Polyurethane glue for protective film

A polyurethane glue and protective film technology, applied in polyurea/polyurethane adhesives, adhesives, film/sheet adhesives, etc., can solve problems such as loss of meaning, glue residue, etc., to reduce the difficulty of film sticking and excellent durability , good leveling effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0018] The protective film polyurethane glue provided by the present invention is prepared by mixing the main agent of 30% by weight and the dissolving agent ethyl acetate of 65% by weight, and then adding a curing agent of 5% by weight and stirring evenly. become.

Embodiment 2

[0020] The polyurethane glue for protective film provided by the present invention is prepared by mixing the main agent of 40% by weight and the dissolving agent ethyl acetate of 50% by weight, and then adding 10% by weight of curing agent and stirring evenly. become.

Embodiment 3

[0022] The polyurethane glue for protective film provided by the present invention is prepared after fully mixing 40% by weight of the main agent and 40% by weight of the dissolving agent ethyl acetate, adding 20% by weight of the curing agent and stirring evenly. become.

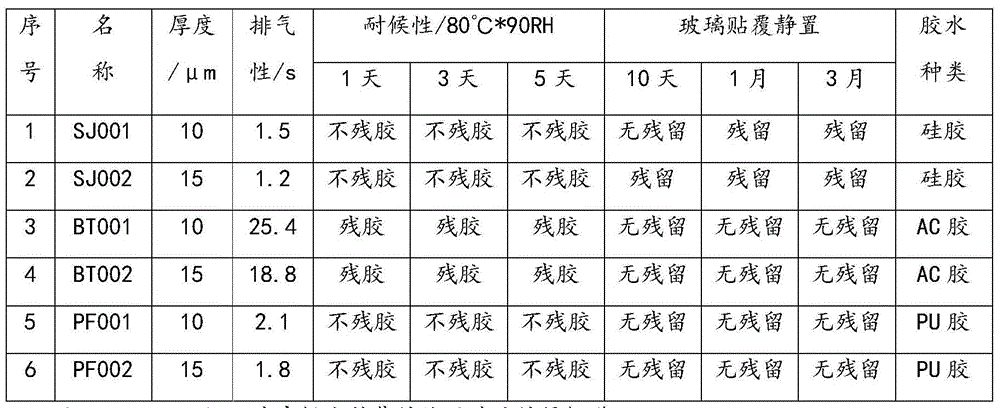

[0023] The following table is a data comparison table using the protective film of polyurethane glue for protective film provided by the present invention and the protective film using silica gel and acrylic glue (AC). It can be seen that compared with the prior art, the protective film provided by the present invention is used Polyurethane glue has excellent performance, and there is no residue after the protective film is attached to the surface of the protected object for a long time.

[0024] Data comparison list of different glue protective films

[0025]

[0026] Note: 1. SJ001 / 002 is a protective film using silica gel sold on the market

[0027] 2. BT001 / 002 is a protective film that uses acry...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com