Positive electrode lithium supplementing method of lithium ion battery, product of positive electrode lithium supplementing method and application of product

A lithium-ion battery and lithium replenishment technology, which is applied in battery electrodes, non-aqueous electrolyte battery electrodes, secondary batteries, etc. The hidden danger of bulging, beneficial to filling and wetting, and the effect of improving electrochemical performance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0097] In this embodiment, the design battery capacity is 2.2Ah;

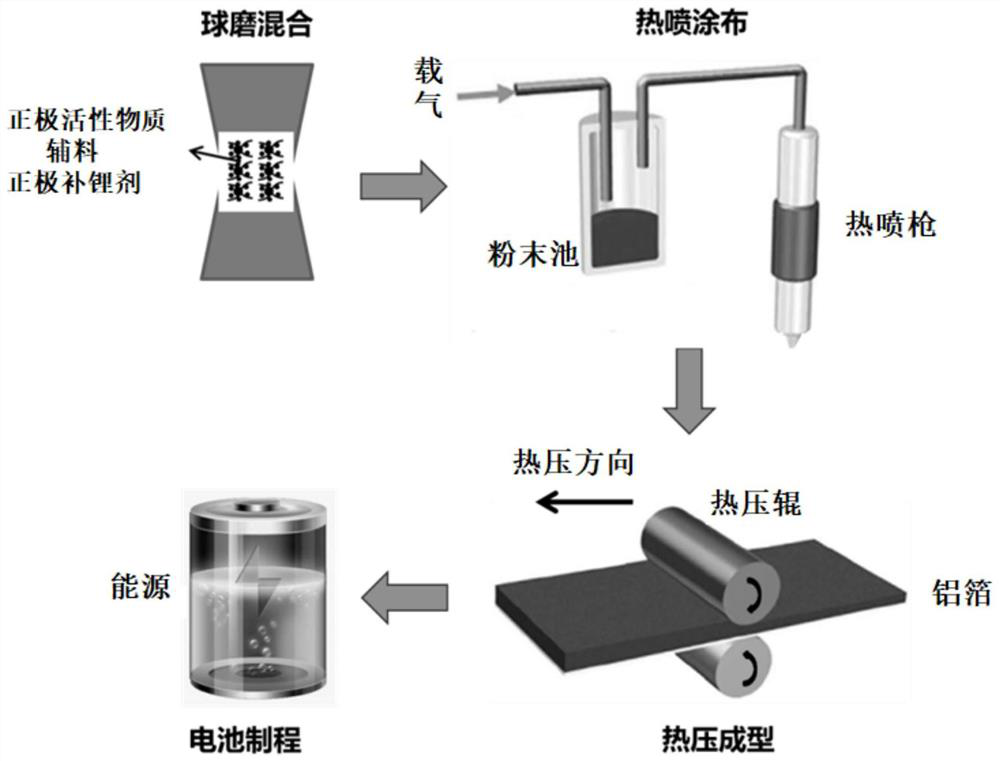

[0098] The positive electrode lithium replenishment method specifically comprises the following steps:

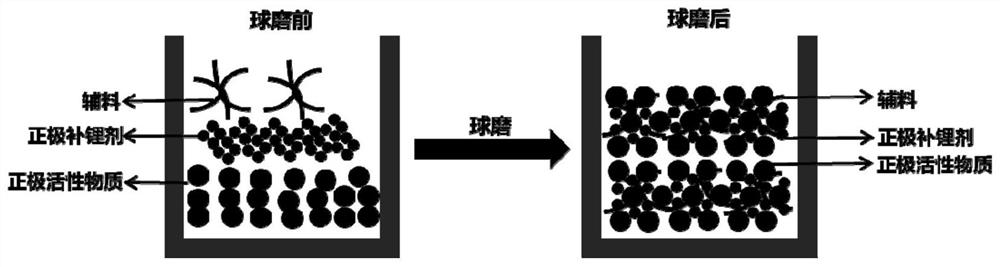

[0099] The positive active material lithium iron phosphate, lithium azide (Li 3 N), conductive agent SP and binder PVDF are mixed by ball milling, wherein, the mass ratio of lithium iron phosphate, conductive agent SP and binder PVDF is 98.4:0.5:1.1; with lithium iron phosphate, conductive agent SP and binder The sum of the mass of PVDF is 100%, Li 3 The mass percentage of N is 3%;

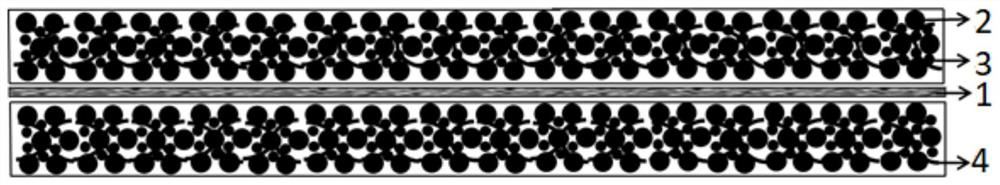

[0100] Using nitrogen as the carrier gas, the mixed material is sprayed through a thermal spray gun (temperature 120°C, voltage 25kV) and evenly attached to the carbon-coated aluminum foil of the current collector under the action of strong static electricity, so that the surface density is 0.20mg / mm 2 , (the area of the wafer obtained by the punching machine is 1540mm 2 , the quality of the active material layer is 300m...

Embodiment 2

[0112] The only difference between this embodiment and embodiment 1 is that the sum of the mass of lithium iron phosphate, conductive agent SP and binder PVDF is 100%, Li 3 The mass percentage of N is 1%; other parameters and conditions are exactly the same as in Example 1.

Embodiment 3

[0114] The only difference between this embodiment and embodiment 1 is that the sum of the mass of lithium iron phosphate, conductive agent SP and binder PVDF is 100%, Li 3 The mass percentage of N is 6%; other parameters and conditions are exactly the same as in Example 1.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com