Self-adhesive protective film and initial adhesion regulating method of self-adhesive protective film

A technology of self-adhesive protective film and self-adhesive layer, which is applied in the direction of adhesives, film/sheet adhesives, instruments, etc. It can solve the problems of different viscosities that have not been considered, the viscosity of the film, and the inconvenience of users. , to achieve the effect of maintaining good appearance, low cost and low difficulty

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

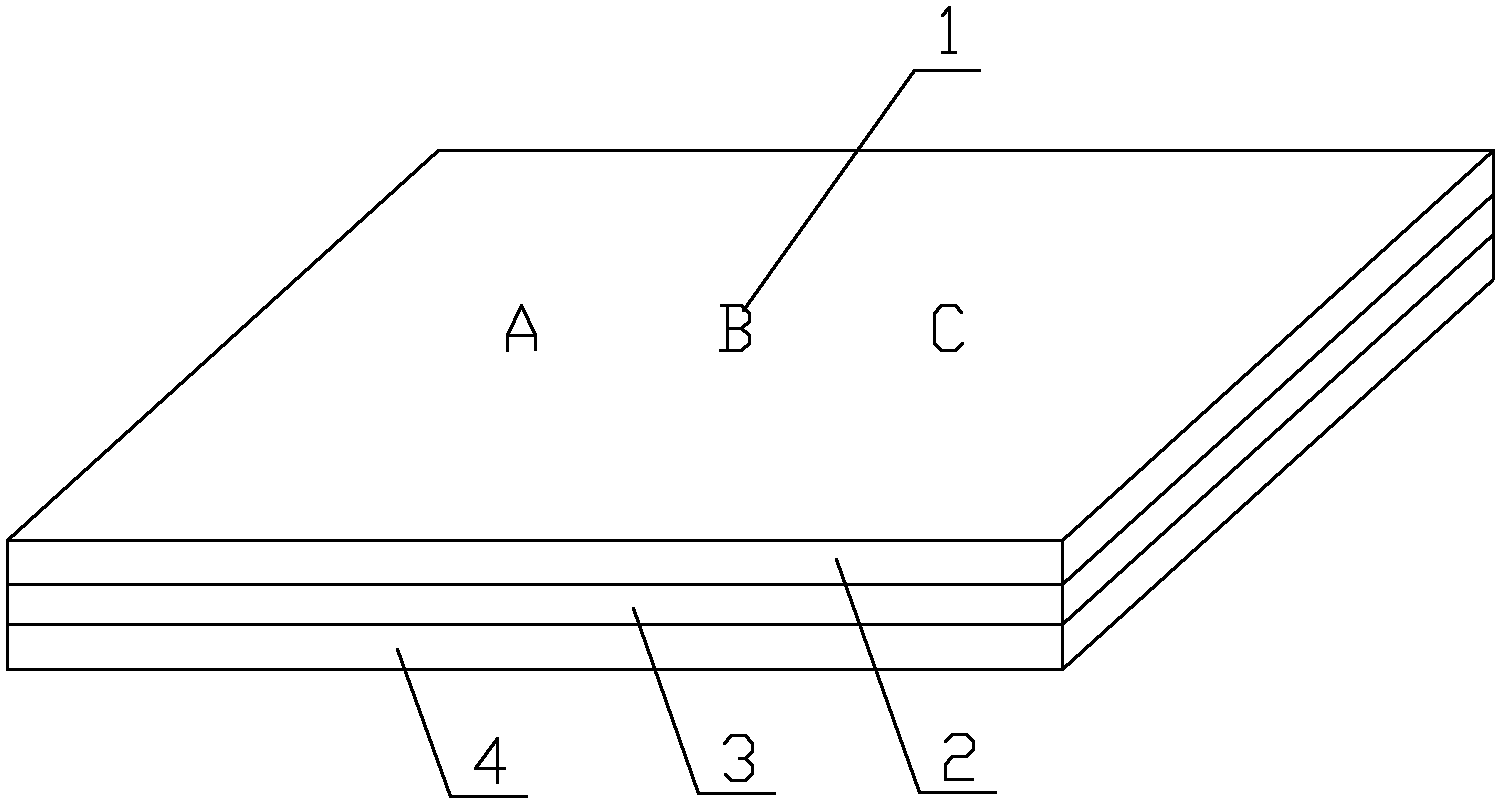

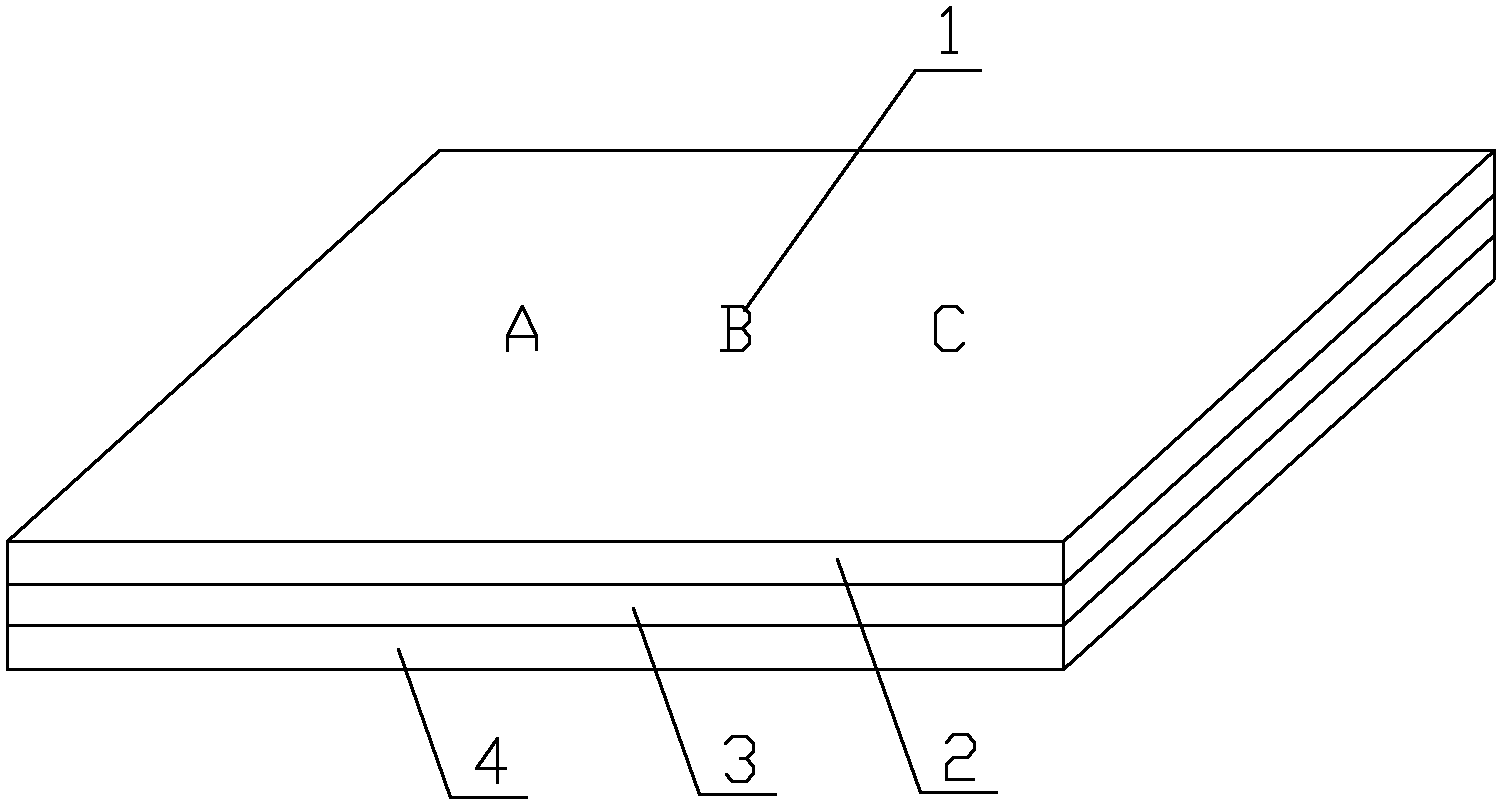

[0020] Such as figure 1 As shown, the self-adhesive protective film includes a low-density printing layer 2, a high-density barrier layer 3, and an elastic body self-adhesive layer 4 arranged in sequence. The outer surface of the low-density printing layer 2 can print characters 1, and the elastic body itself The adhesive layer 4 is formed by first mixing EVA and PE, and then adding POP or POE. The low-density printing layer 2 is a low-density polyethylene printing layer, the high-density barrier layer 3 is a high-density polyethylene barrier layer, and the density of the high-density polyethylene barrier layer is higher than that of the low-density polyethylene printing layer. The POP in the elastomeric self-adhesive layer 4 is a propylene-based elastomer, and the POE is a polyolefin elastomer or a polyolefin elastomer or a heat-shrinkable elastomer.

[0021] The thickness of the low-density printing layer 2 is 20-40%, the thickness of the high-density barrier layer 3 is 20-...

Embodiment 2

[0026] In this embodiment, the mass percentages of the components in the elastomeric self-adhesive layer 4 are EVA: 21-30%; PE: 50-60%; POP or POE: 11-20%. The amount of POP or POE added in this component is moderate, and it is a medium-to-initial viscosity product, suitable for use in regions and seasons with moderate temperatures. An appropriate amount of POP or POE can already meet the requirements of the initial viscosity. Users can paste it directly when using it. Any heating, easy to paste, high efficiency.

Embodiment 3

[0028] In this embodiment, the mass percentages of the components in the elastomeric self-adhesive layer 4 are EVA: 31-40%; PE: 30-40%; POP or POE: 21-30%. The amount of POP or POE added in this component is relatively high, which is a product with high initial viscosity, suitable for use in regions and seasons with low temperature. A large amount of POP or POE can meet the requirements of initial viscosity. Users can paste it directly when using it Any heating required, easy to apply and highly efficient.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com