Silty mudstone similar material and preparation method thereof

A similar material, mudstone technology, applied in the field of silty mudstone similar materials and its preparation, can solve the problems of low similarity of rock materials, uncontrollable compaction, poor colloidal brittleness, etc., to save sample preparation costs and avoid The effects of artificial on-site sampling and sampling speed, increasing compactness

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

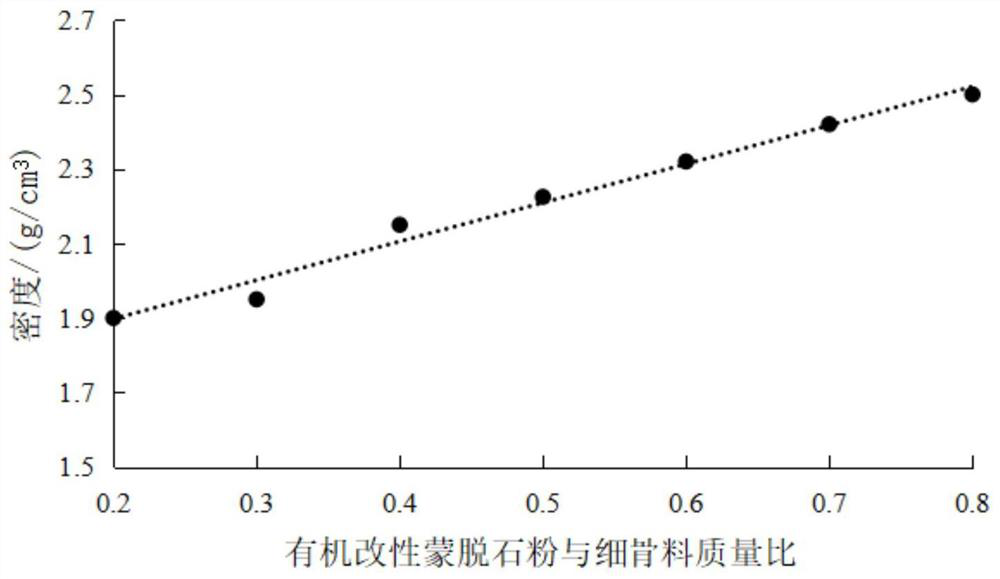

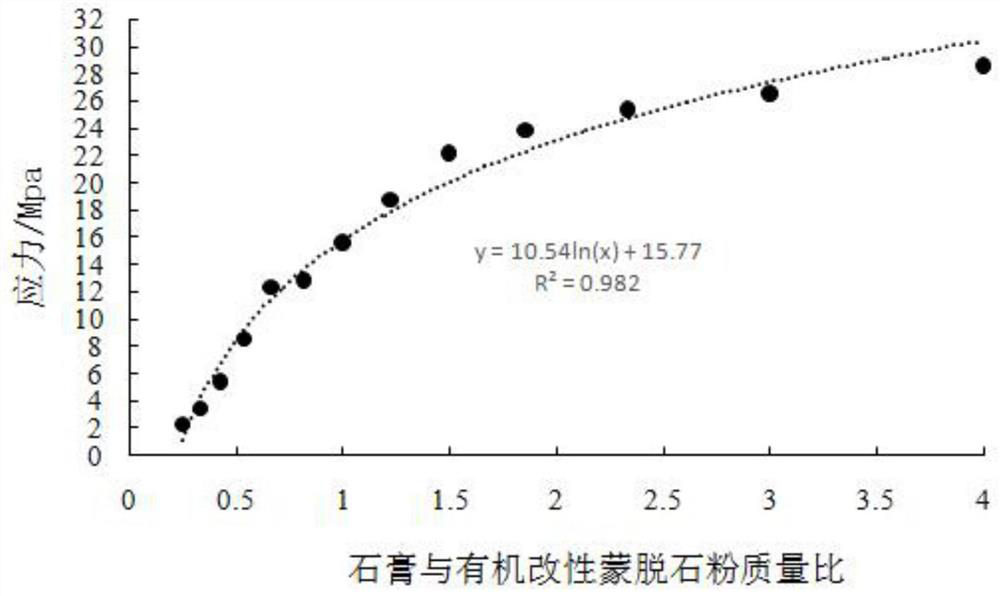

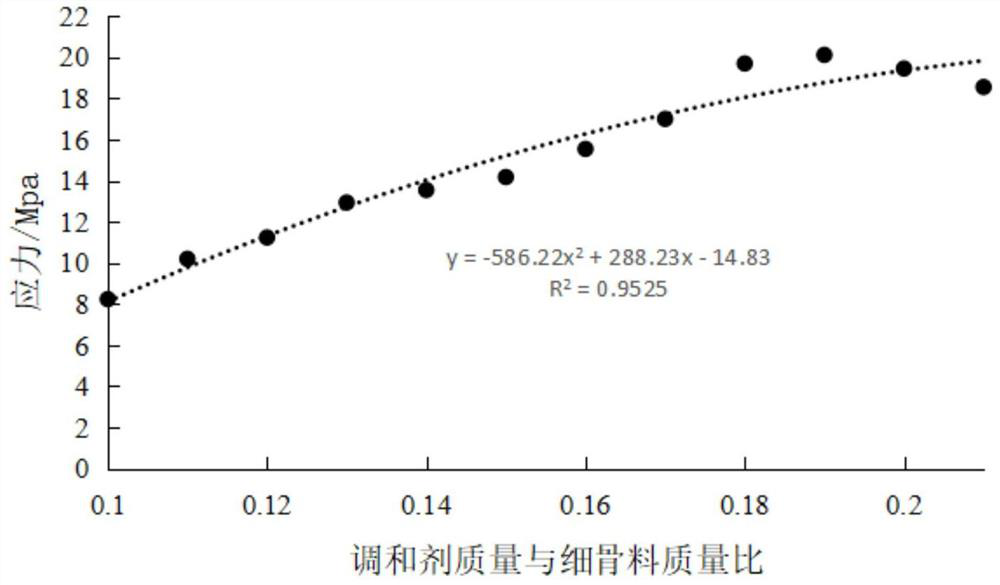

[0046] A kind of preparation method of silty mudstone similar material, concretely carries out according to the following steps:

[0047] S1, according to the following parts by mass, weigh 20-80 parts of gypsum, 20-80 parts of organically modified montmorillonite powder, 0.3-3.6 parts of nano-alumina, and 10-21 parts of saturated alcohol rosin solution; preparation of saturated alcohol rosin solution Method: Put the weighed rosin powder into the container, pour alcohol slowly, stir clockwise with a glass rod at a constant speed, filter out the remaining rosin at the bottom, and obtain a saturated alcohol rosin solution.

[0048] S2, pour the weighed gypsum, organically modified montmorillonite powder, and nano-alumina into the mixer at the same time, mix well and evenly, and form a solid mixture; stir at a speed of 30-50rad / s, stir for 5-10min, and quickly form a uniform mixture material, save sample preparation time, avoid material inhomogeneity in stirring, and cause defect...

Embodiment 1

[0053] A kind of preparation method of silty mudstone similar material, concretely carries out according to the following steps:

[0054] S1, weigh 20 parts of gypsum, 80 parts of organically modified montmorillonite powder, 0.3 parts of nano-alumina, and 21 parts of saturated alcohol rosin solution according to the following parts by mass;

[0055] S2, pour the weighed gypsum, organically modified montmorillonite powder, and nano-alumina into the mixer at the same time, fully mix evenly, form a uniform solid mixture, stir at a stirring speed of 50rad / s, and stir for 5min;

[0056] S3, pour the saturated alcohol rosin solution into the uniform solid mixture and stir quickly evenly, the stirring speed is 80rad / s, stir for 5min, and quickly form a uniform mixture;

[0057] S4, taking out the homogeneous mixture, putting it into a mold to control the degree of compaction in layers, and the degree of compaction of each layer is 0.75; it is used to control the density of similar ma...

Embodiment 2

[0060] A kind of preparation method of silty mudstone similar material, concretely carries out according to the following steps:

[0061] S1, according to the following parts by mass, weigh 80 parts of gypsum, 20 parts of organically modified montmorillonite powder, 3.6 parts of nano-alumina, and 10 parts of saturated alcohol rosin solution;

[0062] S2, pour the weighed gypsum, organically modified montmorillonite powder, and nano-alumina into the mixer at the same time, fully mix evenly, form a uniform solid mixture, stir at a speed of 30rad / s, and stir for 10min;

[0063] S3, pour the saturated alcohol rosin solution into the uniform solid mixture and stir quickly evenly, the stirring speed is 100rad / s, stir for 2min, and quickly form a uniform mixture;

[0064] S4, taking out the homogeneous mixture, putting it into a mold to control the degree of compaction in layers, and the degree of compaction of each layer is 0.85;

[0065] S5, put the filled sample mold in a constan...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle size (mesh) | aaaaa | aaaaa |

| particle diameter | aaaaa | aaaaa |

| density | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com