Oil-rich and loose sandstone standard rock core column freezing coring method and coring clamp

A core and loosening technology, applied in the field of geological exploration, can solve the problems of inability to drill the core column, increase the friction between the drill bit and the core column, and unable to drill the core column, so as to improve the success rate of core extraction and avoid the The effect of crushing and avoiding coring failure

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0036] In order to have a clearer understanding of the technical features, purposes and effects of the present invention, the specific implementation manners of the present invention will now be described with reference to the accompanying drawings.

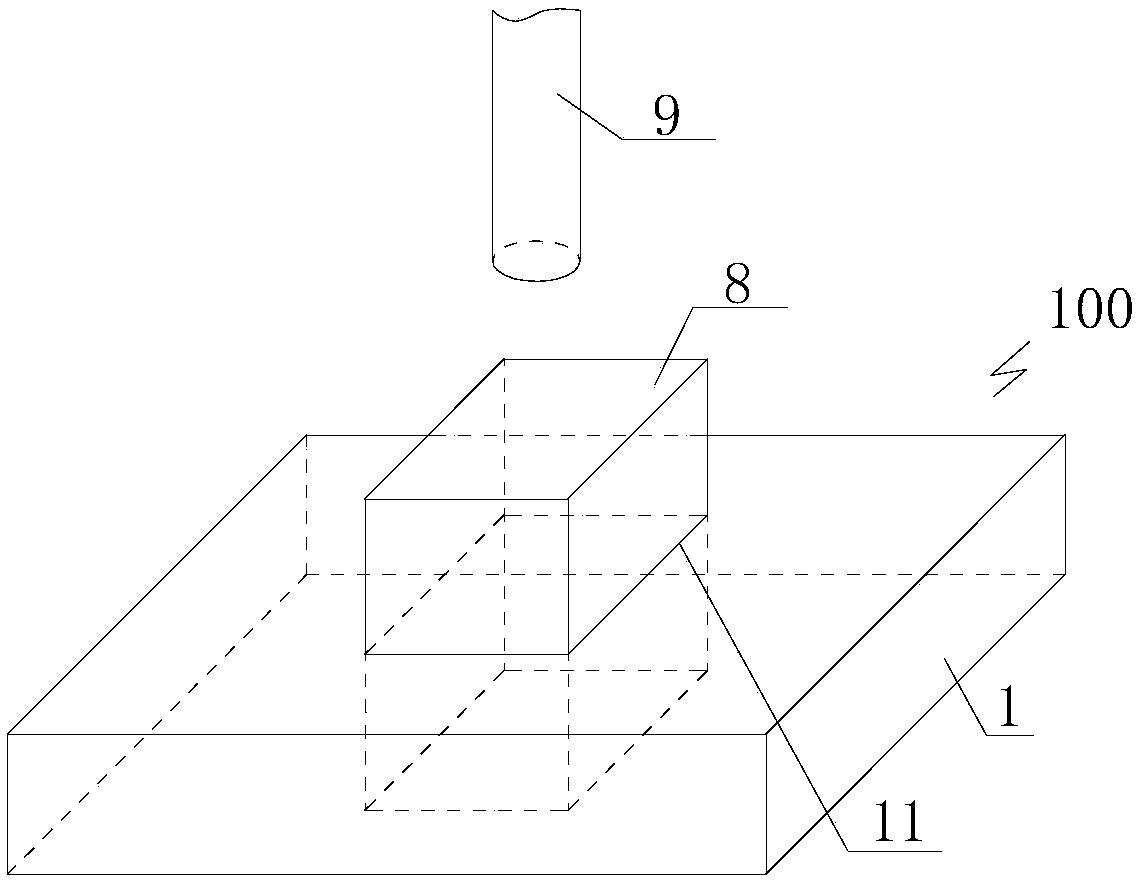

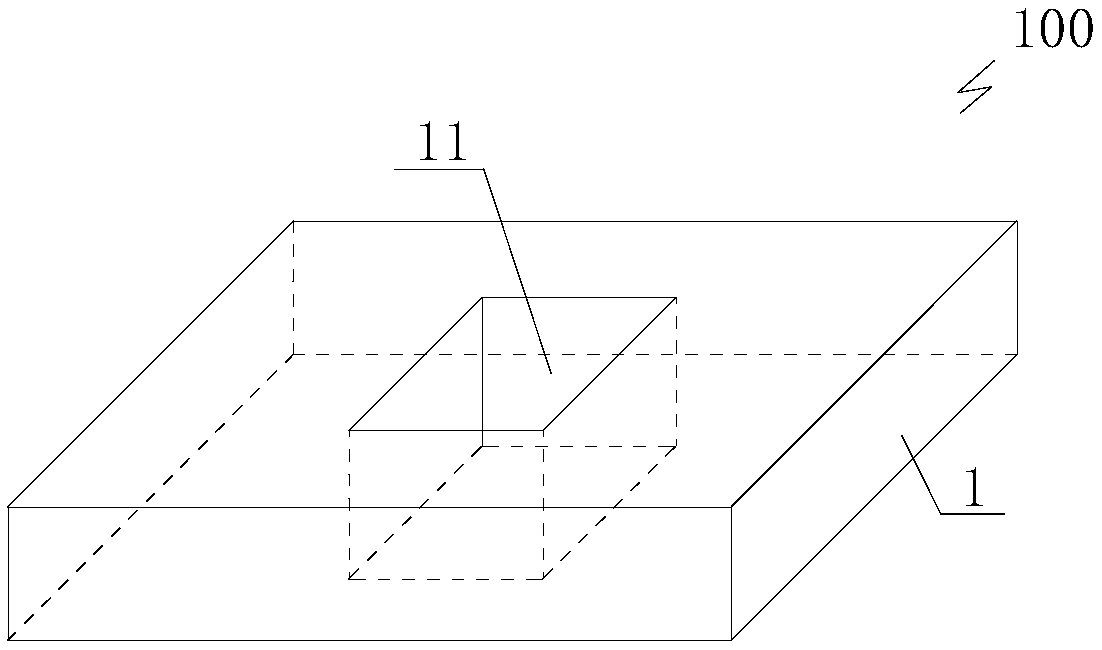

[0037]The present invention provides a standard core column frozen core method of oil-rich unconsolidated sandstone, comprising: drilling a full-diameter core of oil-rich unconsolidated sandstone on-site, freezing and solidifying the full-diameter core after mining and sealing; The full-diameter core is cut at low temperature to form a small-sized rock sample, and the small-sized rock sample is processed by deep freezing; the small-sized rock sample after deep freezing is fixed, and the outer wall of the small-sized rock sample is drilled with a drilling rig to form a standard core column of oil-rich loose sandstone , the oil-rich unconsolidated sandstone standard core column is preserved by pressure-controlled encapsulation.

[...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Height dimension | aaaaa | aaaaa |

| Mesh | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com