Method for firing ceramsite by utilizing active sludge

A technology of activated sludge and ceramsite, used in applications, household appliances, clay products, etc., can solve problems such as being unable to meet the requirements of sustainable environmental development, and achieve the effects of low density, increased use and high strength

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

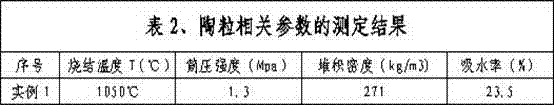

Embodiment 1

[0025] Table 1. Heavy metal content in the sludge of the seventh sewage plant in the main urban area of Kunming / mg·kg -1

[0026] Cadmium Cd

Lead Pb Chromium Cr Arsenic As Nickel Ni Zinc Zn Copper Cu Mercury Hg 3.70 74.30 105.53 53.54 61.60 843.60 214.90 3.81

[0027] The operation steps of firing sludge ceramsite are as follows:

[0028] (1) Material selection: Sludge and clay with a moisture content of 80% produced by sewage treatment plants are selected as raw materials;

[0029] (2) Drying: Stack the sludge obtained in step (1) naturally, and dry the sludge so that the moisture content in the dried sludge is 40%;

[0030] (3) Mixing: Put the clay obtained in step (1) and the dried sludge in step (2) into the mixer according to the weight ratio of 1:1 and mix evenly to obtain the mixed material;

[0031] (4) Granulation: send the mixed material obtained in step (3) into a granulator for granulation, and make granules with a ...

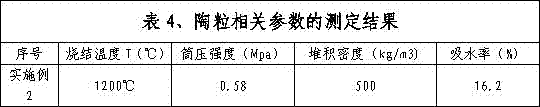

Embodiment 2

[0041] Table 3. Heavy metal content in the sludge of the No. 8 sewage plant in the main urban area of Kunming / mg·kg -1

[0042] Cadmium Cd

Lead Pb Chromium Cr Arsenic As Nickel Ni Zinc Zn Copper Cu Mercury Hg 4.2 43.6 102.44 52.26 59.87 889.66 213.26 3.42

[0043] The operation steps of firing sludge ceramsite are as follows:

[0044] (1) Material selection: Sludge and clay with a moisture content of 80% produced by sewage treatment plants are selected as raw materials;

[0045] (2) Drying: stack the sludge obtained in step (1) naturally, and dry the sludge so that the moisture content in the dried sludge is 50%;

[0046] (3) Mixing: Put the clay obtained in step (1) and the dried sludge in step (2) into the mixer according to the weight ratio of 1:1 and mix evenly to obtain the mixed material;

[0047] (4) Granulation: Send the mixed material obtained in step (3) into a granulator for granulation to make granules with a partic...

PUM

| Property | Measurement | Unit |

|---|---|---|

| density | aaaaa | aaaaa |

| density | aaaaa | aaaaa |

| density | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com