Greening plant brick and manufacture method thereof

A production method and plant technology, applied in botany equipment and methods, horticulture, agriculture, etc., can solve the problems of plant growth nutrient supply, regulation and maintenance difficulties, nutrient matrix scattered, unfavorable plant growth, etc., to reduce temperature and reduce decoration Good effect of cost, water retention

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

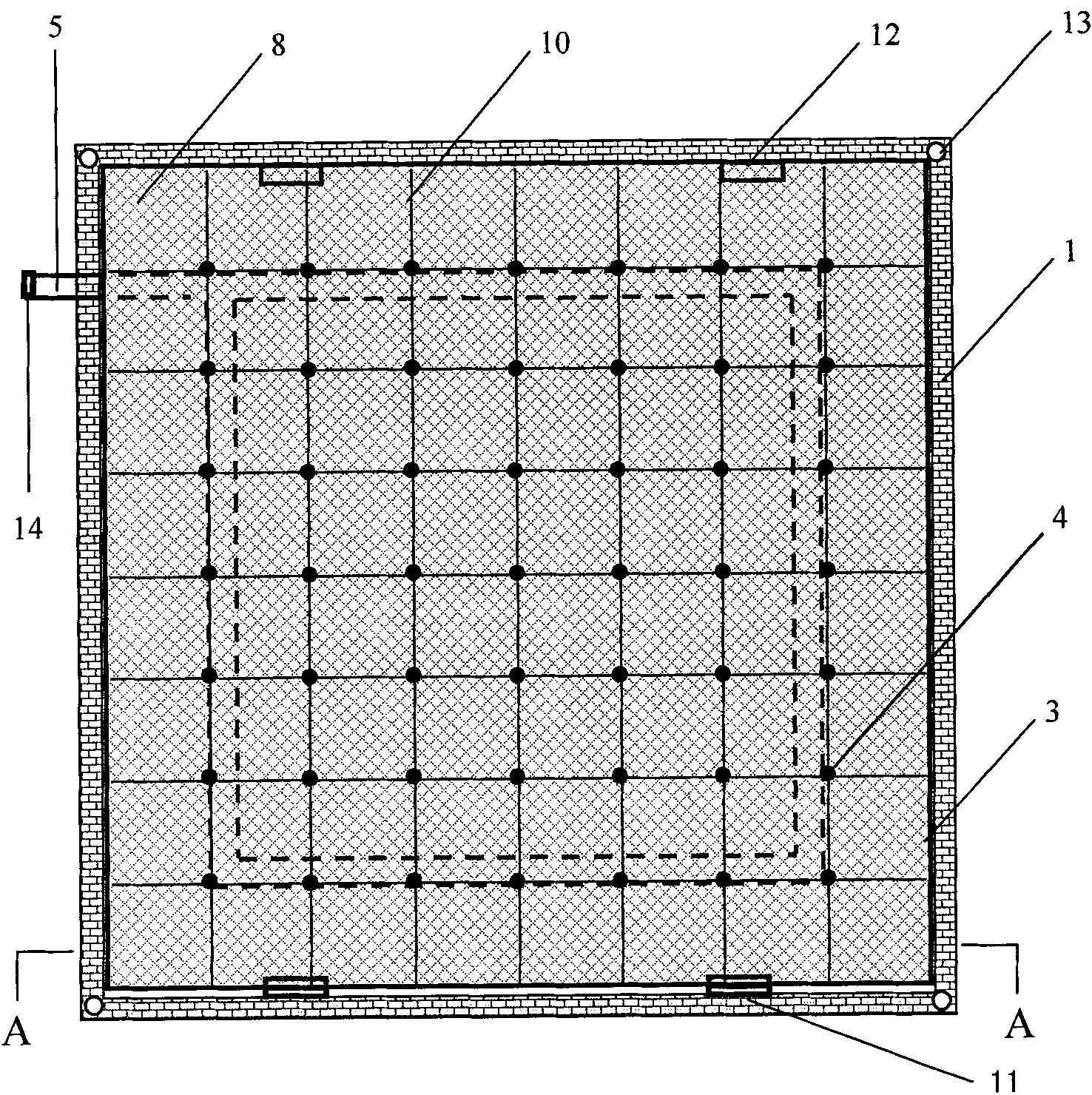

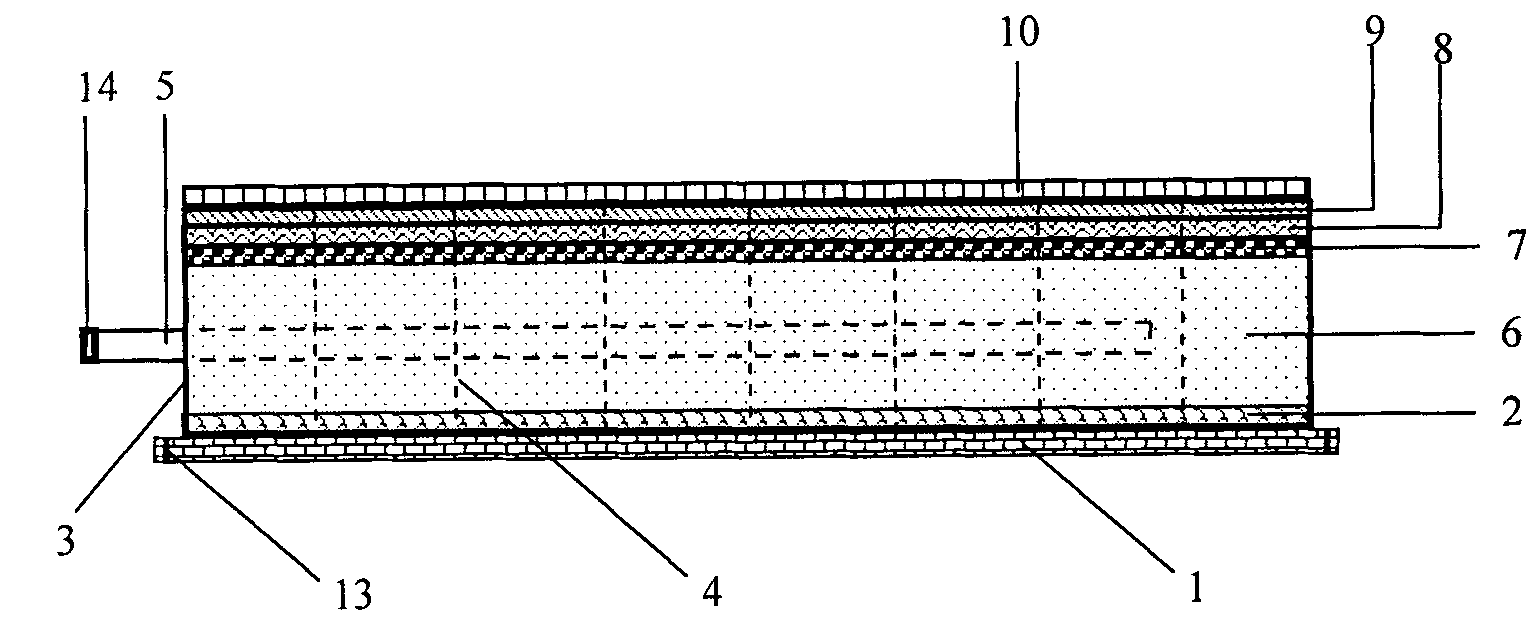

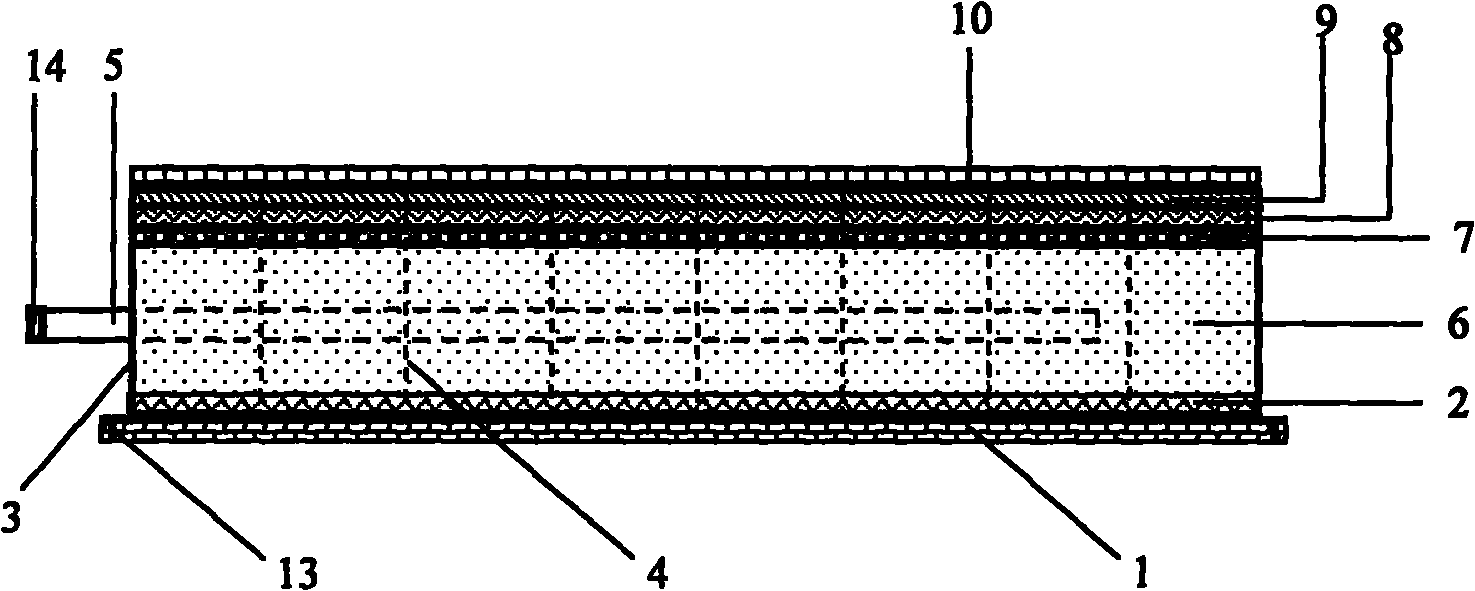

[0032] aUsing hard plastic board to make square or other shaped brick molds,

[0033] b. Pouring fiber concrete in the mold to make the frame body, laying a waterproof layer 2 on the bottom surface of the frame body, consolidating the support rods 4 and the inner bottom surface of the frame body into one body, and the support rods 4 are evenly arranged in a mesh shape,

[0034] c Use a glass fiber mesh with a pore diameter of 6 mm as the mesh isolation layer 8, use a water-absorbing non-woven fabric with an aperture of 6 mm as the water-absorbing layer 9, and use hard plastic as the grid skeleton 10, and use the mesh isolation layer 8 and the water-absorbing layer 9 Consolidated with the grid skeleton 10 to form a frame cover, wherein the water-absorbing layer 9 is located between the mesh isolation layer 8 and the grid skeleton 10, and then one end of the frame cover is connected to the upper edge of the surrounding frame 3 using a hinge 11, and the other end Adopt active pin...

Embodiment 2

[0040] aUsing hard plastic board to make square or other shaped brick molds,

[0041] b. Pouring fiber concrete in the mold to make the frame body, laying a waterproof layer 2 on the bottom surface of the frame body, consolidating the support rods 4 and the inner bottom surface of the frame body into one body, and the support rods 4 are evenly arranged in a mesh shape,

[0042] c Use a glass fiber mesh with a pore diameter of 5 mm as the mesh isolation layer 8, use a water-absorbing non-woven fabric with an aperture of 6 mm as the water-absorbing layer 9, and use hard plastic as the grid skeleton 10, and use the mesh isolation layer 8 and the water-absorbing layer 9 Consolidated with the grid skeleton 10 to form a frame cover, wherein the water-absorbing layer 9 is located between the mesh isolation layer 8 and the grid skeleton 10, and then one end of the frame cover is connected to the upper edge of the surrounding frame 3 using a hinge 11, and the other end Adopt active pin b...

Embodiment 3

[0048] aUsing hard plastic board to make square or other shaped brick molds,

[0049] b. Pouring fiber concrete in the mold to make the frame body, laying a waterproof layer 2 on the bottom surface of the frame body, consolidating the support rods 4 and the inner bottom surface of the frame body into one body, and the support rods 4 are evenly arranged in a mesh shape,

[0050] c Use a glass fiber net with an aperture of 8 mm as the mesh isolation layer 8, use a water-absorbing non-woven fabric with an aperture of 8 mm as the water-absorbing layer 9, and use hard plastic as the grid skeleton 10, and use the mesh isolation layer 8 and the water-absorbing layer 9 Consolidated with the grid skeleton 10 to form a frame cover, wherein the water-absorbing layer 9 is located between the mesh isolation layer 8 and the grid skeleton 10, and then one end of the frame cover is connected to the upper edge of the surrounding frame 3 using a hinge 11, and the other end Adopt active pin bolt...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com