Excellent-exhausting acrylic protection film and production method thereof

A technology of acrylic and protective film, applied in the direction of pressure-sensitive film/sheet, adhesive type, adhesive additive, etc., which can solve the problem of low peeling force of acrylic protective film, poor resistance to high temperature and high humidity, and normal use of the screen. Problems, to achieve the effect of excellent reworkability, low peeling force and cost advantage

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

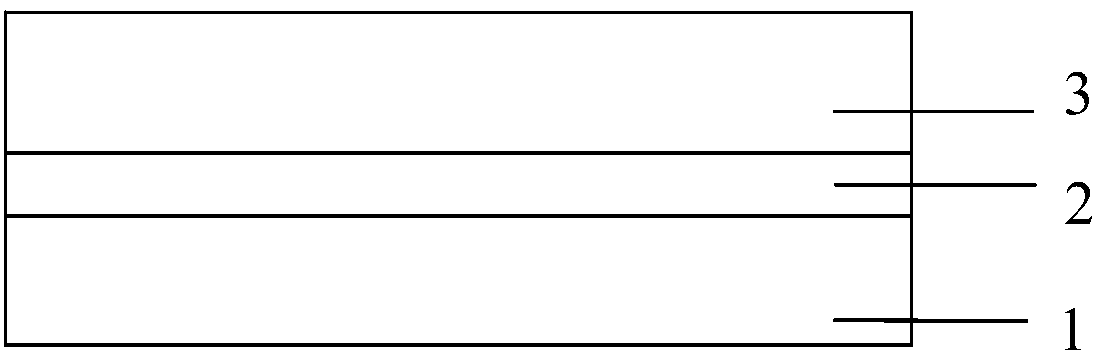

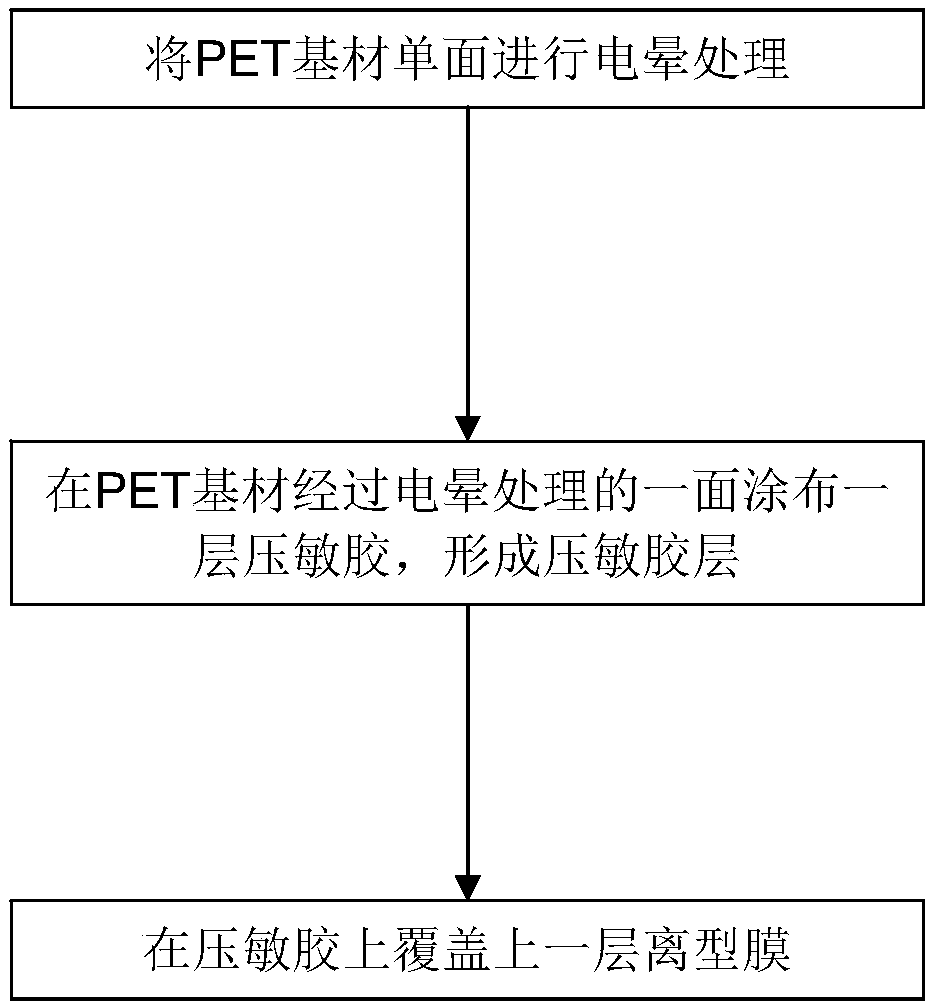

example 1

[0040] Add 20g of acrylic resin to 20g of ethyl acetate to dilute, add 1g of curing agent, 0.5g of curing retarder, 0.1g of catalyst, 5g of exhaust accelerator in sequence, stir well and mix evenly to obtain a pressure-sensitive adhesive; use a 45μm wire bar to coat Coating the above mixture on the corona-treated side of the 36 μm PET substrate 1 to form a pressure-sensitive adhesive layer 2, and then drying it in a dryer at 105°C for 1 min. After leaving the oven, remove the release film 3 The molded surface is laminated on the pressure-sensitive adhesive layer 2 to obtain a finished acrylic protective film with excellent exhaust and exhaust.

example 2

[0042] Add 40g of acrylic resin to 20g of ethyl acetate to dilute, add 3g of curing agent, 2g of curing retarder, 0.2g of catalyst, 15g of exhaust accelerator in sequence, stir well and mix evenly to obtain a pressure-sensitive adhesive; The mixture is coated on the side of the 50 μm PET substrate 1 that has undergone corona treatment to form a pressure-sensitive adhesive layer 2, and then dried in a dryer at 105°C for 1 min. After leaving the dryer, remove the release film 3 The surface is covered with the pressure-sensitive adhesive layer 2 to obtain a finished acrylic protective film with excellent exhaust and exhaust.

example 3

[0044] Add 30g of acrylic resin to 20g of ethyl acetate to dilute, then add 1g of curing agent, 0.8g of curing retarder, 0.15g of catalyst, 10g of exhaust accelerator, stir well and mix evenly to obtain a pressure-sensitive adhesive; use a 45μm wire bar to coat Coating the above mixture on the corona-treated side of 25 μm PET substrate 1 to form a pressure-sensitive adhesive layer 2, and then drying it in a dryer at 105°C for 1 min. After leaving the oven, remove the release film 3 The molded surface is laminated on the pressure-sensitive adhesive layer 2 to obtain a finished acrylic protective film with excellent exhaust and exhaust.

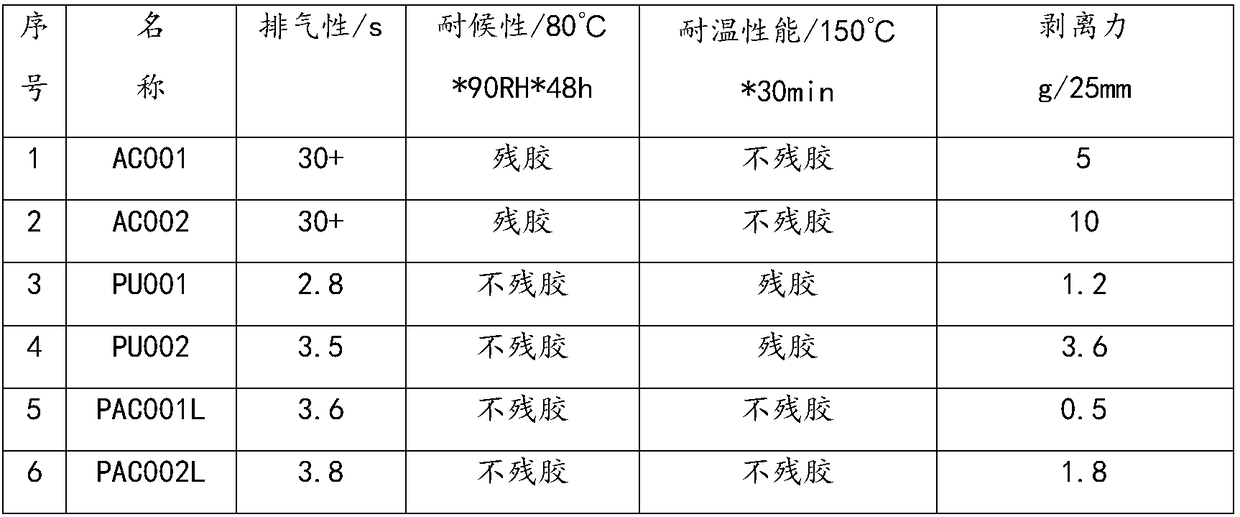

[0045] The performance comparison between the excellent exhaust acrylic protective film provided by the present invention and the ordinary protective film is shown in the table below. It can be seen that, compared with the prior art, the excellent exhaust acrylic protective film provided by the present invention has the advantages of low peelin...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

| coating thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com