Thin plate metallographical thermal embedding method

A technology of hot embedding and thin plate, applied in the preparation of test samples, etc., can solve the problems of capillary action, grinding sample corrosion, corrosion of metallographic surface, etc., and achieve the effect of reducing sample preparation cost, improving efficiency and improving success rate

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

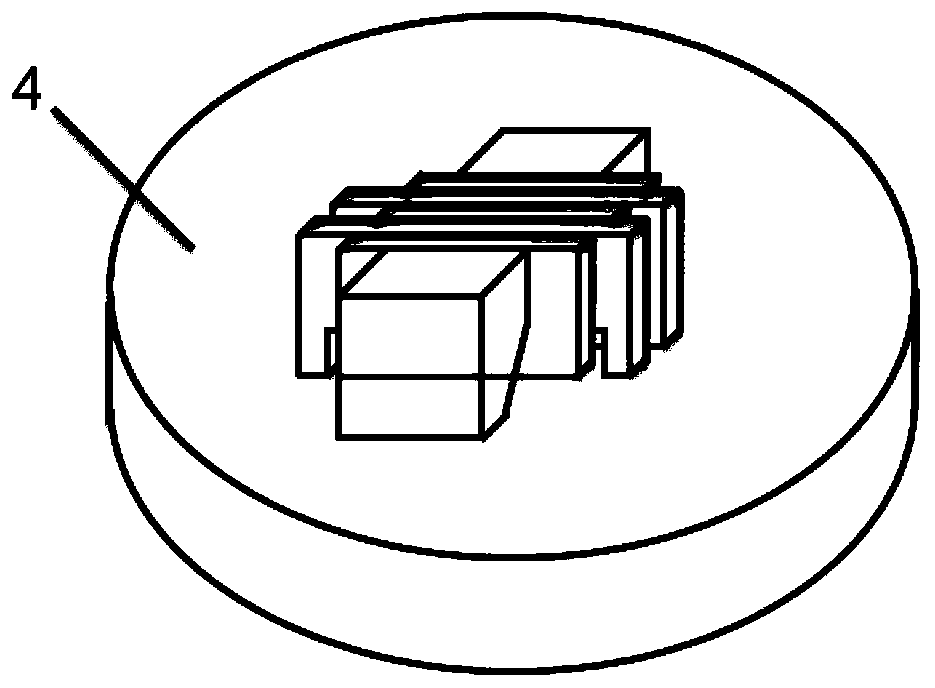

[0028] A single piece of DC04 deep-drawn IF steel sheet (thickness 0.8mm) was inlaid by hot inlay method, and the size and uniformity of ferrite structure were mainly observed. Using the thin plate thermal embedding method in the present invention, first use the inlay material alone to process it into a thermosetting resin block (thickness 4.0mm) with a notch, and the side length of the notch (2.0mm), place the thin plate with the notched thermosetting resin Between the blocks, the whole follows figure 2 Place it on the lower mold platform of the mounting machine, select a heating temperature of 180°C, a heating time of 4 minutes, a pressure of 250 bar, a high-speed cooling, and a water cooling time of 4 minutes for mounting. The cross-section of the thin plate is flat, there is no water stain on the surface after corrosion, and the overall metallographic structure is clean and convenient for shooting.

Embodiment 2

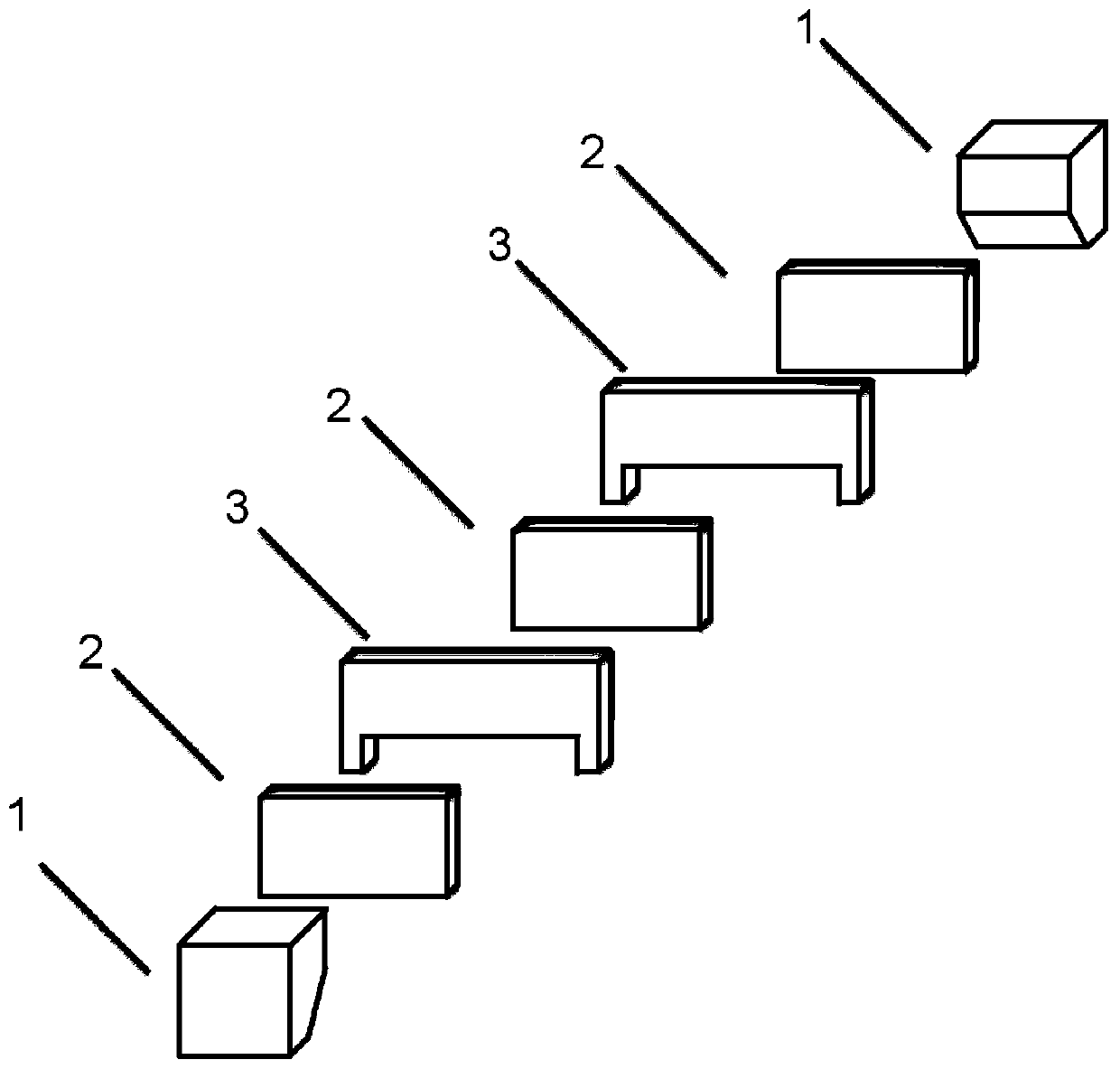

[0030] Eight pieces of DX53D+Z galvanized sheets (thickness 0.5mm, length 6.0mm, width 4.0mm) were inlaid by hot mosaic method, mainly to observe the structure of the zinc layer. Adopt thin plate thermal embedding method in the present invention, at first use inserting material to inlay and process thermosetting resin sheet (thickness 0.2mm, length 10.0mm, width 6.0mm), its notch size (length 8.0mm, width 2.0mm); processing resin Block (4.0mm), notch side length (2.0mm). Adjacent thin plate samples are separated by thermosetting resin sheets with notches, and the two ends are clamped and fixed by thermosetting resin blocks with notches, such as figure 1 shown. Put the whole into the hot mounting machine, such as figure 2 As shown, add resin inserts, select heating temperature 190°C, heating time 6min, pressure 280bar, select medium speed cooling, water cooling time 6min, and mount. There is no gap between the sections of the galvanized sheet, the corroded surface of the sa...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com