Light steel factory post foundation suitable for sedimentation of filled-in ground and construction method

A technology of soil foundation and factory building columns, applied in the direction of basic structure engineering, construction, etc., can solve the problems of light steel factory building superstructure and building deformation, affecting the safety of building structures, high maintenance costs, etc., to achieve convenient construction and good economic benefits and time efficiency, the effect of simple and fast construction

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

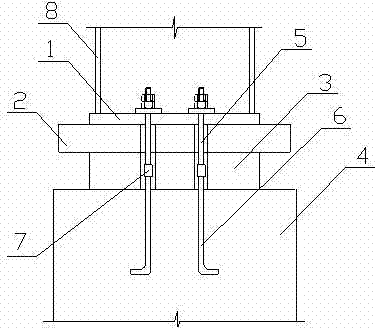

[0040] Embodiment 1: as figure 1 As shown, a light-steel workshop column foundation adapted to the settlement of the filling foundation includes a column bottom plate 1, a steel backing plate 2, a prefabricated spacer 3, and an independent foundation 4 under the column (the independent foundation under the column Foundation 4 is generally made of concrete or reinforced concrete material) and connecting steel bar, and described connecting steel bar comprises top screw bar steel bar 5 and bottom anchor screw bar bar 6, and described top screw bar bar 5 and bottom anchor bar bar bar 6 pass through connecting sleeve 7. The detachable connection is connected with a mechanical sleeve during specific implementation, which is more stable; the I-steel steel column 8 of the light steel factory building is fixedly connected with the column bottom plate 1. Described prefabricated spacer 3 is steel plate, cement mortar spacer or concrete spacer, makes the intensity of prefabricated spacer ...

Embodiment 2

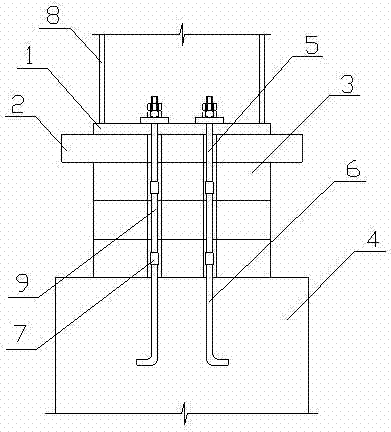

[0052] Example 2, such as figure 2 As shown, there are a plurality of prefabricated pads, and the connecting steel bars include top screw bars, middle screw bars 9, and bottom anchor screw bars, and the top screw bars, middle screw bars 9, and bottom anchor bar bars are connected by The sleeve threaded connection is connected by a mechanical sleeve during specific implementation, which is more stable.

[0053] In the case of large foundation settlement, add or replace the middle screw reinforcement with appropriate length according to the needs, so that when filling the prefabricated pad (pad), the middle screw reinforcement can be connected while filling the prefabricated pad (pad) ,More convenient. After the ground subsidence occurs, the column bottom plate of the I-steel column of the light steel factory building is lifted first, and then the hole prefabricated concrete pad (or pad) is used to fill the resulting independent foundation under the column and the column botto...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com