Method for analyzing content of main elements in nickel cobalt lithium manganate positive electrode material

A technology of nickel cobalt lithium manganese oxide and analysis method, which is applied in the direction of material analysis, material analysis, and measuring device using wave/particle radiation, which can solve the problem of not fully satisfying fast-paced production, large consumption of chemical reagents, and inability to reproduce samples. Utilize and other problems to achieve the effect of great practicability, short detection cycle, and reduce the number of times of exposure to dangerous sources

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

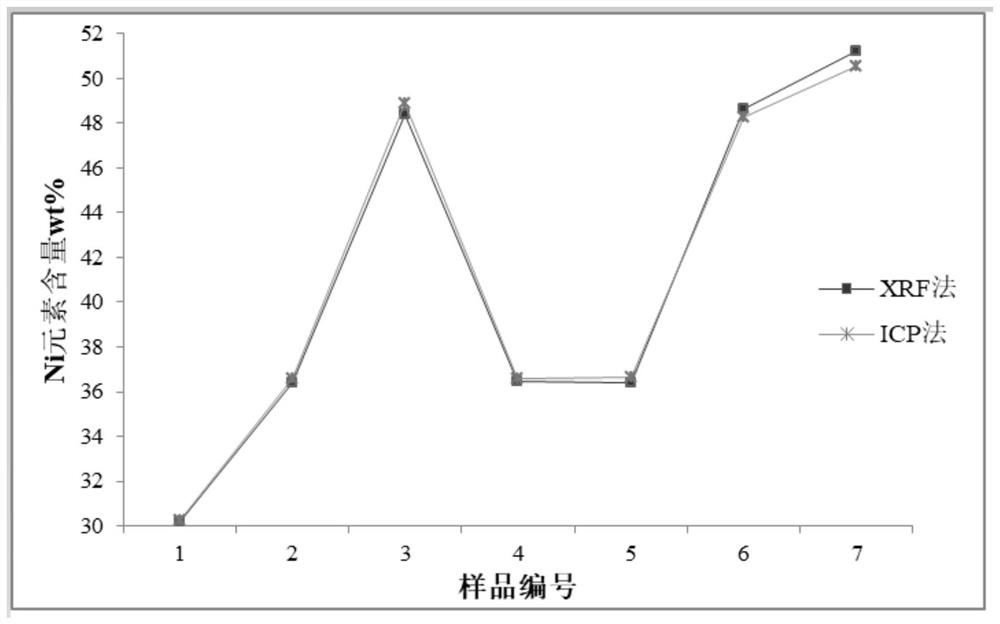

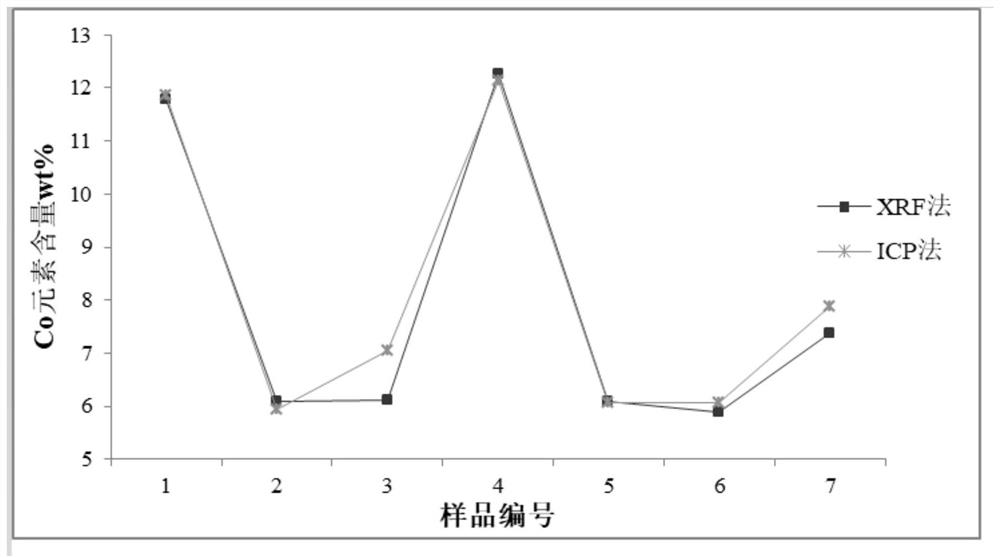

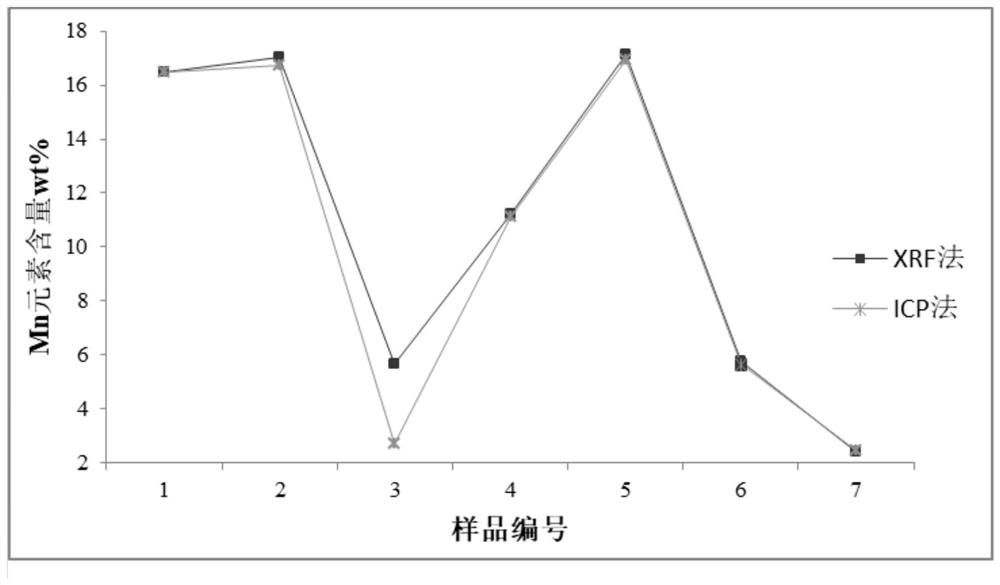

[0064] The present embodiment provides a method for establishing a standard curve in the nickel-cobalt lithium manganese oxide positive electrode material, and its establishment method is carried out based on the above-mentioned specific examples:

[0065] Among them, the chemical formula of the standard sample is LiNi 0.5 co 0.2 mn 0.3 o 2 , the main elements in the standard sample are Ni, Co and Mn, the pressure is 40t, the tablet processing time is 80s, the phototube voltage is 40KV, the phototube current is 900μA, and the test time is 70s.

Embodiment 2

[0067] The present embodiment provides a method for establishing a standard curve in the nickel-cobalt lithium manganese oxide positive electrode material, and its establishment method is carried out based on the above-mentioned specific examples:

[0068] Among them, the chemical formula of the standard sample is LiNi 0.6 co 0.1 mn 0.3 o 2, the main elements in the standard sample are Ni, Co and Mn, the pressure is 30t, the tablet processing time is 100s, the phototube voltage is 30KV, the phototube current is 850μA, and the test time is 80s.

Embodiment 3

[0070] The present embodiment provides a method for establishing a standard curve in the nickel-cobalt lithium manganese oxide positive electrode material, and its establishment method is carried out based on the above-mentioned specific examples:

[0071] Among them, the chemical formula of the standard sample is LiNi 0.8 co 0.1 mn 0.1 o 2 , the main elements in the standard sample are Ni, Co and Mn, the pressure is 35t, the tablet processing time is 90s, the phototube voltage is 45KV, the phototube current is 1000μA, and the test time is 55s.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com