Laser alumite stamping foil with controllable peel strength and preparation method thereof

A technology of anodizing aluminum and peeling force, which is applied in chemical instruments and methods, temperature recording methods, coatings, etc., can solve the problem of difficult to control peeling force, difficult control of wet coating amount of separation layer coating, and peeling off of anodized aluminum film tape. Force relationship is difficult to explore and other problems, to achieve the effect of high production efficiency, good single-plate/seamless molding performance, and good process adaptability

Inactive Publication Date: 2013-07-10

HUBEI LHTC ANTI COUNTERFEITING TECH CO LTD

View PDF6 Cites 8 Cited by

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

However, due to the different types, chemical structures, and film-forming mechanisms of the separation layer, it is difficult to find out the relationship between its concentration and the peeling force of the anodized aluminum film tape, and it is easily affected by factors such as the coating anilox roller and temperature, so that the separation layer is coated. It is difficult to control the amount of wet coating, and the peeling force is difficult to control

How to make the anodized aluminum material self-detachable from the base film and produce a laser anodized aluminum material with a controllable peeling force between the base film and the hot stamping material is an urgent problem that engineers and technicians in this industry need to solve. There is no laser anodized aluminum hot stamping foil with controllable peeling force

Method used

the structure of the environmentally friendly knitted fabric provided by the present invention; figure 2 Flow chart of the yarn wrapping machine for environmentally friendly knitted fabrics and storage devices; image 3 Is the parameter map of the yarn covering machine

View moreImage

Smart Image Click on the blue labels to locate them in the text.

Smart ImageViewing Examples

Examples

Experimental program

Comparison scheme

Effect test

Embodiment 1

Embodiment 2

Embodiment 3

the structure of the environmentally friendly knitted fabric provided by the present invention; figure 2 Flow chart of the yarn wrapping machine for environmentally friendly knitted fabrics and storage devices; image 3 Is the parameter map of the yarn covering machine

Login to View More PUM

| Property | Measurement | Unit |

|---|---|---|

| Glass transition temperature | aaaaa | aaaaa |

| Glass transition temperature | aaaaa | aaaaa |

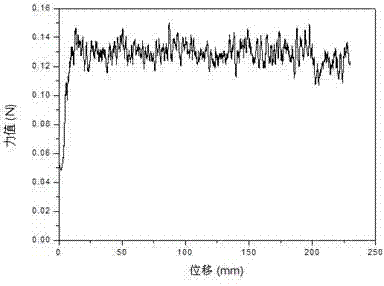

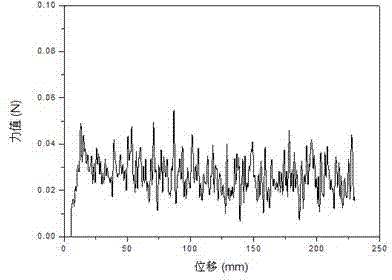

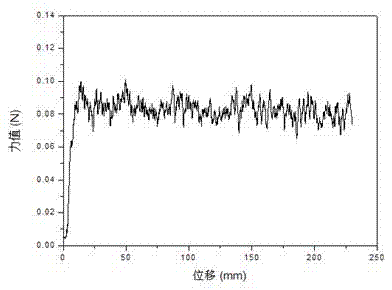

| Average peel strength | aaaaa | aaaaa |

Login to View More

Abstract

The invention relates to a holographic anti-counterfeit alumite material used in the printing industry, especially to a laser alumite stamping foil with controllable peel strength and a preparation method thereof. The invention provides the laser alumite stamping foil with the advantages of capacity of bearing alumite laser anti-counterfeit information, adjustable peel strength of a coating, high resistance to heat, wear, weather and scratches and suitability for a subsequent procedure of single-plate / seamless molding and the preparation method thereof. The laser alumite stamping foil comprises, by mass, 10 to 15 parts of a thermoplastic hard acrylic resin, 3 to 6 parts of a thermoplastic soft acrylic resin, 1 to 11 parts of cellulose ester, 80 to 95 parts of a solvent and 0.1 to 0.2 part of an auxiliary agent. The laser alumite stamping foil can be directly fed into a machine for coating, thereby realizing energy saving and emission reduction to be realized; the peel strength of the coating is adjusted through changing of the addition amount of cellulose ester, the peel strength is reduced when the usage amount of cellulose ester is increased, and the peel strength is allowed to change in a range of 2 to 15 KN / m; the laser electrochemical aluminum stamping foil can meet requirements on peel strength by different hot stamping substrates and different hot stamping processes and has a wide application scope.

Description

technical field [0001] The invention relates to an anodized aluminum material for the holographic anti-counterfeiting printing industry, in particular to a laser anodized aluminum hot stamping foil with controllable peeling force and a preparation method thereof. Background technique [0002] At present, holographic anti-counterfeiting hot stamping film has been widely used in the packaging field. Compared with traditional printing technology, it has bright colors, dynamic and anti-counterfeiting functions. For the production and processing of laser anodized aluminum, it includes hot stamping, transfer, compounding, Labeling, etc., the traditional holographic anti-counterfeiting hot stamping film usually consists of a base film layer, a separation layer, an information layer, an aluminum layer and an adhesive layer. However, with the rapid development of the packaging industry and the widespread use of holographic anti-counterfeiting products, it was originally in Hot stampi...

Claims

the structure of the environmentally friendly knitted fabric provided by the present invention; figure 2 Flow chart of the yarn wrapping machine for environmentally friendly knitted fabrics and storage devices; image 3 Is the parameter map of the yarn covering machine

Login to View More Application Information

Patent Timeline

Login to View More

Login to View More IPC IPC(8): B41M5/42B32B15/082B32B15/20B32B27/20B32B33/00C09D133/12C09D133/10

Inventor 谢瑾

Owner HUBEI LHTC ANTI COUNTERFEITING TECH CO LTD

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com