Method for implementing cement-based spraying and rapid hardening water-borne waterproof coating

A technology of waterproof coating and implementation method, applied in the field of waterproof materials, can solve the problems of low bonding strength, poor waterproof effect, long setting time, etc., and achieve the effect of high bonding strength

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

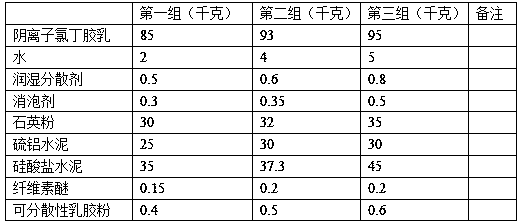

Examples

Embodiment Construction

[0017] The present invention will be further described below in conjunction with embodiment.

[0018] First, some raw materials are introduced as follows:

[0019] Anionic neoprene latex, available in the market, requires a glass transition temperature of -10 degrees, a viscosity of 800, a solid content of about 57%, and a minimum film-forming temperature of -20°;

[0020] Quartz powder: also known as silica powder, quartz powder is a hard, wear-resistant, chemically stable silicate mineral, its main mineral component is SiO2, the fineness is 100 mesh-150 mesh, SiO2≥99-99.5%, available in the market;

[0021] Sulfur-aluminum cement: Sulphoaluminate cement is anhydrous calcium sulphoaluminate (C4A3S) and dicalcium silicate ( C2S) is a clinker mainly composed of minerals, mixed with an appropriate amount of mixed materials (gypsum and limestone, etc.) Divided into 5 varieties such as rapid hardening sulfoaluminate cement, high-strength sulfoaluminate cement, expansive sulfoal...

PUM

| Property | Measurement | Unit |

|---|---|---|

| solid content | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com