Transparent solvent type low-construction VOC polyurethane composition for woodware surfaces and preparation method thereof

A solvent-based, polyurethane technology, applied in the field of solvent-based low-construction VOC polyurethane compositions and their preparation, can solve the problems of difficult film thickness extinction, easy cracking, dark bubbles, etc., and achieve the effects of good resistance, VOC reduction, and easy construction.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0058] A preparation method for a transparent solvent-based low-construction VOC polyurethane composition for wood surfaces, comprising the following steps:

[0059] a. Preparation of component A:

[0060] ⅰ, the preparation of prepolymer:

[0061] Weigh alkyd resin, slowly add dispersant at 600~800rpm, disperse and stir for 5~10min, then continue to add part of defoamer, stir and disperse, then slowly add matting powder, disperse at 1500~2500rpm for 10~20min, and use Clean the inner wall with some ketone solvents, and finally, under airtight conditions, stir evenly at a low speed in a 50°C constant temperature water bath for 24 hours to obtain a prepolymer;

[0062] ii. Preparation of Component A:

[0063] In the prepolymer, add polyester resin, reactive diluent, remaining defoamer, leveling agent, remaining ketone solvent, ester solvent, anti-sedimentation agent at 1000 rpm, and disperse evenly to obtain component A;

[0064] Component A described therein has a compositio...

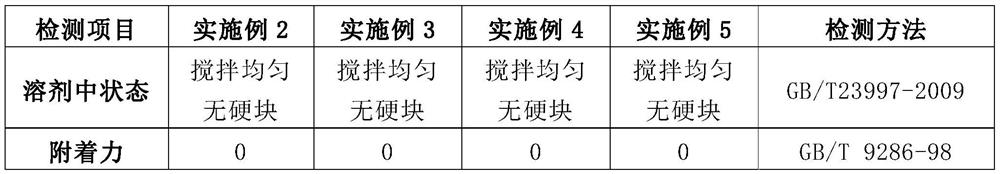

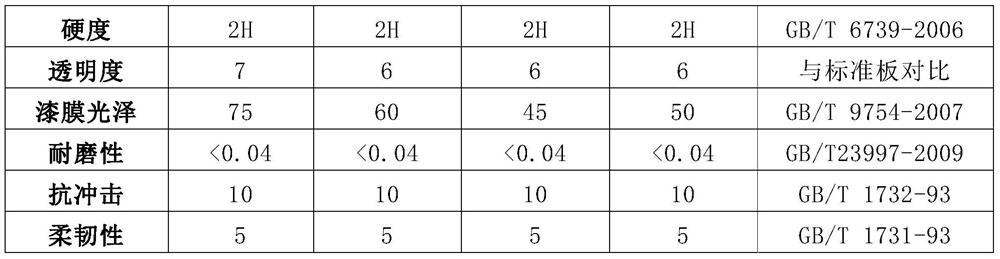

Embodiment 2

[0106] A preparation method for a transparent solvent-based low-construction VOC polyurethane composition for wooden surfaces, comprising component A, component B and component C, wherein the weight ratio of component A, component B and component C is 100 :100:30;

[0107] Its preparation steps are:

[0108] a. Preparation of component A:

[0109] ⅰ, the preparation of prepolymer:

[0110] Stir 60 parts of Changxing ETERKYD 36093-B-80 resin at 600-800rpm, slowly add 0.5 parts of dispersant AFCONA-5051 to disperse and stir for 5-8 minutes, then add 0.2 parts of defoamer BYK-066N and continue to stir evenly; then slowly Add 20 parts of Grace MSK-D1 matting powder, disperse at 1500-2500 rpm for 10-20 minutes, and wash the inner wall with 1.5 parts of MAK solvent, and finally, under airtight conditions, stir evenly at a low speed in a 50°C constant temperature water bath for 24 hours to obtain a prepolymer;

[0111] ii. Preparation of Component A:

[0112] Add 7 parts of DSM U...

Embodiment 3

[0119] A preparation method for a transparent solvent-based low-construction VOC polyurethane composition for wooden surfaces, comprising component A, component B and component C, wherein the weight ratio of component A, component B and component C is 100 :100:30;

[0120] Its preparation steps are:

[0121] a. Preparation of component A:

[0122] ⅰ, the preparation of prepolymer:

[0123] Stir 60 parts of Changxing ETERKYD 3609-B-80 resin at 600-800rpm, slowly add 0.5 parts of dispersant AFCONA-5051 to disperse and stir for 5-8 minutes, then add 0.2 parts of defoamer BYK-066N and continue to stir evenly; then slowly Add 17 parts of Grace MSK-D1 matting powder and 3 parts of SYLOID ED5 matting powder, disperse at 1500-2500 rpm for 10-20 minutes, and clean the inner wall with 1.5 parts of MAK solvent, and finally, under airtight conditions, stir evenly at a low speed in a 50°C constant temperature water bath for 24 hours , to obtain the prepolymer;

[0124] ii. Preparation ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| porosity | aaaaa | aaaaa |

| porosity | aaaaa | aaaaa |

| porosity | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com