Equipment and method for preparing reinforcing sheets in batches

A reinforcing sheet and batch technology, which is applied in the field of batch preparation of reinforcing sheets, can solve the problems of surface slippage, inaccurate test results, and large tensile fracture force of 48K carbon rods, so as to reduce the cost of sample preparation and improve the efficiency of sample preparation. , the effect of reducing the amount of waste

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0021] It is stated that the present invention will be further described in conjunction with the accompanying drawings and embodiments, but the protection scope of the present invention should not be limited thereby.

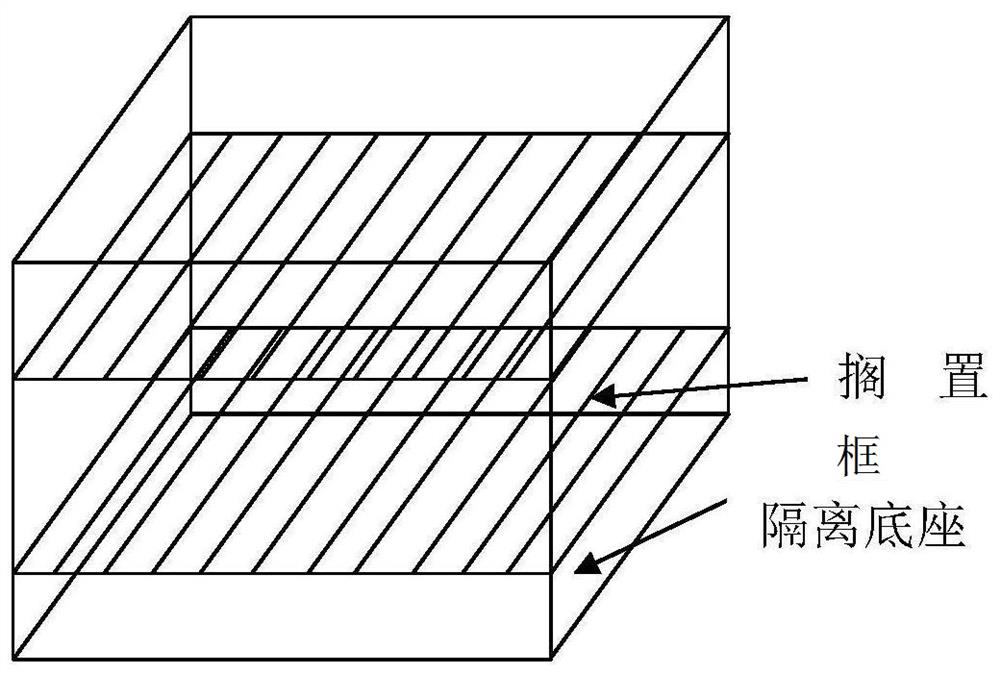

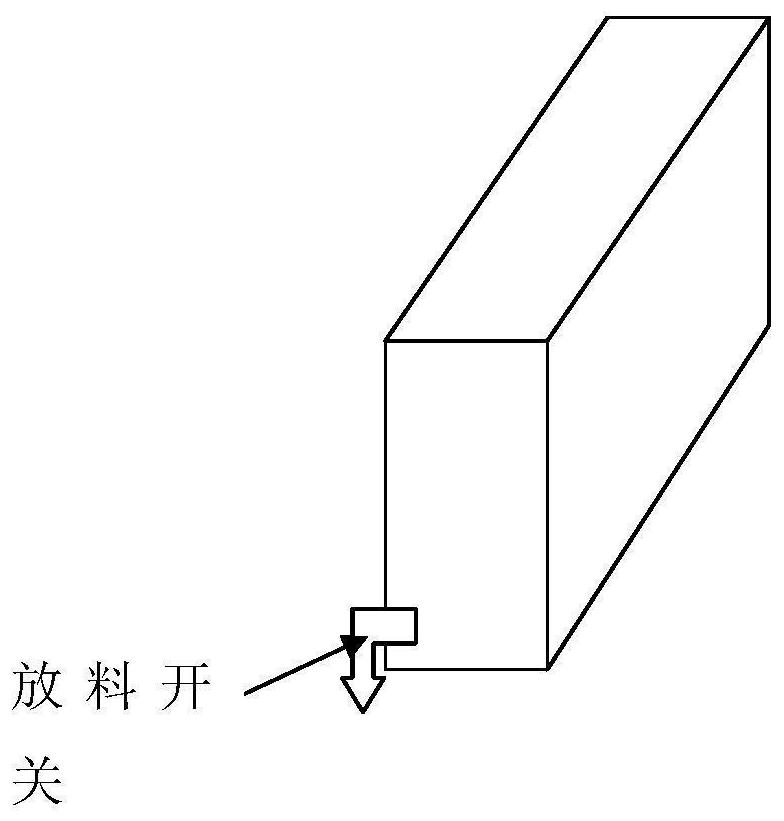

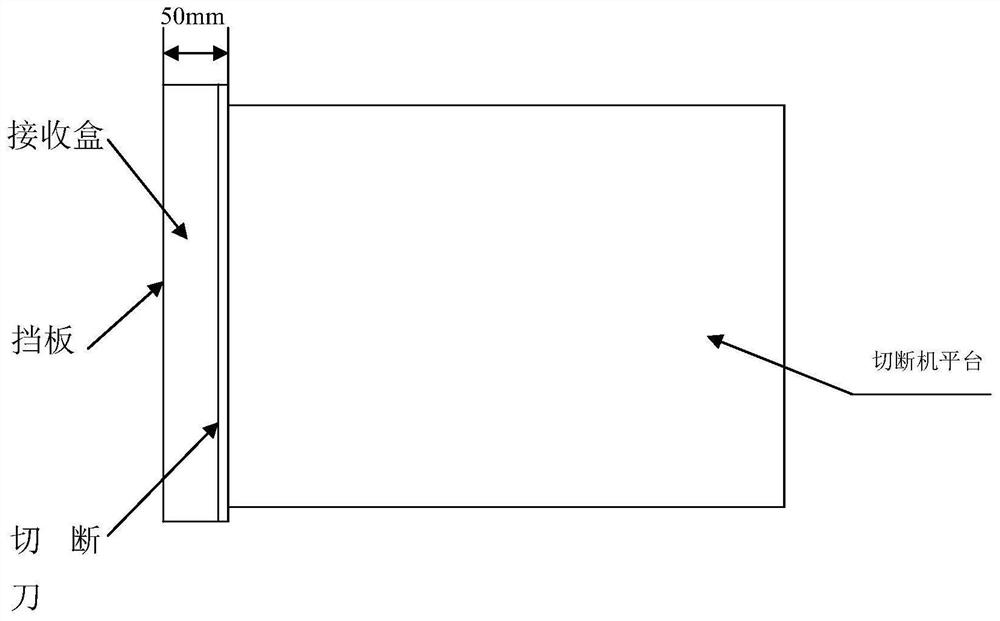

[0022] see first figure 1 , 2 , 3, figure 1 It is a three-dimensional view of the dipping tank of the equipment for preparing reinforcing sheets in batches according to the present invention, figure 2 It is a three-dimensional view of the shelving frame of the equipment for preparing reinforcing sheets in batches according to the present invention, image 3 It is a top view of the cutting machine of the equipment for preparing reinforcing sheets in batches according to the present invention. It can be seen from the figure that the equipment for preparing reinforcing sheets in batches of the present invention includes a dipping tank, a shelf and a cutting machine. The dipping tank is made of plastic with a An upward narrow opening (not shown in the figure), a...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com