Oil-water well chemical resin type sand consolidating agent and sand prevention technology

A technology of resin type and sand consolidating agent, which is applied in the direction of chemical instruments and methods, drilling compositions, etc., can solve problems such as oil and water well damage, and achieve high permeability effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

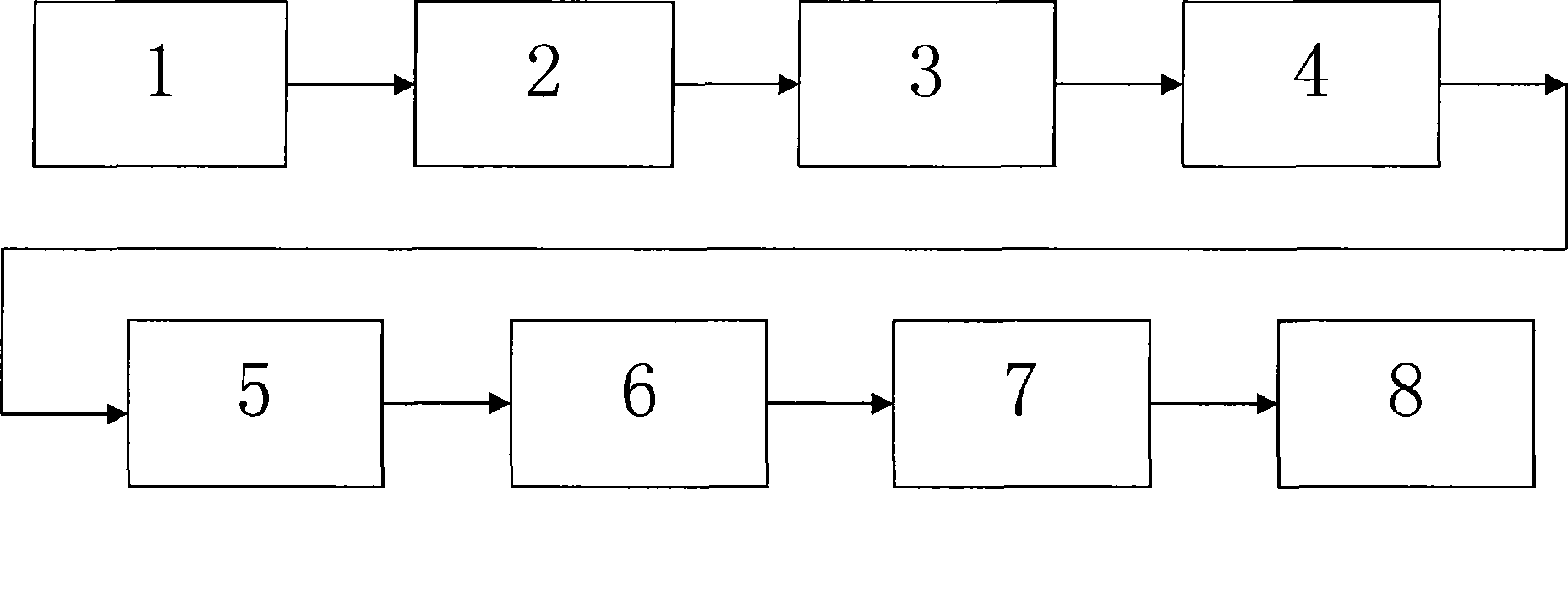

[0016] In order to further disclose the technical solutions of the present invention, the following will be described in detail through the embodiments in conjunction with the accompanying drawings:

[0017] The sand-consolidating agent formula of the present invention is the improvement carried out aiming at the sand control agent currently used in oil-water wells, and the percentages by weight of various medicament formulas are: organic silicon resin 5-10%, dispersant (furfural) 15-20%, mutual solvent (Acetaldehyde) 10-15%, curing agent (metaphosphoric acid) 10-15%, demulsifier 15-20%, aniline modified phenolic resin 15-20%, hydrochloric acid 25-30%, triethanolamine 5-10%, Aluminum sulfate 5-10%, OP10: 5-10%.

[0018] The sand control method is implemented as shown in the block diagram:

[0019] 1——Select a well with good liquid supply capacity and good permeability, and wash the sand to the position required by the design;

[0020] 2——Launch the construction string accord...

PUM

| Property | Measurement | Unit |

|---|---|---|

| viscosity | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com