Silk-screen printing ink for polyethylene terephthalate material

A technology of screen printing ink and polyester resin liquid, applied in ink, application, household appliances and other directions, can solve problems such as use restrictions, and achieve excellent performance, good ink layer leveling, and excellent adhesion.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0086] Take 70.2 parts (weight) of polyester resin liquid, 6.8 parts (weight) of aldehyde and ketone resin, add 0.5 parts (weight) of wetting agent, and after the formed mixture is uniformly dispersed at a low speed of 400-500RPM, slowly add 0.8 parts of thickener (weight) and then stir for 10 minutes, then add 10 parts (weight) of carbon black, 5 parts (weight) of filler, after grinding, add 1.5 parts (weight) of defoamer, 5.2 parts (weight) of isophorone solvent, and disperse evenly Finally, filter with 200 mesh to get the finished product.

Embodiment 2

[0088] Take 47.5 parts (weight) of polyester resin liquid, 5.7 parts (weight) of aldehyde and ketone resin, add 0.5 parts (weight) of wetting agent, and disperse the formed mixture evenly at a low speed of 400-500RPM, then slowly add 0.5 parts of thickener (weight), then stir for 10 minutes, then add 45 parts (weight) of titanium dioxide, 5 parts (weight) of filler, and add 1.5 parts (weight) of defoamer after grinding by three-roller machine, disperse evenly and filter with 200 mesh gauze , the finished product is obtained.

Embodiment 3

[0090] Take 90 parts (weight) of polyester resin liquid, 8 parts (weight) of aldehyde and ketone resin, add 1 part (weight) of defoamer, 1 part (weight) of filler, and disperse evenly at a high speed of 800-1200 RPM, then use 200 mesh mesh Filter to get the finished product.

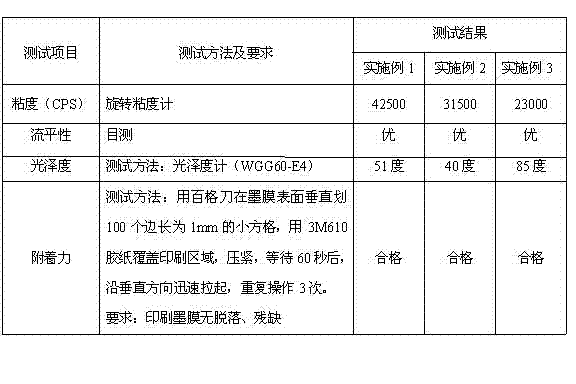

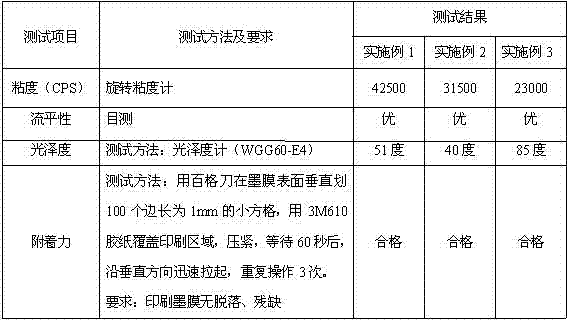

[0091] The printing effect and physical and chemical index state of the environmentally friendly ink without halogen and PAHS obtained in the above examples are shown in figure 1 shown.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com