Patents

Literature

57results about How to "Good patience" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

Releasing agent composition and releasing material

ActiveCN101952380AHigh glossExcellent peelabilityOther chemical processesFilm/foil adhesivesAcrylic resinGlass transition

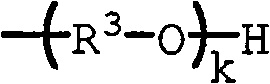

Disclosed is a releasing agent composition having excellent gloss, releasing power and surface state, which can maintain excellent releasability even after repeated use. The releasing agent composition contains a hydroxy group-containing acrylic resin having a specific structure, an amino resin, and a silicone resin having a functional group which can be chemically bonded to at least one of the hydroxy group-containing acrylic resin and the amino resin. The hydroxy group-containing acrylic resin has a hydroxyl number of 10-150 mgKOH / g, a glass transition temperature of 20-100 DEG C and a weight average molecular weight of 20,000-100,000.

Owner:株式会社力森诺科 +1

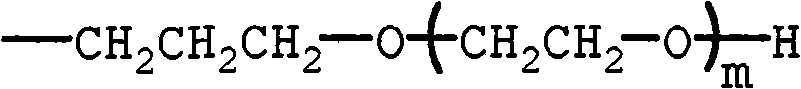

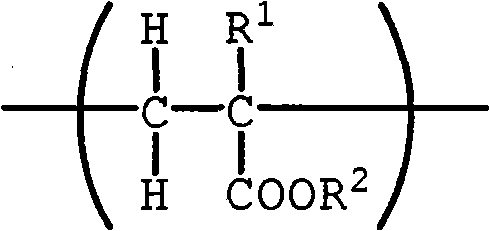

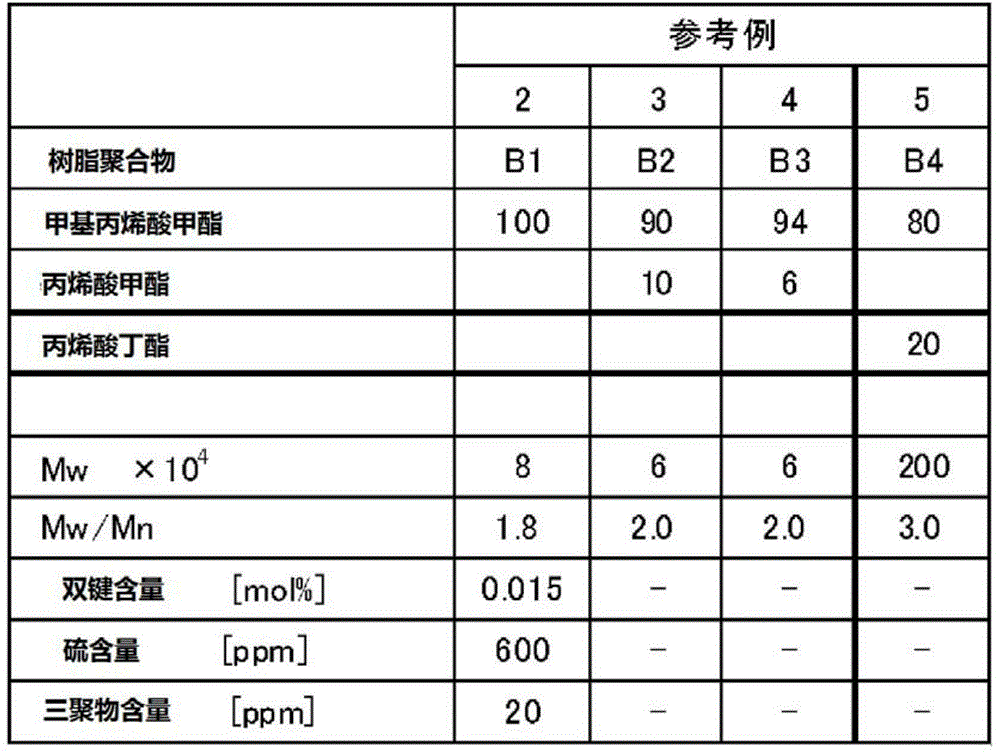

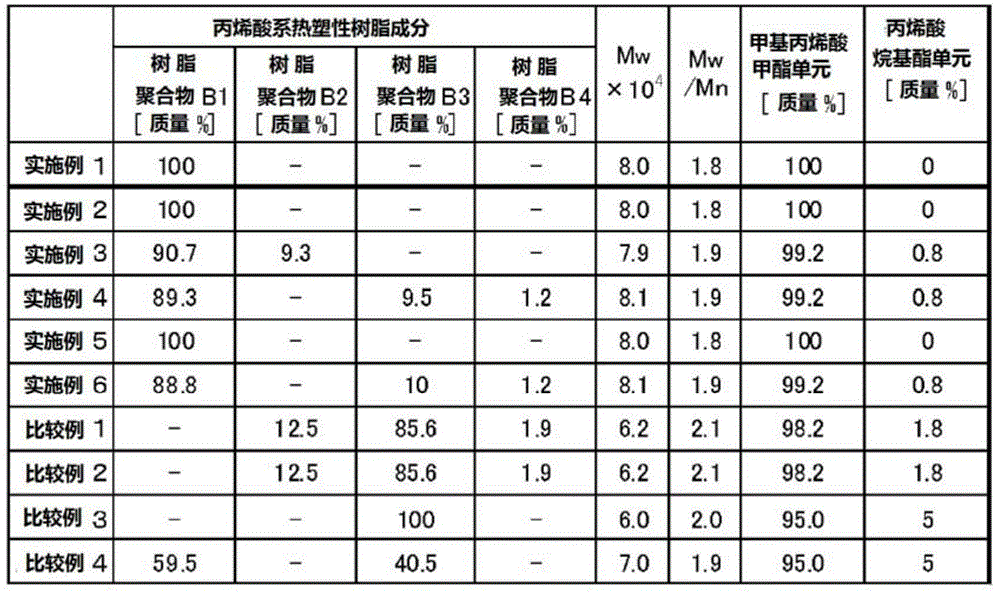

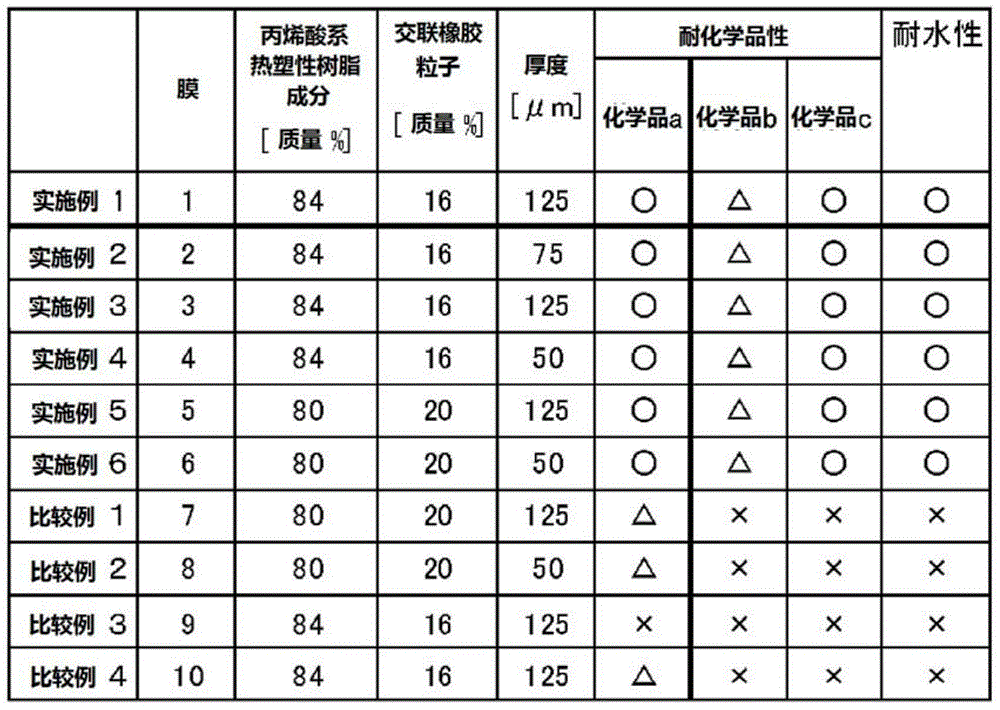

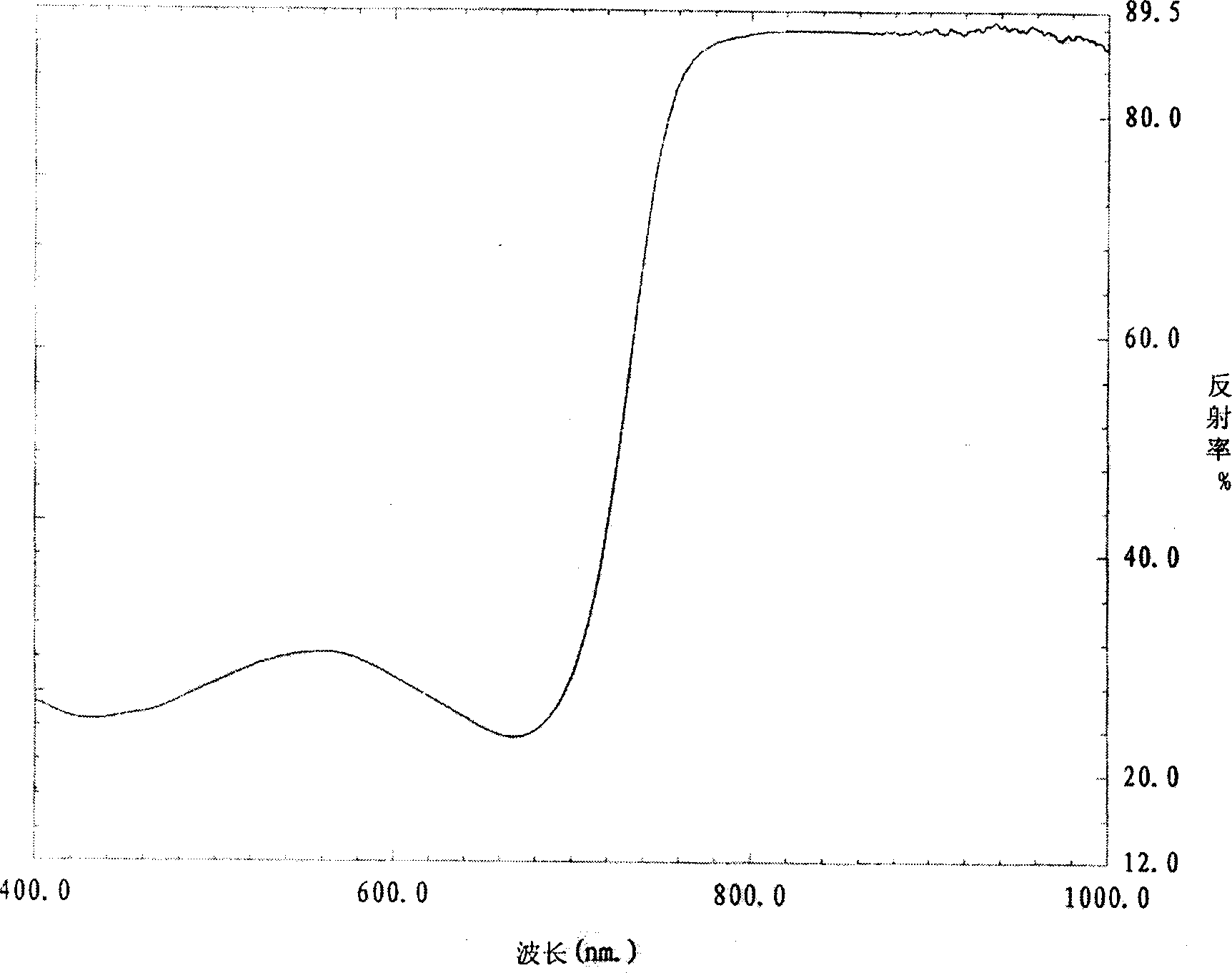

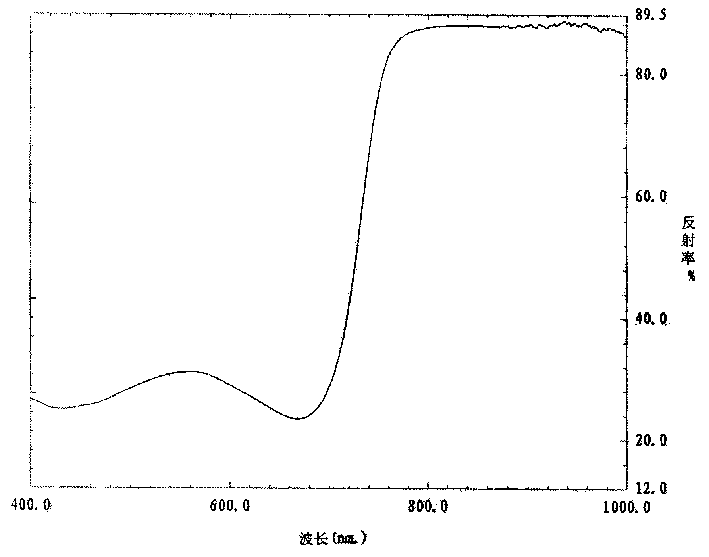

Acrylic resin film

According to the present invention, an acrylic resin film is obtained by a method including bulk polymerizing methyl methacrylate and an acrylic acid alkyl ester, obtaining an acrylic thermoplastic resin component having more than 99 mass% methyl methacrylate units and 1 mass% or less acrylic acid alkyl ester units, extruding a resin composition containing 70-95 mass% of the acrylic thermoplastic resin component and 5-30 mass% of a crosslinked rubber particle component from a T die, and then molding the extrudate to a thickness of 20-300 μm without a bank.

Owner:KURARAY CO LTD

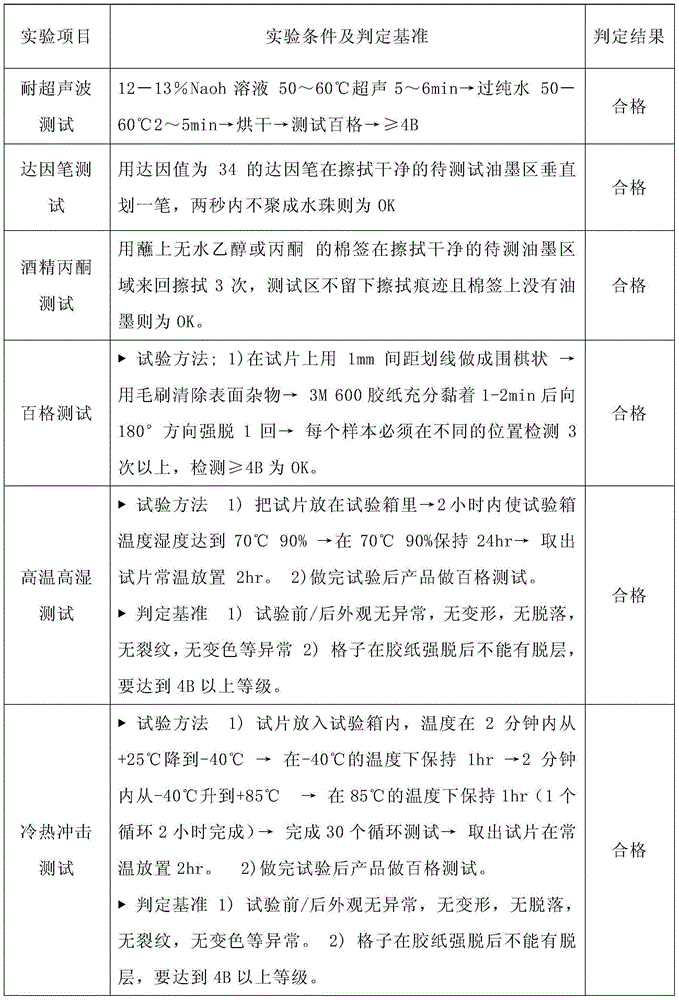

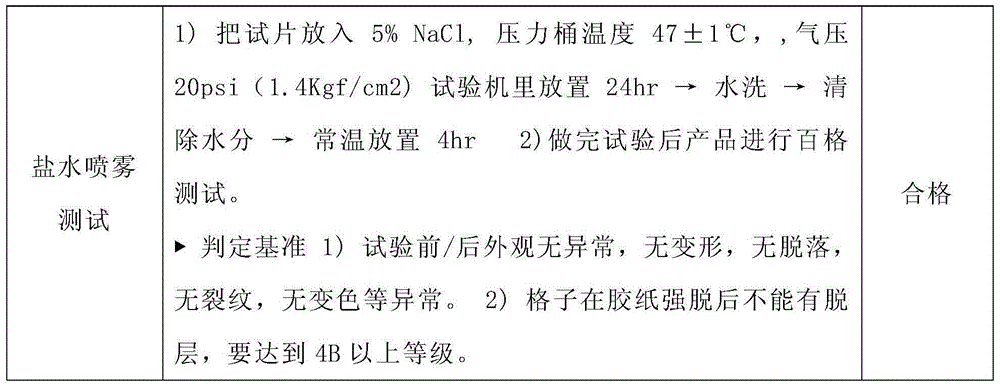

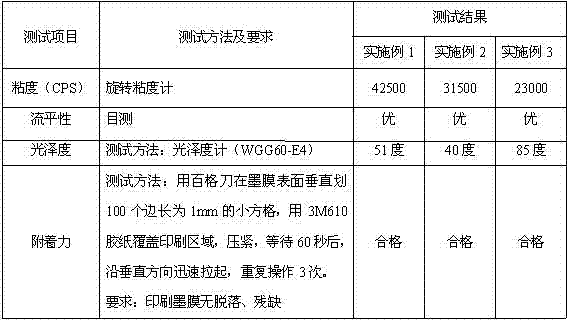

Mirror surface golden ink for glass cover plates

The invention discloses a mirror surface golden ink for glass cover plates, which comprises the following components in percentage by weight: 15-25 parts of silver powder, 60-70 parts of mirror surface gloss oil, 5-10 parts of diluter, 3-8 parts of red color paste, 2-6 parts of yellow color paste, 1-5 parts of accelerator, 0.5-1.5 parts of defoaming agent, 5-10 parts of curing agent, 1-2 parts of cellophane anchoring agent, 1.5-2.5 parts of anionic starch and 0.5-1.5 parts of acramoll W paste. Compared with the prior art, by adding the silver powder, mirror surface gloss oil, red color paste, yellow color paste, accelerator, defoaming agent, curing agent, diluter and other components and mixing with the especially added cellophane anchoring agent, anionic starch and acramoll W paste, the ink has the advantages of favorable adhesion, high reliability, ultrasonic cleaning resistance, acid / alkali resistance, solvent resistance, scrubbing resistance, high adhesion, high brightness, favorable color and stable silk screen printing effect, and can resist 220-DEG C high temperature without discoloration.

Owner:蓝思旺科技(深圳)有限公司

Curable resin composition for optical semiconductor encapsulation, and cured product of same

InactiveCN102597042AExcellent lead-free solder resistanceEase of mass productionSemiconductor/solid-state device detailsSolid-state devicesPhosphoric acidTransfer molding

Disclosed is a curable resin composition for optical semiconductor encapsulation which contains: a multi-functional biphenyl novolac epoxy resin component (A); a bisphenol epoxy resin (B) having an epoxy equivalent weight of 500-800g / eq; a bisphenol epoxy resin (C) having an epoxy equivalent weight of 850-1500g / eq; a multi-functional anhydride curing component (D); a phenol curing component (E) having a biphenyl skeleton or an alicyclic skeleton; and a (meth)acrylate component (F) having a phosphoric acid group. During transfer molding the resin composition exhibits excellent reactivity, has a short gel time, and does not include voids; under the high temperatures during mold removal, the resin composition exhibits excellent hardness, and has excellent gate-break properties. Additionally the encapsulated optical semiconductor element which can be obtained using the composition exhibits excellent re-flow properties.

Owner:NIPPON KAYAKU CO LTD

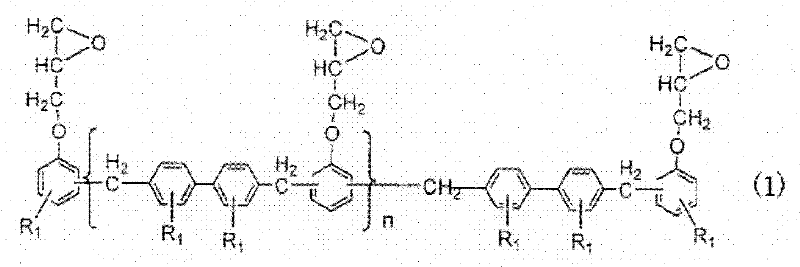

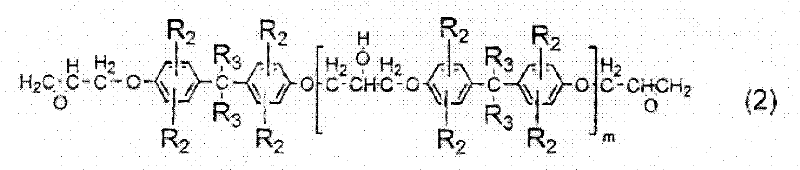

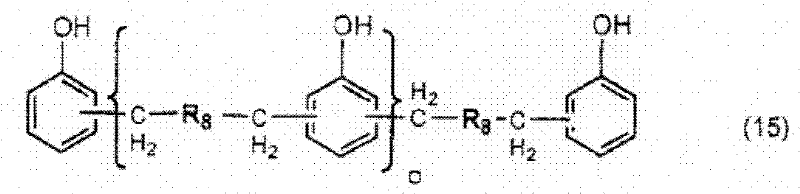

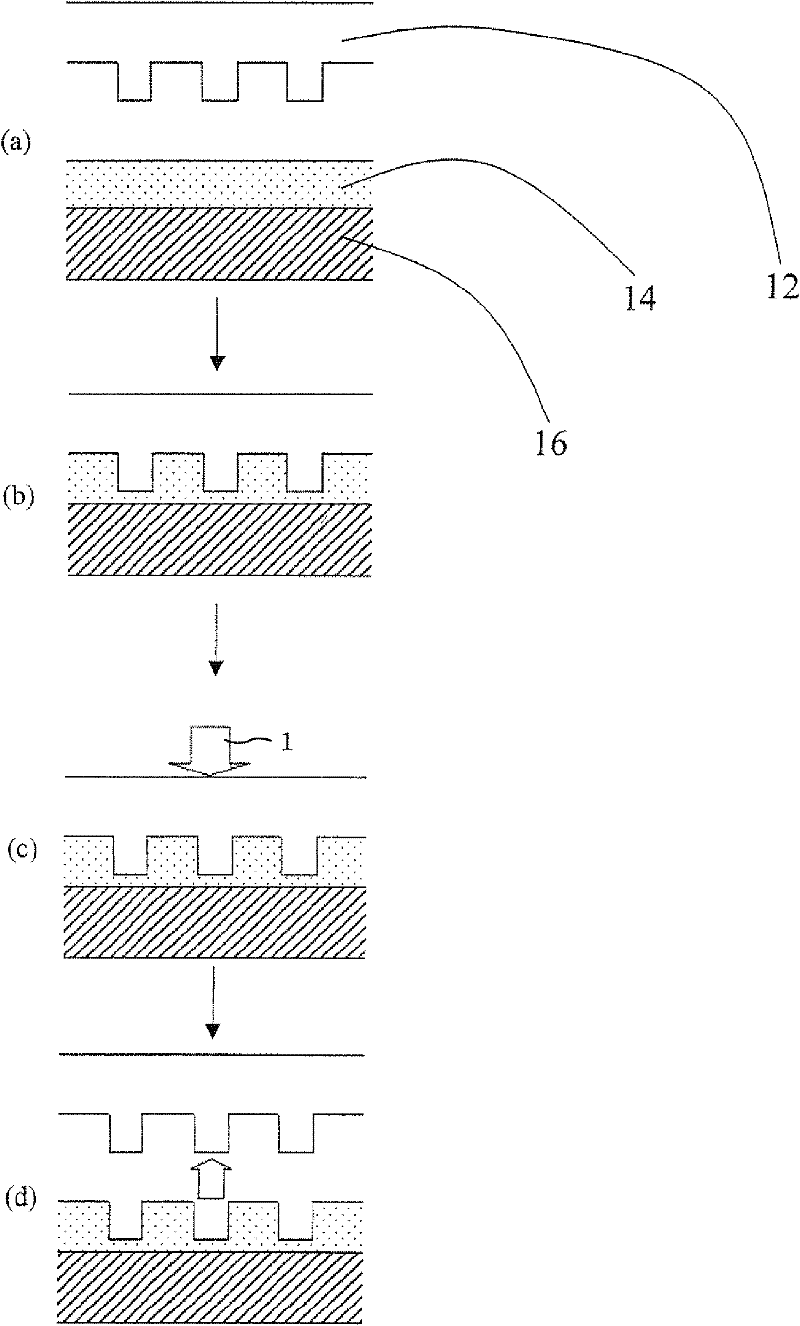

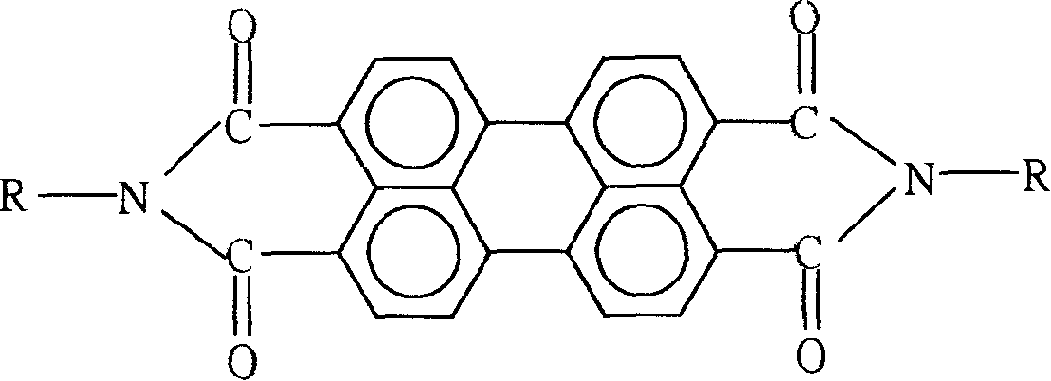

Curable composition for transfer material and (meth)acryloyl group-containing urea compound

InactiveCN102301449AGood transferabilityHigh selectivityOrganic chemistryNanoinformaticsMeth-Chemical compound

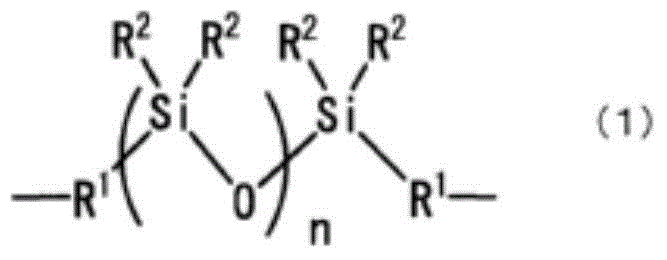

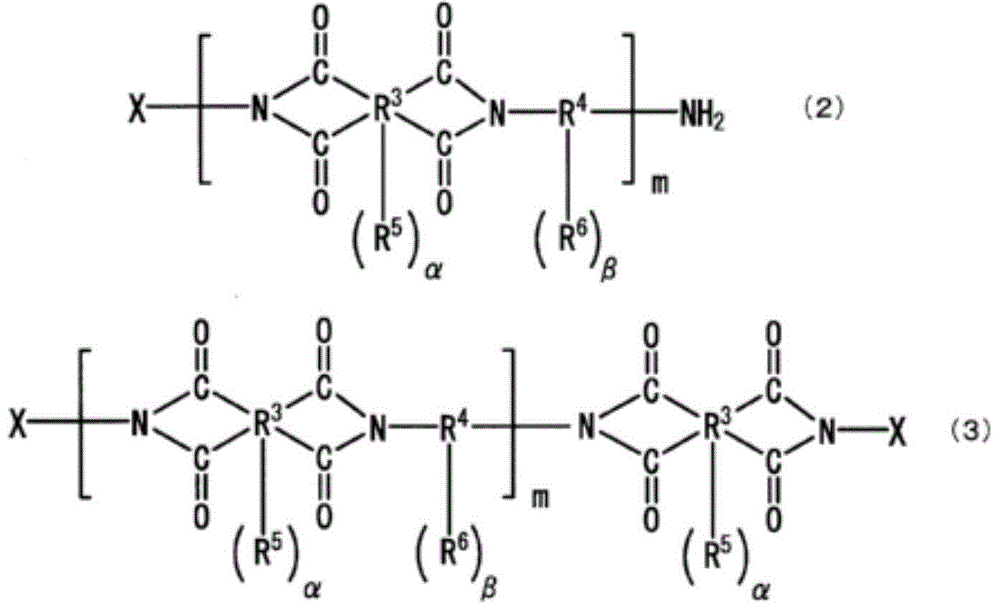

The invention provides curable compositions for transfer materials suited for nanoimprinting, which have very high transfer properties in a nanoimprinting process, show high selectivity in dry etching rate between by argon gas and by oxygen gas, and can be fabricated into fine patterns with high throughput. The curable composition for transfer materials includes a compound (A) having at least one skeleton selected from Formulae (1) to (3) below, and a (meth)acryloyl group:

Owner:SHOWA DENKO KK

Acid oil-in-water emulsion composition

InactiveCN1476765AAdd flavorGood lookingEdible oils/fats ingredientsEdible oils/fats with fatty acid estersWater solubleDiglyceride

The acidic oil-in-water type emulsion composition contains (A) an oil and fat containing >=30% diglyceride, (B) egg york and (C) a water soluble soybean polysaccharide. To provide an acidic oil-in-water type emulsion composition excellent in taste and stability in appearance, having resistance to pressurized shearing loads during production and application, having little change in physical properties such as viscosity reduction and the like and stable quality without any change of appearance such as syneresis and the like.

Owner:KAO CORP

Water-based bright gloss topcoat with high brightness, high tolerance and no dark bubbles or seeds, and preparation method and application thereof

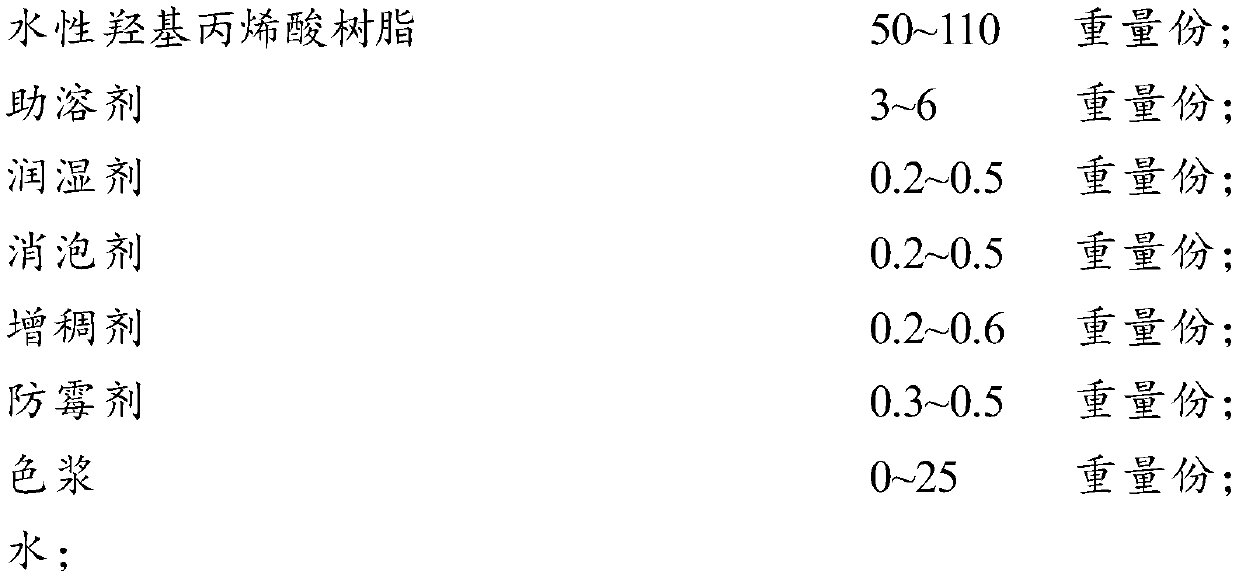

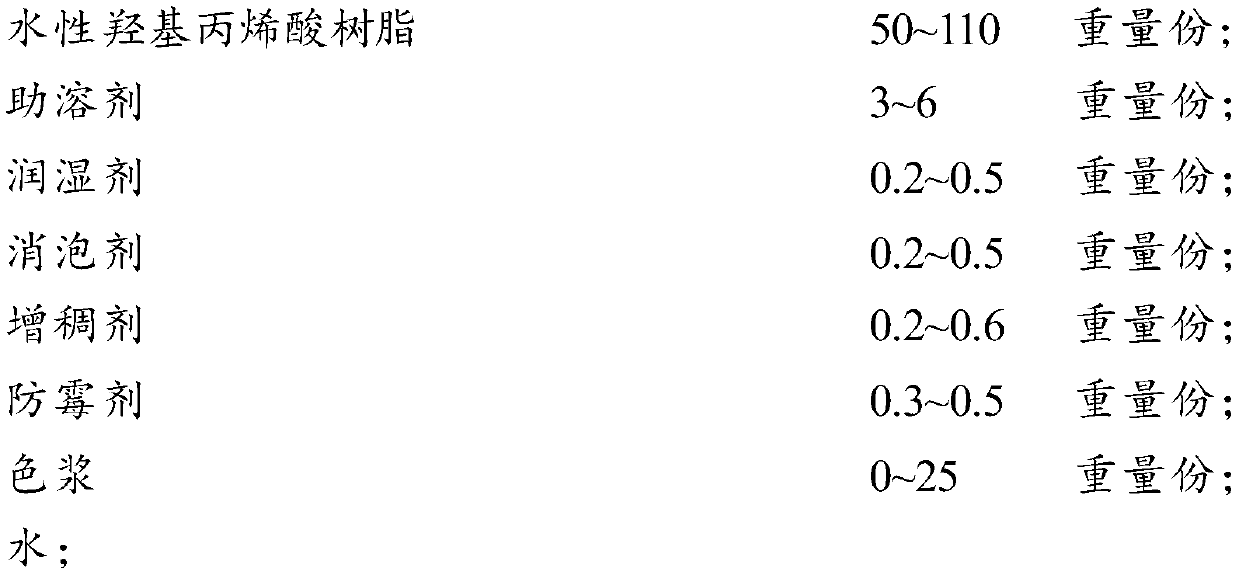

The present invention provides a water-based gloss topcoat. The water-based gloss topcoat comprises a component A and a component B; the component A comprises, by weight, 50-110 parts of waterborne hydroxy acrylic resin, 3-6 parts of a cosolvent, 0.2-0.5 part of a wetting agent, 0.2-0.5 part of an antifoaming agent, 0.2-0.6 part of a thickener, 0.3-0.5 part of a mildew inhibitor, 0-25 parts of a color paste, and water; and the component B comprises, by weight, 60-110 parts of hydrophilic modified isophorone diisocyanate and hexamethylene diisocyanate, 15-30 parts of propylene glycol methyl ether acetate and 0.5-2 parts of a water scavenger. The water-based gloss topcoat provided by the invention has the advantages of high brightness, environmental protection, good yellowing resistance, high hardness, high water resistance and high chemical resistance; and the water-based gloss topcoat has high tolerance to the temperature, and can be cured at room temperature without seeds, and a filmformed by the gloss topcoat has high fullness, has almost no dark bubbles, thereby the gloss topcoat is very suitable for the coating production of toilet and bathroom cabinets.

Owner:深圳市雷巴环保材料有限公司

Curable composition for transfer material and pattern formation method

InactiveCN102197055AIncreased etch resistanceHigh selectivityNanoinformaticsPhotomechanical apparatusResistTriazine

Owner:RESONAC HOLDINGS CORPORATION

Dual anticorrosive waterborne primer suitable for outdoor metal substrate

InactiveCN107353737AFast crosslinkingGood patienceAntifouling/underwater paintsPaints with biocidesWater basedPolyamide

Belonging to the field of paint, the invention in particular relates to a dual anticorrosive waterborne primer suitable for an outdoor metal substrate. The primer is composed of a component A and a component B in a weight ratio of 20:3. The component A consists of the following raw materials by weight: 20-30 parts of deionized water, 20-40 parts of water-based resin, 20-30 parts of pigment, 3-7 parts of graphene oxide, 1-2 parts of a coupling agent, 0.5-1 part of a dispersant, 0.3-1 part of an organosilicon leveling agent, and 5-6 parts of lotus leaf powder. The component B consists of the following raw materials by weight: 20-40 parts of polyamide, 3-8 parts of a catalyst, and 40-60 parts of pyromellitic acid. The primer film can undergo crosslinking rapidly to form a film under an ultralow temperature condition, is good in various tolerance, can tolerate salt mist for 3000h, acid and alkali for 1000h or more and water up to 180d or more.

Owner:ZHANGZHOU XIN ZHAN WANG CHEM IND

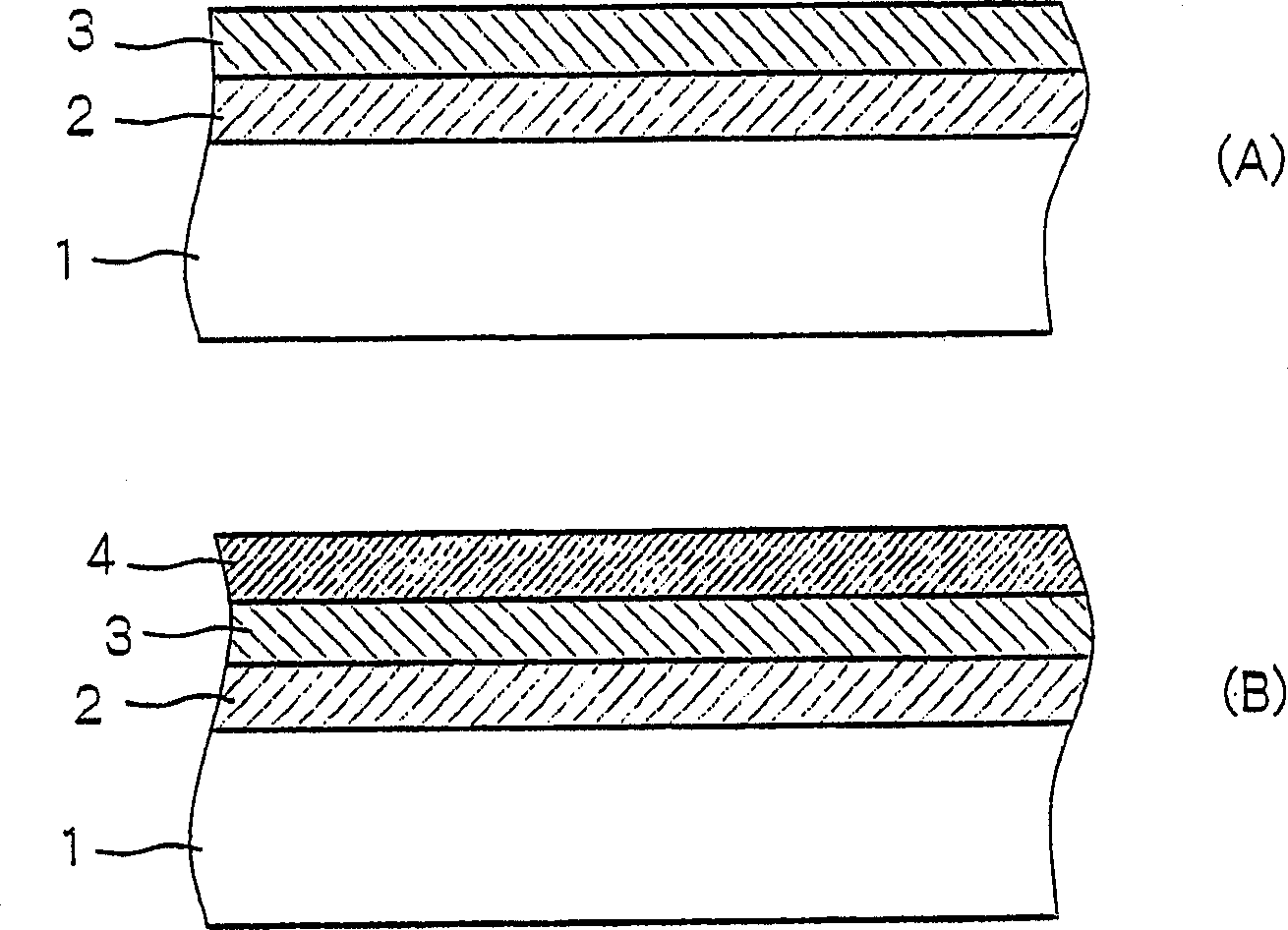

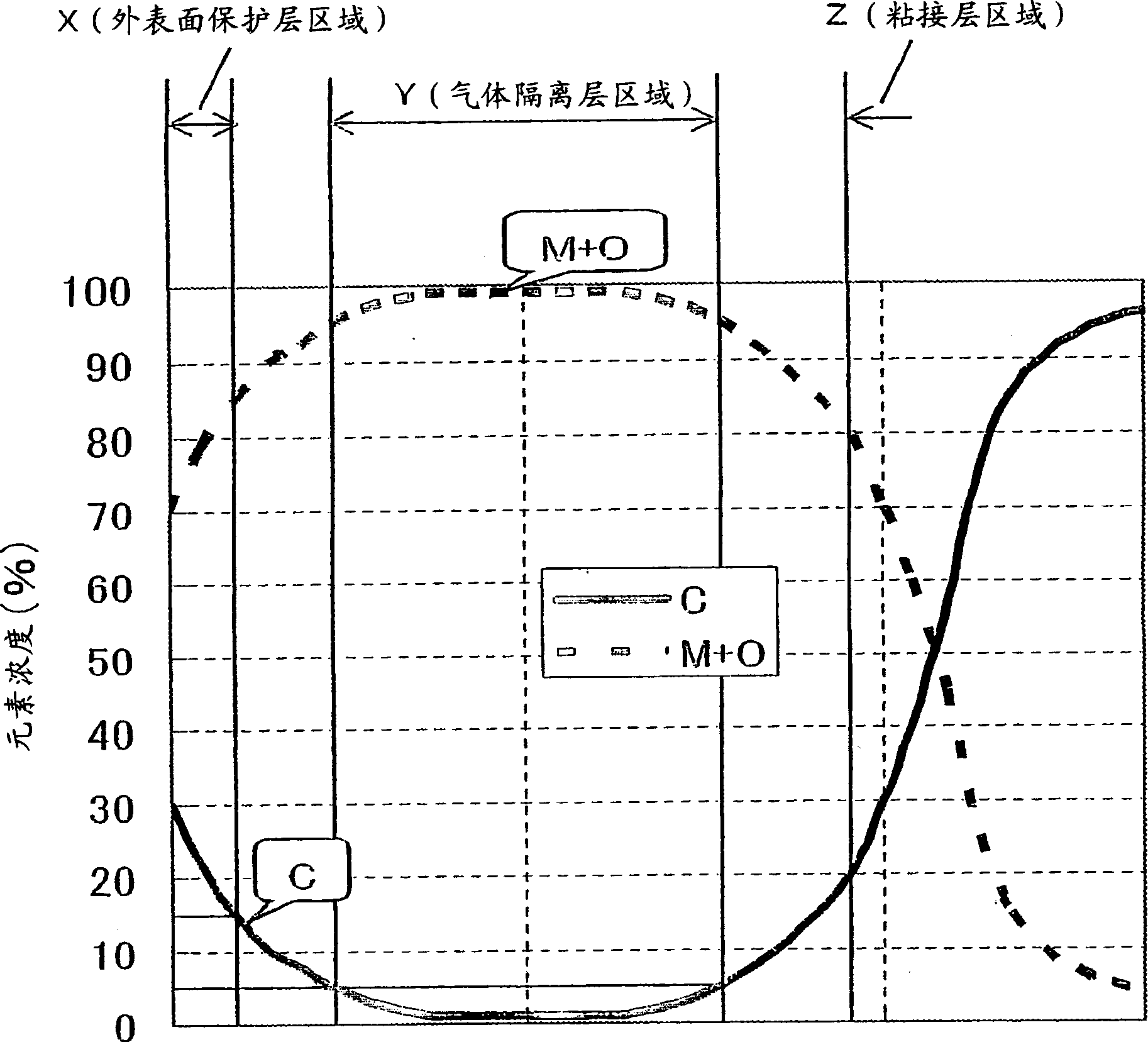

Chemical vapor deposition film formed by plasma cvd process and method for forming same

InactiveCN1795289AStable formationExcellent adhesionPretreated surfacesLinings/internal coatingsChemical treatmentSilicon oxide

A method of forming a vapor-deposited film by holding a substrate to be treated in a plasma processing chamber, and supplying an organosilicon compound and an oxidizing gas into the processing chamber to perform chemical plasma treatment to form a silicon oxide on the surface of a substrate. In this method, the vapor-deposited film is formed by maintaining a constant supply amount of the organosilicon compound gas in the plasma processing chamber and changing the supply amount of the oxidizing gas during the film-forming process for preparing the vapor-deposited film. It is a chemical vapor deposition film with excellent compatibility, flexibility, flexibility, oxygen barrier properties and moisture barrier properties.

Owner:TOYO SEIKAN KAISHA LTD

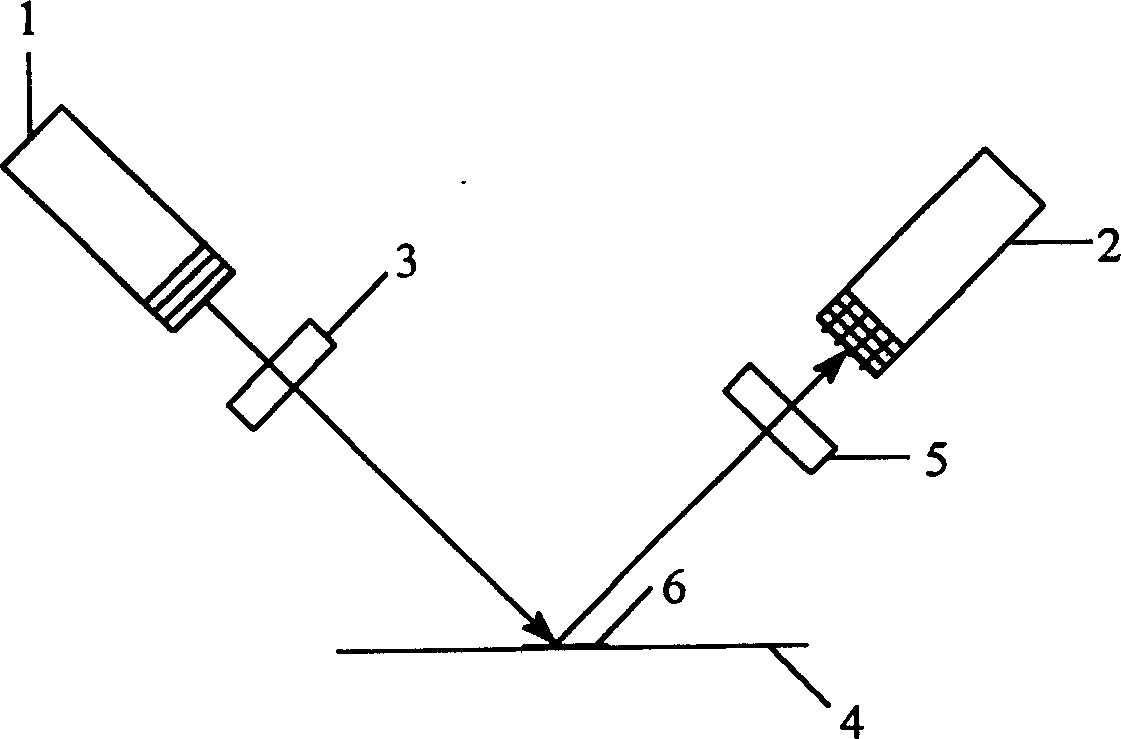

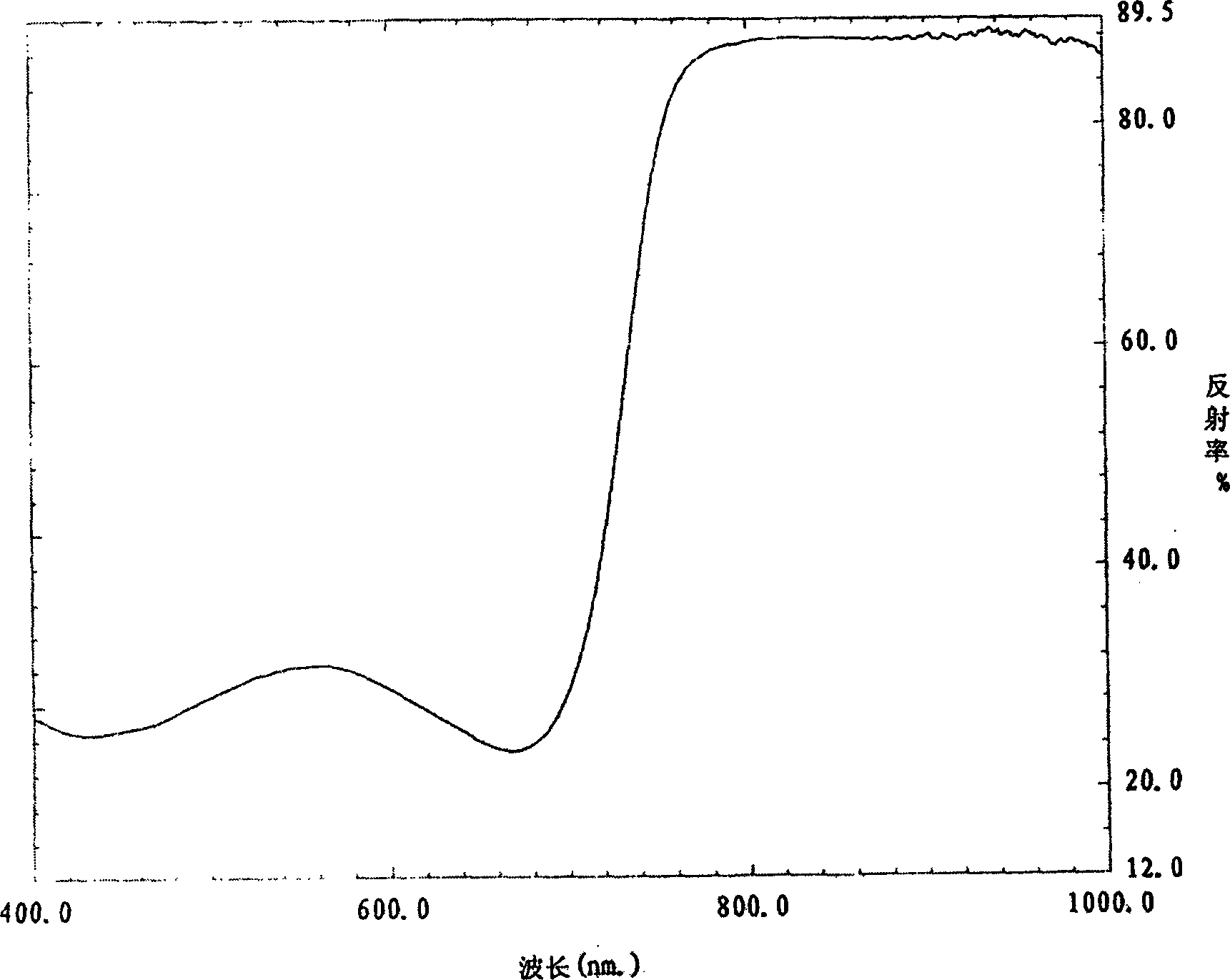

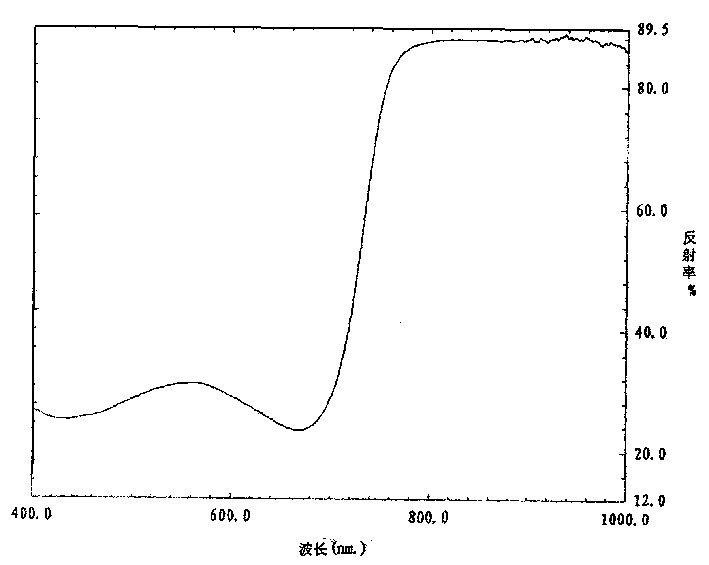

Luminous anti-forgery ink and its preparation method and use

The invention discloses a light anti-falsification printing ink and the preparing method. The printing ink contains a light material which can emit another visible light under the excitation of one visible light, the content of the material accounting for 20-50% of the printing-ink weight. The preparing method; making mixing, pre-separation and rolling on the light material and the printing-ink connecting material to get it. The printing ink can be used to the anti-falsification printing of the carrier like bill and to the carrier needing identification, and the detecting method; use the visible light to excite, and detect another one emitted from the impression.

Owner:CHINA BANKNOTE PRINTING & MINTING

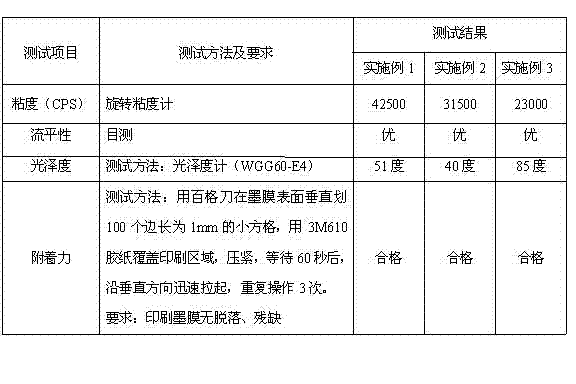

Silk-screen printing ink for polyethylene terephthalate material

The invention discloses a silk-screen printing ink for a polyethylene terephthalate (PET) material. The ink is composed of the following components in percentage by weight: 50-92% of polyester resin solution, 5-15% of aldehyde and ketone resin solution, 0.5-2% of defoamer, 0-0.5% of wetting agent, 0.5-3% of thickener and 0.5-2% of filler. The silk-screen printing ink for the PET material effectively overcomes the applicable limitation of the traditional ink for the PET material, has good resistance to viscose glue, has the characteristics of wide applicable materials, and is suitable for various PET materials. Because the ink disclosed by the invention mainly comprises polyester resin and an appropriate amount of auxiliary agents and filler, the ink has excellent use performance, has goodink layer leveling property and high hiding rate when used for silk-screen printing of PET and hardened surfaces, is suitable for high-mesh fine silk-screen printing, and has the advantages of dry ink layer, strong adhesion force of a coating film to the material, excellent water resistance, acid resistance, base resistance and impact resistance, and excellent temperature resistance, scratch and scrape resistance and glue water resistance.

Owner:深圳市美丽华科技股份有限公司

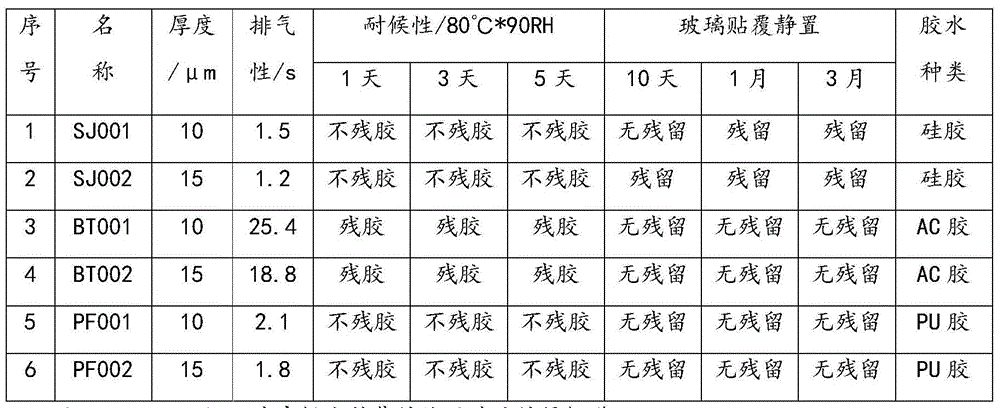

Polyurethane glue for protective film

InactiveCN106147683AReduce the difficulty of sticking the filmGood patienceFilm/foil adhesivesPolyureas/polyurethane adhesivesTectorial membraneWeather resistance

The invention discloses polyurethane glue for a protective film. The polyurethane glue is prepared by mixing 30%-60% by weight of a main agent with 30%-60% by weight of a dissolving agent and then adding 5%-20% by weight of a curing agent into the mixture. The glue has the good adhesiveness, good air exhaustion property and excellent weather resistance on plastic thin film substrates such as PET, PE and PC and can significantly improve the product quality of the protective film.

Owner:上海精珅新材料有限公司

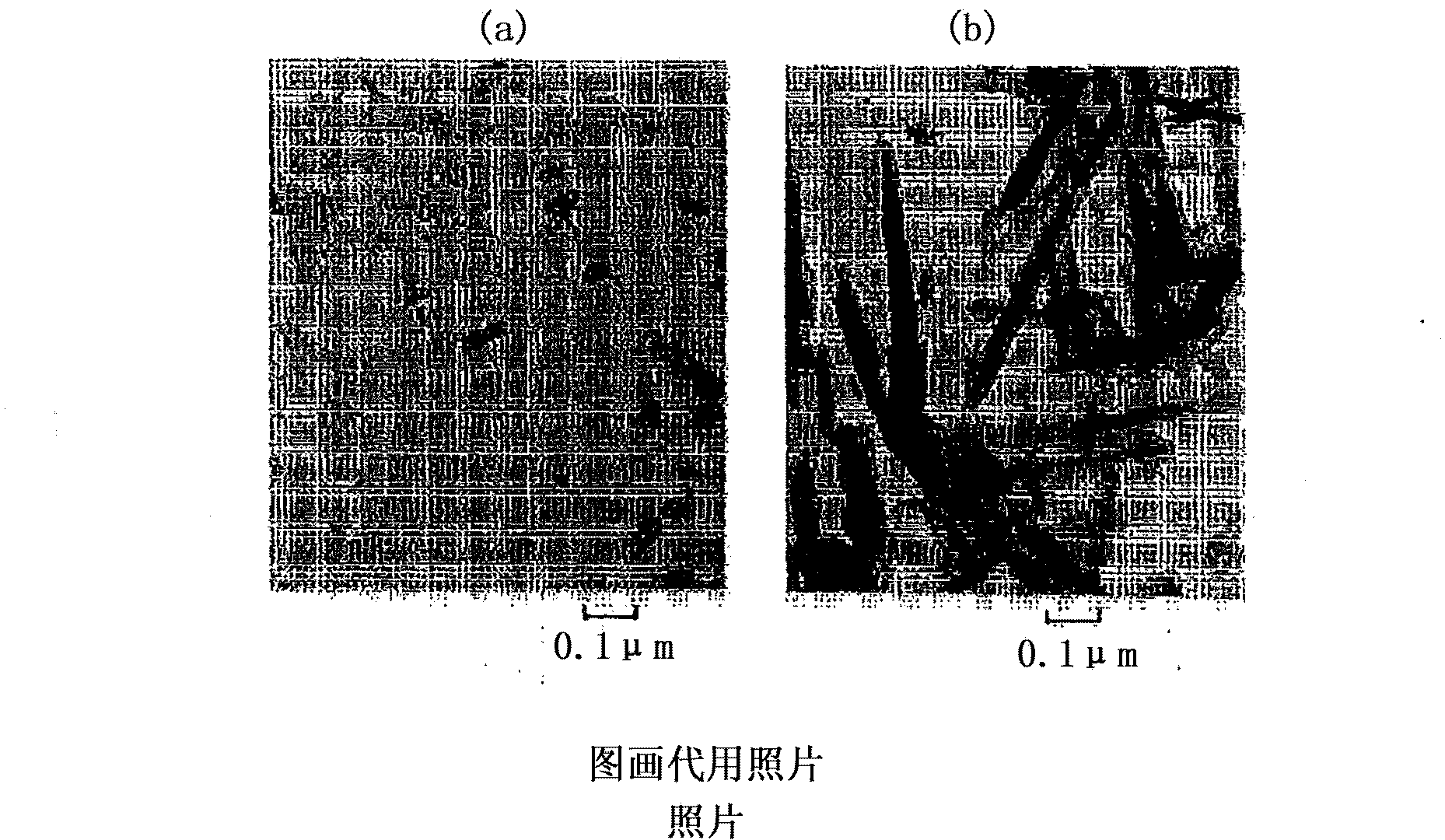

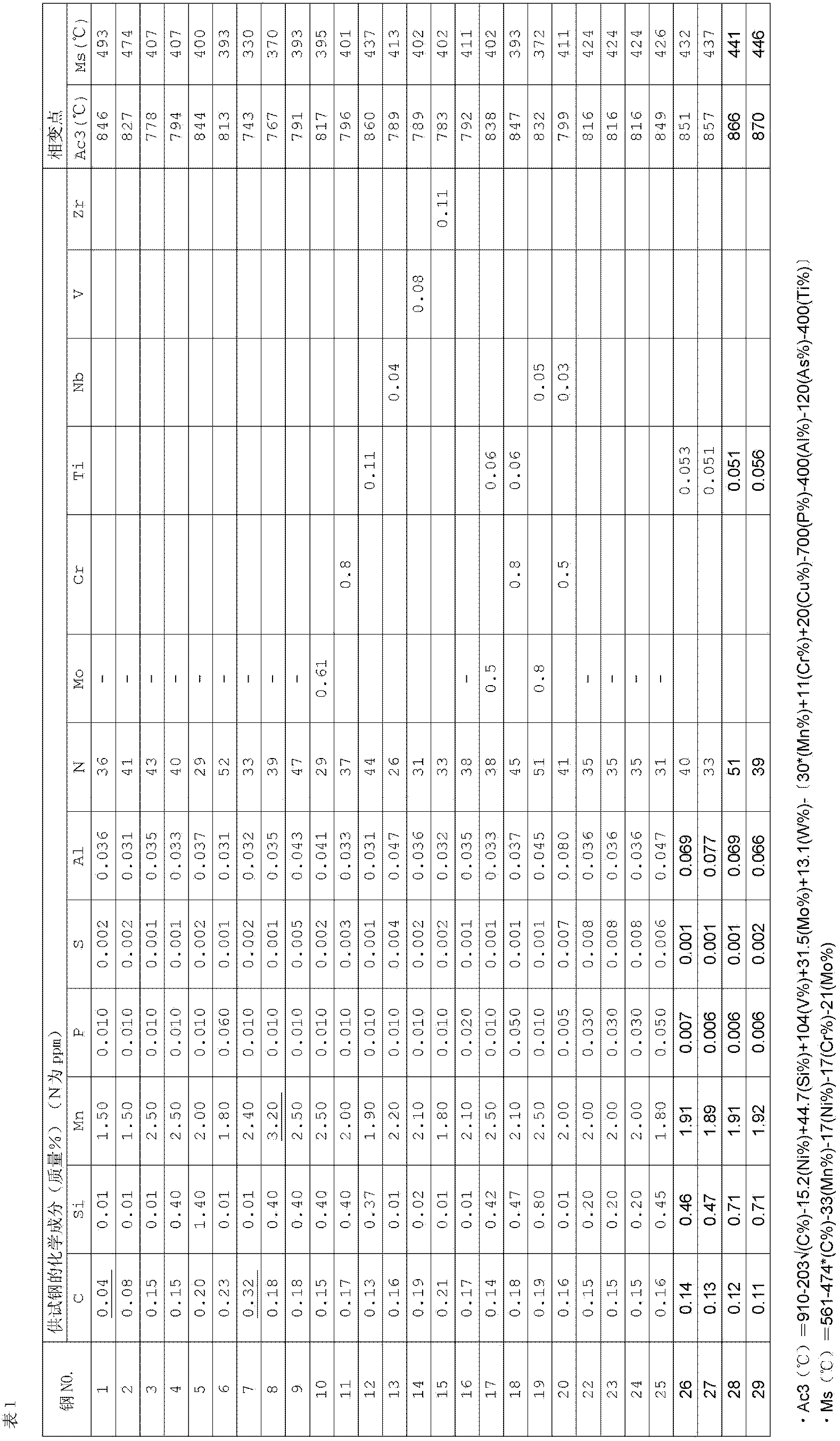

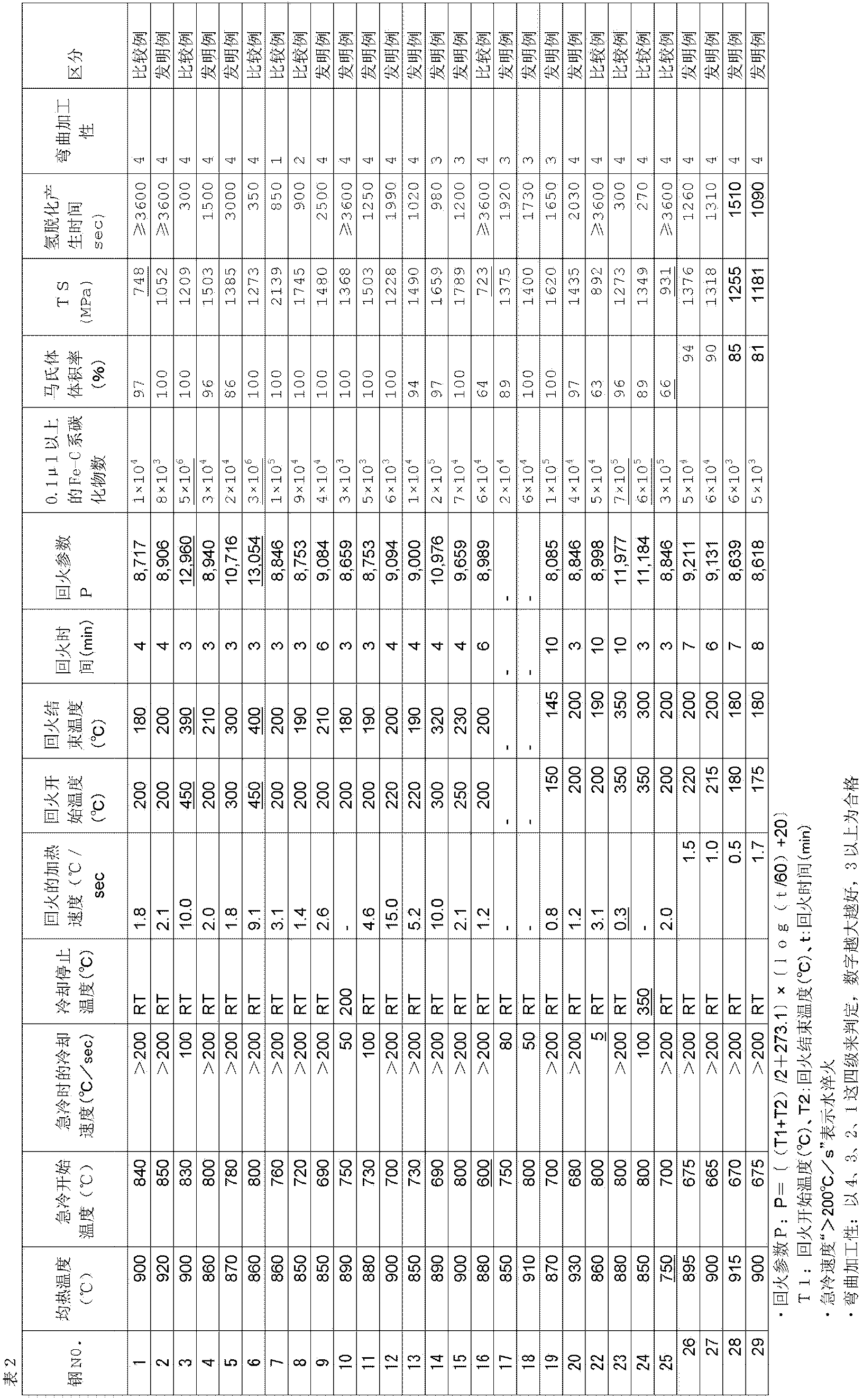

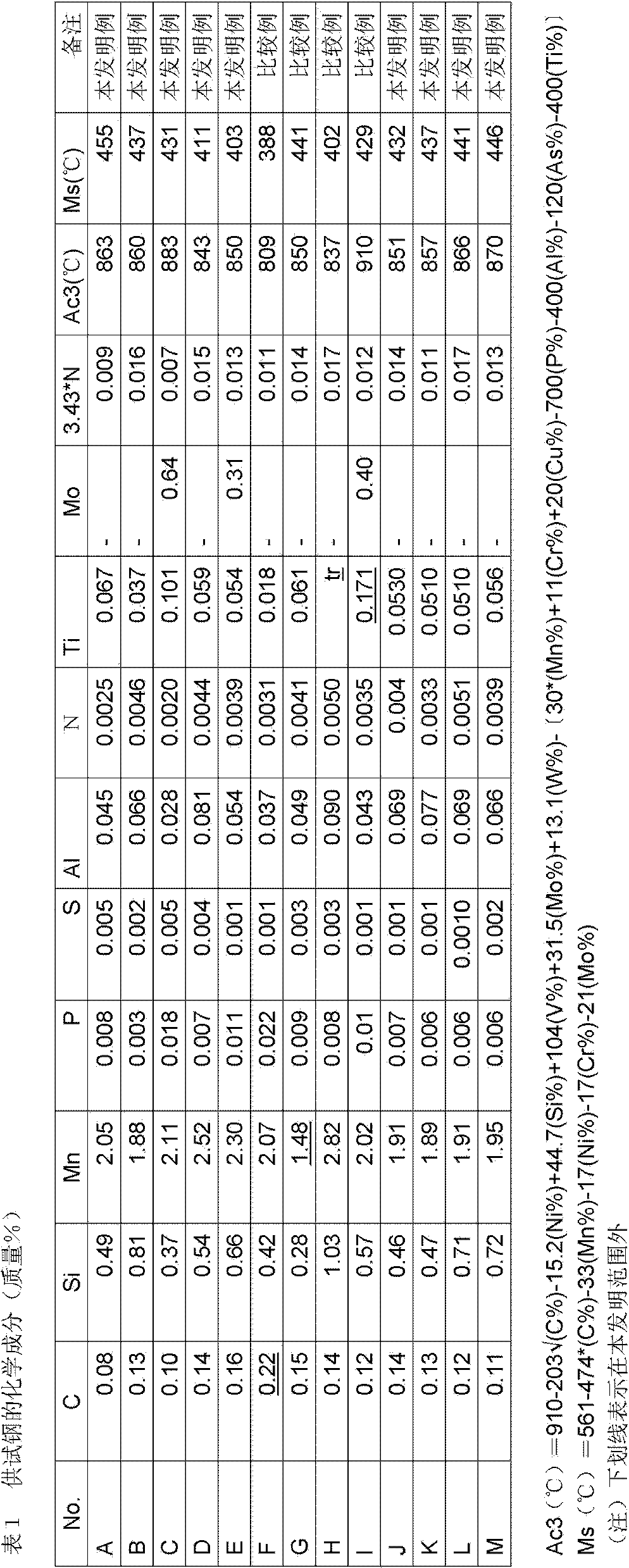

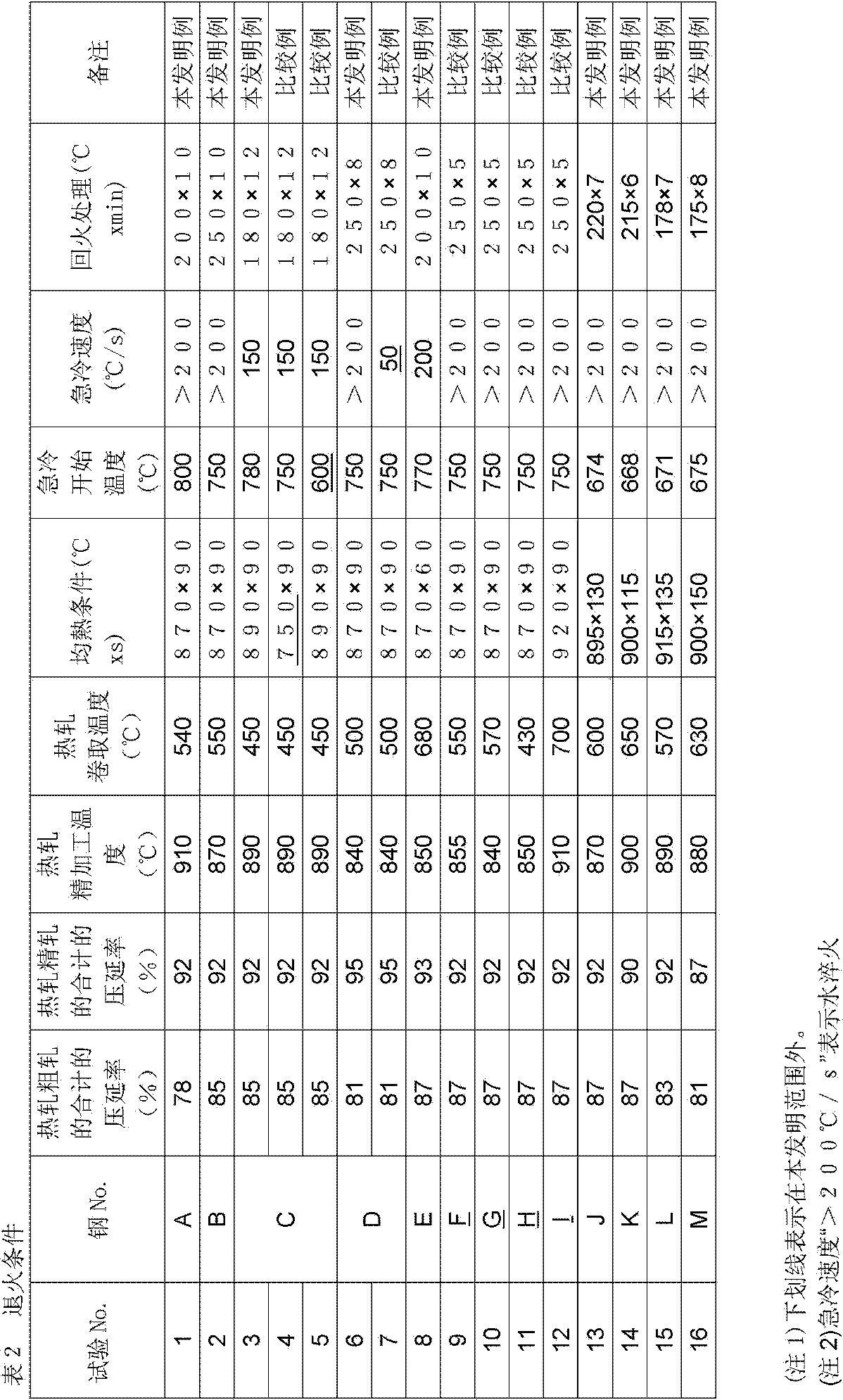

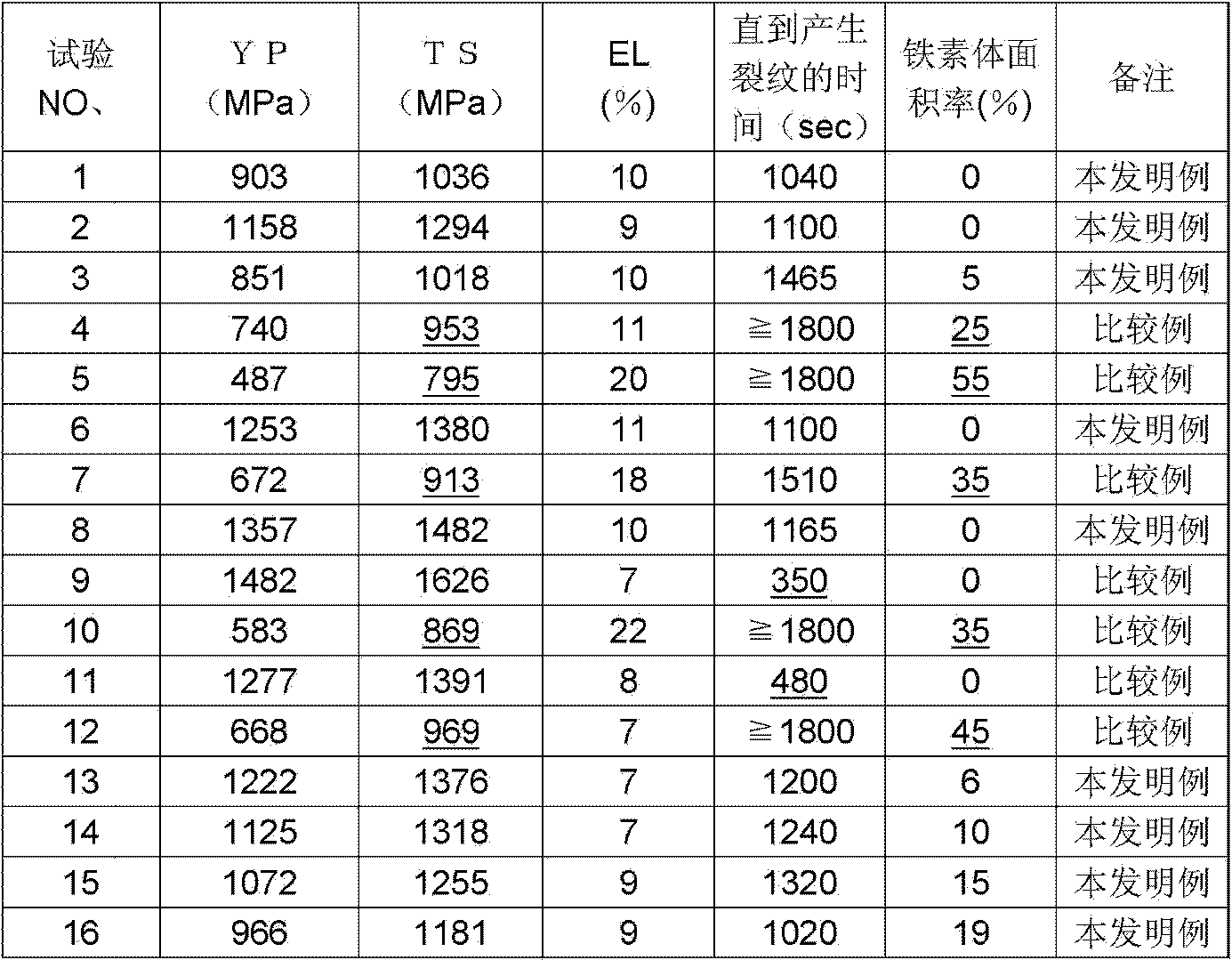

Ultra high strength steel sheet generating no hydrogen embrittlement and its manufacturing method

ActiveCN103572171AEasy to processRemarkable effect of light weightMartensiteUltimate tensile strength

The invention provides an ultra high strength steel sheet that has tensile strength of over 980MPa, generates no hydrogen embrittlement and is used for processing. The ultra high strength steel sheet generating no hydrogen embrittlement is composed of, by mass percent: 0.05-0.25% of C, 1.0-3.0% of Mn, 0.025-0.100% of Al, less than 0.01% of S, less than 0.008% of N, and the balance iron and unavoidable impurities. With tensile strength of more than 980MPa and a martensite content of over 70% by volume, the ultra high strength steel sheet is characterized in that the content of Fe-C system precipitates greater than 0.1 micrometer is less than 3*10<5> per 1mm<2>.

Owner:KOBE STEEL LTD

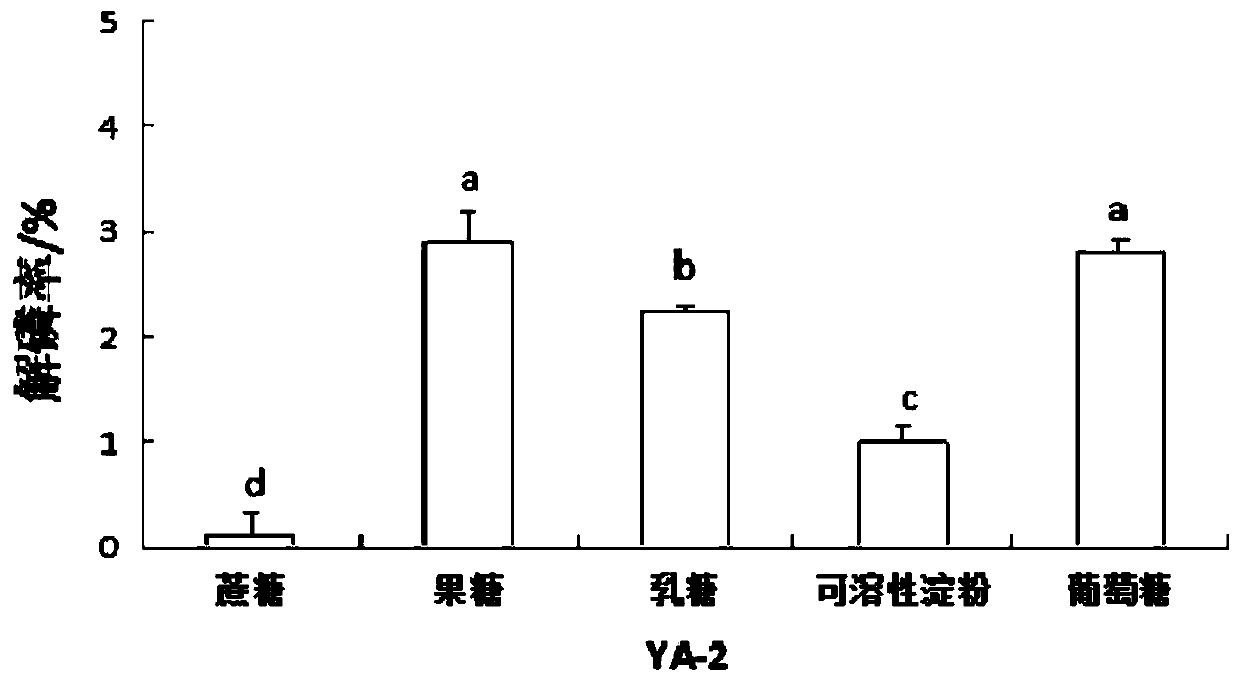

A kind of enterobacteriaceae bacterial strain with phosphate-solubilizing ability and application thereof

ActiveCN106318889BEnhance colonization abilityImprove utilization efficiencyBacteriaMicroorganism based processesBiotechnologyPhosphate

The invention discloses an Enterobacter strain with phosphorus-solubilizing ability and application thereof. The strain is classified as Enterobacter sp.YA-2 (Enterobacter sp.YA-2), and was deposited in the China Center for Type Culture Collection on March 7, 2016, with a preservation number of CCTCC NO: M 2016094. The bacterial strain provided by the invention is suitable for scrubbing tailings, and is also suitable for other insoluble phosphate and phosphorus-deficient soils. The strain can convert the insoluble phosphate in the scrubbing tailings into soluble phosphate, thereby improving the utilization efficiency of the scrubbing tailings. By studying its most suitable growth conditions and its salt and alkali resistance, temperature resistance, etc., and The bacterial strain is inoculated in the acidic red soil, the colonization ability of the bacterial strain is strong, and the dry weight and the fresh weight of the pakchoi are significantly improved, so it is suitable for increasing the output of crops.

Owner:YUNNAN PHOSPHATE CHEM GROUP CORP

High-crack resistance resistant fire-proof stopper

InactiveCN109266215AReduce in quantityFine-grained structureConjugated diene hydrocarbon coatingsStress concentrationTetramethylammonium hydroxide

The invention relates to a high-crack resistance resistant fire-proof stopper, and belongs to the field of refractory materials. According to the high-crack resistance resistant fire-proof stopper, serpentine and dolomite are treated, the number of harmful pores is reduced, a fine structure of a fire-proof crack-resistant base material is refined, the compactness is improved, stress concentrationis reduced, expansion stress is relieved, cracks due to a hard heat effecthigh temperature are avoided, a rheological agent and sodium metasilicate are introduced for wrapping and assisting in fillingof stopper pores, and the compaction and a thermal crack resistance effect of the base material are improved; octamethylcyclotetrasiloxane, tetramethylammonium hydroxide and the like are used as rawmaterials, so that the internal stability of the high-crack resistance resistant fire-proof stopper is improved, and different levels of expansions which is generated after heating is conducted is reduced; coal ash is subjected to pre-treatment, so that the bonding strength in a system is further improved, the treated coal ash further plays a part inand further filling and toughening effects are realized, the problem that under heating action, the stopper cracks due to heating can be effectively solved, and the internal mechanical performance is improved. By means of the high-crack resistanceresistant fire-proof stopper, the problems that currently, commonly used fire-proof stoppers are prone to crack in the presence of heat, and the internal mechanical performance is poor are solved.

Owner:佛山齐安建筑科技有限公司

Abrasion-proof sheet metal and preparation method thereof

The invention provides abrasion-proof sheet metal and a preparation method thereof, and relate to the technical field of production of abrasion-proof materials. The abrasion-proof sheet metal is prepared from the following components in percentage:1.9-3.1% of C, 0.4-0.6% of Si, 0.2-0.8% of Mn, 0.2-0.6% of Mu,11.5-13.5% of Cr, S which is smaller than or equal to 0.10%, P which is smaller than or equal to 0.10%, 0.5-1.5% of Mo, 0.05-0.15% of V, 0.1-1.0% of Ti, 0.3-1.0% of Cu, and the balance being Fe. The preparation method comprises the following steps of melting raw materials; performing constant-temperature pouring; performing heat treatment, heating the sheet metal shaped through pouring for 3-5 hours at the temperature of 700-720 DEG C, performing warming until the temperature is 800-900 DEG C, performing quenching in quenching oil for 7-10 minutes at the temperature of 90-100 DEG C, and then performing tempering for 6-10 hours at the temperature of 300-350 DEG C; and performing heat treatment once again, putting the sheet metal obtained after the heat treatment in high-temperature-resistant silicone oil for soaking for 3-5 hours, fishing out the sheet metal, and removing external silicone oil. The abrasion-proof sheet metal disclosed by the invention is impact-resistant, long in service life, and good in abrasion resistance, so that the abrasion-proof sheet metal can be used in serious environment, and can resist strong corrosion and ultrahigh temperature.

Owner:安徽创新电磁离合器有限公司

Efficient grinding ball special for environment-friendly mill of cement plant and manufacturing method of efficient grinding ball

The invention provides an efficient grinding ball special for an environment-friendly mill of a cement plant and a manufacturing method of the efficient grinding ball and relates to the technical field of wear-resistant material production. The efficient grinding ball is characterized by comprising 1.9% to 3.1% of C, 0.3% to 0.9% of Si, 0.2% to 0.8% of Mn, 11.5% to 13.5% of Cr, not larger than 0.10% of S, not larger than 0.10% of P, 0.5% to 1.5% of Mo, 0.05% to 0.15% of V, 0.1% to 1.0% of Ti, 0.3% to 1.0% of Cu and the balance Fe. The method includes the following steps that firstly, raw materials are smelted at the temperature from 1490 DEG C to 1550 DEG C; secondly, constant-temperature casting is performed at the temperature from 1440 DEG C to 1500 DEG C; and thirdly, thermal treatment is performed, wherein the raw materials are heated at the temperature from 700 DEG C to 720 DEG C for 7 hours to 10 hours, the temperature is increased to 960 DEG C to 990 DEG C, and the raw materials are quenched for 7 minutes to 15 minutes in quenching oil at the temperature from 110 DEG C to 145 DEG C and annealed for 8 hours to 10 hours at the temperature from 330 DEG C to 380 DEG C. The efficient grinding ball is resistant to impact, long in service life and good in abrasion resistance, so that the efficient grinding ball adapts to the severe ball-milling working condition environment, and the HRC ranges from 60 to 65; the impact value is larger than or equal to 6.5 J / cm<2>; the fallen ball impact fatigue service life is larger than 40000 times; and strong corrosion and ultra-high temperature are resisted.

Owner:ANHUI RUITAI NEW MATERIALS TECH

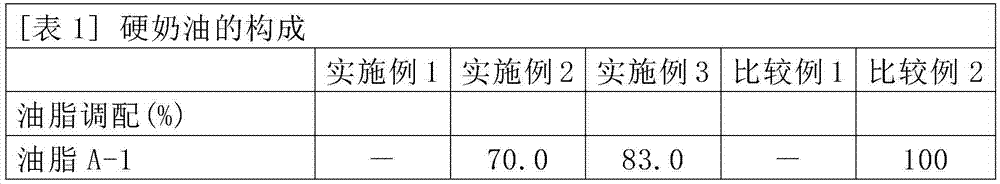

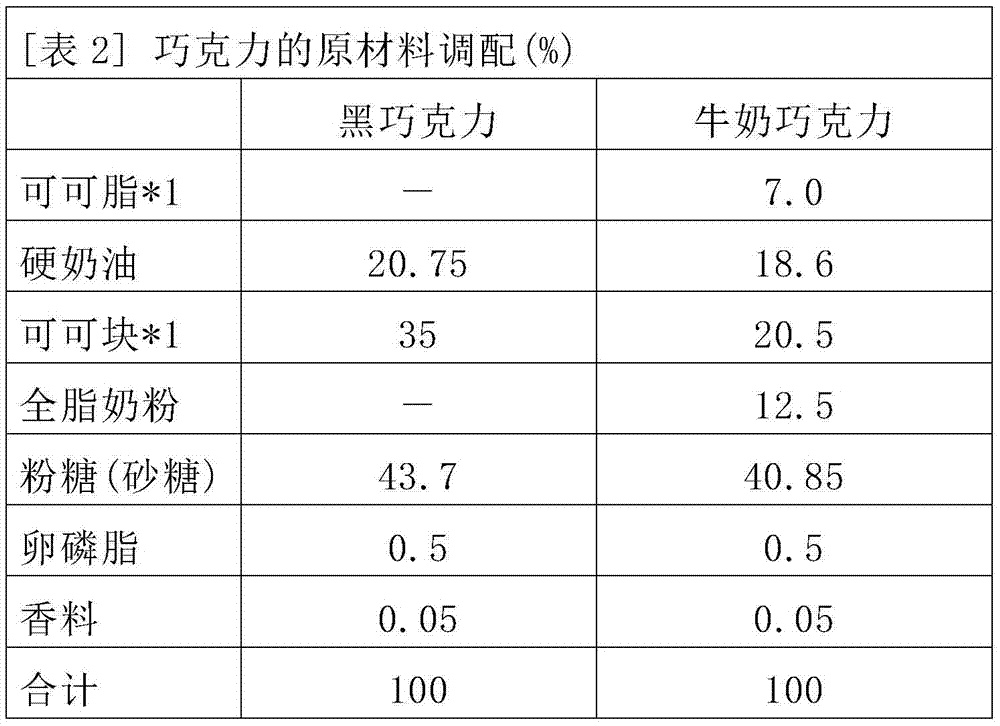

Chocolate and hard butter

ActiveCN105451568AGood patienceSoft and refreshing palatabilityCocoaEdible oils/fatsFat contentShea butter

Provided is a chocolate that can be molded into a block or plate shape or granulated and which has a soft and refreshing melt-in-the-mouth effect (spreading softly in the mouth with a cooling, refreshing effect). Also provided is a hard butter suitable for production of said chocolate. The chocolate has an oil and fat content of 25-65 mass% and the oil and fat fulfill conditions (1)-(5). (1) The SOS content is 65-88 mass%. (2) The POP content is 25-44 mass%. (3) The StOSt content is 10-25 mass%. (4) The POSt content is 15-32 mass%. (5) The liquid oil and fat content is at least 9 mass% and less than 14 mass%.

Owner:THE NISSHIN OILLIO GRP LTD

Ultrahigh strength cold rolled steel sheet with superior hydrogen embrittlement resistance and manufacturing method thereof

The invention provides an ultrahigh strength steel sheet used for processing and a manufacturing method thereof. The ultrahigh strength steel sheet has tensile strength of 980-1670MPa and superior hydrogen embrittlement resistance, and comprises, by mass%: 0.05-0.17% of C, 0.2-1.5% of Si, 1.7-3.5% of Mn, less than or equal to 0.030% of P, less than or equal to 0.010% of S, 0.025-0.120% of Al, less than or equal to 0.0100% of N, 3.43*N-0.150% of Ti, and the balance iron and unavoidable impurities.

Owner:KOBE STEEL LTD

Resin composition, resin composition sheet, semiconductor device and method for manufacturing same

InactiveCN103958602AReduce melt viscosityGood storage stabilityNon-macromolecular adhesive additivesSolid-state devicesInorganic particleInorganic particles

Owner:TORAY IND INC

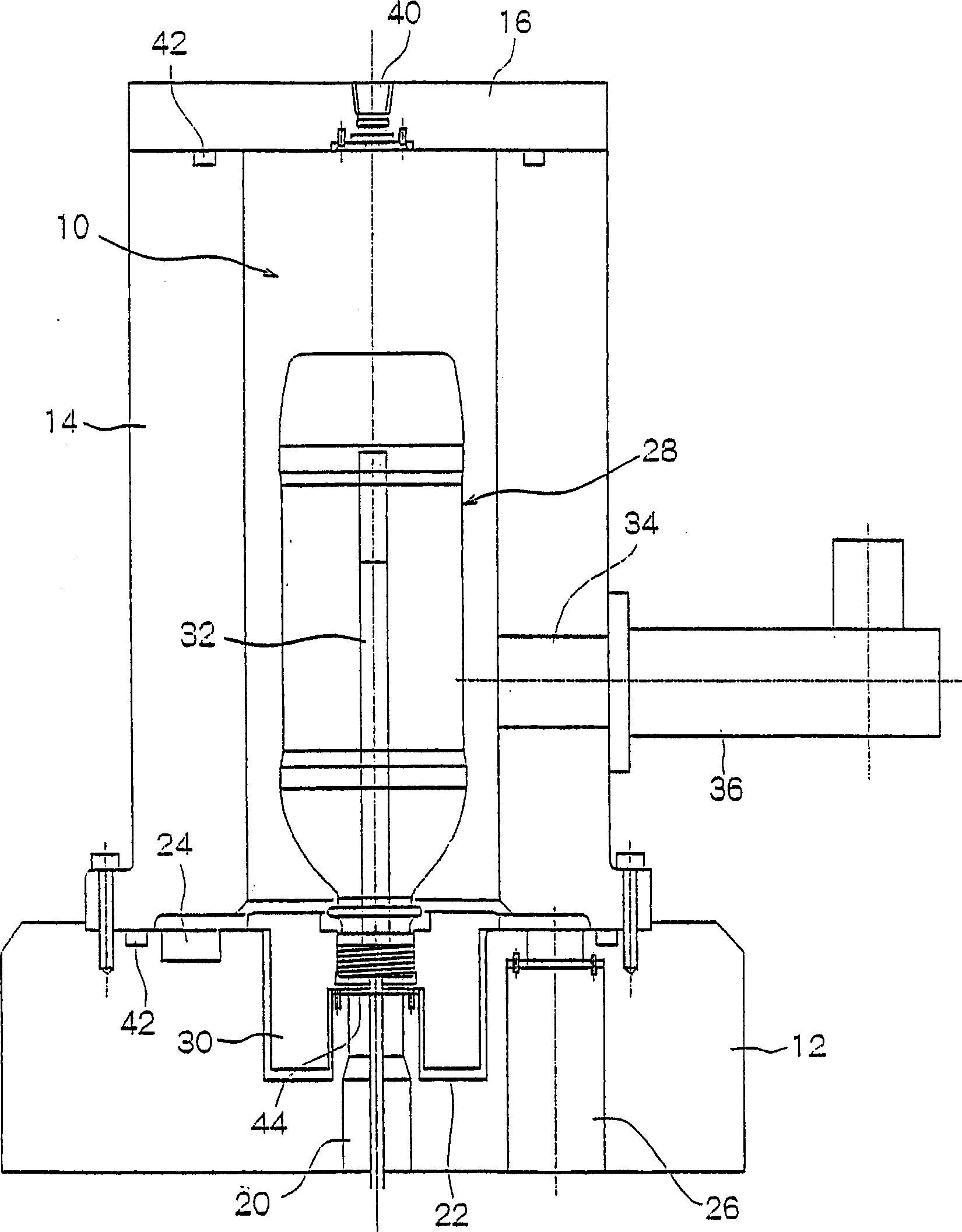

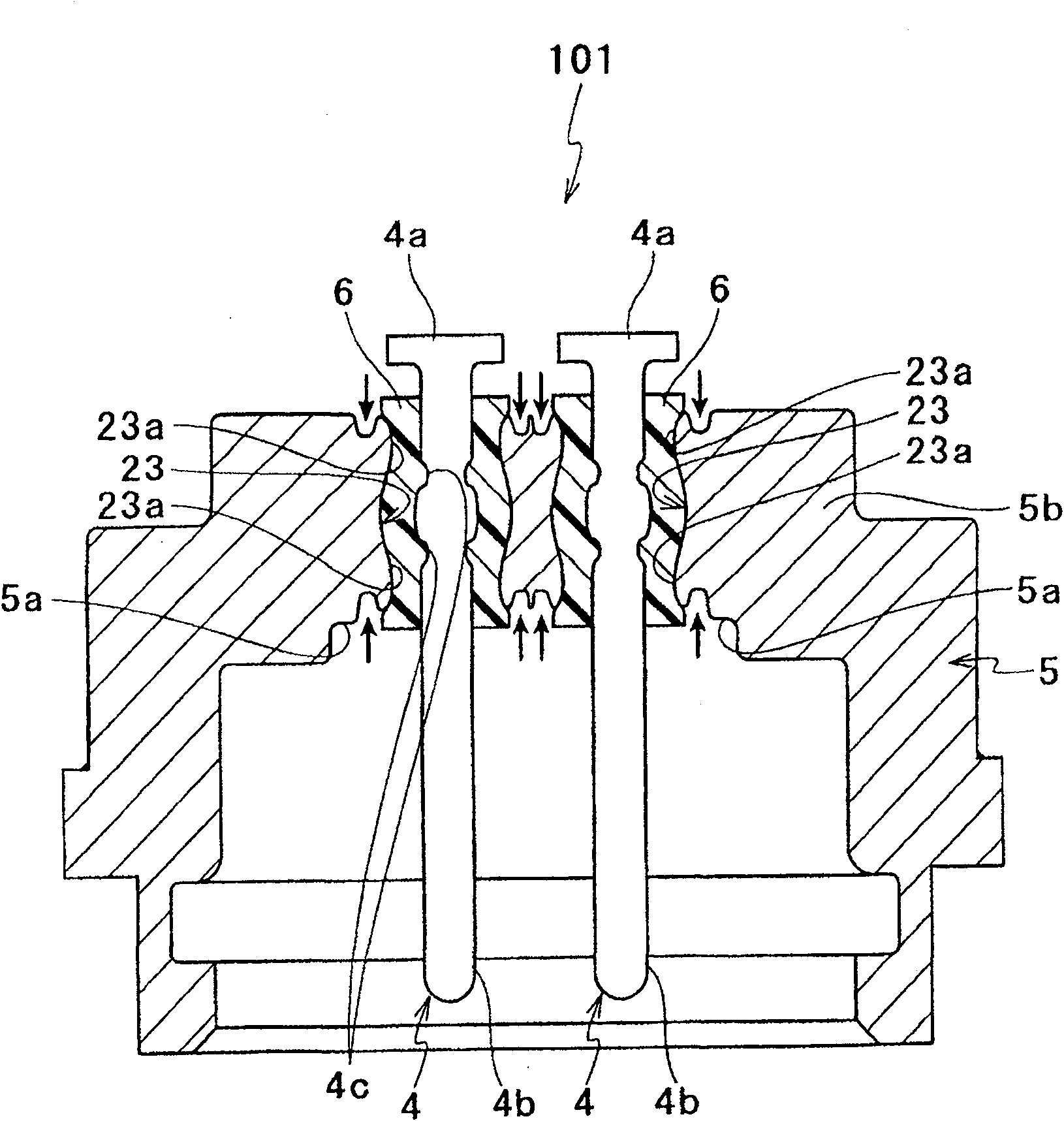

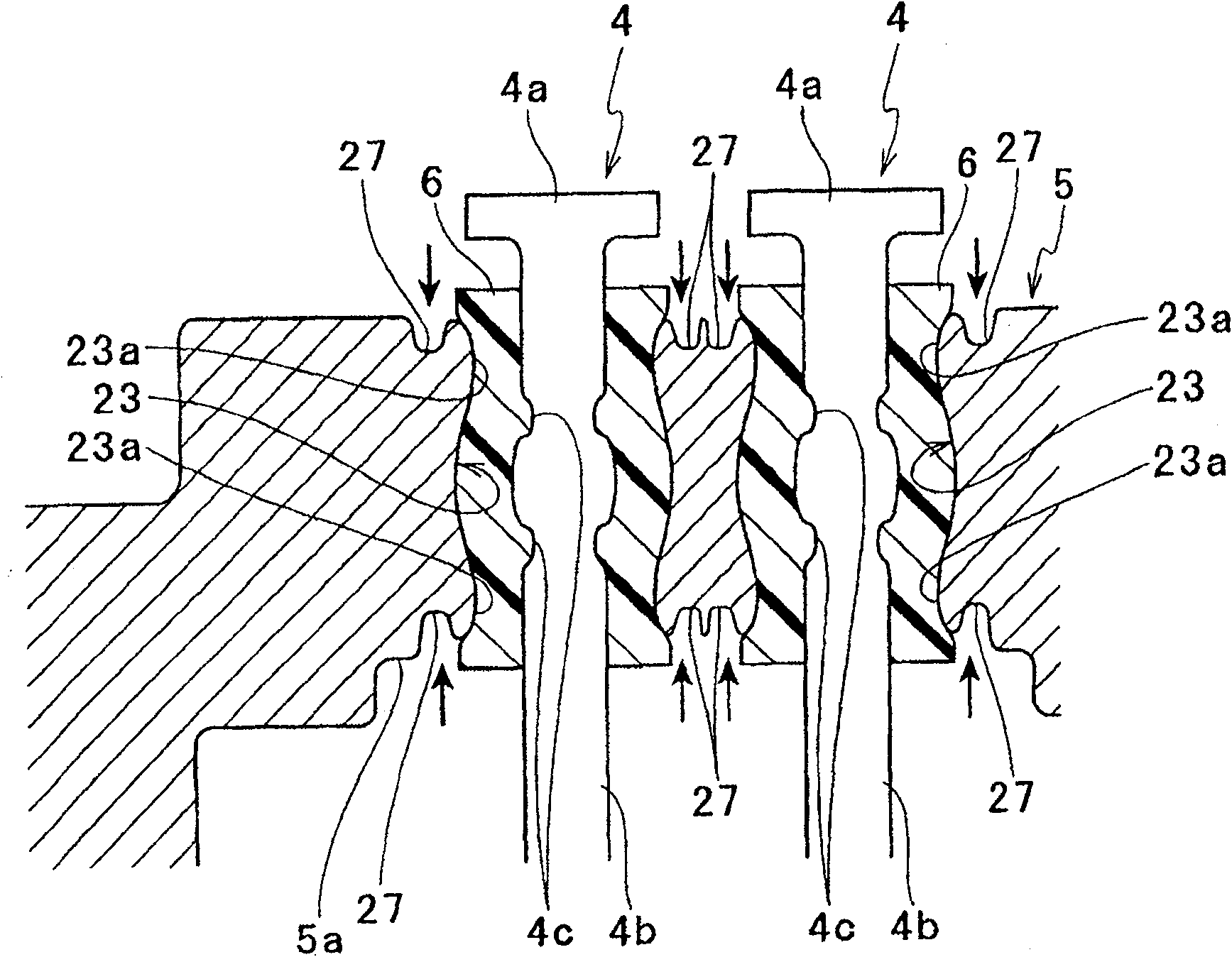

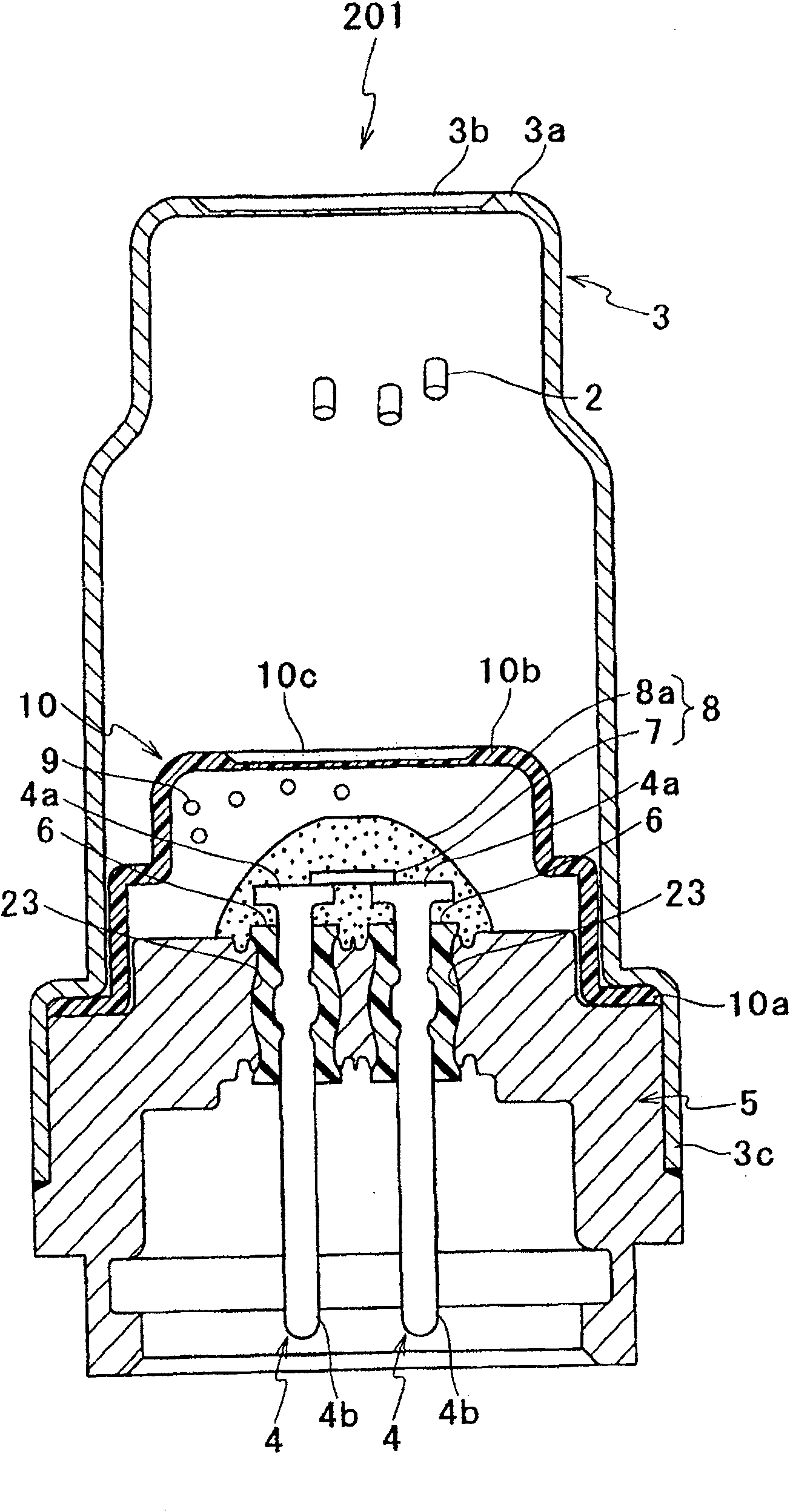

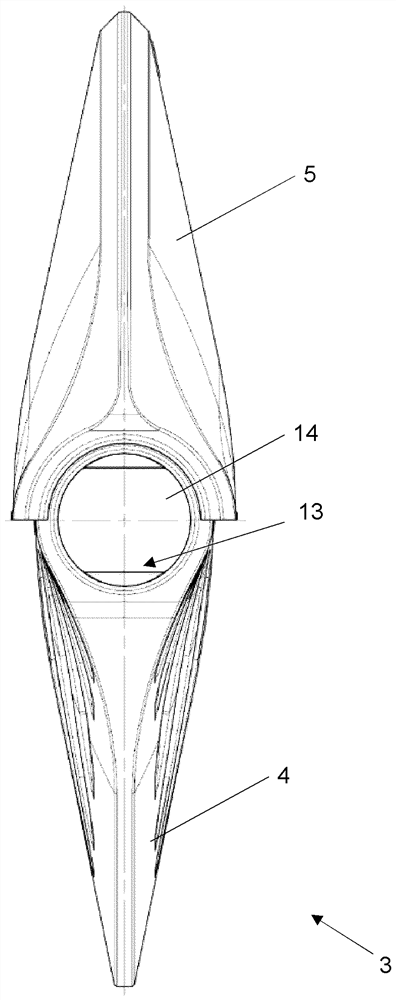

Metal holder with electrode pin, method of manufacturing the metal holder, and gas generator

InactiveCN100554046CReduce the numberNot easy to fly outBelt retractorsBlasting cartridgesEngineeringGas generator

The present invention provides a method for inexpensively manufacturing a metal holder with an electrode pin suitable for use as a gas generator and having excellent sealing properties. Even if the gas generator is operated at high temperature, the electrode pin is less likely to fly out. The present invention provides a metal holder with an electrode pin, a manufacturing method thereof, and a gas generator having the metal holder with an electrode pin. The metal holder with an electrode pin is characterized by having A metal holder (5) and two or more electrode pins (4) for conducting electricity, the head portion (4a) of each of the electrode pins (4) having a diameter larger than the terminal portion (4b) of the electrode pin (4) with a diameter of Each electrode pin (4) is fixed in the hole (23) via the plastic member (6), and has a reduced diameter portion (23a) in a part of the hole (23).

Owner:NIPPON KAYAKU CO LTD

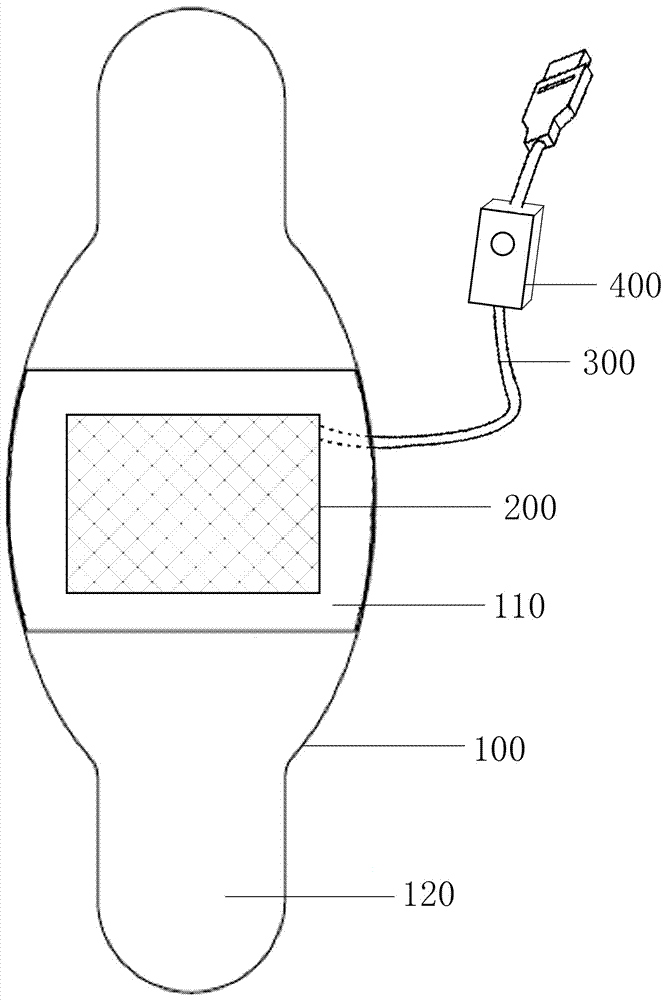

Pillow towel having health-care function

InactiveCN107259900APromote thermoregulation effectFacilitate the resonance effectElectrotherapyBlanketHuman bodyCarbon fibers

The invention relates to the field of auxiliary supplies for cervical vertebra rehabilitation and prevention and discloses a pillow towel having a health-care function. The pillow towel comprises a pillow towel body and connecting bodies located on two sides of the pillow towel body, wherein the connecting bodies on two sides are mutually and movably connected, a heating piece is arranged in the pillow towel body, and a material for the pillow towel body includes bamboo charcoal powder, tourmaline powder and germanium powder according to the weight part ratio of 10-30 to 7-9 to 2. The heating piece adopts a carbon fiber woven net structure. The pillow towel integrates the heating piece and the tourmaline powder and the germanium powder, the infrared ray transmitting rate, the negative air ion releasing amount and an ion permeation effect are improved through the joint effect of temperature rise and human body extrusion, the blood circulation and metabolism of the human body are further promoted, and the pillow towel has an excellent thermal-therapy health-care effect.

Owner:广东安胜仪器有限公司

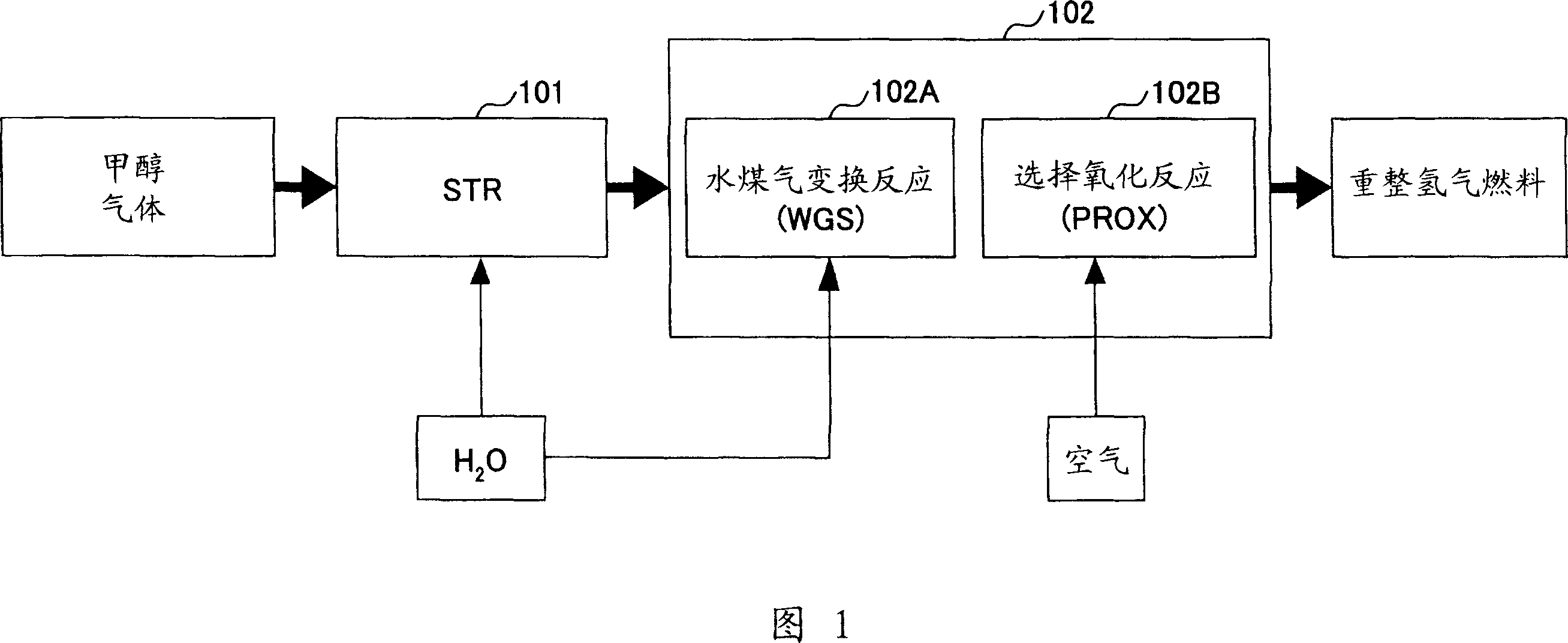

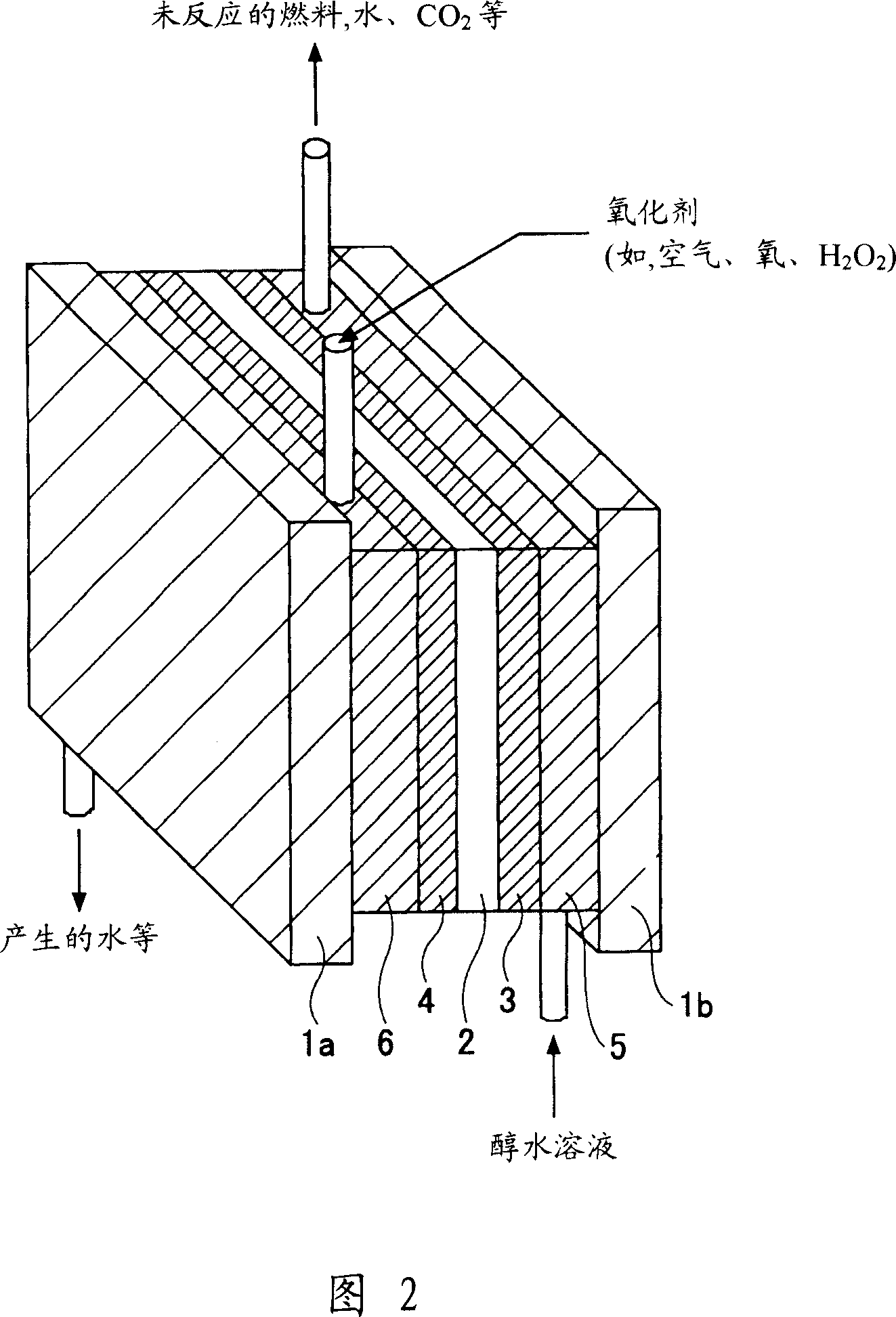

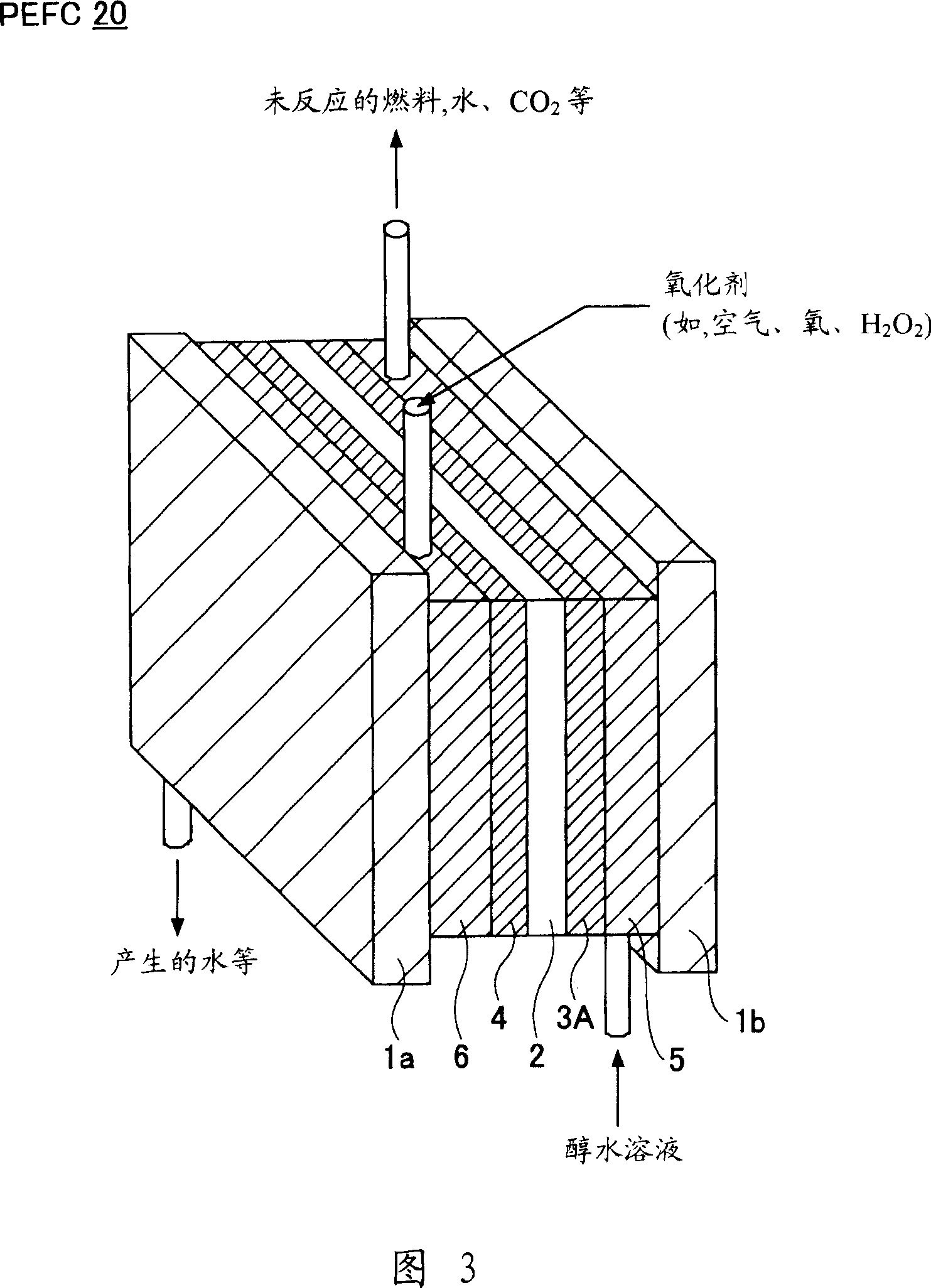

Electrode catalyst, method for manufacturing the same, and direct alcohol fuel cell

InactiveCN1922746AReduce usageHigh electromotive forceFuel cells groupingCell electrodesPlatinumPtru catalyst

Owner:RICOH KK

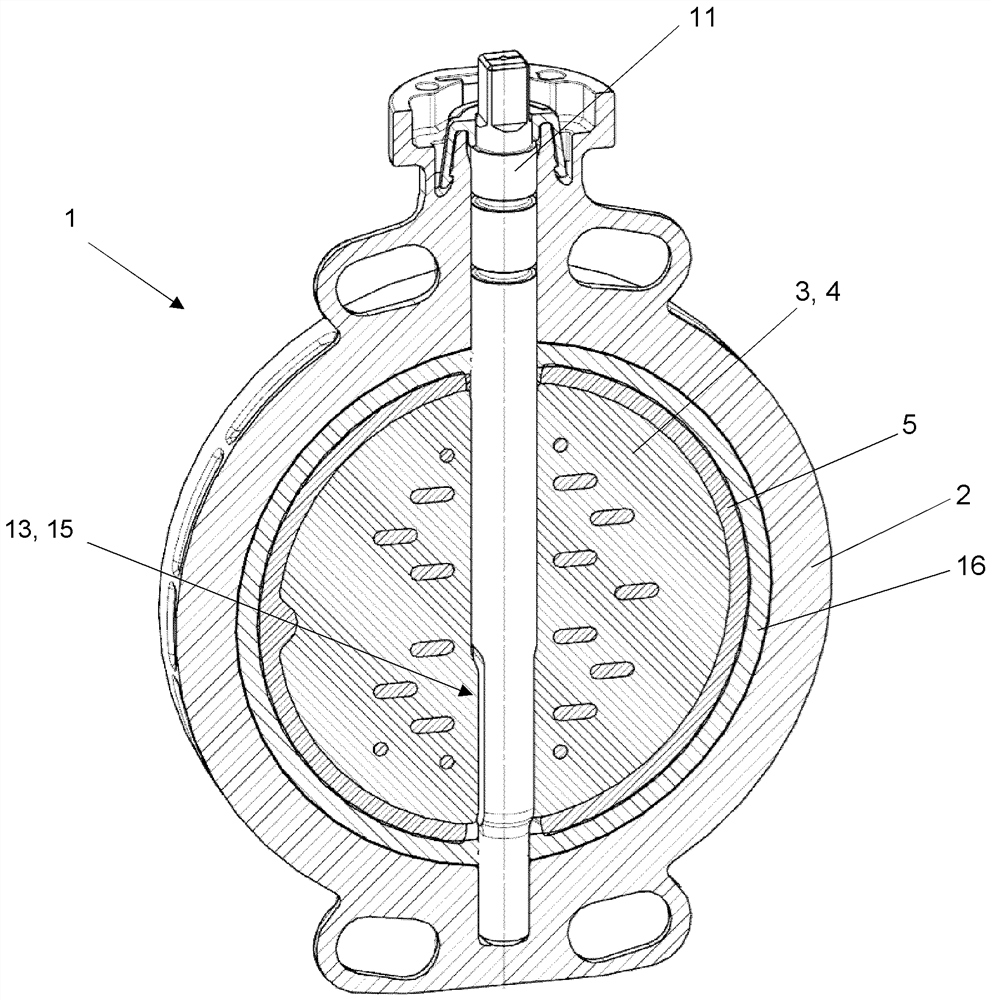

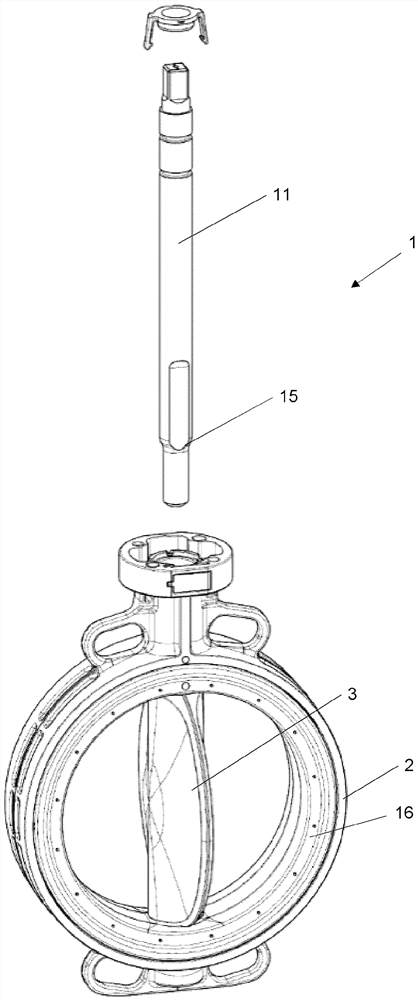

Butterfly valve

The invention relates to a butterfly valve. A butterfly valve for shutting off or regulating a medium, which flows through a pipeline, contains a housing, a disc and a shaft, wherein the housing is configured in one piece and is preferably composed of plastic, the disc can be pivoted along the shaft between an open position and a closed position, the disc comprises a core composed of plastic and ashell composed of plastic, and the plastic of the core and the plastic of the shell are different.

Owner:GEORG FISCHER PIPING SYST PLC

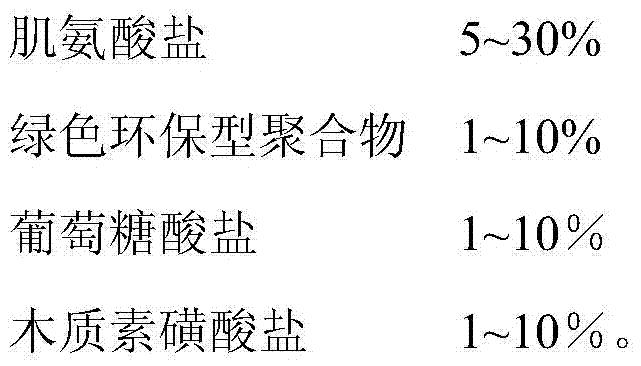

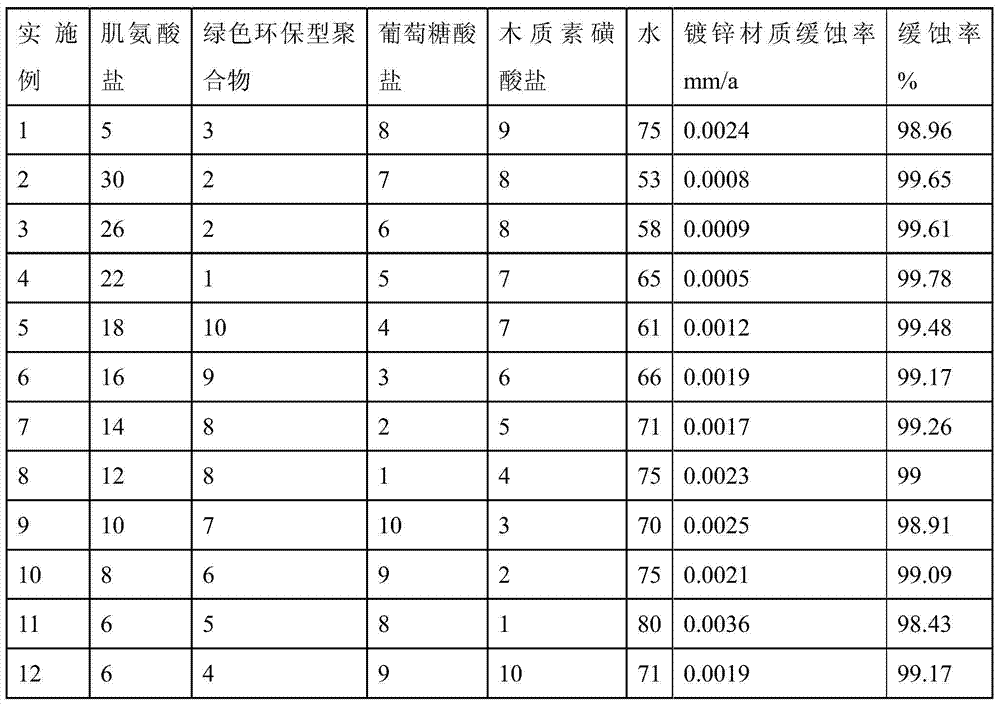

A high-performance sealed environment-friendly carbon steel corrosion inhibitor and its preparation and application

The invention discloses a high-performance, closed and environment-friendly carbon steel corrosion inhibitor. With the total mass of the corrosion inhibitor as a benchmark, besides water, the corrosion inhibitor further comprises the following raw material components in percentage by weight: 1-30% of sarcosinate, 1-10% of environment-friendly polymer, 1-10% of gluconate, 1-5% of lignin and the balance of water. The high-performance, closed and environment-friendly carbon steel corrosion inhibitor disclosed by the invention is suitable for corrosion inhibition treatment of carbon steel pipelines of closed circulating refrigerated water systems, and can effectively reduce the corrosion rate of the carbon steel material and well protect the carbon steel pipelines; the formula is environmentally friendly and is biodegradable, and system drain contamination is not worsen water body pollution, thereby reducing the sewage treatment cost and conforming to the current general trend of environmental protection development.

Owner:SHANGHAI YIKE GREEN ENG

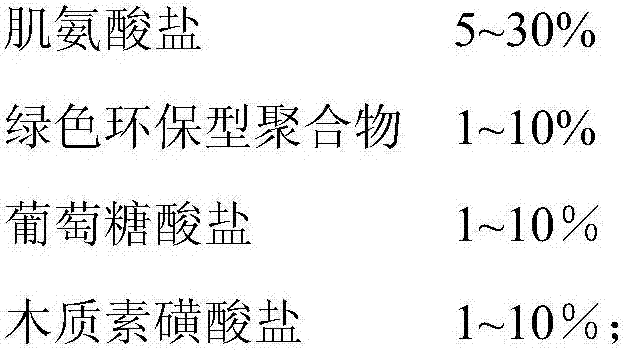

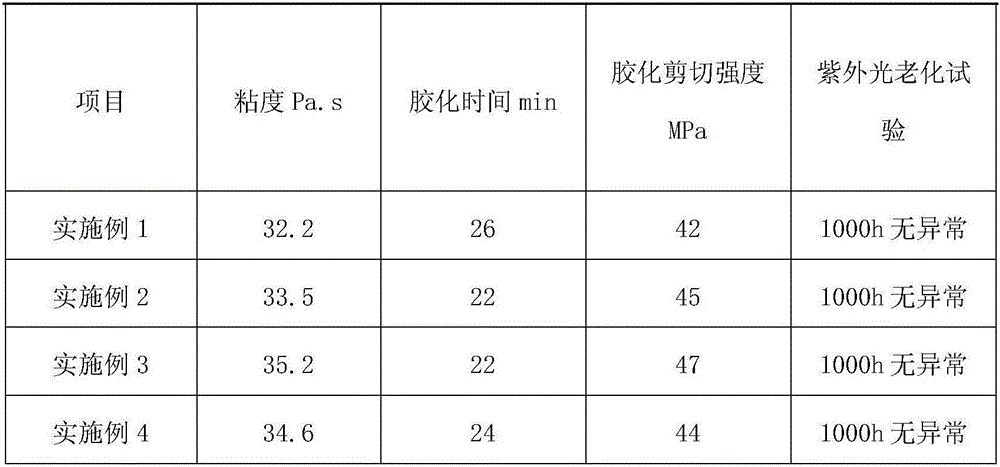

Glass cement and preparation method thereof

InactiveCN106833399AGood adhesivenessShort gel timeNon-macromolecular adhesive additivesMacromolecular adhesive additivesPolyethylene glycolStearic acid

The invention discloses glass cement and a preparation method thereof. The glass cement is prepared from the following components: 2-ethyl cyanoacrylate, polyvinyl butyral, soft butadiene styrene rubber, diethylamino ethyl methylacrylate, carnauba wax, an anti-oxidant, stearic acid, sodium silicate, silicon dioxide, polyethylene glycol and aluminum oxide. A preparation process comprises the following steps: uniformly mixing the 2-ethyl cyanoacrylate, the soft butadiene styrene rubber, the polyvinyl butyral and the carnauba wax, thus obtaining a mixture I; then transferring the mixture I into a reaction kettle, adding the diethylamino ethyl methylacrylate, the sodium silicate, the silicon dioxide and the aluminum oxide, and heating and reacting under a vacuum condition, thus obtaining a mixture II; finally, adding the anti-oxidant, the stearic acid and the polyethylene glycol into the mixture II, and uniformly stirring and mixing, thus obtaining the glass cement. The glass cement provided by the invention has good adhesion performance and good light aging resistance, and can be well applied to glass adhesion.

Owner:ZHENJIANG HUAYU ENVIRONMENTAL PROTECTION EQUIP MFG

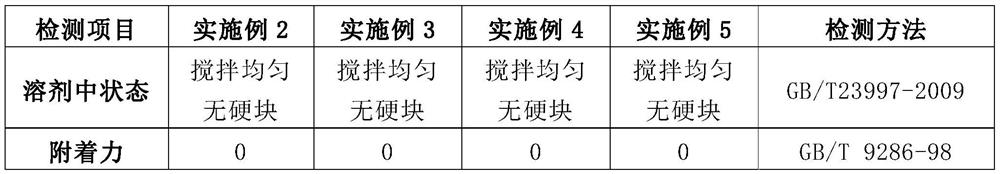

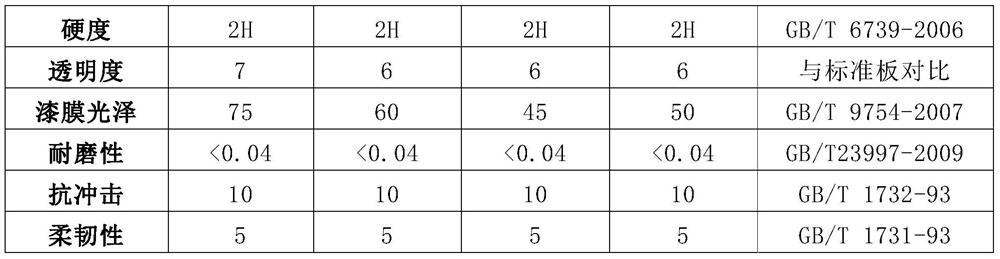

Transparent solvent type low-construction VOC polyurethane composition for woodware surfaces and preparation method thereof

InactiveCN112442316AHigh hardnessTo achieve tax-free purposesPolyurea/polyurethane coatingsPolymer scienceLacquer

The invention discloses a transparent solvent type low-construction VOC polyurethane composition for woodware surfaces and a preparation method thereof. Alkyd resin with high solid content and low viscosity, polyester resin containing hydroxyl and a special curing agent with high solid content are adopted, a special process is adopted under specific matching, and the polyurethane composition withlow viscosity is obtained. On the basis of not changing the construction and coating habits and conditions of the existing wood lacquer, the polyurethane composition disclosed by the invention is lessin coating times, so that the raw materials and the labor cost are further saved. In addition, the low VOC emission requirement (less than 420g / L) is achieved, and the purpose of tax exemption is achieved. A paint film obtained by using the polyurethane composition has the advantages of high transparency, high fullness, favorable hardness, favorable mechanical properties and excellent decorativeeffect. Aiming at the fact that no such commodity is sold and used in the market, the invention fills market vacancy.

Owner:NIPPON PAINT CHINA +1

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com