Glass cement and preparation method thereof

A glass glue and anti-oxidant technology, applied in the direction of adhesives, non-polymer adhesive additives, adhesive additives, etc., can solve the problems of oxidative discoloration on the surface of glass glue, discoloration of glass glue, long bonding time, etc., and achieve gelation Short time, good adhesive performance, rapid adhesive curing effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

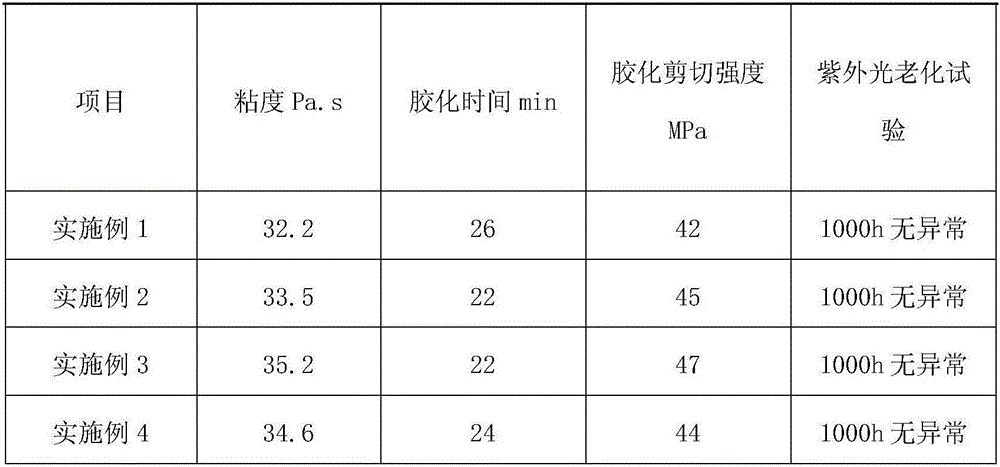

Examples

Embodiment 1

[0024] A kind of glass glue, comprising by weight components: 10 parts of ethyl 2-cyanoacrylate, 1 part of polyvinyl butyral, 2 parts of soft styrene-butadiene rubber, 0.5 part of diethylaminoethyl methacrylate, 1 part of carnauba wax, 0.2 part of antioxidant 1010, 0.5 part of stearic acid, 0.5 part of sodium silicate, 1 part of nano silicon dioxide, 0.6 part of polyethylene glycol 800, 0.8 part of aluminum oxide.

[0025] The preparation method of described glass glue, comprises the following steps:

[0026] Step 1, taking each component according to parts by weight;

[0027] Step 2, mixing ethyl 2-cyanoacrylate, soft styrene-butadiene rubber, polyvinyl butyral and carnauba wax evenly to obtain mixture 1;

[0028] Step 3, transfer the mixture into a reaction kettle, add diethylaminoethyl methacrylate, sodium silicate, silicon dioxide and aluminum oxide, and raise the temperature to 70°C under a vacuum condition of 0.04MPa, Hold for 20 minutes to obtain mixture 2;

[0029] ...

Embodiment 2

[0031] A kind of glass glue, comprising by weight components: 12 parts of ethyl cyanoacrylate, 2 parts of polyvinyl butyral, 3 parts of soft styrene-butadiene rubber, 0.6 part of diethylaminoethyl methacrylate, 2 parts of carnauba wax, 0.3 part of antioxidant 1010, 0.6 part of stearic acid, 0.6 part of sodium silicate, 2 parts of nano silicon dioxide, 0.7 part of polyethylene glycol 800, 1 part of aluminum oxide.

[0032] The preparation method of described glass glue, comprises the following steps:

[0033] Step 1, taking each component according to parts by weight;

[0034] Step 2, mixing ethyl 2-cyanoacrylate, soft styrene-butadiene rubber, polyvinyl butyral and carnauba wax evenly to obtain mixture 1;

[0035] Step 3, transfer the mixture into a reaction kettle, add diethylaminoethyl methacrylate, sodium silicate, silicon dioxide and aluminum oxide, and raise the temperature to 73°C under a vacuum condition of 0.05MPa, Hold for 24 minutes to obtain mixture 2;

[0036] S...

Embodiment 3

[0038] A kind of glass glue, comprising by weight components: 16 parts of ethyl 2-cyanoacrylate, 3 parts of polyvinyl butyral, 5 parts of soft styrene-butadiene rubber, 0.7 part of diethylaminoethyl methacrylate, 2 parts of carnauba wax, 0.5 part of antioxidant 1010, 0.7 part of stearic acid, 0.9 part of sodium silicate, 3 parts of nano silicon dioxide, 1 part of polyethylene glycol 800, 1.2 parts of aluminum oxide.

[0039] The preparation method of described glass glue, comprises the following steps:

[0040] Step 1, taking each component according to parts by weight;

[0041] Step 2, mixing ethyl 2-cyanoacrylate, soft styrene-butadiene rubber, polyvinyl butyral and carnauba wax evenly to obtain mixture 1;

[0042] Step 3, transfer the mixture into a reaction kettle, add diethylaminoethyl methacrylate, sodium silicate, silicon dioxide and aluminum oxide, and raise the temperature to 75°C under a vacuum condition of 0.06MPa, Hold for 28 minutes to obtain mixture 2;

[0043...

PUM

| Property | Measurement | Unit |

|---|---|---|

| shear strength | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com