Water-based bright gloss topcoat with high brightness, high tolerance and no dark bubbles or seeds, and preparation method and application thereof

A water-based, bright technology, applied in the direction of polyurea/polyurethane coatings, coatings, etc., can solve the problems of easy prickly heat and dark foam, affect the coating effect, insufficient brightness, etc., achieve high fullness, strong chemical resistance and other properties , the effect of good tolerance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

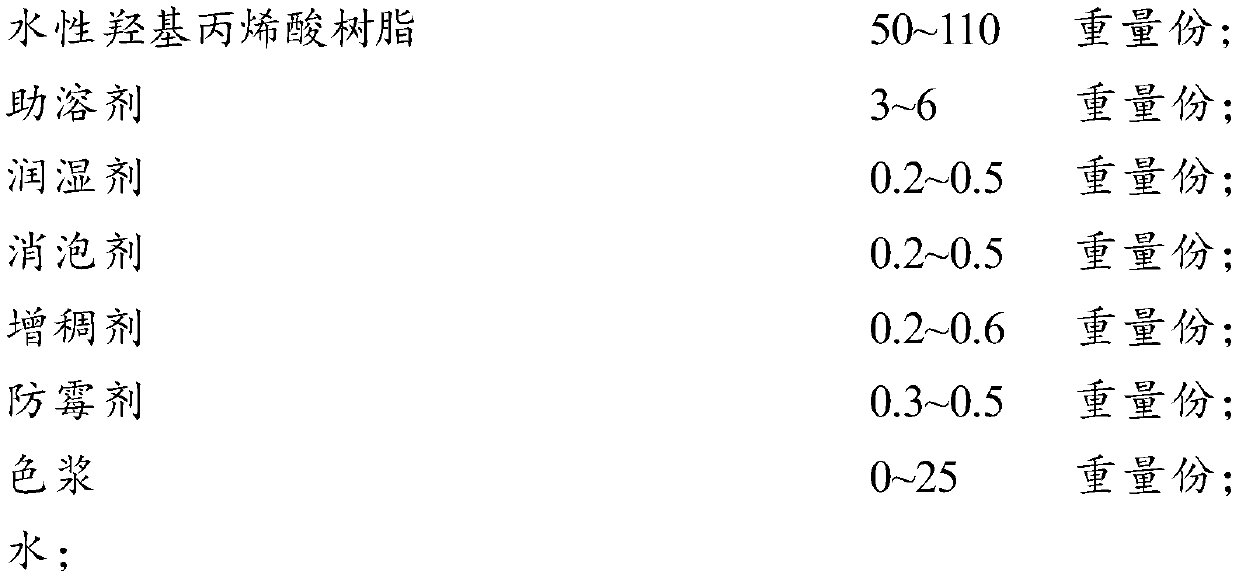

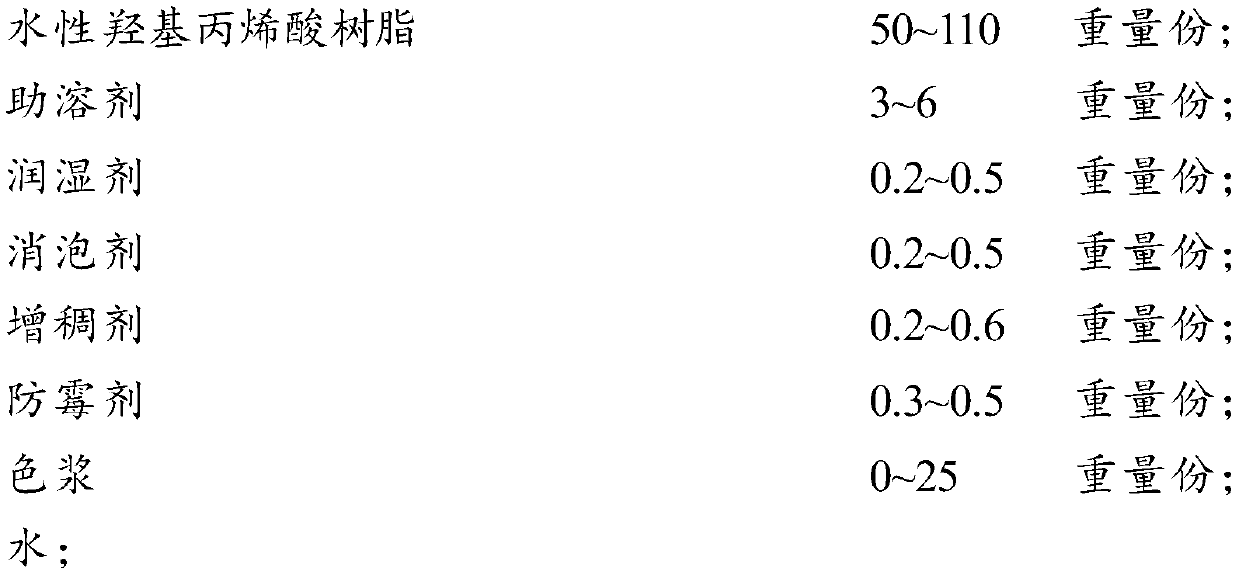

[0103] The present invention also provides a kind of preparation method of water-based bright topcoat as described in any one of above-mentioned technical scheme, comprises the following steps:

[0104] 1) Add co-solvent, wetting agent, anti-mold agent, thickener and defoamer to the water-based hydroxyacrylic resin, and mix to obtain component A;

[0105] After mixing the hydrophilic modified diisocyanate curing agent, propylene glycol methyl ether acetate and water remover for the second time, component B is obtained;

[0106] When in use, after combining component A and component B obtained in the above steps, a water-based glossy finish paint is obtained.

[0107] In the preparation method of the present invention, the specific preferred scheme of the raw material, and the preferred numerical value of the added number of parts are consistent with the specific preferred scheme of the components in the aforementioned water-based gloss finish paint, and the preferred numerical...

Embodiment 1

[0138] Prepare high-gloss, high-resistance water-based wood varnishes without heat rash and dark bubbles in the following proportions:

[0139] Component A: A2601: 50%, PA-4801: 35%, texanol: 5%, BYK028: 0.3%, tego wet 4200: 0.3%, OS6050: 1%, BEK-200L: 0.2%, deionized water: 8 %;

[0140] Component B: 4098-71: 40%, 2655: 45%, PMA: 14%, Additive Ti: 1%.

[0141] The weight ratio of components A and B is 100:30.

[0142] The preparation method comprises the following steps:

[0143] A component production method:

[0144] 1) Use a 300-mesh filter to filter the water-based resin A2601 and PA-4801 into a clean container, add BYK028, adjust the disperser to 1500-1800r / min, and disperse for 25 minutes;

[0145] 2) Sampling and spraying with two drops of tego wet 4200 to observe whether the appearance of the coating film has shrinkage cavity. After confirming that there is no shrinkage cavity, adjust the speed of the disperser to 800-1000r / min;

[0146] 3) Slowly add texanol, te...

Embodiment 2

[0153] Prepare high-gloss, high-resistance water-based wood varnishes without heat rash and dark bubbles in the following proportions:

[0154] Component A: A2601: 40%, PA-4801: 30%, texanol: 5%, BYK028: 0.3%, tego wet 4200: 0.3%, OS6050: 1%, BEK-200L: 0.2%, white pulp: 20% , deionized water: 3.2%

[0155] Component B: 4098-71: 40%, 2655: 45%, PMA: 14%, Additive Ti: 1%

[0156] The weight ratio of A and B components is 100:20.

[0157] The preparation method comprises the following steps:

[0158] A component production method:

[0159] 1) Use a 300-mesh filter to filter the water-based resin A2601 and PA-4801 into a clean container, add BYK028, adjust the disperser to 1500-1800r / min, and disperse for 25 minutes;

[0160] 2) Sampling and spraying with two drops of tego wet 4200 to observe whether the appearance of the coating film has shrinkage cavity. After confirming that there is no shrinkage cavity, adjust the speed of the disperser to 800-1000r / min;

[0161]3) Slowly...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Fineness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com