Sheared towel with one-side terry and one-side velutum

A technology of towels and terry, which is applied in fabrics, textiles, textiles and papermaking, etc. It can solve the problems of poor consolidation of terry and velvet piles, and large consumption of raw materials for sheared towels, so as to achieve rich texture, reduce production processes, Wide range of effects

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

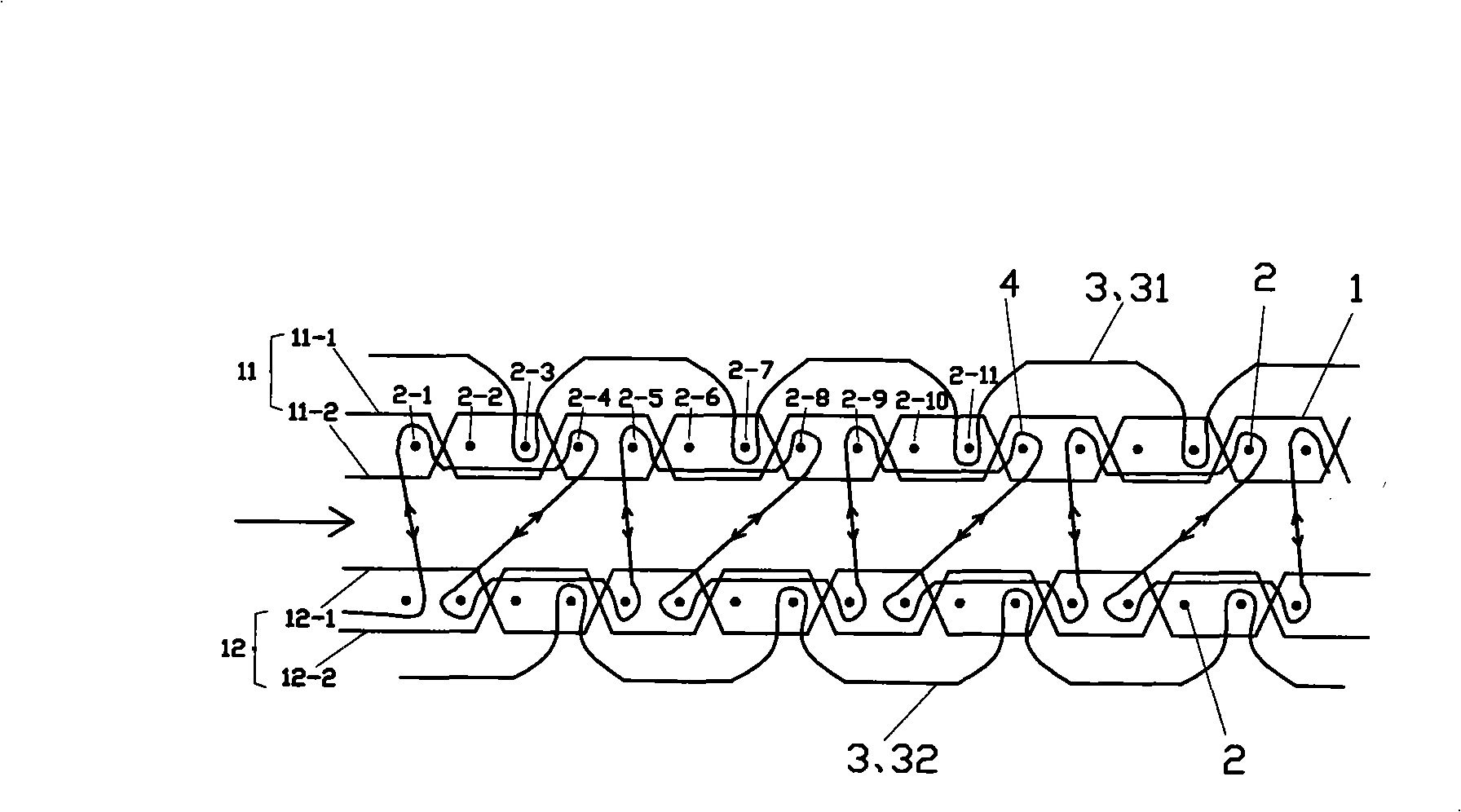

[0017] See figure 1 , The cut pile towel in this embodiment includes ground warp yarn 1, weft yarn 2, wool warp yarn 3 and pile warp yarn 4. Wherein ground warp yarn 1 is divided into upper and lower groups, towel yarn 3 is also divided into upper and lower groups, and velvet warp yarn 4 is a group.

[0018] The weft yarn 2 and two sets of ground warp yarns 1 (wherein the upper set of ground warp yarns are numbered 11, and the lower set of ground warp yarns are numbered 12) are interwoven into upper and lower two-layer bottom fabrics; One group of wool warp yarns numbered 31, and one group of wool warp yarns numbered 32 located below) are synchronous with the formation of the upper and lower two-layer bottom fabrics and alternately interweave with the weft yarns 2 of the upper bottom bottom fabric and the lower bottom bottom fabric respectively. The outermost two sides of the single-sided pile are formed; thereby forming a towel structure with the same structure of the upper ...

Embodiment 2

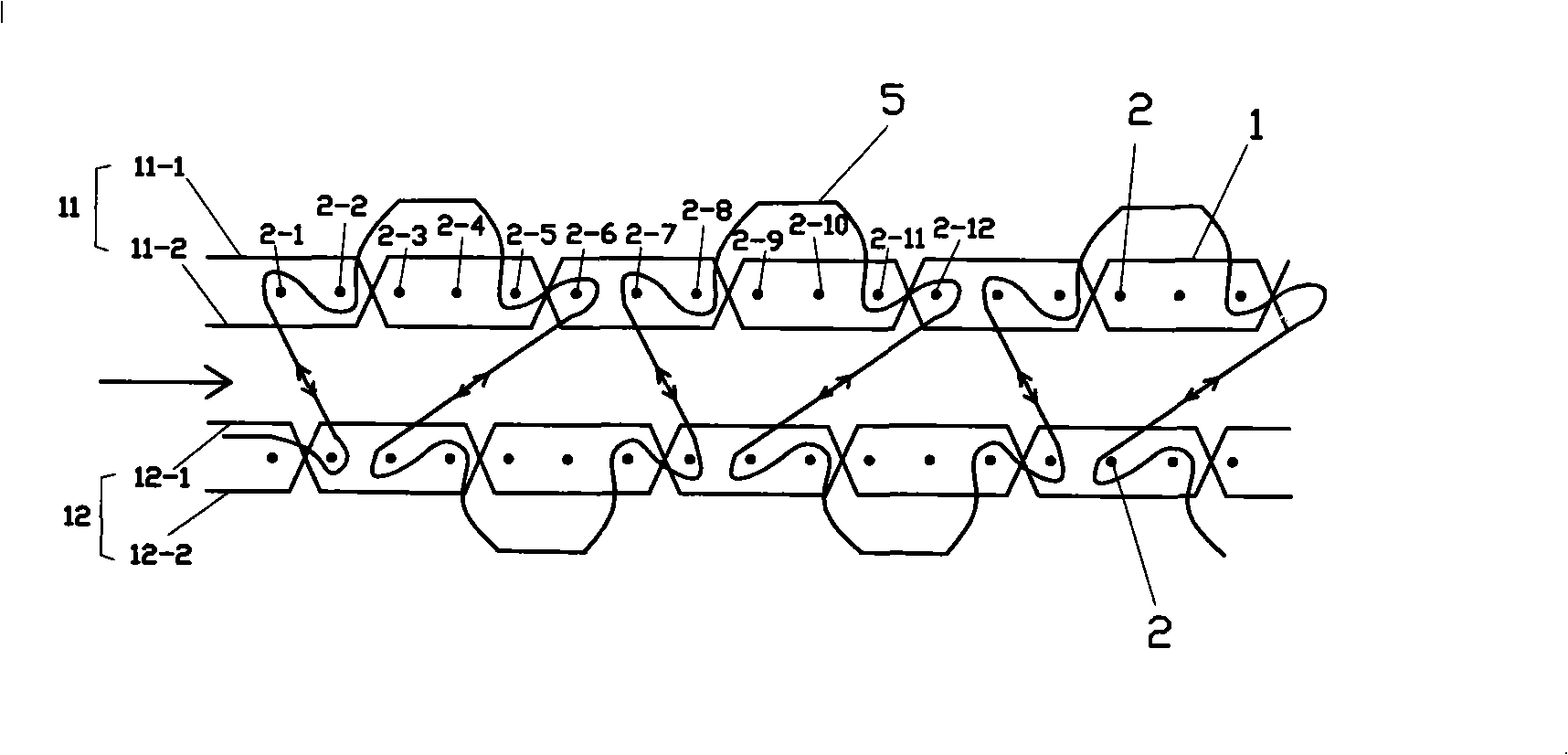

[0028] See figure 2 , The cut pile towel in this embodiment includes a ground warp yarn 1, a weft yarn 2, and a plush warp yarn 5.

[0029] Wherein, the weft yarn 2 and two groups of ground warp yarns 1 (wherein the ground warp yarn label of one group at the top is 11, and the ground warp yarn label of one group at the bottom is 12) are interwoven into upper and lower two-layer bottom fabrics; one group of plush warp yarns 5 and form The upper and lower bottom fabrics are synchronously interlaced with the weft yarns 21 of the upper bottom fabric and the weft yarns 22 of the lower bottom fabric respectively on the one hand, forming single-sided piles on the upper surface of the upper bottom fabric and the lower surface of the lower bottom fabric. Thereby forming the upper and lower layers of towel tissue with the same two-layer tissue structure. Plush warp yarn 5 also connects two layers of towel tissue up and down simultaneously on the other hand. The plush warp yarn 5 and th...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com