Erase color variable ink

A friction discoloration and ink technology, applied in ink, household appliances, applications, etc., can solve the problems of poor resistance, general resistance to circulation, instability, etc., to achieve excellent printability, improve anti-counterfeiting level, and improve the effect of anti-counterfeiting level.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0020] Embodiment 1, the preparation of wiping variable color offset printing ink:

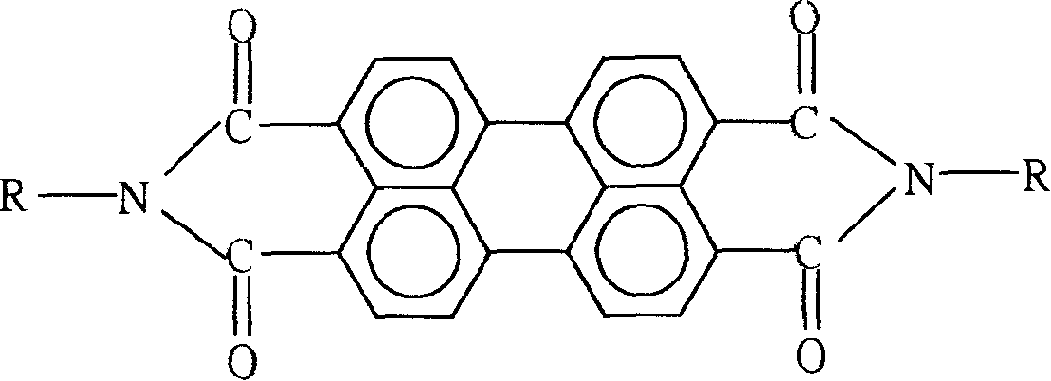

[0021] Tribochromic material: 25%

[0022] Phenolic resin oil: 30%

[0023] Alkyd resin (oil degree 70): 22%

[0024] Calcium carbonate filler: 20%

[0025] Desiccant: 1%

[0026] High boiling point kerosene: 2%

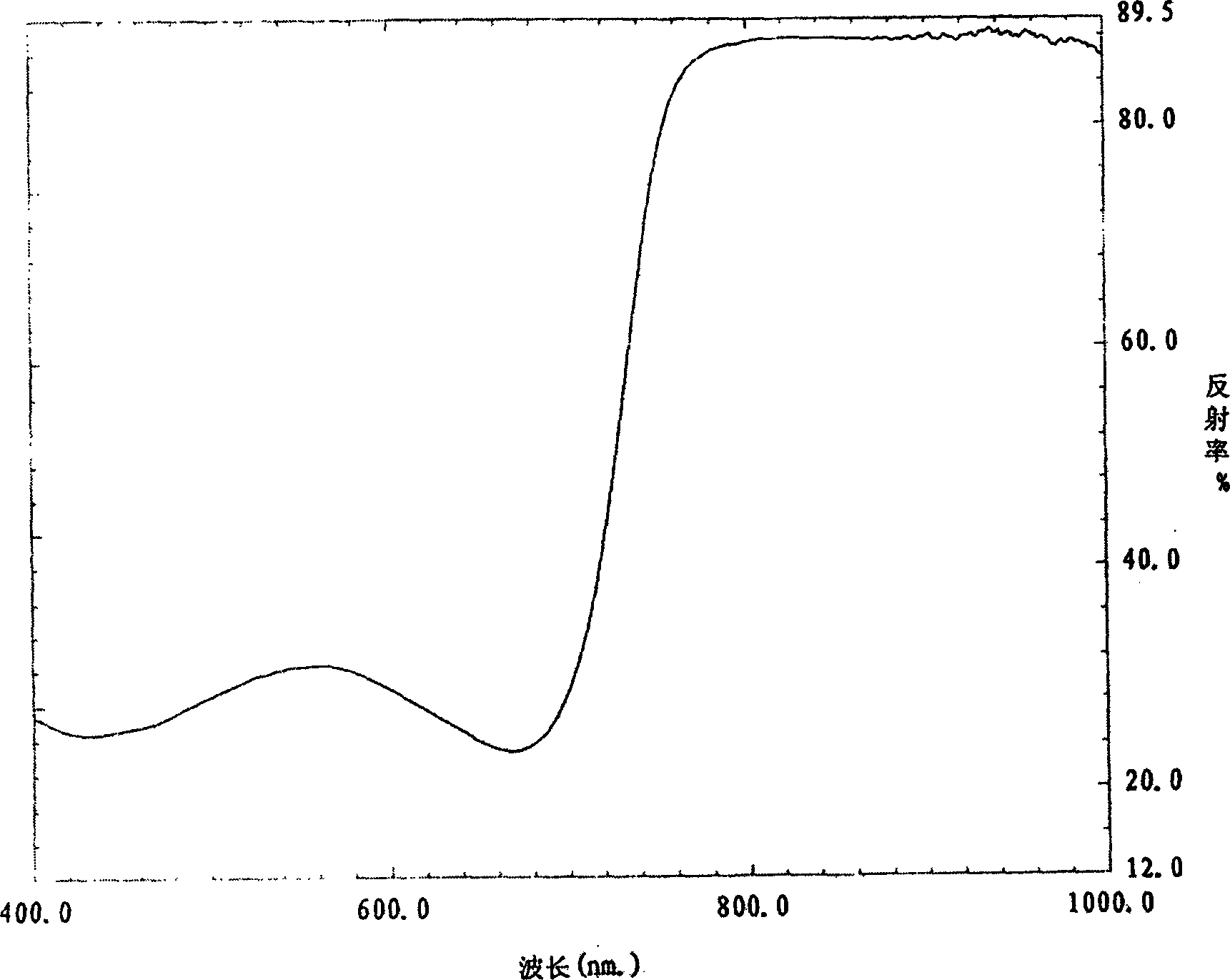

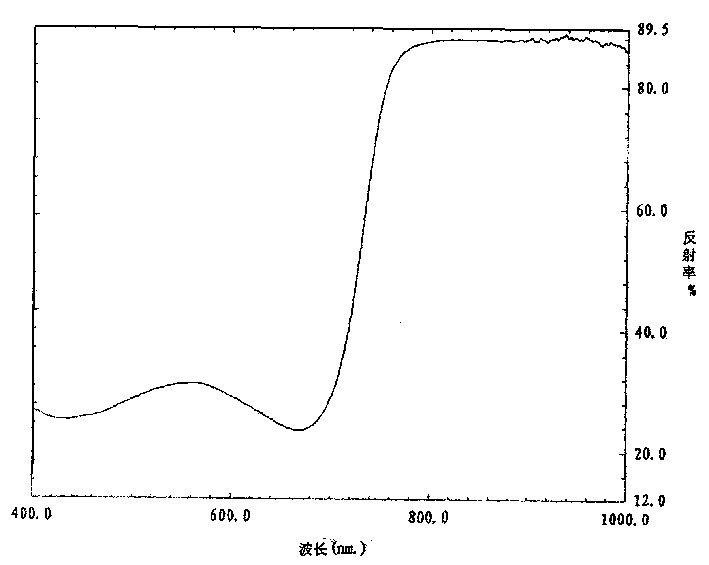

[0027] After the above-mentioned substances are weighed in proportion, they are stirred in the mixing tank for 20-30 minutes, pre-dispersed, and then rolled on a three-roll ink padding machine to make it reach the technical index of offset printing ink application (ink fineness≤15 microns, The fluidity is 28--35mm), which is the finished product of rubbing variable color offset printing ink. Its imprint is black and green. Under a certain force, rubbing with white paper can turn red, and it is completely transparent in the near-infrared region.

Embodiment 2

[0028]Example 2, add 20% ZnS:Cu ultraviolet fluorescent pigment (under the excitation of 365nm ultraviolet light, emit visible green light) to the wiping variable color offset printing ink prepared in Example 1, according to the known ink processing method, It can be made into printing ink. In addition to the anti-counterfeiting features of frictional discoloration and full transmission in the near-infrared region, it also has the anti-counterfeiting function of ultraviolet fluorescence.

Embodiment 3

[0029] Embodiment 3, in the wiping variable color offset printing ink prepared in embodiment 1, add 20% Y 2 O 2 S: Eu ultraviolet fluorescent pigment (under the excitation of 365nm ultraviolet light, emits visible red light) can be made into printing ink according to the known ink processing method. Anti-counterfeit function with UV fluorescent feature.

PUM

| Property | Measurement | Unit |

|---|---|---|

| melting point | aaaaa | aaaaa |

| particle size | aaaaa | aaaaa |

| melting point | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com