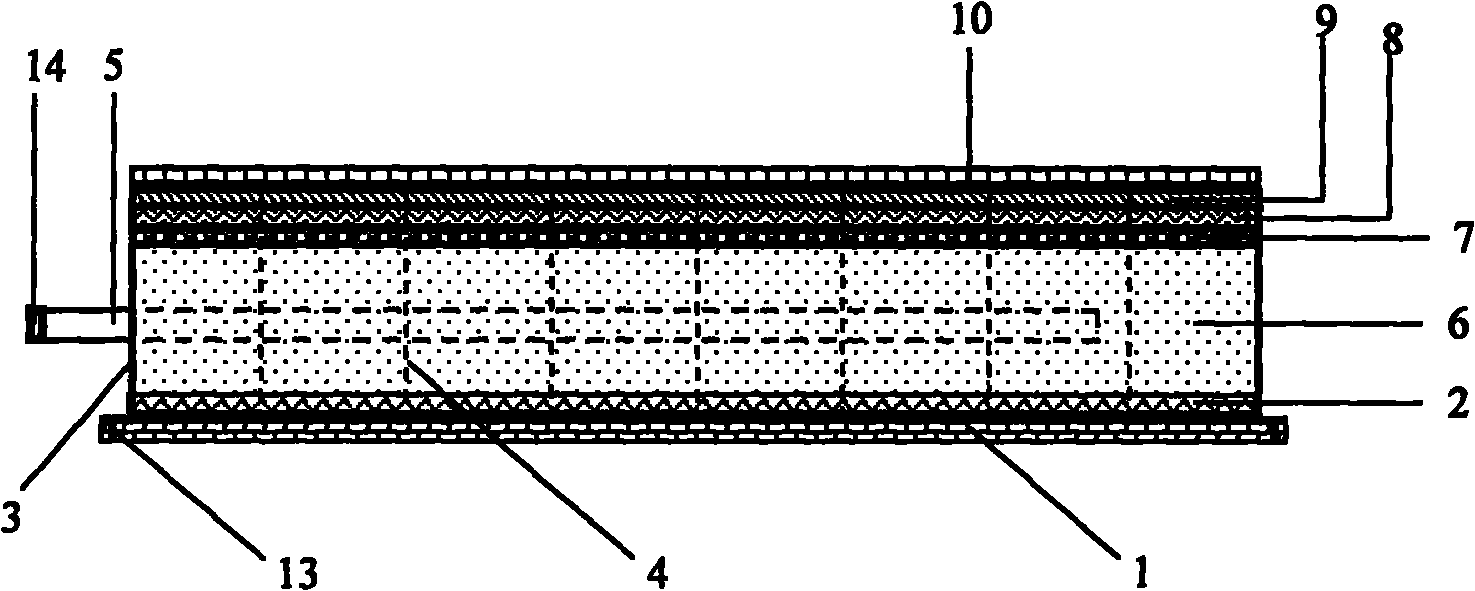

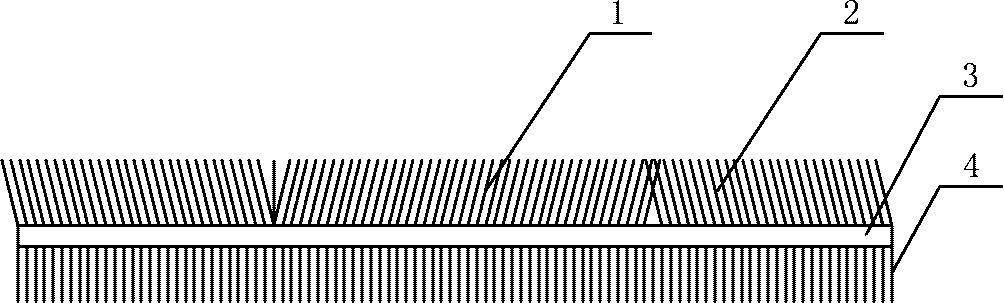

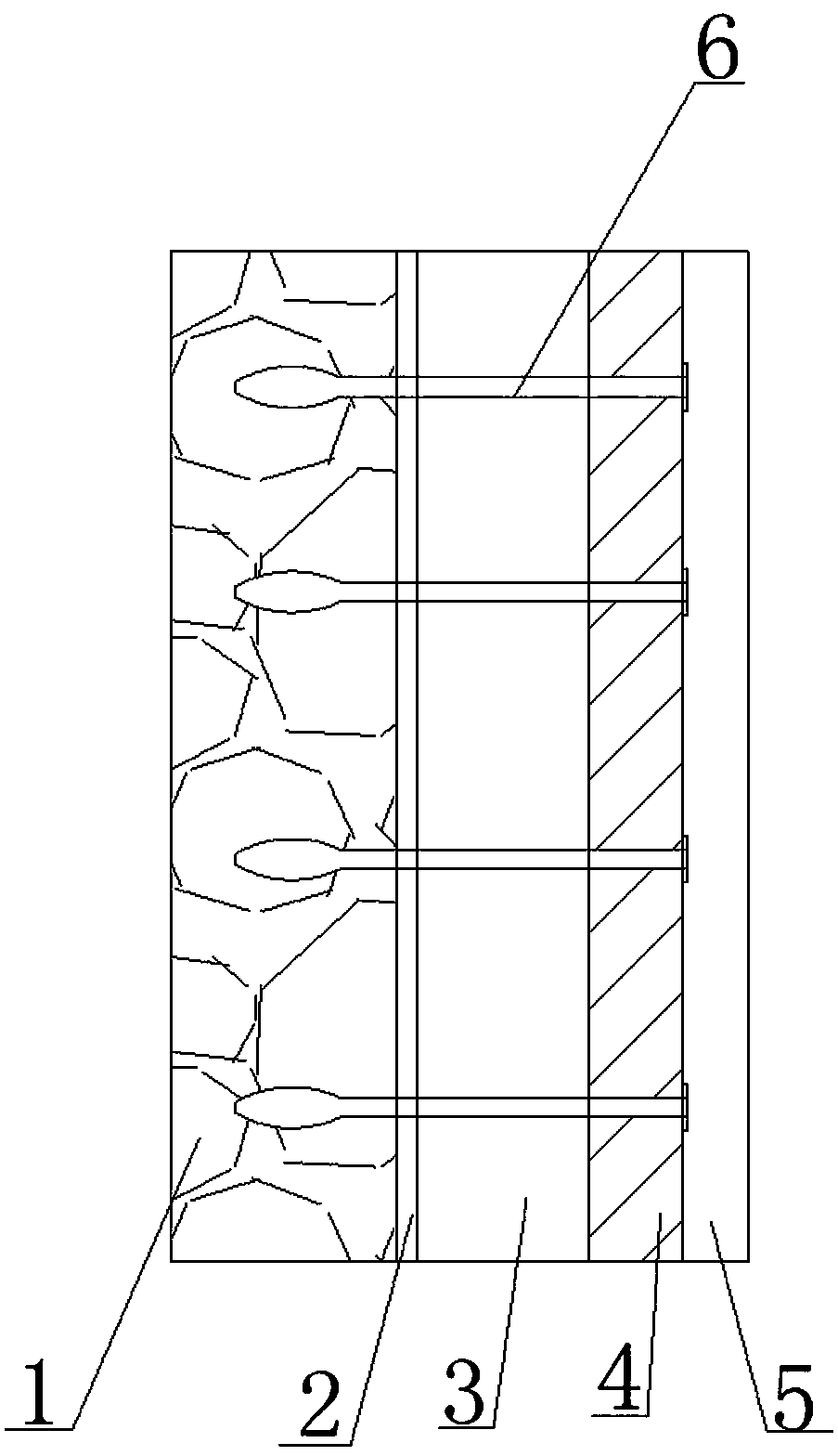

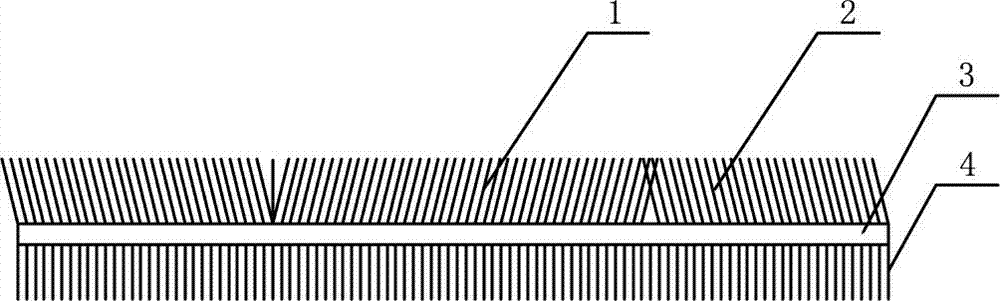

Greening plant brick and manufacture method thereof

InactiveCN101864824ASolidifiedFast greeningConstruction materialWatering devicesConnection typeInsulation layer

The invention provides a greening plant brick and a manufacture method thereof. A brick body of the plant brick consists of a frame body, a lining plate (1), a water-proof layer (2), a nutritive substrate (6), a drip irrigation tube (5) and a humus layer (7), wherein the frame body consists of a surrounding frame (3) with the bottom surface, a support rod (4) and a frame cover, and the frame cover consists of a reticular insulation layer (8), a water absorbing layer (9) and a lattice framework (10). Plants can be cultured in an early stage, and then are transplanted into the brick, the survival rate is high, and the goal of fast greening of vertical buildings can be reached. At the same time, because the plant brick is provided with a parallel connection type drip irrigation device, water, fertilizers, pesticide and the like can be conveniently and fast supplied to the plants, and the maintenance and management efficiency can be improved. The plant brick has wide application range, can be applicable to the greening of internal and external walls of buildings such as channels and the like, rock slopes and the like.

Owner:INST OF ROCK & SOIL MECHANICS CHINESE ACAD OF SCI

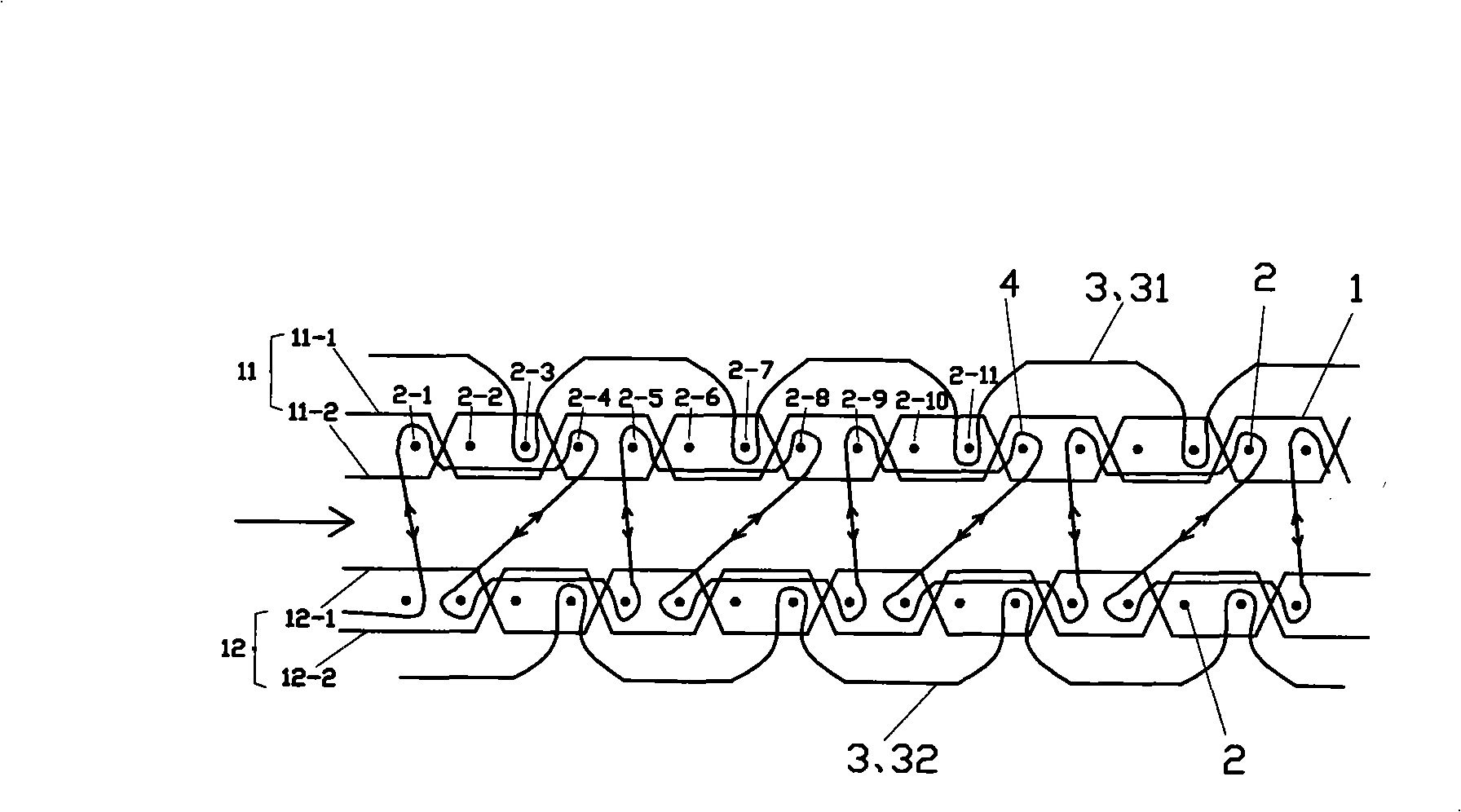

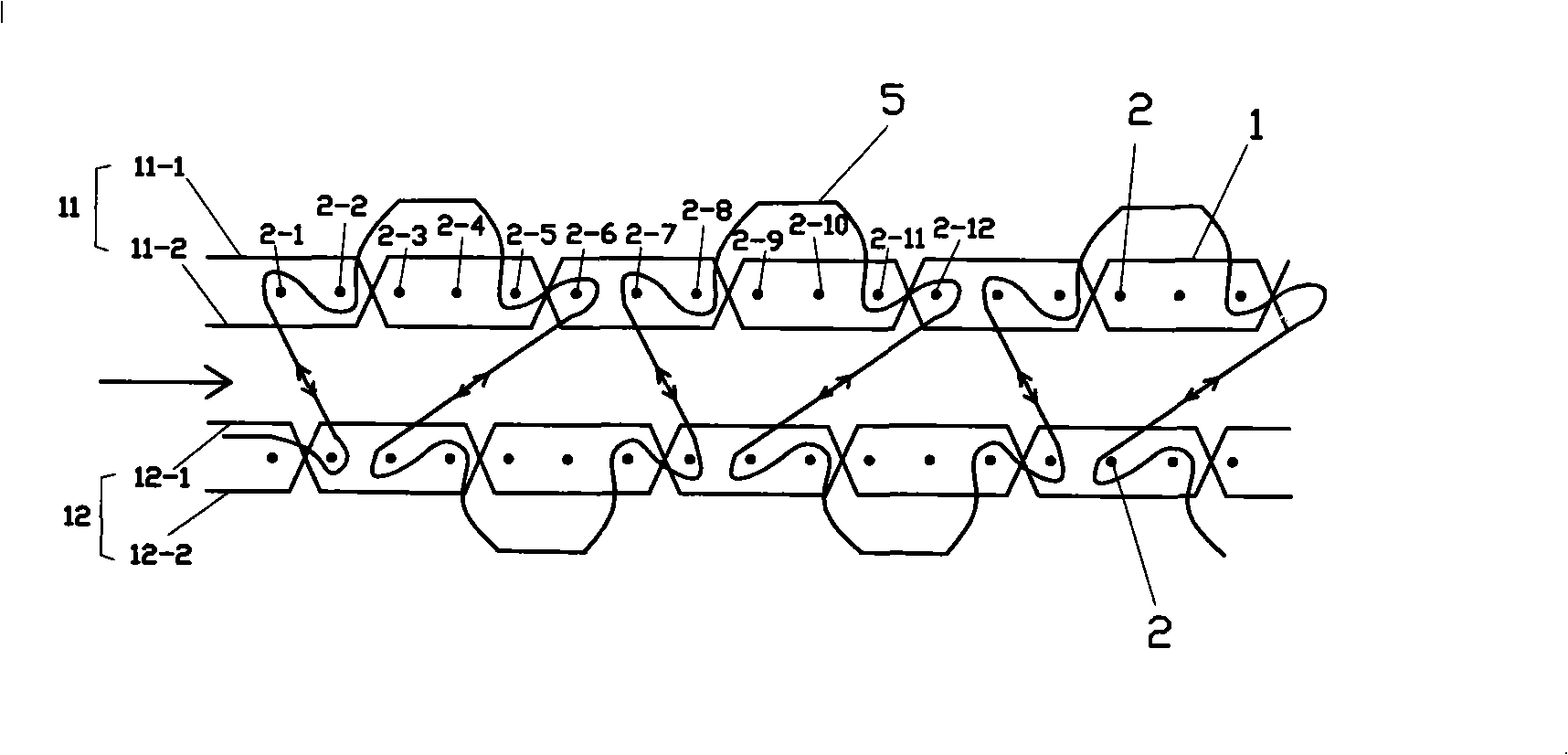

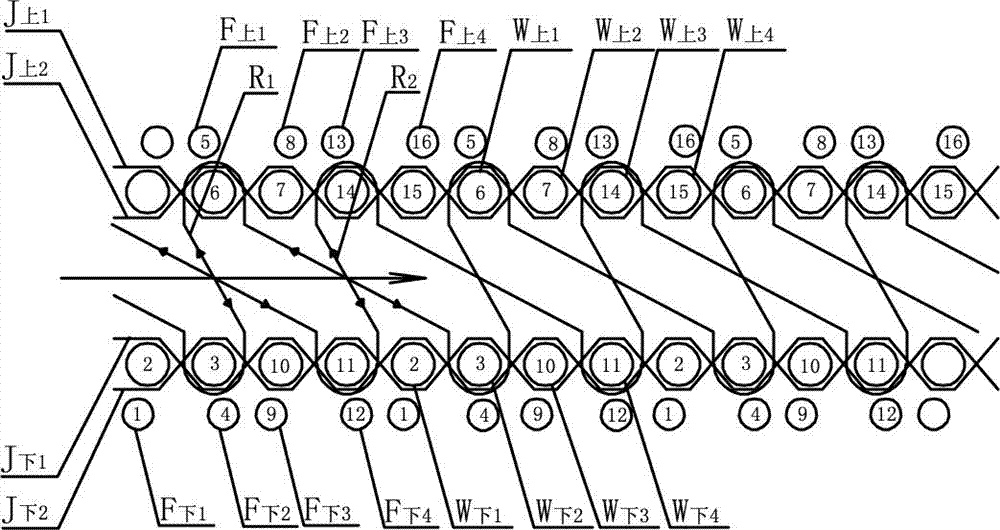

Sheared towel with one-side terry and one-side velutum

ActiveCN101343811AReasonable organizational structureRich textureWoven fabricsWater storageMoisture absorption

The invention discloses a cutting velvet towel, which comprises a two-layer bottom fabric composed of warp yarns and weft yarns, a double-layer nap fabric which is formed by alternatively interweaving worsted warp yarns which have looped piles on both surfaces of the most outside of the two-layer bottom fabric, and worsted weft yarns through which the two-layer bottom fabric is connected, and after the warp yarns are cut from the middle of the two layers of fabrics, the cutting velvet towel with two pieces, one surface of which adopts a looped pile, and the other surface of which adopts a knap surface, is formed, and the two pieces are arranged up and down and face to face, and have the identical patterns. The two-layer bottom fabric can be also woven with the knap warp yarns which have looped piles on both surfaces at the most outside of the two-layer bottom fabric and simultaneously connect the two-layer bottom fabric. The invention solves the problems existing in the prior art and caused by the cutting of the looped piles on one surface of the double surface looped pile towel that the working procedures are multiple, the raw material consumption is large, the looped pipes and knops are not firm, and the towel is easy to depilate, the manufacture procedures are reduced, the cost of raw material is reduced, the product quality is improved, and the cutting velvet towel has theadvantages that the looped piles and the knops are firm, the hand feeling are soft and the moisture absorption and water storage rate is high.

Owner:常州市悦腾机械有限公司

Oil-water well chemical resin type sand consolidating agent and sand prevention technology

The invention relates to an oil-water well chemical resin type sand consolidating agent and a sand prevention technology. The technology formula includes: 5 percent to 10 percent of organic silicon resin, 15 percent to 20 percent of dispersant (furfural), 10 percent to 15 percent of mutual solvent (acetaldehyde), 10 percent to 15 percent of curing agent (metaphosphoric acid), 15 percent to 20 percent of emulsion splitter, 15 percent to 20 percent of aniline modified phenol formaldehyde resin, 25 percent to 30 percent of hydrochloric acid, 5 percent to 10 percent of trolamine, 5 percent to 10 percent of aluminium sulphate, and 5 percent to 10 percent of OP10. The technology includes: washing sand to the required position of design, putting sand in an operating tool string according to design requirements, pre-processing the oil layer, then selecting a positive-substitute resin type sand consolidating agent for squeezing the resin type sand consolidating agent and displacing liquid, lifting the sand out from the operating tool string after pressure naturally diffuses, and finally coming to well completion after 72 hours of coagulation.

Owner:覃忠校

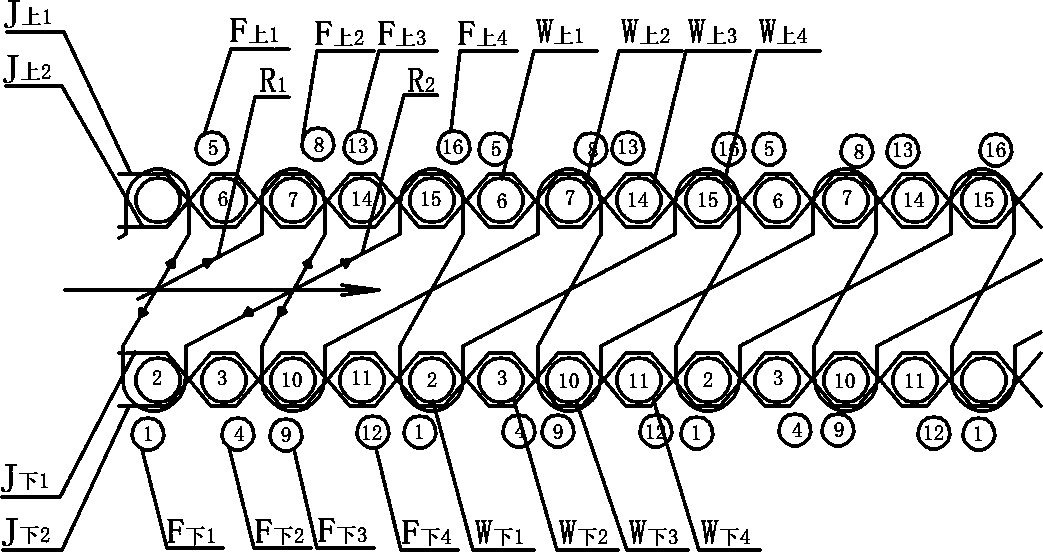

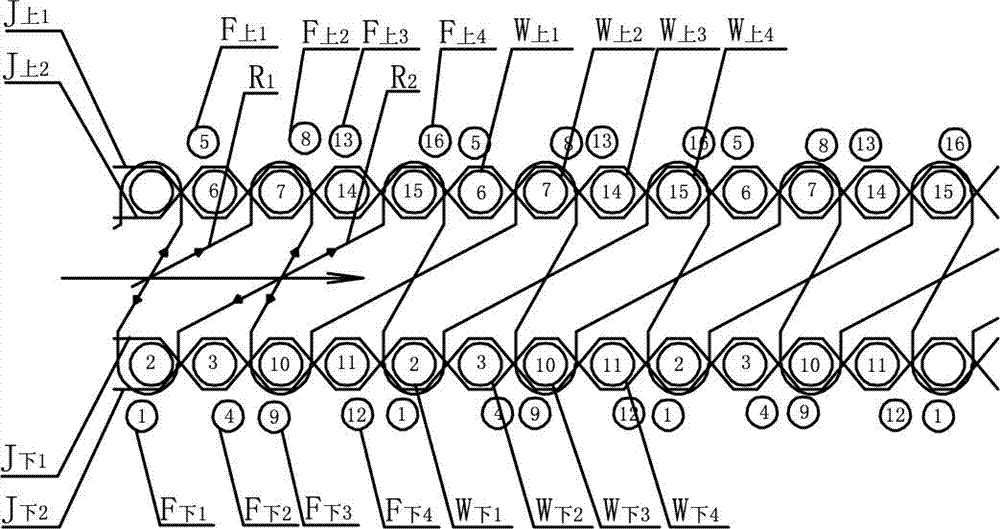

Single-layer and double-face velveting and weaving method thereof

InactiveCN104032454ASimple production processReduce manufacturing costMulti-ply fabricsThermoplasticEngineering

The invention discloses single-layer and double-face velveting and a weaving method thereof. The single-layer and double-face velveting comprises base cloth and suede on the two sides of the base cloth. The suede on one side is provided with a pattern formed by combining different bright areas and dark areas, and the suede on the other side is not provided with a pattern. Silk suede heads of the suede on the pattern side are formed by cut piles and pattern pile warp fixedly connected to weft of the base cloth, the pattern pile warp is woven by continuously inclining forwards or backwards within a certain length of section on the base cloth in the warp direction, and suede patterns are formed by the suede head forward-inclining erecting area or the suede head backward-inclining erecting area. The single-layer and double-face velveting does not need to be dyed or processed in a thermoplastics mode, the pattern formed by combining the bright areas and the dark areas can be formed on one face of the velveting only through weaving, and the face, not provided with the pattern, of the velveting is not affected, the comfort of face attached to the skin is good, and the single-layer and double-face velveting has the advantages that the production technology is simple, the requirement for equipment is low, and the manufacturing cost is low.

Owner:LIAONING CAIYI WILD SILK PROD

Safety treatment method for fluorine-containing solid waste

ActiveCN105130346AAvoid pollutionPlay the role of binding the fluorine-containing solid waste residueSolid waste managementWater insolubleFluorine containing

The invention relates to a safety treatment method for fluorine-containing solid waste. According to the method, a calcium compound is added into the fluorine-containing solid waste, and a composition fluorine ions in the fluorine-containing solid waste and calcium ions in the calcium compound form a water-insoluble compound calcium fluoride, so that free fluorine ions in the fluorine-containing solid waste are greatly reduced, and the phenomenon that the fluorine ion content of the fluorine-containing solid waste is large and the fluorine-containing solid waste is easily dissolved in soil and groundwater to cause pollution in the prior art is avoided; a curing agent is added to achieve the effect of bonding the fluorine-containing solid waste, and meanwhile, a layer of low-permeability substance is formed on the surface of the fluorine-containing solid waste to limit the transfer of harmful compositions, mainly the fluorine ions, in the fluorine-containing solid waste, so that soil and underground pollution is also avoided.

Owner:韩素梅

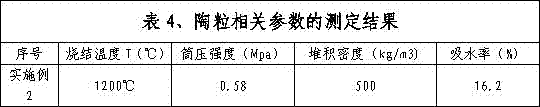

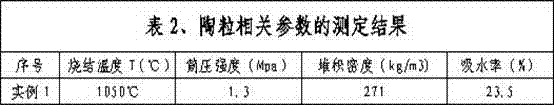

Method for firing ceramsite by utilizing active sludge

ActiveCN106995306AWith insulationWith heat insulationCeramic materials productionClaywaresActivated sludgeExpanded clay aggregate

The invention belongs to the technical field of a treatment device of solid wastes and in particular relates to a recycling, harmless and minimized production method for firing ceramsite by utilizing sludge generated in a municipal domestic wastewater treatment process. The production method comprises the following steps: selecting materials: selecting sludge which is generated by a sewage treatment plant and has the moisture content of 80 percent and clay as raw materials; drying: naturally stacking the sludge and drying the sludge to enable the moisture content of the dried sludge to be 40 percent to 50 percent; mixing: conveying the clay and the dried sludge into a stirrer according to the weight ratio of 1 to 1 and uniformly mixing to obtain mixed materials; granulating: conveying the obtained mixed materials into a granulator and granulating to prepare particles with the grain diameter of 1cm to 2cm; firing: firing at three phases. The method for firing the lightweight ceramsite by utilizing the sludge, provided by the invention, provides a new concept for sludge treatment.

Owner:YUNNAN UNIV

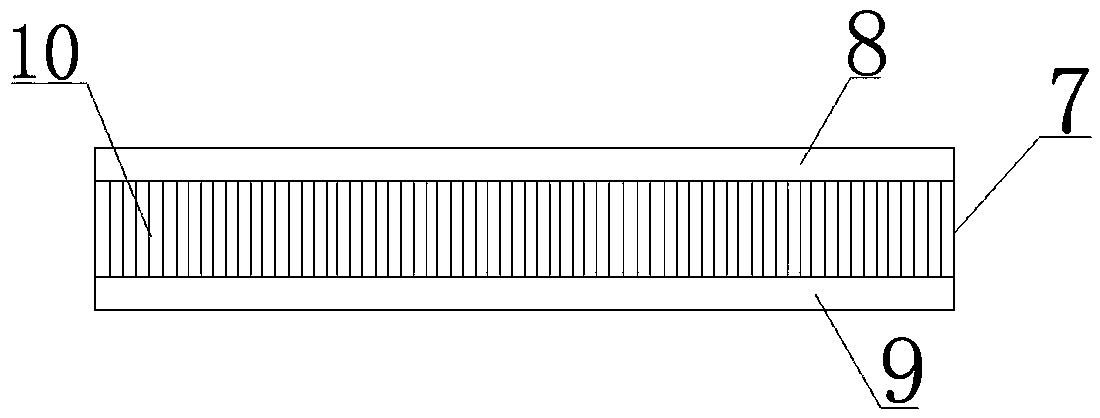

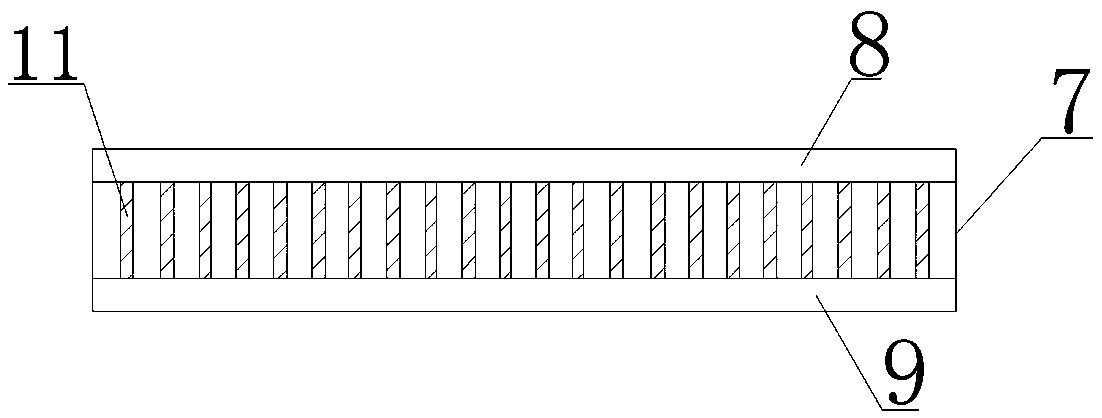

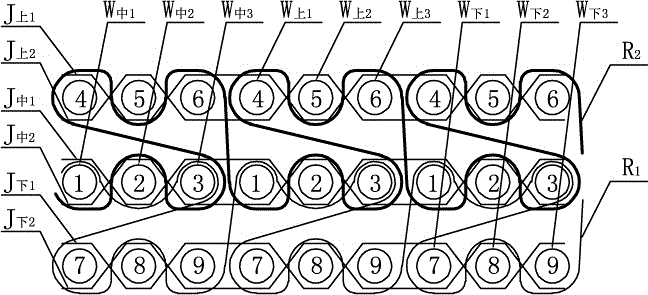

Lightweight dismantle-free heat insulation template integrated composite heat insulation system and manufacturing technology thereof

PendingCN110258867AReduce manual labor intensityEnhanced deformation stressWallsClimate change adaptationInsulation layerManufacturing technology

The invention belongs to a lightweight dismantle-free heat insulation template integrated composite heat insulation system and manufacturing technology thereof. The lightweight dismantle-free heat insulation template integrated composite heat insulation system comprises a cast-in-place concrete base wall body, a heat insulation template inner protective layer, an organic heat insulation material layer, seamed reinforced glass wool or a rock wool board inorganic material insulation layer, and a polymer mortar layer are sequentially arranged on the outer side of the cast-in-place concrete base wall body, and are fixedly mounted and connected with the cast-in-place concrete base wall body through pre-embedded anchoring connecting parts, and the outer surface of the seamed reinforced glass wool or the rock wool board inorganic material insulation layer is coated with the polymer mortar layer. The lightweight dismantle-free heat insulation template integrated composite heat insulation system has the advantages that structure design is reasonable, the lightweight, high intensity and low heat conductivity performance are achieved, the comprehensive cost can be lowered, the load of buildings is relieved, the whole thickness of the mortar layer on the outer surface of the wall body is advantageously controlled, and the safety of anti-cracking, anti-falling-off and anti-fire is improved.

Owner:河南省澳科保温节能材料技术开发有限公司

Single-layer and double-face velveting and weaving method thereof

InactiveCN104032454BSimple production processReduce manufacturing costMulti-ply fabricsThermoplasticStructural engineering

The invention discloses single-layer and double-face velveting and a weaving method thereof. The single-layer and double-face velveting comprises base cloth and suede on the two sides of the base cloth. The suede on one side is provided with a pattern formed by combining different bright areas and dark areas, and the suede on the other side is not provided with a pattern. Silk suede heads of the suede on the pattern side are formed by cut piles and pattern pile warp fixedly connected to weft of the base cloth, the pattern pile warp is woven by continuously inclining forwards or backwards within a certain length of section on the base cloth in the warp direction, and suede patterns are formed by the suede head forward-inclining erecting area or the suede head backward-inclining erecting area. The single-layer and double-face velveting does not need to be dyed or processed in a thermoplastics mode, the pattern formed by combining the bright areas and the dark areas can be formed on one face of the velveting only through weaving, and the face, not provided with the pattern, of the velveting is not affected, the comfort of face attached to the skin is good, and the single-layer and double-face velveting has the advantages that the production technology is simple, the requirement for equipment is low, and the manufacturing cost is low.

Owner:LIAONING CAIYI WILD SILK PROD

Restoration method for chromium-polluted soil

InactiveCN105750317AReduce in quantityReduce the number of selected measurement pointsContaminated soil reclamationMeasurement pointAdhesive

The invention discloses a long-effecting restoration method for chromium-polluted soil. The restoration method is good in treatment effect, low in cost, low in secondary pollution possibility and high in practicability, and comprises the following steps: drawing a chromium pollution distribution diagram of measurement points, simulating a chromium pollution distribution diagram of a whole soil block, excavating heavily polluted soil according to the pollution distribution diagram, putting the heavily polluted soil into a ball grinder, reducing hexavalent chromium in chromate into trivalent chromium through a reducing agent, then adding an adhesive to cure the reduced soil, ploughing moderately polluted soil to flatten the soil, spraying a sulfate aqueous solution into the soil according to the chromate concentration obtained by calculation, soaking the soil, extracting to separate the chromate out, further reducing the hexavalent chromium in the extracted chromate into trivalent chromium through the reducing agent, and adding the adhesive to cure the soil.

Owner:侯绪华

Lawn planting method specially used for aviation flying camp

InactiveCN108076977AFast germinationImprove wear resistanceHops/wine cultivationTurf growingAviationMonsoon

The invention discloses a lawn planting method specially used for an aviation flying camp. The planting method includes the following steps: sowing is performed by adopting a mixed sowing manner, andmixed grass species are selected from Bermudagrass, festuca rubra, perennial ryegrass and poa annua; a basic layer, a water discharging layer and a sand layer are sequentially arranged on the flattened and compressed land, a foundation is formed, planting soil covers the foundation, and a fertilizer is mixed in the planting soil; and lawn sowing, fertilization, watering and maintenance are performed on a soil layer to form a lawn. The special lawn provided by the invention can adapt to hard soil, only moderate irrigation is needed, greenness appears in three seasons, the lawn is resistant to trampling, the root system is firm and stable, the community is stable and the lawn has less pruning. The method provided by the invention is very suitable for temperate monsoon climate regions in highlatitudes in China (Heilongjiang, Jilin, Liaoning, and most non-desert regions in Inner Mongolia).

Owner:中体飞行(北京)体育产业发展有限公司

Oil-water well self-accumulation and sand prevention construction method

ActiveCN110454120AScatter will notScatter does not happenFluid removalDrilling compositionSoil scienceOil water

The invention belongs to the technical field of petroleum reservoir exploitation, and particularly relates to an oil-water well self-accumulation and sand prevention construction method. The oil-waterwell self-accumulation and sand prevention construction method includes the following steps that (1) an oil-water well is processed in the early stage; (2) site fluid preparation is conducted, specifically, self-accumulation fluid, a self-accumulation assistant and consolidating fluid are prepared correspondingly on site; and (3) squeezing into is conducted. According to the method, through the construction method by injecting different chemical reagents in sections, the purposes of oil-water well formation gravel self-accumulation and sand prevention are achieved.

Owner:青岛大地新能源技术研究院

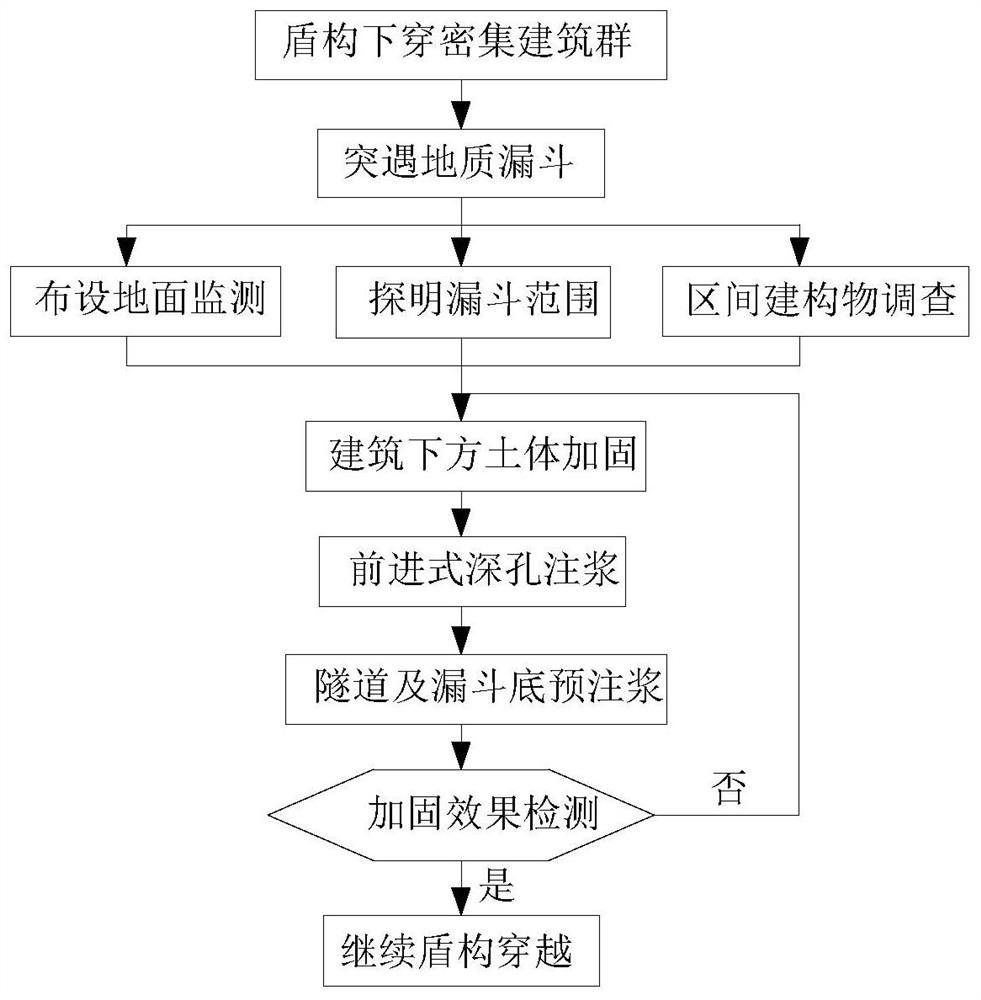

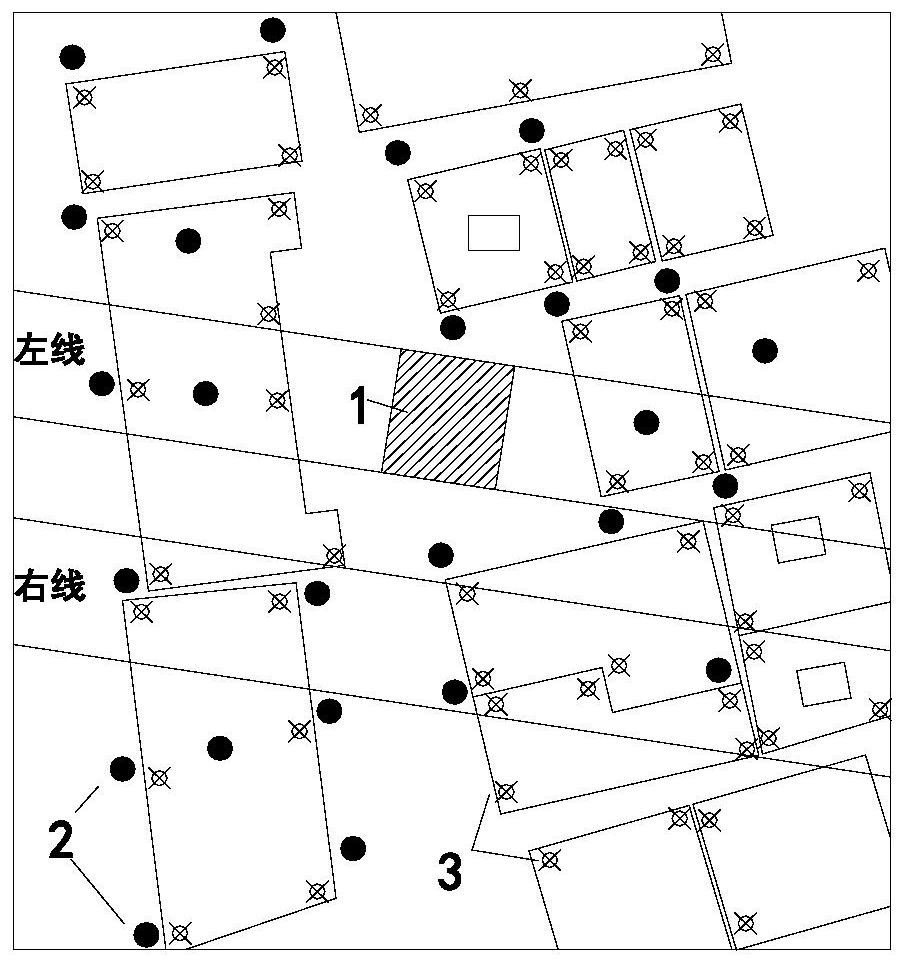

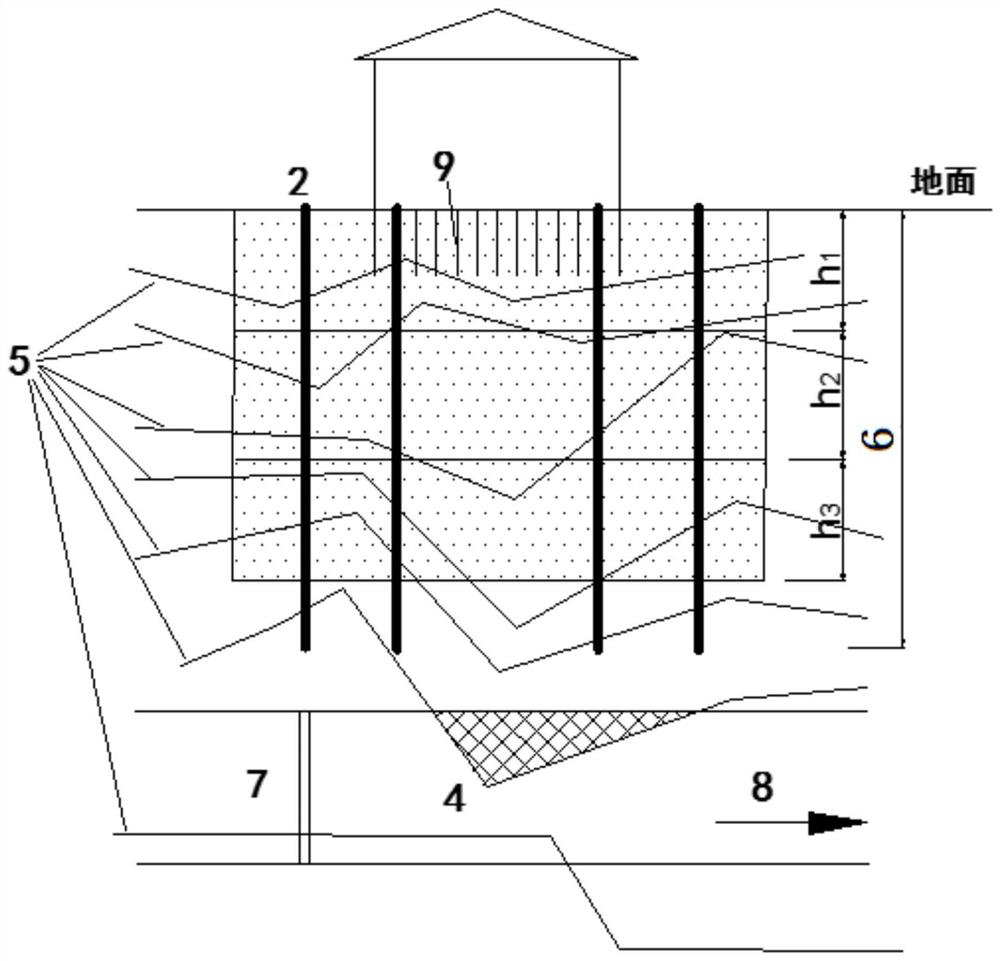

Rapid treatment method for controlling ground surface settlement caused by stratum funnel of large-diameter shield construction

ActiveCN111878084AImprove securityEasy constructionMining devicesTunnelsStructural engineeringSurface construction

The invention discloses a rapid treatment method for controlling ground surface settlement caused by sudden stratum funnel of large-diameter shield construction. The method comprises the following steps of Exploring the range of the stratum funnel, investigating interval buildings, performing ground monitoring, reinforcing soil below the ground buildings through layer-by-layer deep hole grouting,performing pre-grouting reinforcement on a tunnel and the stratum funnel above the tunnel, and detecting the reinforcement effect. According to the steps, disturbed soil under the building is vertically drilled from the ground for layered grouting reinforcement, a water outlet channel at the bottom of the stratum funnel is sealed and blocked from bottom to top by adopting a grouting process, and besides, the reinforcement effect is inspected by combining multiple modes, so that the continuous safety and stability of the ground building and the tunnel are ensured. The method can solve the problem of ground surface settlement caused by the sudden stratum funnel of large-diameter shield construction, and overcomes the engineering difficulties of large constraint of early-stage exploration means and settlement damage of dense and old buildings on the ground caused by sudden unfavorable geology shield water inflow.

Owner:CHINA RAILWAY 18TH BUREAU GRP CO LTD +1

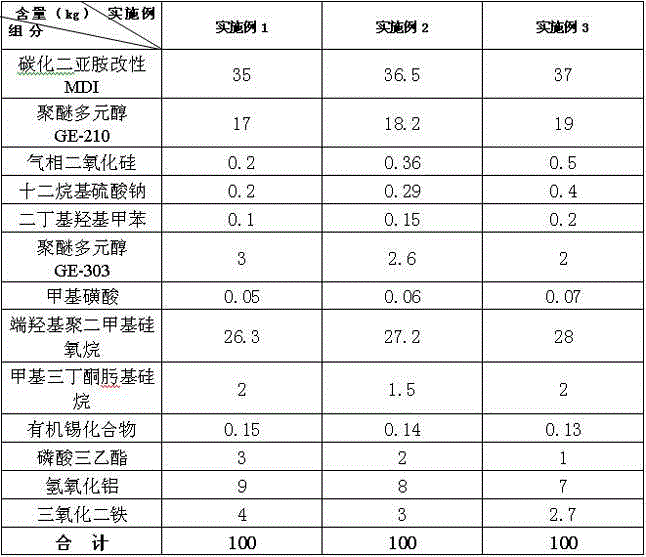

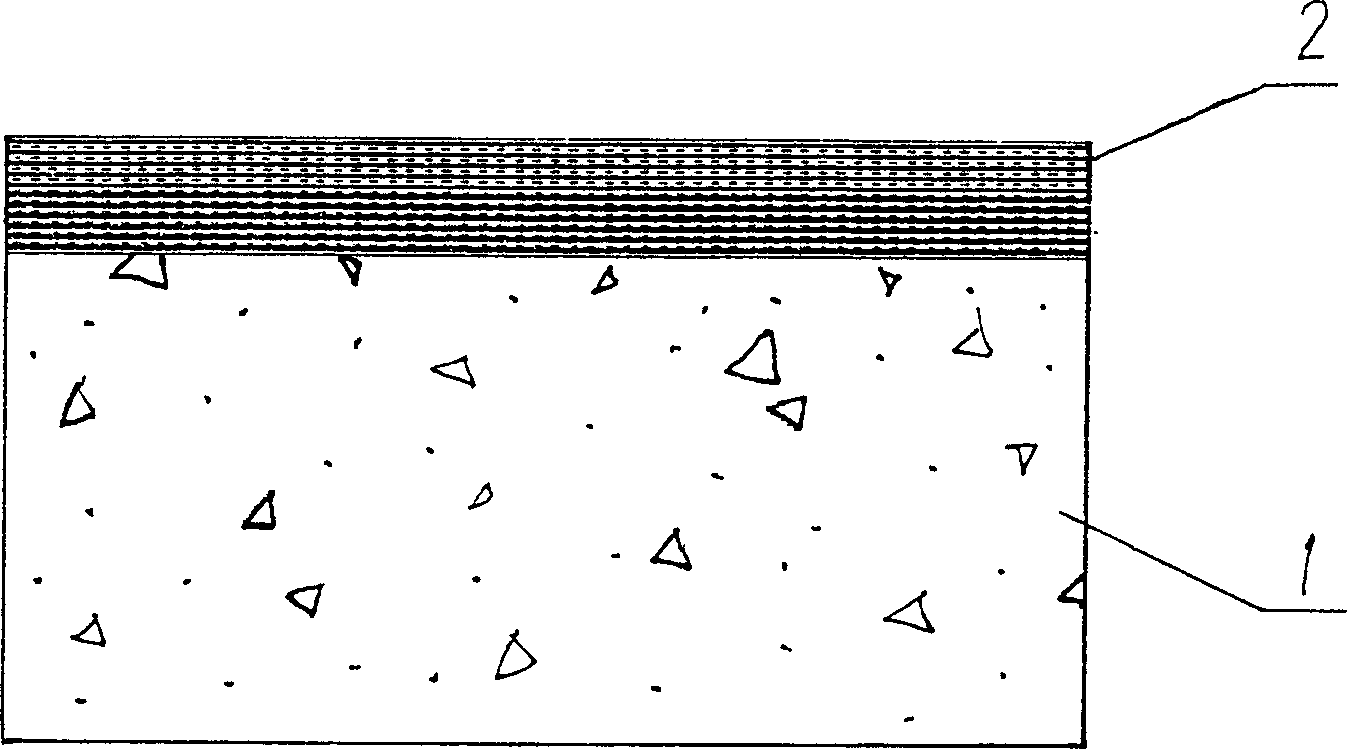

Organic silicone modified polyurethane synthetic adhesive and preparation method thereof

ActiveCN105385401AAnti-agingHigh temperature resistantNon-macromolecular adhesive additivesPolyureas/polyurethane adhesivesPolymer scienceAdhesive

The invention relates to an organic silicone modified polyurethane synthetic adhesive and a preparation method thereof. Traditional bandaging can easily cause displacement of a fracture portion, and accordingly pain of a patient is aggravated. The organic silicone modified polyurethane synthetic adhesive is prepared from, by mass, 35-37% of carbodiimide modification MDI, 17-19% of polyether glycol GE-210, 2-4% of polyether glycol GE-303, 26-28% of hydroxy-terminated polydimethylsiloxane, 1-2% of methyl-tri-(butanone-oxime) silane, 0.2-0.4% of sodium dodecyl sulfate, 0.1-0.2% of organic tin compounds, 1-3% of triethyl phosphate, 7-9% of aluminum hydroxide and 2-4% of ferric oxide. The invention further provides a preparation method of the organic silicone modified polyurethane synthetic adhesive. The organic silicone modified polyurethane synthetic adhesive serves as an adhering agent of a fixing and adhering band, the finished fixing and adhering band is packaged in an aluminum plastic bag to be in a non-solidification state, and the fixing and adhering band becomes hard when making contact with air and can be used for body position fixing after fracture of a person.

Owner:YANCHENG SENOLO MEDICAL TECH CO LTD

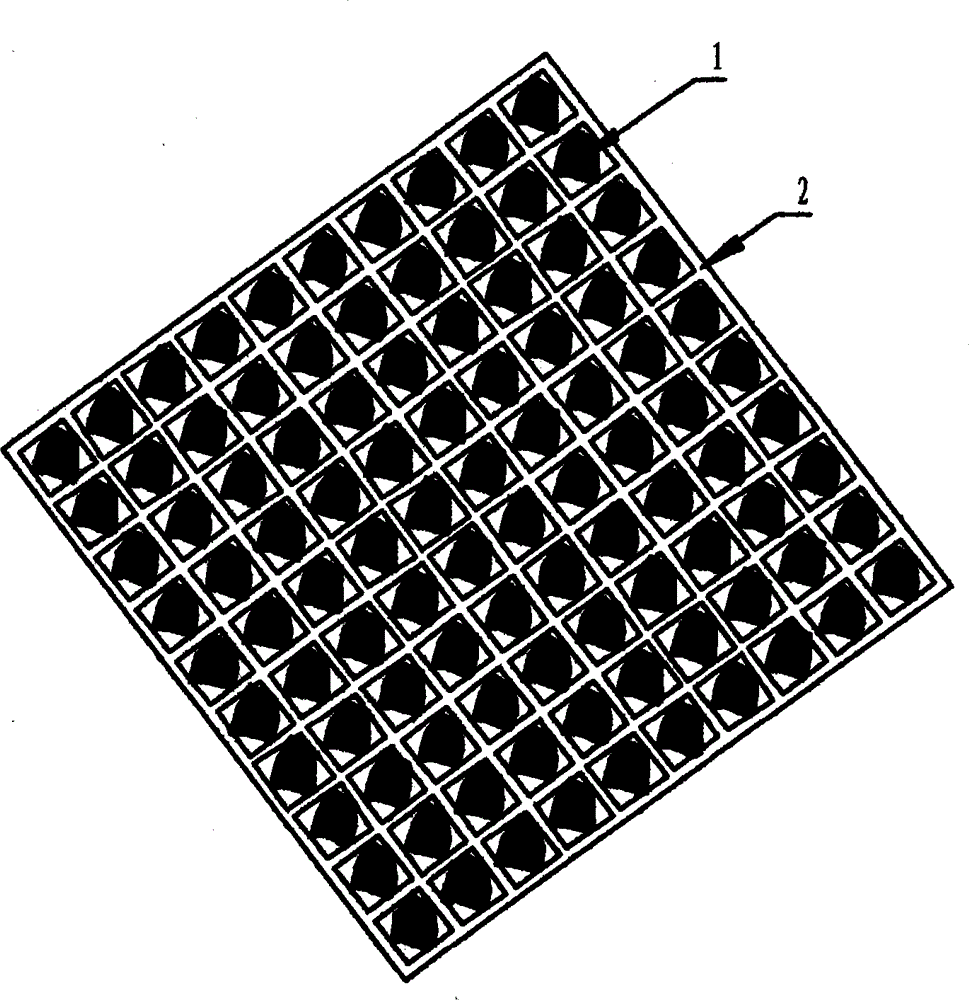

Casting method for fusing metal gridding reinforcing body and a metal matrix

The invention provides a casting method for fusing a metal gridding reinforcing body and a metal matrix. The casting method comprises the following steps of fixing reinforcing bodies (1) by using metal grids (2); mounting the reinforcing bodies (1) in corresponding positions of a foam mould; injecting pre-foamed foam beads in the foam mould to obtain a bright and clean foam mould with reinforcing body metal grids; accurately positioning the reinforcing bodies (1); uniformly coating foam mould clusters by using foam mold casting coatings; performing vibratory modeling on the foam mould clusters in a casting sand box; connecting a vacuumizing system to the casting sand box; pouring qualified smelted liquid metal on the foam mould; performing vacuumizing while pouring; and taking out the foam mould after cooling down the foam mold so as to obtain a casting on which the reinforcing bodies (1) are fused at accurate surface positions of the metal matrix. By the casting method, the reinforcing bodies (1) can be accurately positioned and uniformly distributed on the casting of the metal matrix; after the metal grids (2) and the metal matrix are fused, a transitional layer is formed; the reinforcing bodies (1) can be firmly fused with the metal matrix; the yield of products is improved; the cost is effectively reduced; and the quality of products is guaranteed.

Owner:吴建化

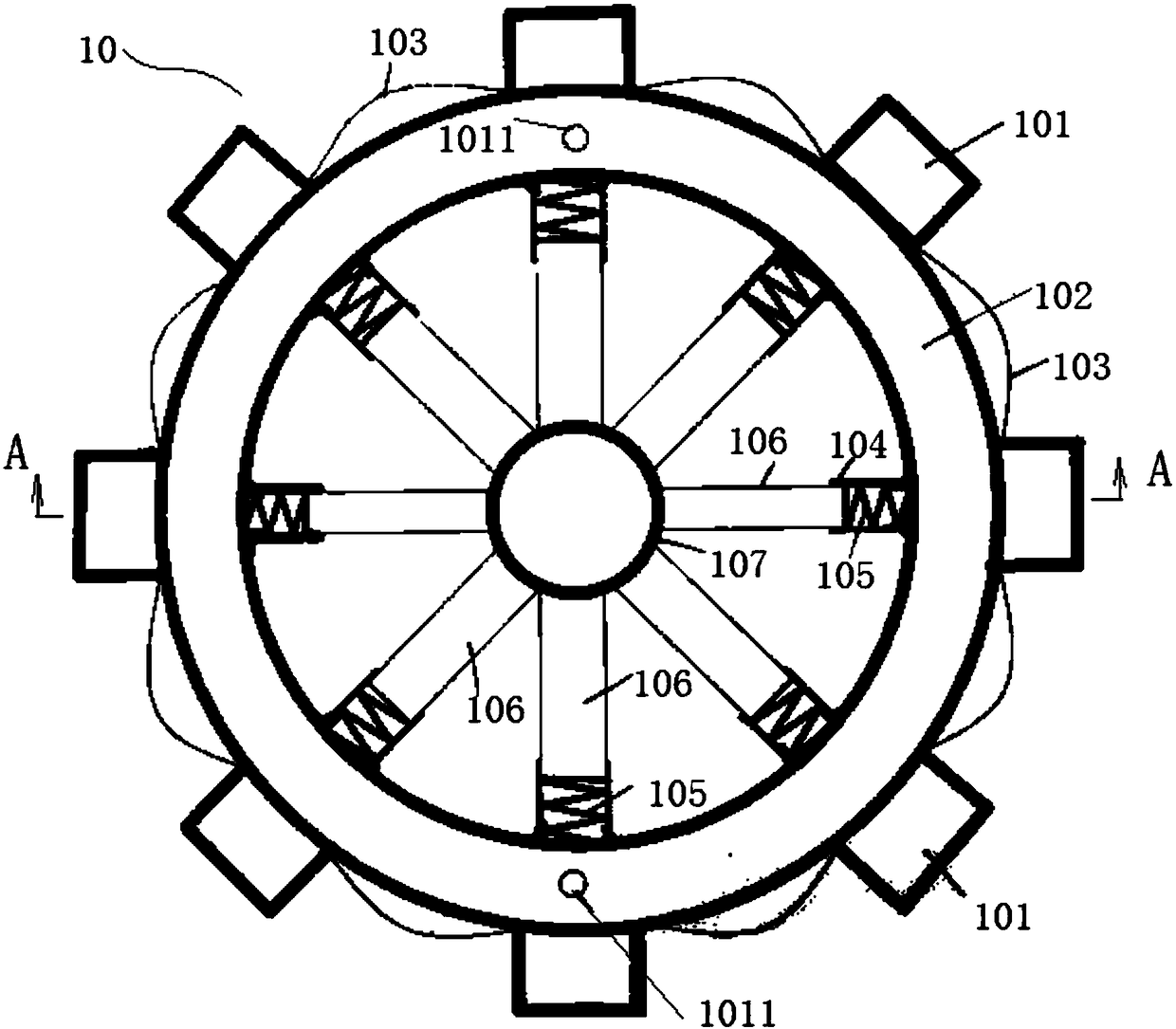

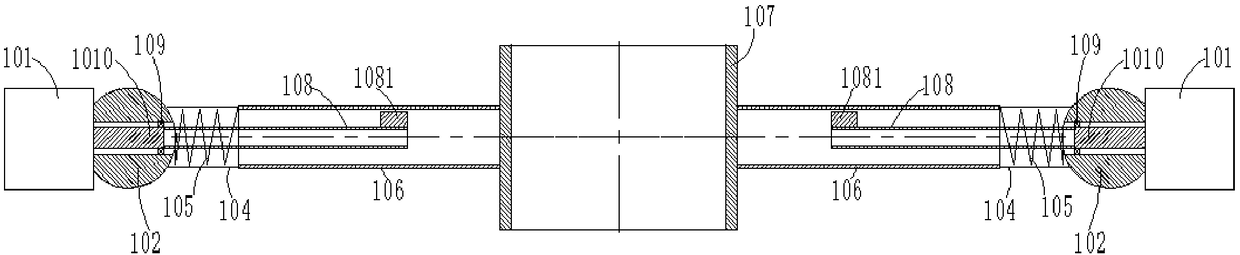

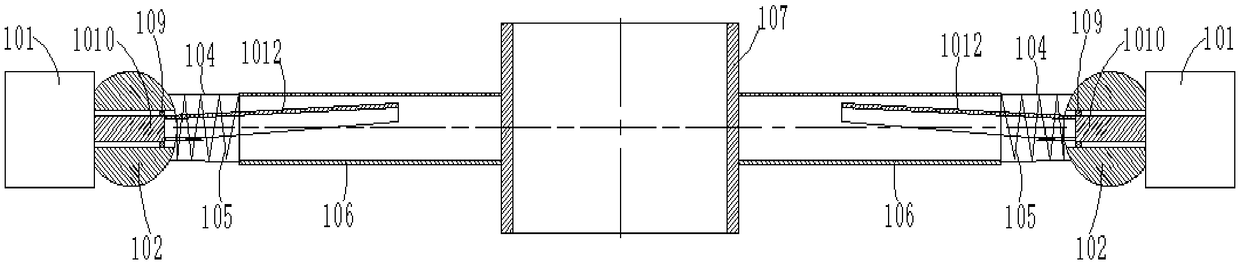

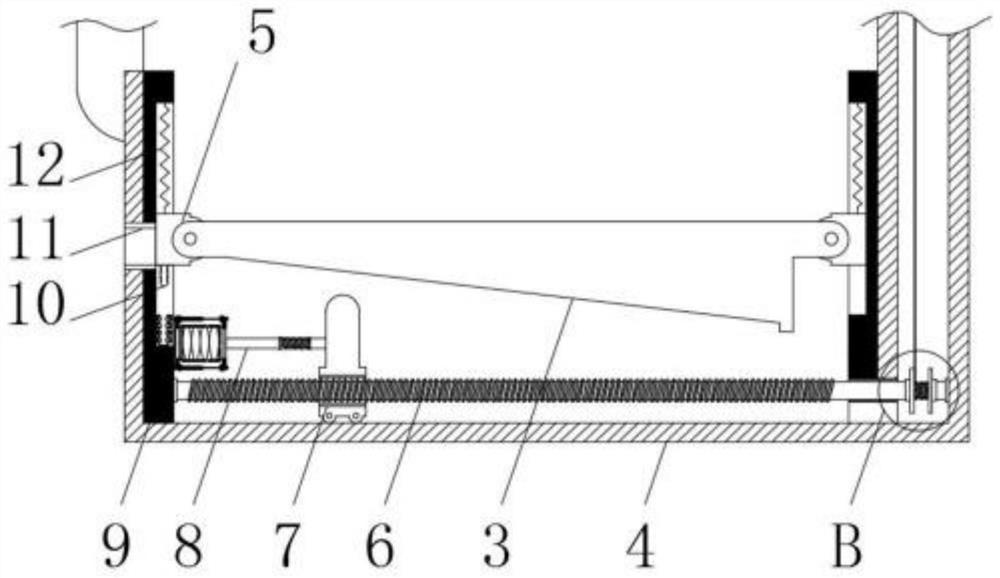

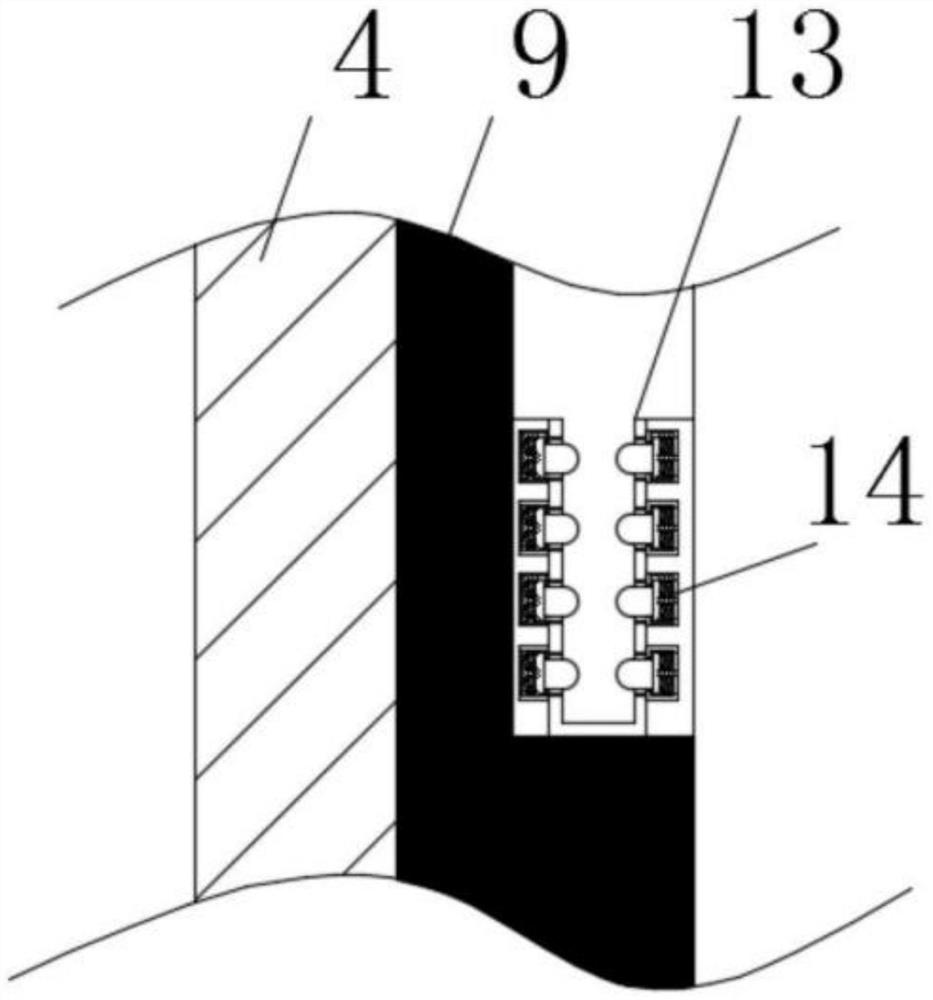

Vibrating device and vibrating method of cast-in-place pile concrete

The invention relates to a vibrating device and a vibrating method of cast-in-place pile concrete. The vibrating device comprises a vibrating ring, one or more motors, a positioning barrel, and one ormore vibrating sleeves, wherein the motors are arranged at the periphery of the vibrating ring in a circumferential direction; rotating shafts of the motors inwards penetrate through the vibrating ring in a radial direction of the vibrating ring; the positioning barrel is a hollow tube body and coaxially arranged in the center of the vibrating ring; the vibrating sleeves are connected between thepositioning barrel and the vibrating ring and internally provided with vibrating shafts; one end of each vibrating shaft is connected with each rotating shaft of the motor; an eccentric block is arranged at the other end of each vibrating shaft; and when the vibrating shafts rotate, the eccentric block continuously collide peripheral internal walls of the vibrating sleeves to further drive the vibrating ring to generate high-frequency vibration. A compaction pile foundation is filled with the concrete vibrated by the vibrating device of the cast-in-place pile concrete, and the grip of the concrete and a steel reinforcement cage is better. The pile body concrete is bonded with soil around the concrete more securely. A conduit vibrates by the action of the vibrating device; the flow of theconcrete in the conduit is accelerated; and a blocking phenomenon due to poor placeability of the concrete is avoided.

Owner:MCC COMM CONSTR GRP CO LTD

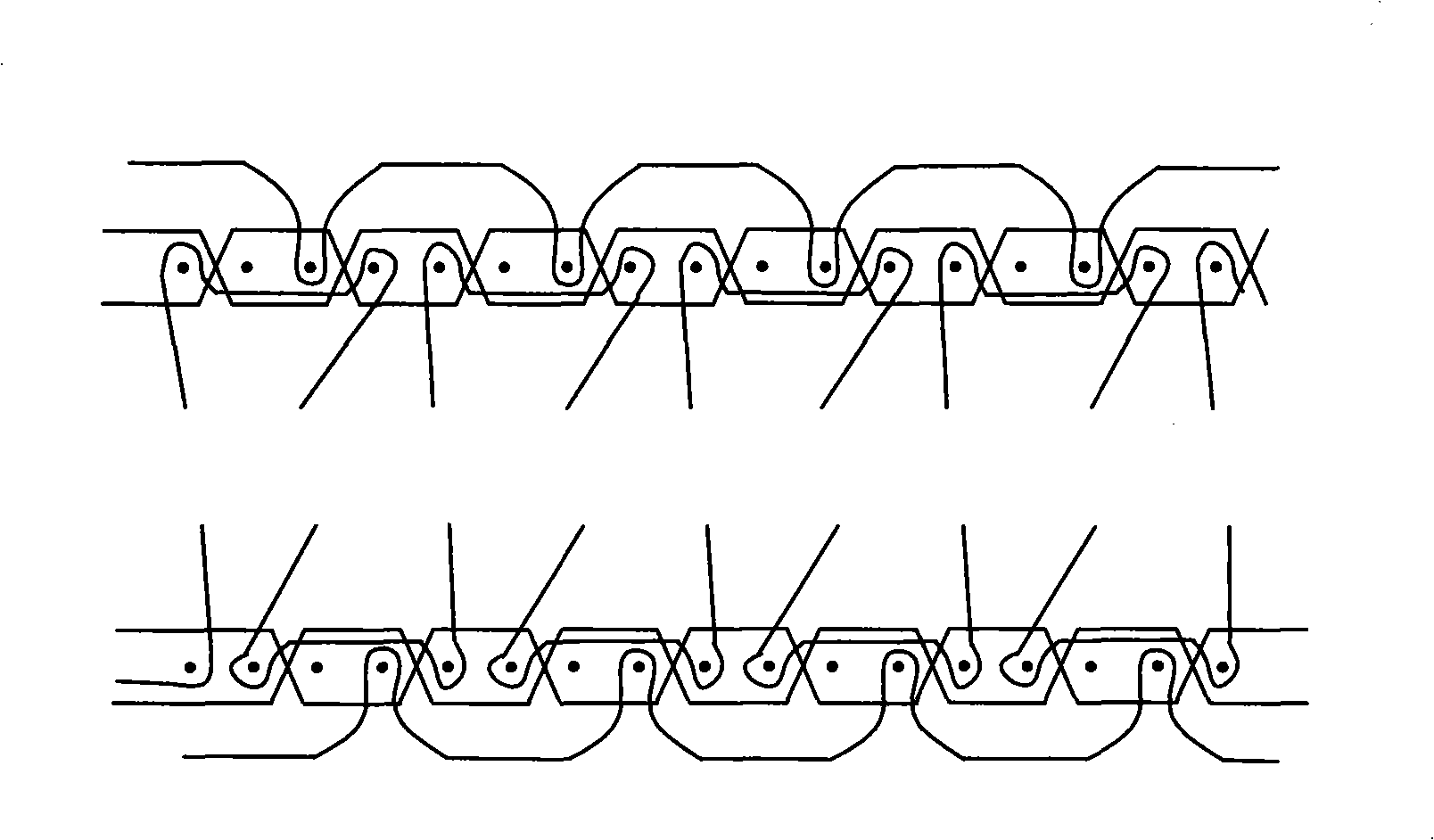

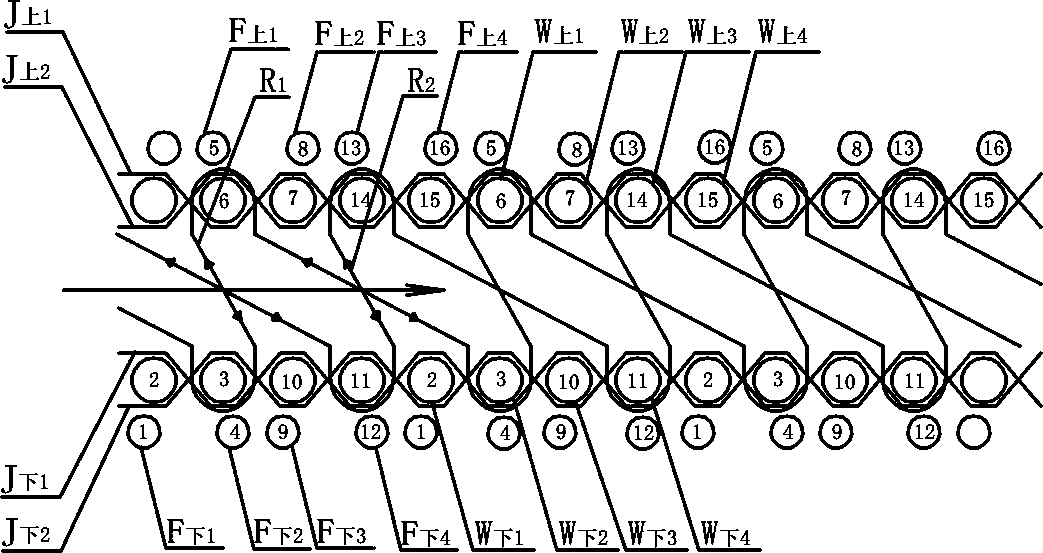

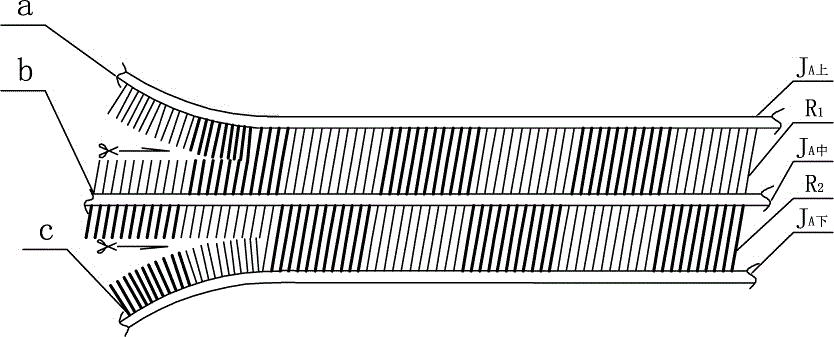

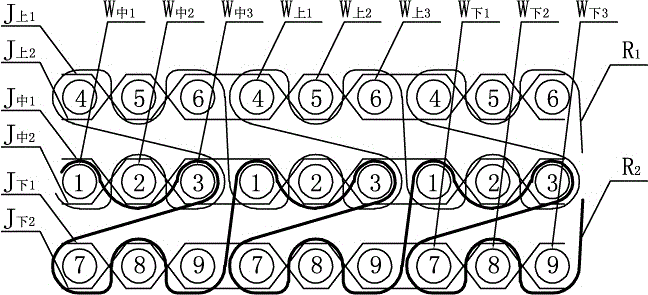

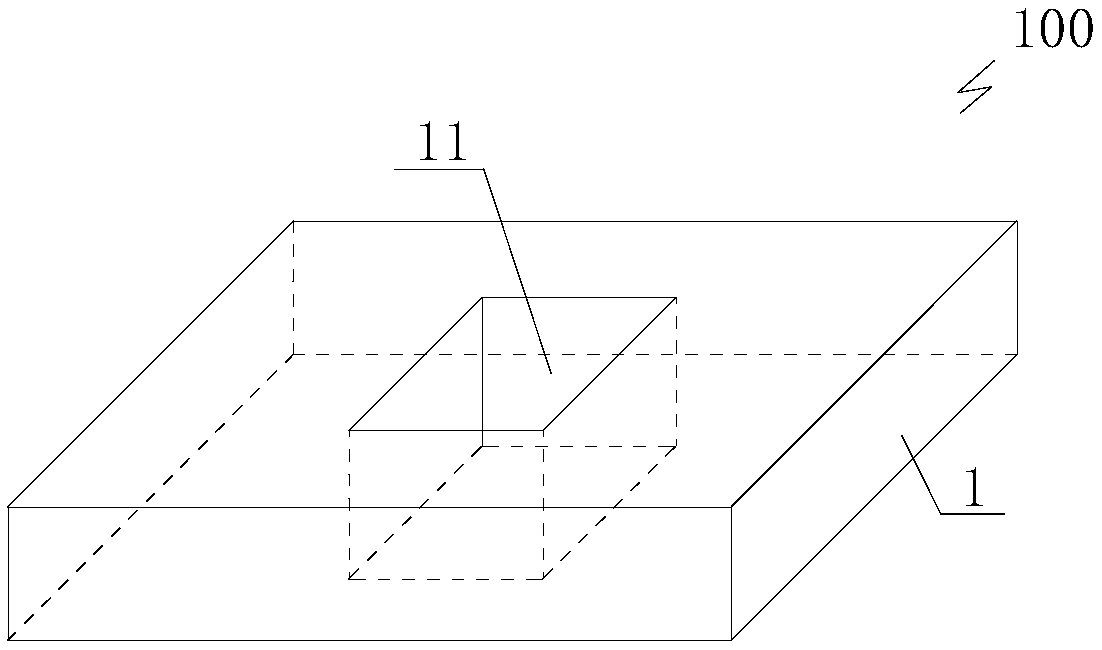

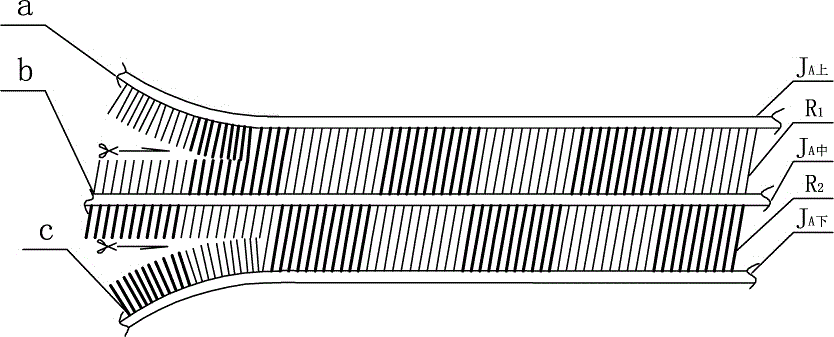

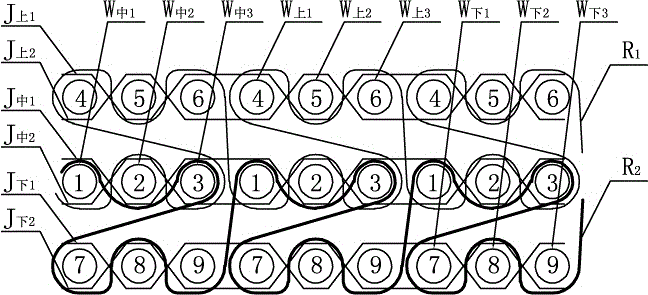

Double-color jacquard three-layer base cloth fabric and weaving method thereof

InactiveCN105734765AQuality improvementSolidifiedMulti-ply fabricsSwivel-woven fabricsBobbinEngineering

The invention discloses a double-color jacquard three-layer base cloth fabric. The double-color jacquard three-layer base cloth fabric consists of an upper base cloth layer, a middle base cloth layer, a lower base cloth layer, and nap warps, wherein the nap warps are weaved among the upper base cloth layer, the middle base cloth layer and the lower base cloth layer in a reciprocating way; the nap warps consist of nap warps of two colors, and the nap warps of two colors are performed with conversion and jacquard weaving between the upper base cloth layer and the middle base cloth layer as well as between the lower base cloth layer and the middle base cloth layer; nap tissues of the same pattern and different colors are formed on the two surfaces of the middle base cloth layer, the lower surface of the upper base cloth layer and the upper surface of the lower base cloth layer; after secondary nap cutting, the upper layer is a single-surface nap fabric, the middle layer is a double-surface nap fabric, and the lower layer is a single-surface nap fabric. The double-color jacquard three-layer base cloth fabric has the advantages that a bobbin creel and the warp drawing are not needed, and the double-color jacquard three-layer base cloth fabric with two single-surface double-color jacquard nap pieces and one double-surface double-color jacquard nap piece can be directly obtained through primary weaving and secondary nap cutting. The invention also discloses a weaving method of the double-color jacquard three-layer base cloth fabric.

Owner:LIAONING CAIYI WILD SILK PROD

Oil-rich and loose sandstone standard rock core column freezing coring method and coring clamp

InactiveCN109372458AThoroughly frozen rock samplesSolidifiedWithdrawing sample devicesCore removalArenitePetrology

The invention relates to an oil-rich and loose sandstone standard rock core column freezing coring method and a coring clamp. The method comprises the steps that a full-diameter rock core of an oil-rich and loose sandstone is drilled on site, and the full-diameter rock core is frozen and solidified after sampling and sealing; the frozen full-diameter rock core is sectioned into small-sized rock samples at low temperature, and small-sized rock samples are subjected to deep freezing treatment; the small-sized rock samples subjected to deep freezing are fixed, the outer walls of the small-sized rock samples are drilled through a drilling machine, oil-rich and loose sandstone standard rock core columns are formed, and the oil-rich and loose sandstone standard rock core columns are subjected topressure control, packed and stored. According to the method, sealing is conducted after sampling in the sampling process, the frozen full-diameter rock cores are broken into parts, the small samplesare subjected to deep freezing, in combination with the novel coring clamp, the oil-rich and loose sandstone standard rock core columns can be successfully drilled through the method, the demands ofvarious analysis and testing of the oil-rich and loose sandstones are met, the integrity and comprehensiveness of various test data of the oil-rich and loose sandstones are guaranteed, and powerful guarantees for the adjustment of oilfield development programs and potential tapping of measures in high water content stage are provided.

Owner:PETROCHINA CO LTD

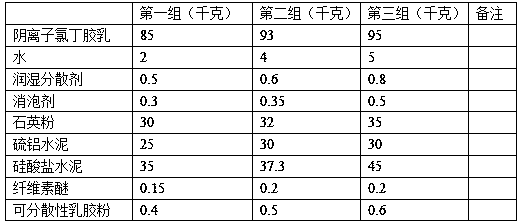

Method for implementing cement-based spraying and rapid hardening water-borne waterproof coating

The invention relates to the technical field of waterproof materials, in particular to a method for implementing a cement-based spraying and rapid hardening water-borne waterproof coating. The methodcomprises the following steps: a, injecting an anionic neoprene latex into a mixing reaction kettle, performing stirring at the normal temperature, slowly adding water, a wetting dispersant and a defoamer, and performing uniform stirring to prepare a first auxiliary; b, adding sulfur aluminum cement and portland cement powder mixing stirrer, then adding quartz powder, cellulose ether and dispersible latex powder at different times, and uniformly stirring the raw materials to prepare a second auxiliary; c, spraying the first auxiliary and the second auxiliary onto the surface of a building according to the spray amount ratio of 1:2 to form the cement-based spraying and rapid hardening water-borne waterproof coating. The cement-based spraying and rapid hardening water-borne waterproof coating has a very high condensation speed, can be condensed firmly within 15 min and cannot drop off or be stripped off a base plane.

Owner:北新防水(河南)有限公司

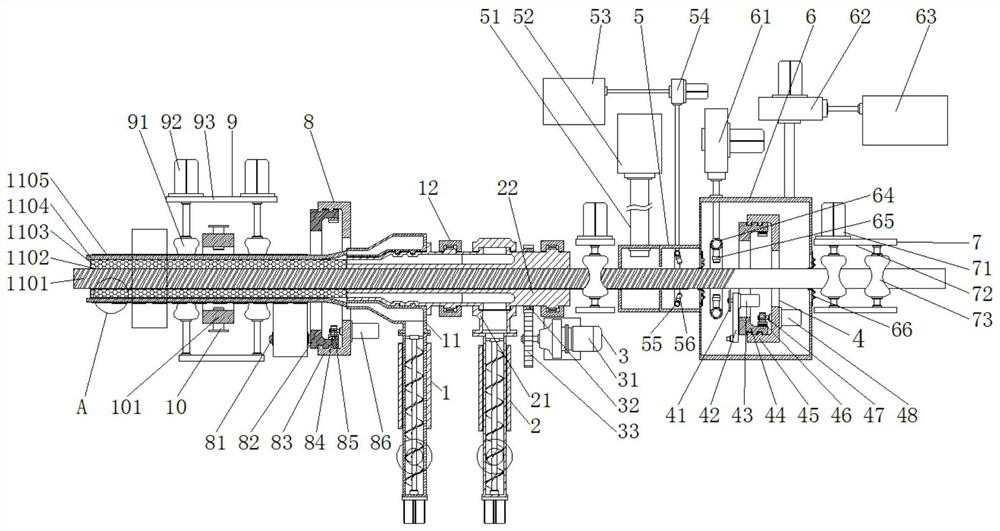

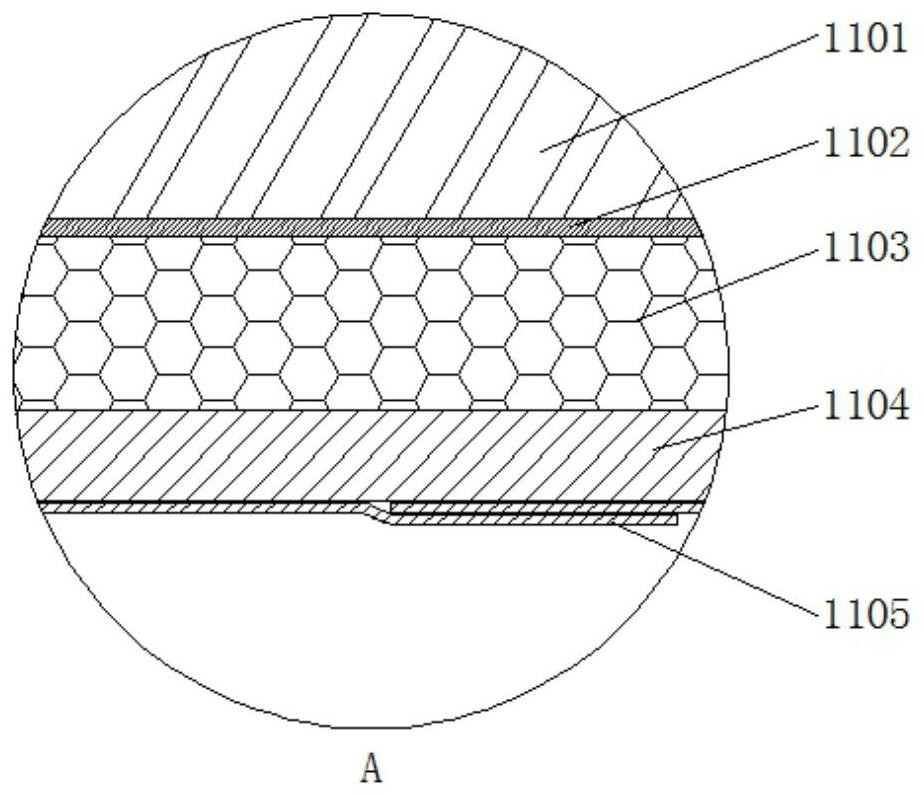

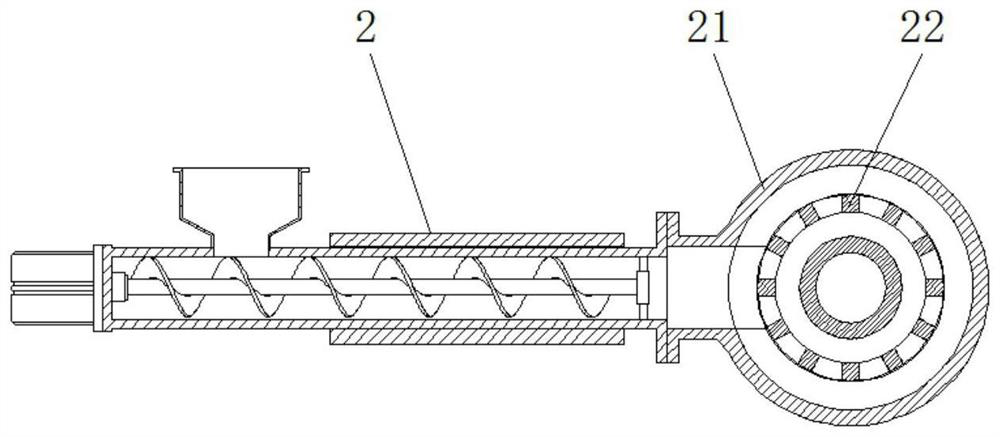

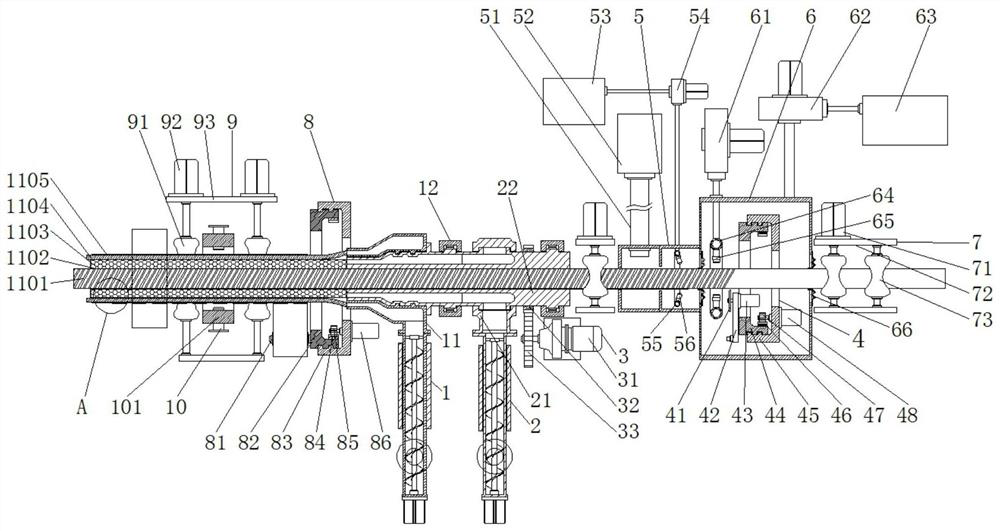

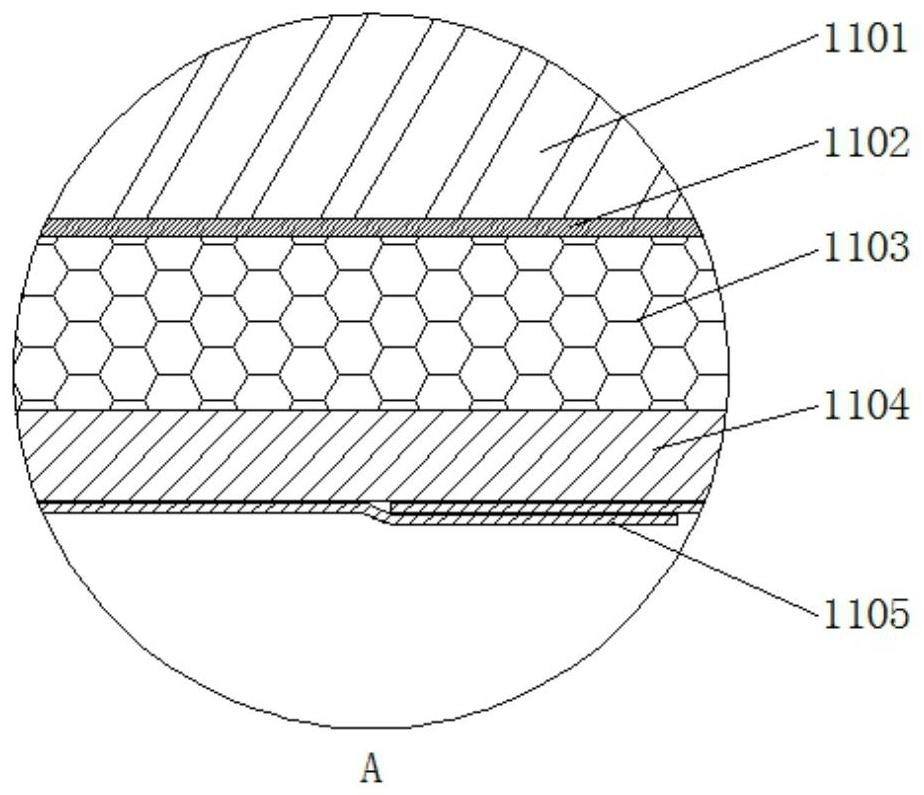

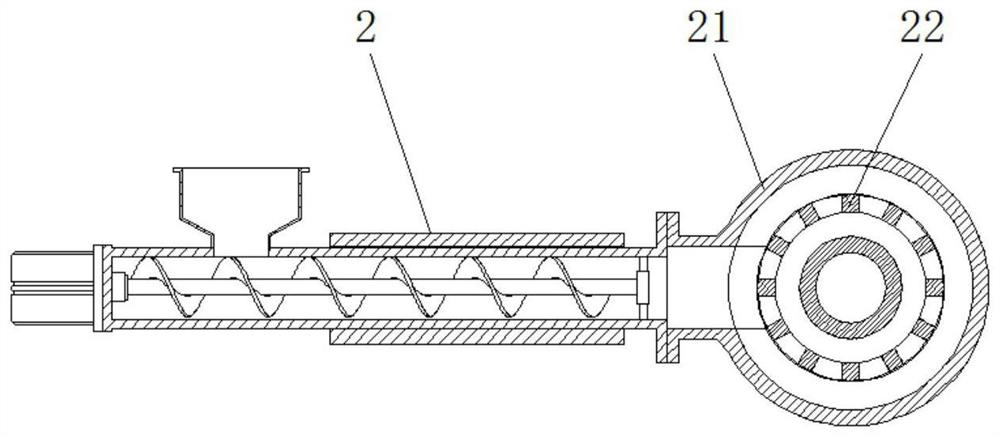

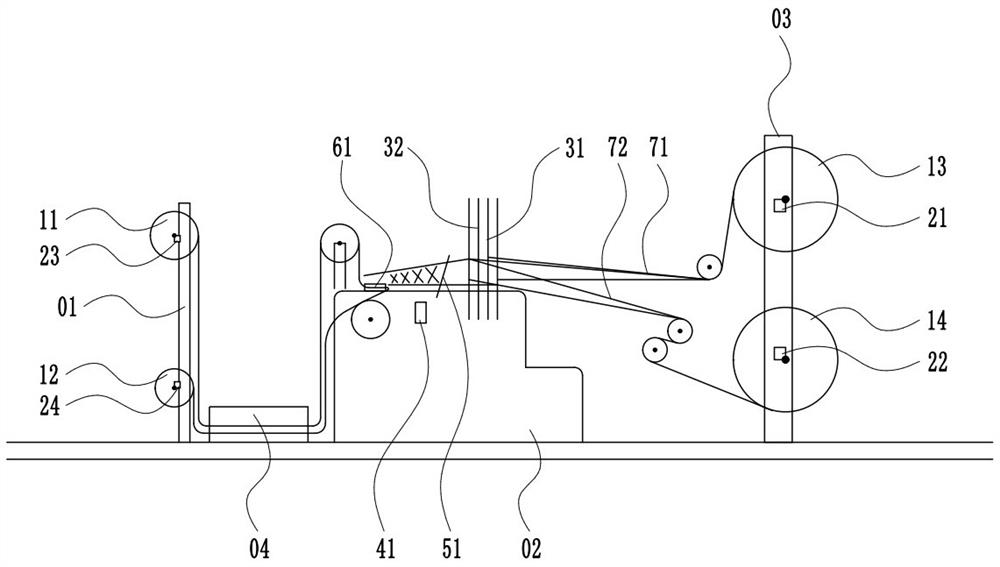

Polyurethane thermal insulation composite tube and forming device thereof

ActiveCN113513638AImprove integrityBond evenly and firmlyThermal insulationPipe protection by thermal insulationPolymer scienceInsulation layer

The invention relates to the technical field of polyurethane thermal insulation materials, in particular to a polyurethane thermal insulation composite tube. The polyurethane thermal insulation composite tube comprises an inner tube, wherein the outer wall of the inner tube is evenly covered with an anti-corrosion layer; the inner tube is sleeved with an outer tube; a polyurethane insulation coating is filled between the anti-corrosion layer on the outer tube and the anti-corrosion layer on the inner tube; the outer tube is wrapped with a thermal insulation layer. A forming device of the polyurethane thermal insulation composite tube comprises a foaming extrusion machine head, wherein a round hole matched with the diameter of an inner tube is formed in the middle of the foaming extrusion machine head, the foaming extrusion machine head is rotationally sleeved with an outer tube extrusion machine head, and a spraying box is arranged at one side of the tail end of the foaming extrusion machine head. By means of the matching structure of the foaming extrusion machine head and the outer tube extrusion machine head, the inner tube can penetrate through, meanwhile, wrapping and covering of the outer tube and filling of the polyurethane insulation coating are conducted, the inner tube, the polyurethane insulation coating and the outer tube are synchronously formed in a section of area, higher efficiency is achieved, and the integrity of the tube is higher after the tube is formed.

Owner:浙江天诚绝热科技股份有限公司

Tasty and refreshing bean curd easy to melt and preparation method thereof

PendingCN114766631ASolidifiedPromote meltingFood thermal treatmentFood ingredient as agglomerating agentBiotechnologyAnimal science

The invention discloses tasty and refreshing bean curd easy to melt and a preparation method thereof, and belongs to the technical field of bean products. The selenium-enriched soybean milk is prepared from the following raw materials by weight: 9 kg of selenium-enriched soybean milk, 25-30 g of gypsum, 50-100 g of egg white and 10 g of glucolactone. Wherein the slurry concentration of the selenium-enriched soybean milk is 10-12 degrees. The selenium-rich soybean is adopted to prepare the selenium-rich soybean milk, and the egg white is added into the bean curd, so that the protein content is increased, the generation of a gel network structure of the bean curd is promoted, and moisture contained in the bean curd is promoted while the network structure is generated, so that the bean curd is more tasty and refreshing and is easy to melt in the mouth. And the added egg white is easy to solidify, so that the taste of the bean curd can be effectively improved. The composite coagulator of gypsum and glucolactone is added at the same time, so that the effects of mutual compensation, neutralization and promotion are achieved, the reaction speed can be prevented from being too high, the bean curd can be coagulated, and the obtained bean curd has the advantages of being moderate in hole, good in water-retaining property, moderate in hardness, appropriate in structure, tasty and refreshing in taste and easy to melt in the mouth.

Owner:广州一号豆食品科技有限公司

Forming device for polyurethane thermal insulation composite pipe

ActiveCN113513638BImprove integrityBond evenly and firmlyThermal insulationPipe protection by thermal insulationPolymer scienceInsulation layer

The invention relates to the technical field of polyurethane thermal insulation materials, in particular to polyurethane thermal insulation composite pipes, including an inner pipe, the outer wall of the inner pipe is evenly covered with an anti-corrosion layer, and an outer pipe is provided on the outer wall of the inner pipe, and the anti-corrosion layer on the outer pipe and the inner pipe The polyurethane insulation layer is filled in between, and the outer pipe is covered with a heat insulation layer. The molding device of the polyurethane insulation composite pipe includes a foaming extrusion head, and the middle of the foaming extrusion head is provided with an inner pipe. Round holes with matching diameters, and an outer tube extruder head is set on the outer rotating sleeve of the foam extruder head, and a spray box is arranged on the tail end side of the foam extruder head. The present invention can realize the wrapping and covering of the outer pipe and the filling of the polyurethane insulation layer while the inner pipe passes through the matching structure of the foam extrusion head and the outer pipe extrusion head, so that the inner pipe, the polyurethane insulation layer and the The outer tube is formed synchronously in a certain area, which is more efficient and makes the integrity of the tube higher after forming.

Owner:浙江天诚绝热科技股份有限公司

A two-color jacquard three-layer base fabric and its weaving method

InactiveCN105734765BQuality improvementSolidifiedMulti-ply fabricsSwivel-woven fabricsYarnPolymer science

Owner:LIAONING CAIYI WILD SILK PROD

Luminous reflective concrete floor tile and its producing method

The production process of luminous reflective concrete floor tile includes making base layer of common concrete material including cement, sand and stone, concrete additive and water, and through mixing, molding and vibrating; mixing the luminous reflective layer materials including cement, graded glass beads, luminous powder, color powder, concrete additive, dispersive glue powder and water via stirring; pouring the mixture on the freshly formed base layer; vibrating to densify and combine the base layer and the luminous reflective layer; demolding and curing. The luminous reflective concrete floor tile may be produced in plant or in site, and may be used widely in expressway, highway, sports ground, warehouse, building and other places needing luminous or fluorescent indication and warning.

Owner:潘英豪

A kind of organosilicon modified polyurethane synthetic glue and preparation method thereof

ActiveCN105385401BIncrease viscosityImprove high temperature resistanceNon-macromolecular adhesive additivesPolyureas/polyurethane adhesivesPolymer scienceDimethyl siloxane

Owner:YANCHENG SENOLO MEDICAL TECH CO LTD

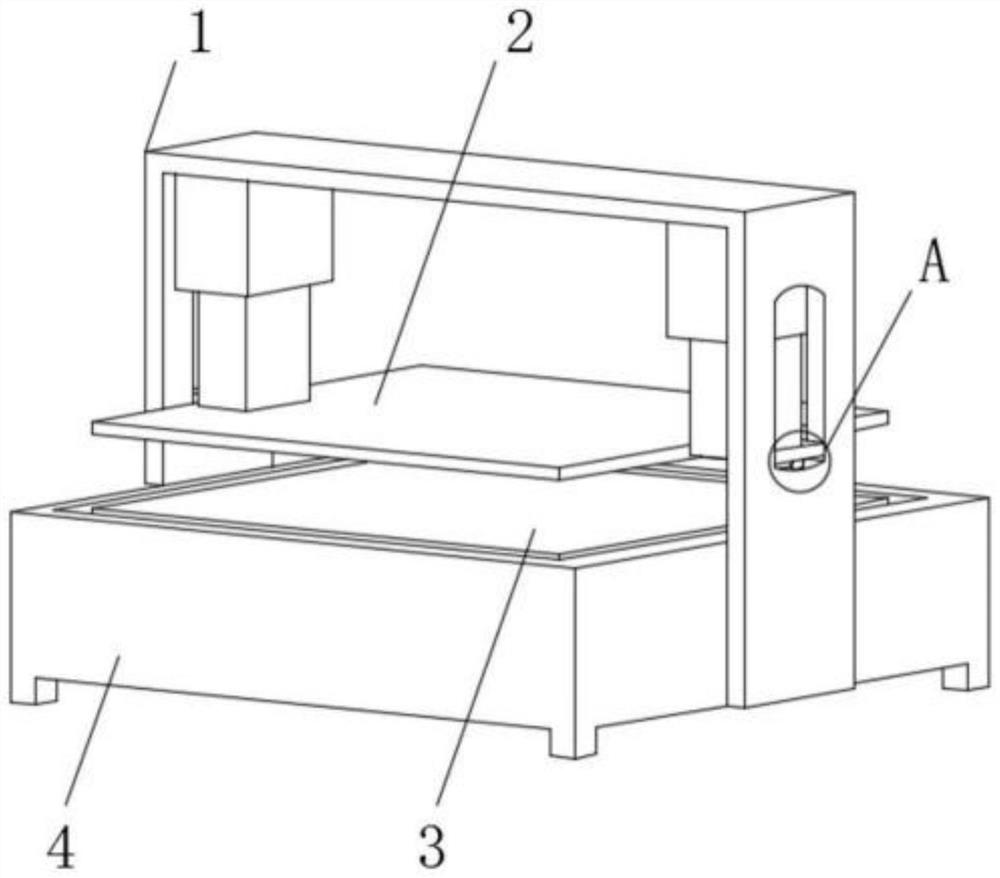

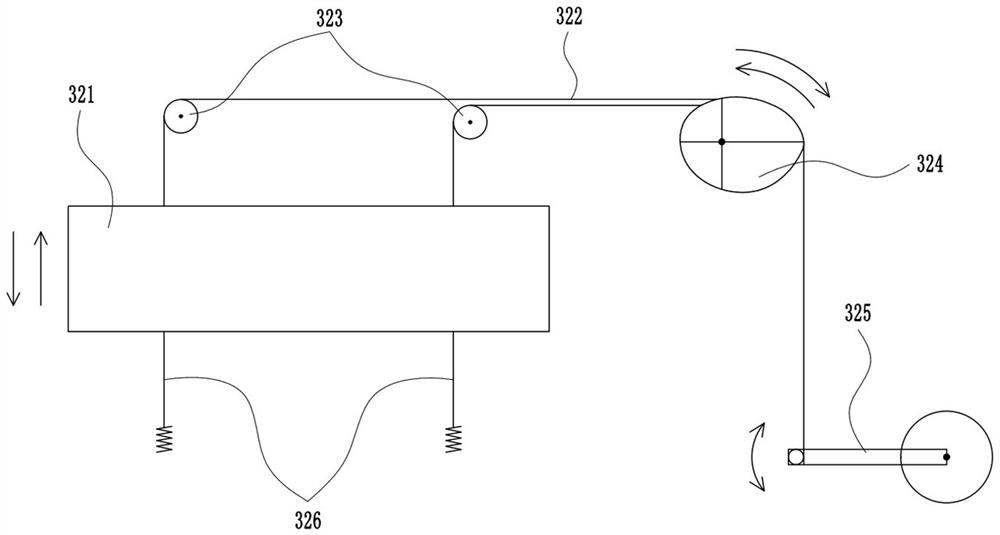

An energy-saving and environment-friendly extrusion equipment for plywood production

ActiveCN111873094BReduce labor intensityReduce job riskPlywood pressesPretreated surfacesIndustrial engineeringEnvironmentally friendly

The invention relates to the technical field of extrusion equipment, in particular to an energy-saving and environment-friendly extrusion equipment for plywood production. The inside of the body is slidably connected with a bearing plate, the inside of the housing is fixedly connected with a slide rail, the inside of the slide rail is slidably connected with a slider, and the upper surface of the slider is elastically connected to the inner surface of the slide rail through a connecting spring. connected, the inner side of the slider is rotatably connected to a bearing plate, and the bottom end of the inner surface of the housing is rotatably connected to a worm. The sliding sleeve engaged with the worm slides on the outer surface of the worm from left to right when the worm rotates, and then pushes the bearing plate to tilt, sliding the plywood on the bearing plate out from the inside of the through hole, which can reduce the labor of the staff Strength, no need to manually take out the plywood through the staff, which not only improves the work efficiency of the equipment, but also reduces the work risk of the staff.

Owner:LINYI SHANDA WOOD IND CO LTD

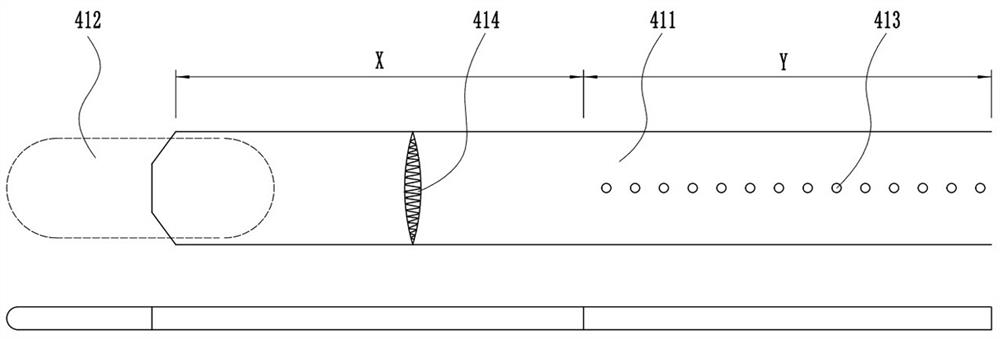

Velvet loom with flexible large rapier

ActiveCN112981671AIncrease stand rateSolidifiedCam shedding mechanismPile-fabric loomsReciprocating motionStructural engineering

The invention provides a velvet loom with a flexible large rapier, and belongs to the technical field of textile machinery. A uniform acceleration heald lifting opening device is designed and manufactured according to the special curve principle of an eccentric cam; in a picking and beating-up device, a flexible rapier belt reciprocates to enable a rapier head to receive and send wefts so as to complete picking motion; the cross section, entering a shed part, of the flexible rapier belt is in a slightly-protruding arc shape; the reciprocating motion of the flexible rapier belt is completed by driving a chain hole in the rapier belt through a chain wheel of a rapier transmission gear box of the rapier loom; and devices capable of adjusting front-back swinging and left-right lifting are arranged on bases at the two ends of a linear guide rail of a velvet cutting device for velvet. The velvet loom not only solves the key problem that a double-layer double-shed double-rapier velvet loom cannot weave thin velvet, but also can break through the problem that the double-layer double-shed double-rapier velvet cutting surface is single, and also solves the problems that a single-layer single-shed shuttle velvet loom is low in yield and poor in quality and a weft winding process is added.

Owner:常州市锦铄源纺织机械有限公司

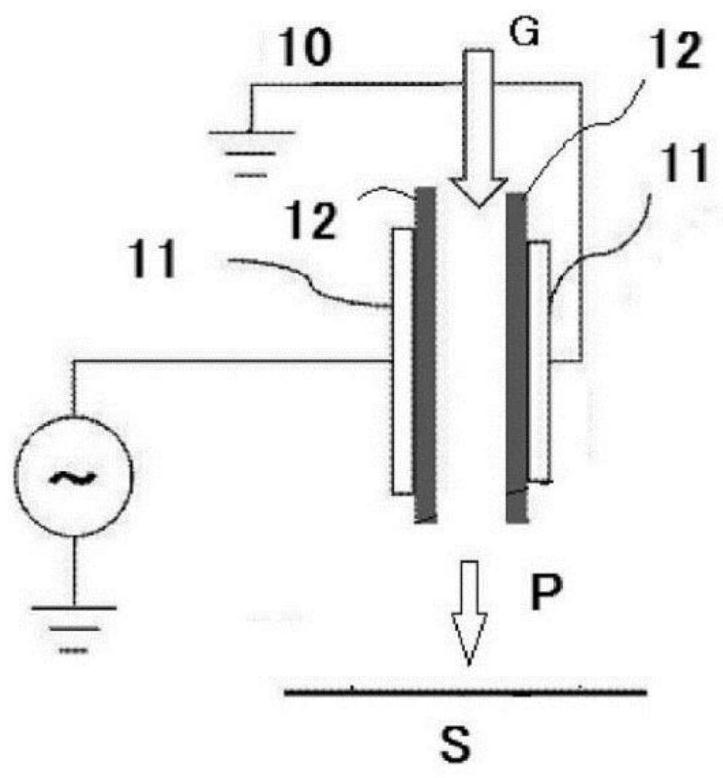

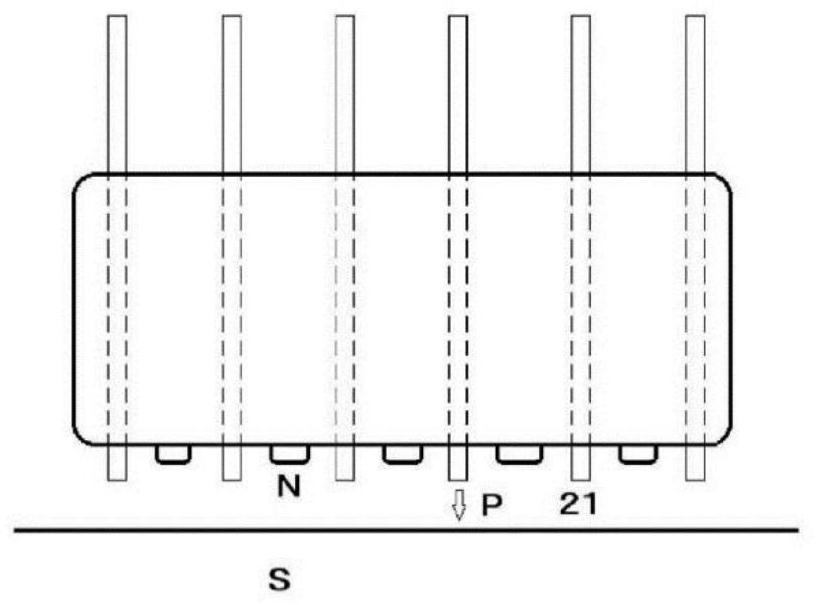

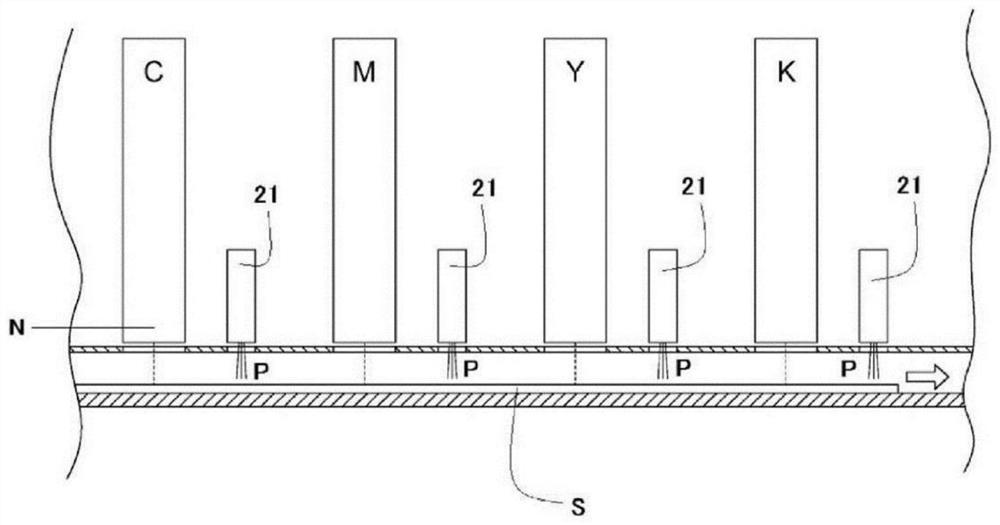

Plasma electron beam processing inkjet printing device

PendingCN112839818ASolidifiedGood patienceOther printing apparatusPlasma techniquePlasma electronPhysical chemistry

The purpose of the present invention is to obtain a device that can be cured reliably even when printing is performed using an ink that does not contain a photopolymerization initiator, that can perform printing without modifying the surface of a substrate to be printed, and that, after printing of various colors, can be cured reliably without causing the surface of the substrate to be printed to be modified. The surface of the dots of the ink is cured by atmospheric pressure plasma, and thus an image having excellent resistance to the cured coating film can be obtained. Specifically, as a solution, provided is an inkjet printing device for multicolor printing, provided with: a multicolor inkjet nozzle that moves in the vertical direction with respect to the moving direction of a substrate to be printed and moves in the parallel direction with respect to the surface of the substrate to be printed; and a plasma discharge port facing the multicolor ink surface printed on the substrate to be printed downstream of the multicolor inkjet nozzle, and having an electron beam irradiation unit facing the moving direction of the substrate to be printed on the downstream side of the inkjet nozzle and the plasma discharge port.

Owner:SAKATA INX

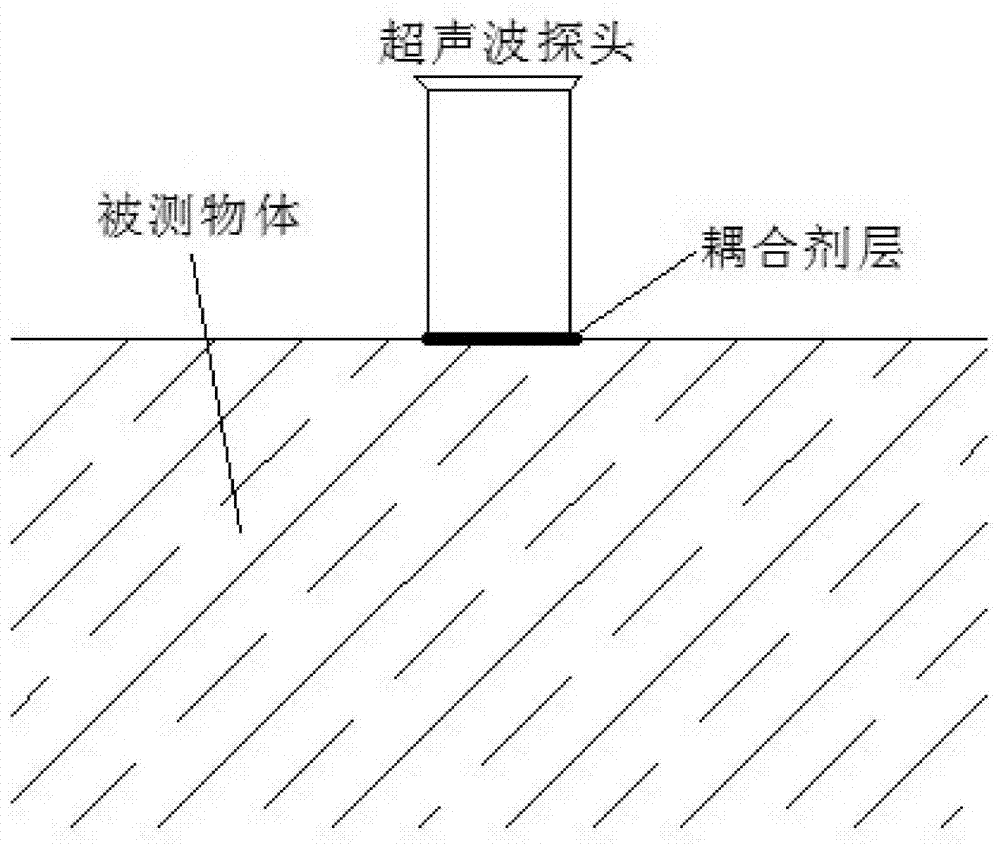

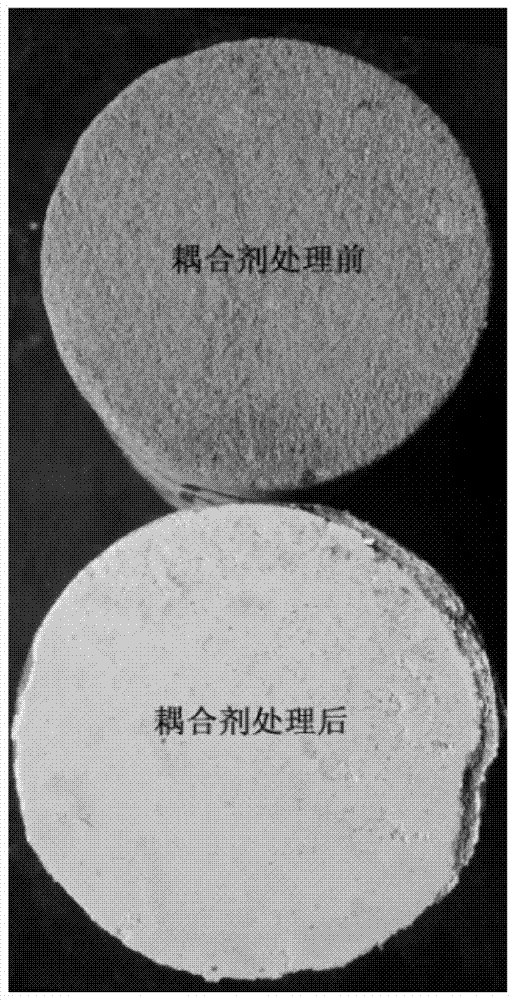

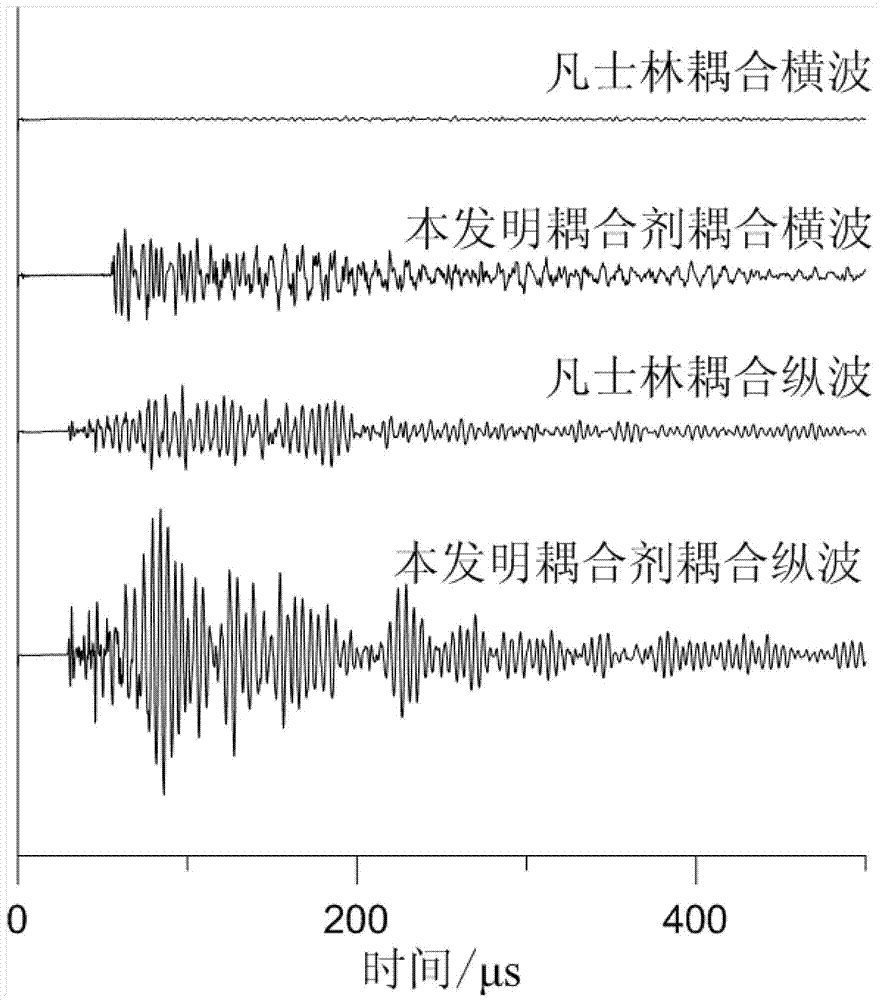

Slow-speed couplant that eliminates the effect of end surface roughness and improves the test effect of longitudinal and transverse waves

InactiveCN103983701BReduce processingSolidifiedMaterial analysis using sonic/ultrasonic/infrasonic wavesChemical reactionPolyvinyl alcohol

A slow-speed couplant that eliminates the effect of end surface roughness and improves the test effect of longitudinal and shear waves. The coupling agent is made of cheap and easy-to-obtain materials such as gypsum, plaster of paris, polyvinyl alcohol, white latex, sodium hexaphosphate, calcium oxide and magnesium chloride according to a certain process, and is stored in a sealed bag for use. , mix with water when used, apply it on the surface of the object to be tested after fully stirring and install the ultrasonic probe, and then the ultrasonic test can be carried out. The couplant is in a flow-plastic state during the pretreatment stage of the ultrasonic test, which can fully fill the gap between the probe and the end face of the object to be measured, and eliminate the influence of the end face roughness on the ultrasonic test. It is in a hard plastic state during the ultrasonic test, and has an appropriate bonding strength to bond the ultrasonic probe and the object under test as a whole, so that better longitudinal and transverse wave test results can be obtained. At the same time, the present invention calculates the reaction quality of each material through the chemical reaction equation, makes the coupling agent close to neutral, and reduces the corrosion to the measured object and the probe.

Owner:LANZHOU UNIVERSITY

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com