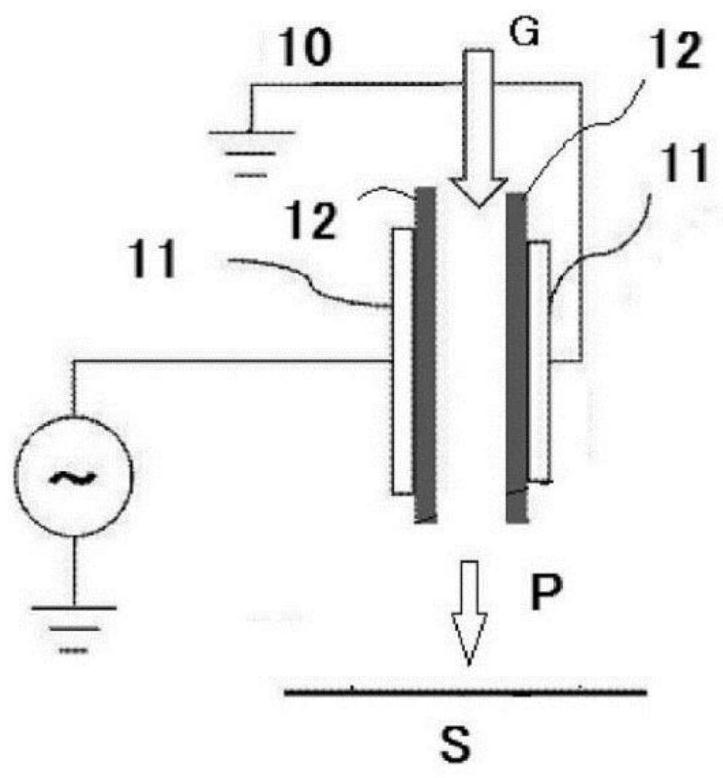

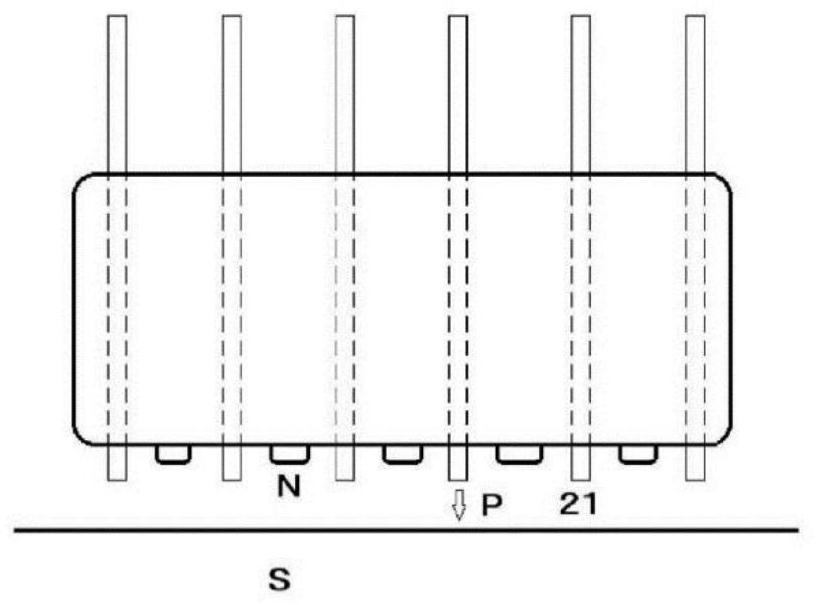

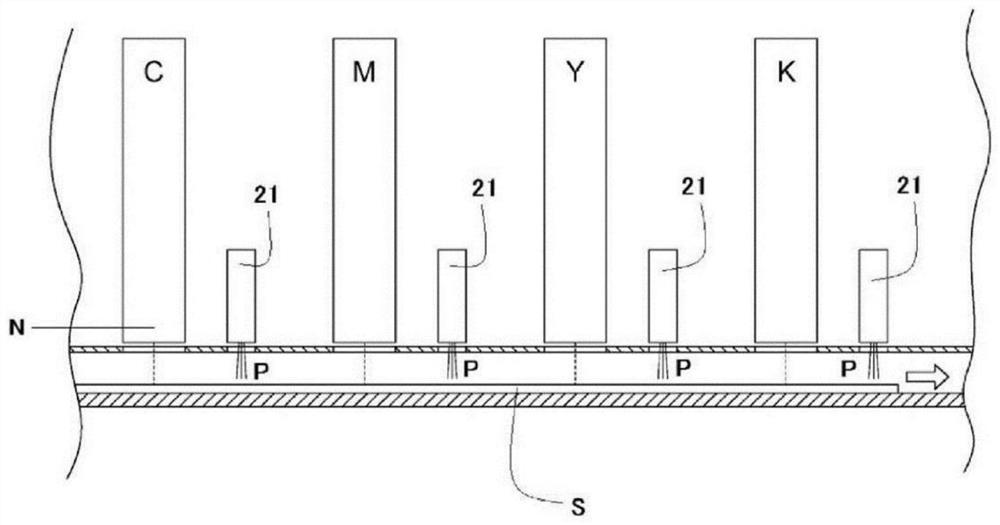

Plasma electron beam processing inkjet printing device

An inkjet printing and plasma technology, applied in the direction of plasma, printing device, printing, etc., can solve the problems of difficult surface curing, low oxygen concentration, disturbed printing, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

[0117] A polyethylene terephthalate film with a width of 21 cm was supplied to a line inkjet printing device at a printing speed of 12 m / min, and printed using the compositions of Examples and Comparative Examples shown in Table 1 below, And curing was carried out under the conditions shown in Table 1, respectively. The compounding quantity of the composition in a table|surface is a mass.

[0118] In addition, the intercolor plasma curing gas type N2 is available, which means that inkjet printing inks of various colors are used for printing, and after full-color printing, the gas type is nitrogen gas irradiated from a slit with a width of 300 mm at a gas flow rate of 30 L / min. An example of an atmospheric pressure plasma. EB irradiation 30kGray 90kV means that after full-color printing, the ink is irradiated with an electron beam generated at a voltage of 90kV at 30kGray in an atmosphere purified by nitrogen gas.

[0119] (coating erasing)

[0120] Using fine white cloth (c...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com