Ultra high strength steel sheet generating no hydrogen embrittlement and its manufacturing method

An ultra-high-strength, manufacturing method technology, applied in the field of ultra-high-strength thin steel plates, can solve problems such as strength reduction, poor processability, and failure to take into account, and achieve significant effects and significant lightweight effects

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

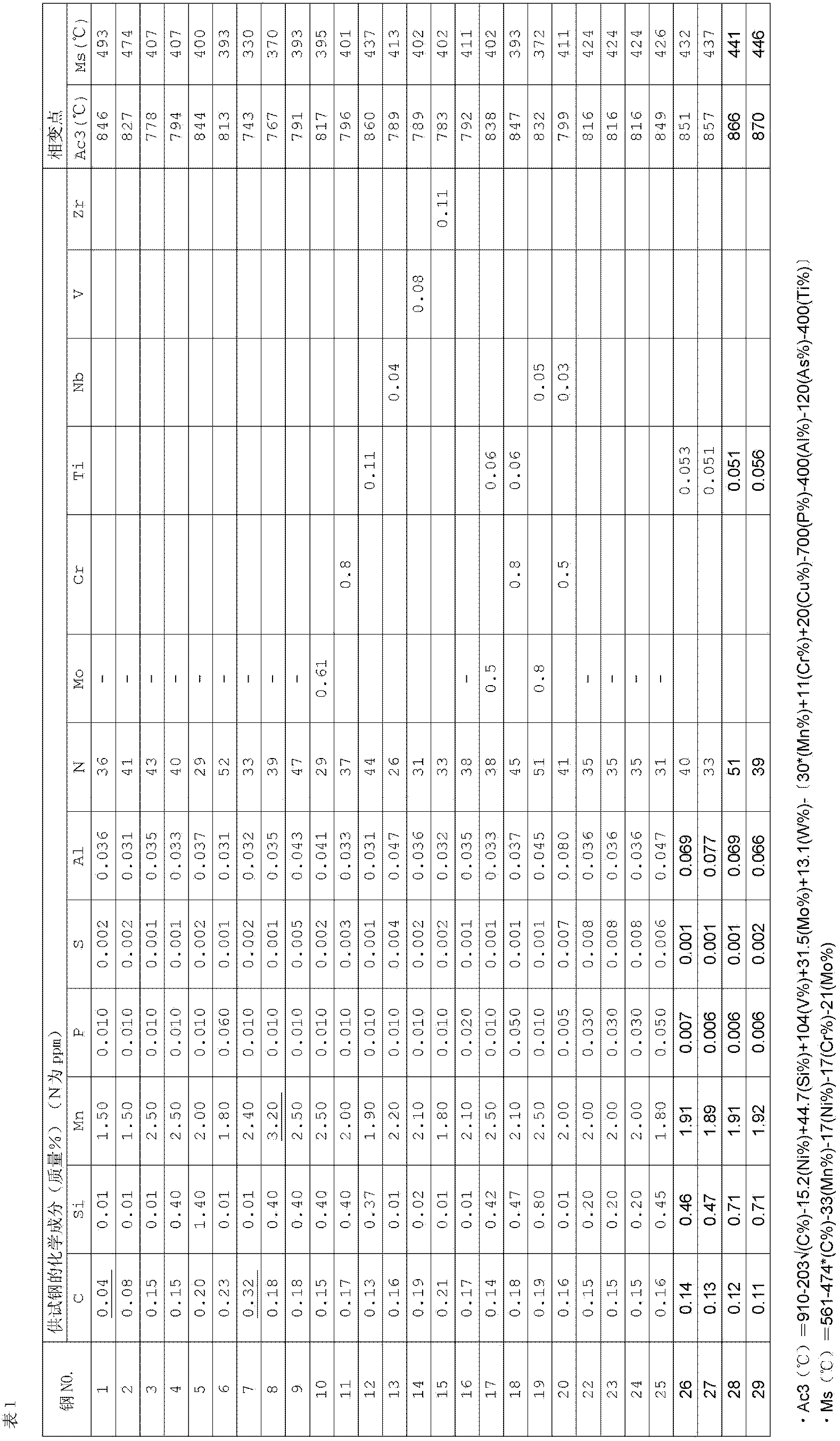

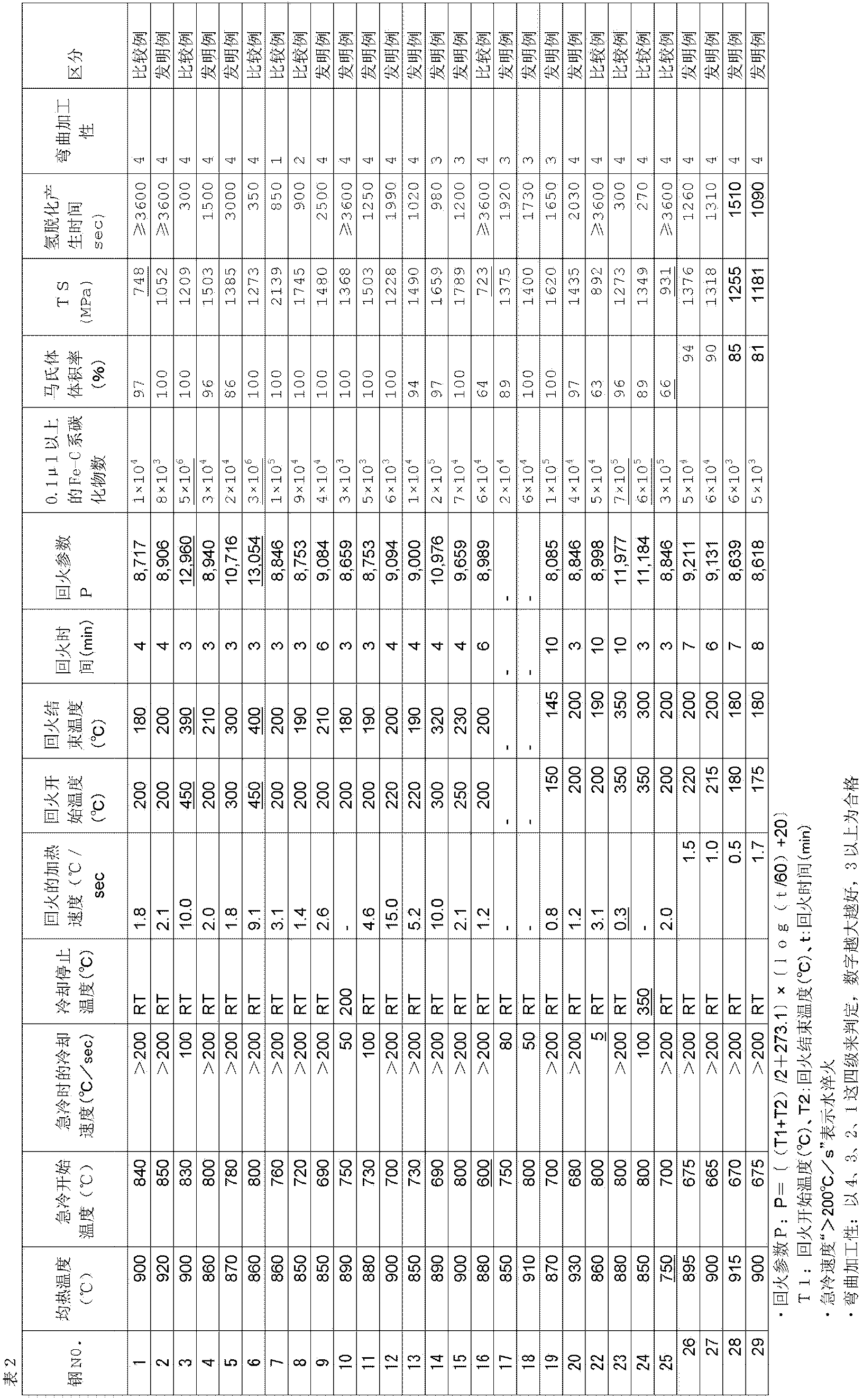

[0022] The present invention will be described in further detail below. First, the reason for the limitation of the carbide of the present invention will be explained.

[0023] The present inventors have conducted intensive research on the hydrogen embrittlement of ultra-high-strength steel sheets subjected to cold processing such as press forming and bending processing under corrosive environments such as the atmosphere and salt water spray.

[0024] As a result, the damage caused by hydrogen embrittlement is generated from the cold-worked part. In the steel plate that is damaged in a short time, the grain boundary damage is the main damage surface, and the ratio of Fe-C precipitates of 0.1μm or more per 1mm 2 3×10 5 Also more precipitated. On the other hand, it was found that in steel plates with a long failure time, intragranular failure is the main failure surface. Like steel plates without hydrogen embrittlement, Fe-C precipitates of 0.1 μm or more are present per 1 mm 2 3×10 ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| tensile strength | aaaaa | aaaaa |

| tensile strength | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com