A high-performance sealed environment-friendly carbon steel corrosion inhibitor and its preparation and application

A corrosion inhibitor, an environmentally friendly technology, applied in the field of corrosion inhibitors for circulating chilled water, to achieve the effects of excellent corrosion inhibition performance, wide pH adaptability, and simple preparation methods

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

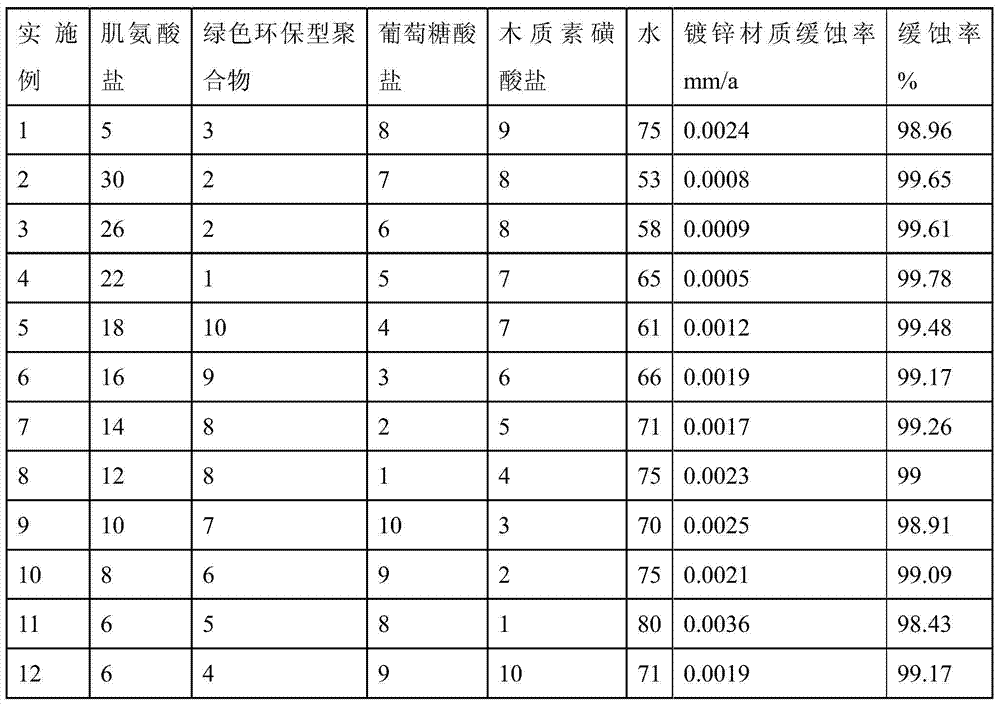

Examples

Embodiment 1

[0020] To prepare 100kg of environment-friendly carbon steel corrosion inhibitor, the preparation process: first add 8kg of gluconate and 9kg of lignosulfonate into the container, then add 5kg of sarcosinate, 3kg of green and environment-friendly polymer, 75kg water, and mix well to obtain a brown liquid.

[0021] The sarcosinate is selected from sodium sarcosinate.

[0022] The green environment-friendly polymer is polyepoxysuccinic acid.

[0023] Described gluconate is sodium gluconate.

[0024] The lignosulfonate is sodium lignin.

[0025] Referring to "GB / T 18175-2000 Determination of Corrosion Inhibition Performance of Water Treatment Agents by Rotating Coupon Method", the measured corrosion rate of carbon steel coupons is 0.0024mm / a, and the corrosion inhibition rate is 98.96%.

Embodiment 2

[0027] To prepare 100kg of environment-friendly carbon steel corrosion inhibitor, the preparation process: first add 7kg of gluconate and 8kg of lignosulfonate into the container, then add 30kg of sarcosinate, 2kg of green environment-friendly polymer, 53kg water, and mix well to obtain a brown liquid.

[0028] The sarcosinate is selected from potassium sarcosinate.

[0029] The green environment-friendly polymer is polyaspartic acid.

[0030] Described gluconate is potassium gluconate.

[0031] The lignosulfonate is potassium lignin.

[0032] Referring to "GB / T 18175-2000 Determination of Corrosion Inhibition Performance of Water Treatment Agents by Rotary Coupon Method", the measured corrosion rate of carbon steel coupons is 0.0008mm / a, and the corrosion inhibition rate is 99.65%.

Embodiment 3

[0034] To prepare 100kg of environment-friendly carbon steel corrosion inhibitor, the preparation process: first add 6kg of gluconate and 8kg of lignosulfonate into the container, then add 26kg of sarcosinate, 2kg of green environment-friendly polymer, 58kg water, and mix well to obtain a brown liquid.

[0035] The sarcosinate is selected from potassium sarcosinate.

[0036] The green environment-friendly polymer is polyepoxysuccinic acid.

[0037] Described gluconate is sodium gluconate.

[0038] The lignosulfonate is sodium lignin.

[0039] Referring to "GB / T 18175-2000 Determination of Corrosion Inhibition Performance of Water Treatment Agents by Rotary Coupon Method", the measured corrosion rate of carbon steel coupons is 0.0009mm / a, and the corrosion inhibition rate is 99.61%.

PUM

| Property | Measurement | Unit |

|---|---|---|

| corrosion rate | aaaaa | aaaaa |

| corrosion rate | aaaaa | aaaaa |

| corrosion rate | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com