Preparation method of nickel steel-containing sample for EBSD analysis

A sample, nickel steel technology, applied in the field of electron microscope sample preparation, can solve the problems of unsatisfactory EBSD samples, long sample preparation time, etc., to achieve the reduction of special sample preparation links, high operability, and reduced sample preparation costs Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

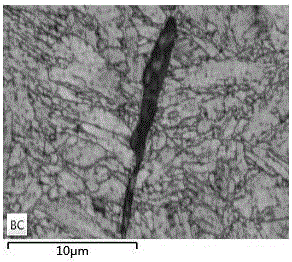

[0020] The preparation method of the sample for EBSD analysis of this nickel-containing steel adopts the following method steps to prepare:

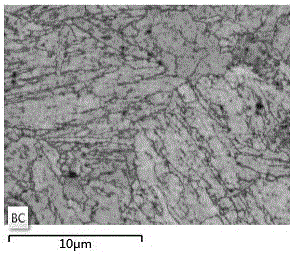

[0021] (1) Rough machining process: the Ni content in the nickel-containing steel is 8.5wt% to 9.5wt%. It is a low-carbon quenched and tempered steel. The structure is martensite plus bainite. Toughness and strength are the main materials used to manufacture liquefied natural gas storage tanks and transport ships.

[0022] Prepare the sample according to the requirements of metallographic sample preparation, process the sample into a suitable size, and polish it with 240#, 400#, 800# and 1000# water sandpaper in sequence. The next sandpaper can be replaced; after replacing the sandpaper, the sample needs to be rotated 90 degrees; finally a rough sample is obtained. This process does not introduce new sample preparation requirements, the main purpose is to make the sample preparation simple and effective, and the final test of the sample...

Embodiment 1

[0030] Embodiment 1: The specific process of the preparation method of the sample for EBSD analysis of the nickel-containing steel is as follows.

[0031] (1) Rough processing: Prepare the sample according to the requirements of metallographic sample preparation, and then polish it with 240#, 400#, 800# and 1000# water sandpaper.

[0032] (2) Polishing erosion: 2.5 micron particle size diamond suspension is used, the polishing disc speed is 400r / min, and the polishing time is 5min; the etching agent is 4% nitric acid alcohol solution, and the erosion time is 40 seconds.

[0033] (3) Fine polishing: 1 micron diamond suspension is used for polishing, and the rotational speed of the polishing disc is 100r / min. Use 0.05 micron alumina suspension to polish again, the polishing speed is 70r / min, and the polishing time is 20 minutes.

[0034] (4) Clean the surface: Throw the treated sample dry, clean the surface with alcohol, and dry it with a hair dryer to obtain the sample for EBS...

Embodiment 2

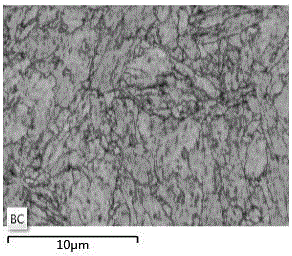

[0036] Embodiment 2: The specific process of the preparation method of the sample for EBSD analysis of the nickel-containing steel is as follows.

[0037] (1) Rough processing: Prepare the sample according to the requirements of metallographic sample preparation, and then polish it with 240#, 400#, 800# and 1000# water sandpaper.

[0038] (2) Polishing erosion: use diamond suspension with a particle size of 5 microns, the rotational speed of the polishing disc is 600r / min, and the polishing time is 3 minutes; the etching agent is 4% nitric acid alcohol solution, and the erosion time is 30 seconds.

[0039] (3) Fine polishing: 1.5 micron diamond suspension is used for polishing, and the rotational speed of the polishing disc is 80r / min. Use 0.05 micron aluminum oxide suspension to polish again, the polishing speed is 80r / min, and the polishing time is 15 minutes.

[0040] (4) Clean the surface: Throw the treated sample dry, clean the surface with alcohol, and dry it with a hai...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle size | aaaaa | aaaaa |

| particle size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com