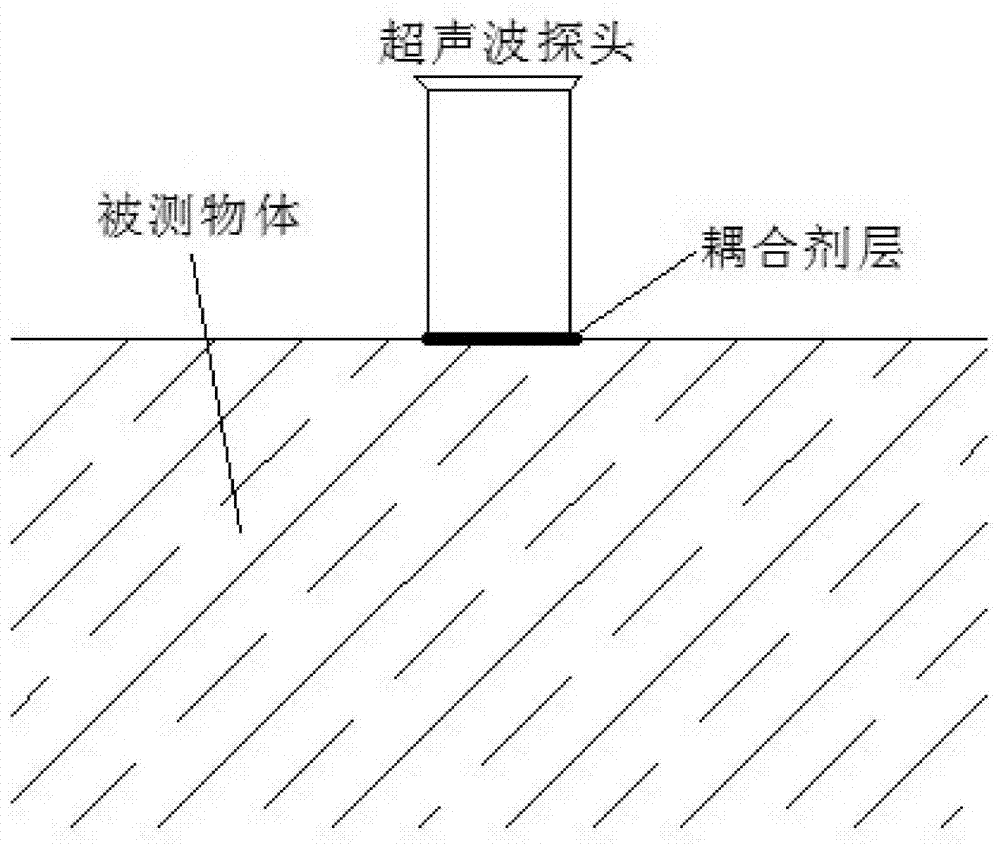

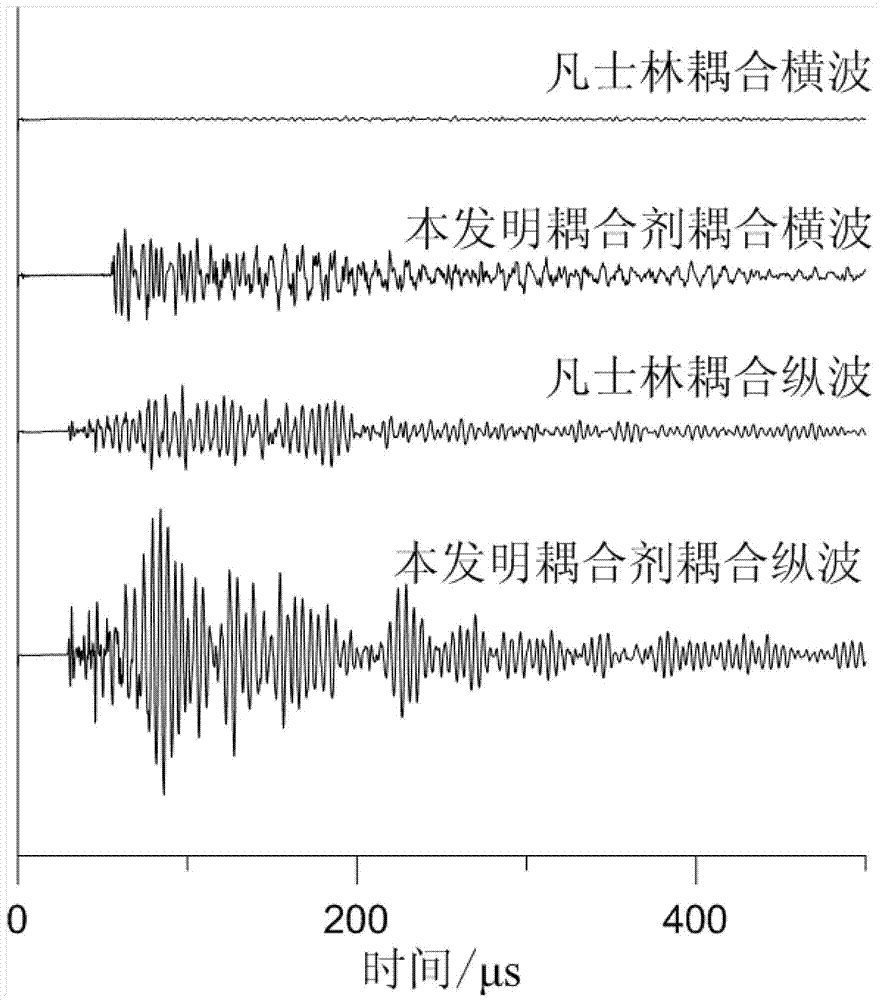

Slow-speed couplant that eliminates the effect of end surface roughness and improves the test effect of longitudinal and transverse waves

A roughness, longitudinal and transverse wave technology, applied in the direction of measuring devices, material analysis using sound waves/ultrasonic waves/infrasonic waves, instruments, etc. Widely applicable and other issues, to achieve the effect of reducing sample preparation costs, reducing processing, and preventing consolidation from being too strong

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

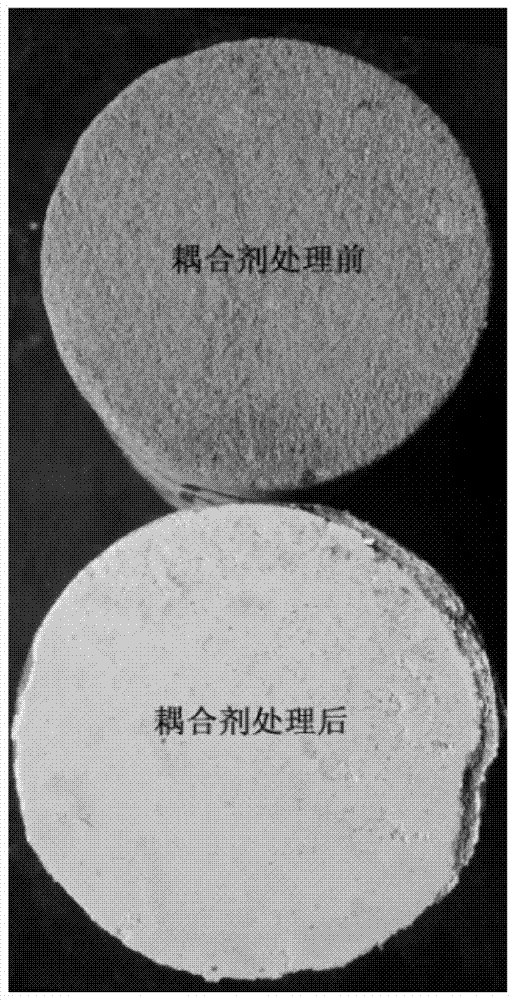

[0031] Embodiment 1. A slow-speed couplant that eliminates the influence of end surface roughness and improves the test effect of longitudinal and transverse waves, including:

[0032] Consolidator: Plaster of Paris CaSO 4 0.5H 2 O,

[0033] Consolidation strength modifier: raw gypsum CaSO 4 2H 2 O,

[0034] Lubricants and early strength agents: white latex, polyvinyl alcohol,

[0035] Consolidation retarder: sodium hexaphosphate metaphosphate 6 o 18 P 6 ,

[0036] In severe cold areas, the mixed powder of magnesium chloride MgCl and calcium oxide CaO can also be used as a warming additive.

[0037] Described couplant making comprises the steps:

[0038] (1) Mix boiling water, 8% polyvinyl alcohol liquid glue and white latex in a ratio of 20:14:1 and stir fully to form a high-temperature diluted polyvinyl alcohol solution.

[0039] (2) Mix raw gypsum powder passed through a 0.075mm sieve with synthetic high-temperature liquid glue at a mass ratio of 3:2 to form a pa...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com