A method of preparing "nose tip" specimen for fib three-dimensional reconstruction

A technology of three-dimensional reconstruction and nose tip, which is applied in the direction of material analysis, instruments, and measuring devices using wave/particle radiation, which can solve the problems of high cost, reduce sample preparation costs, promote popularization and application, and shorten the use time.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

example 1

[0023] (1) Al-Si alloy ingots are prepared by induction melting;

[0024] (2) The sample is mechanically polished, and the sample area to be tested is marked under an optical microscope;

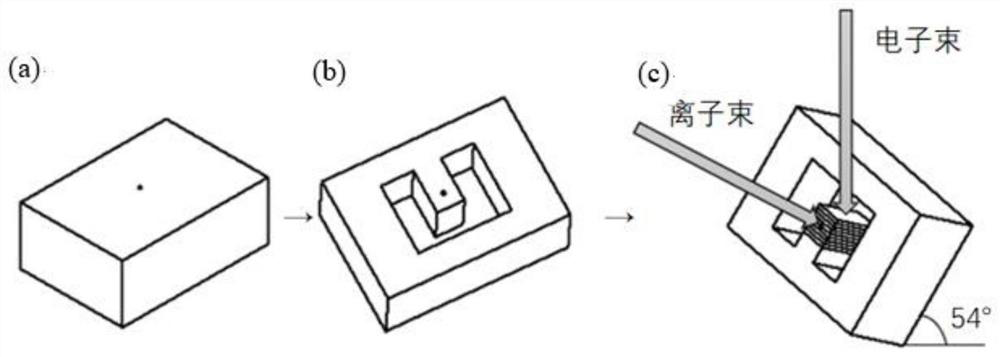

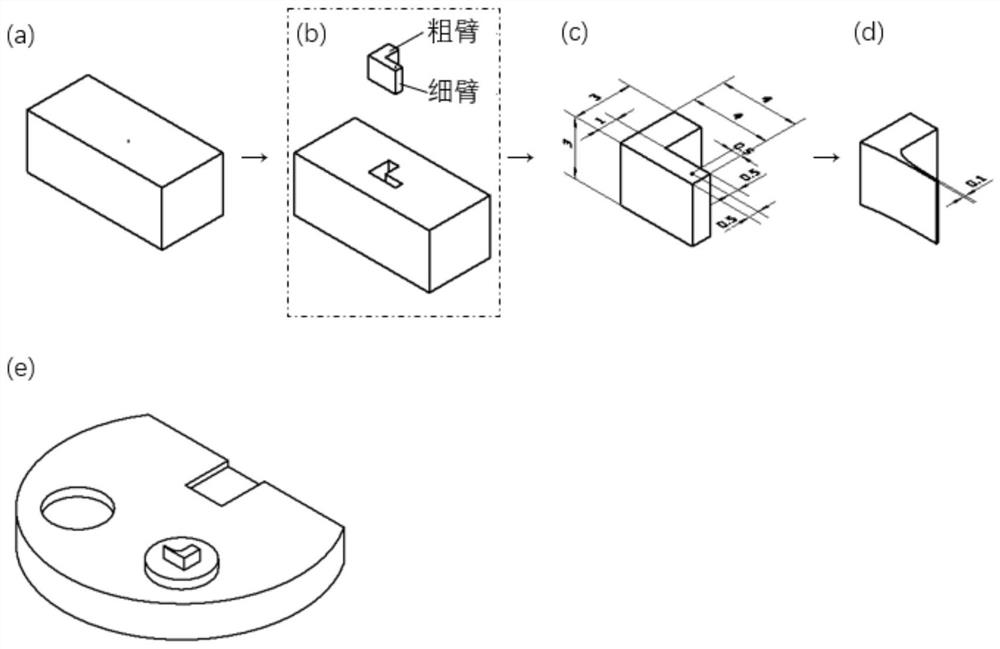

[0025] (3) if figure 2 As shown in (b), with the area to be tested as the center, leave 0.5mm for the left, right, and front parts respectively, so that the sample is in an "L" shape, and the area to be tested is located at the front end of the "L" shape, and the "L" shaped block is generally Length 4mm, width 3mm, depth 3mm, paste copper tape on the surface of the area to be tested (purpose: to protect the sample to be tested from being polluted by wire cutting oil, and the conduction of copper tape will not affect wire cutting, just remove the copper tape after wire cutting) , use the wire cutting method to cut the sample, and initially form the "nose tip", the width of the "nose tip" is 1mm;

[0026] (4) if figure 2 (d) Polish both sides of the "nose tip" with high-grit sandpaper, fr...

example 2

[0030] (1) Prepare titanium alloy ingot ((Ti-5.5Mo-7.2Al-4.5Zr-2.6Sn-2.1Cr)) by vacuum consumable arc melting; heat treatment at 740°C for 5 hours after forging and solution treatment , water quenching to maintain high temperature microstructure;

[0031] (2) After the sample is mechanically polished, electropolishing is performed to remove the surface layer. Polishing parameters: 25°C, 25V, about 30s, polishing liquid: 6% HClO 4 , 34% CH 3 (CH 2 ) 3 OH and 60% CH 3 OH;

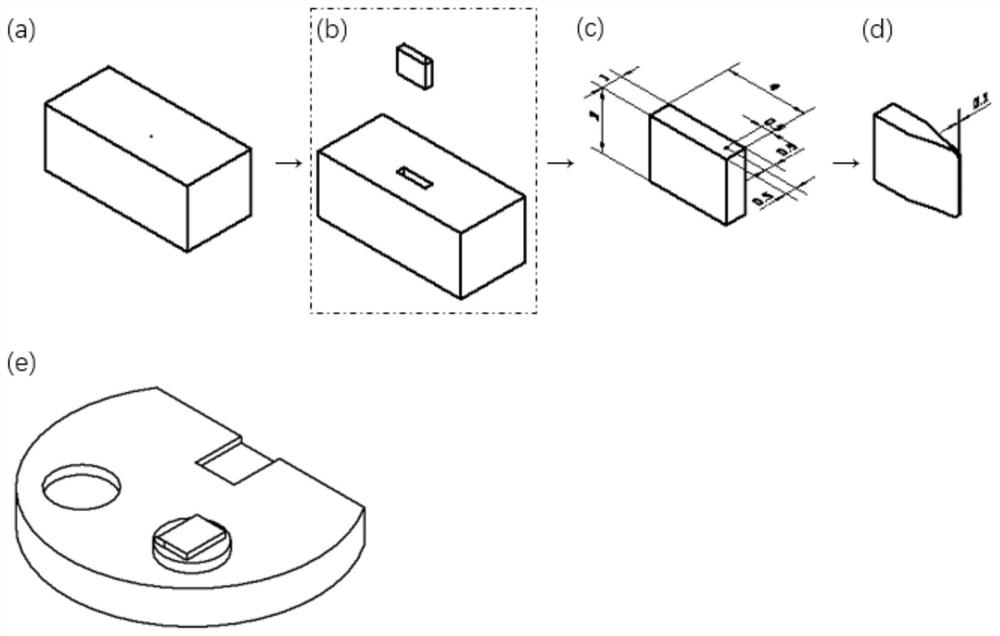

[0032] (3) A sample of 5 mm x 1 mm x 0.5 mm is cut out from the polished sample. Make the area to be measured close to the edge of the sample, and electrochemically polish the sample to a thickness of about 26 μm, such as Figure 5 As shown in (a): Clean the aluminum block with alcohol, and polish the surface of the aluminum block to be glued with sandpaper, stick the sample to the aluminum block with silver glue, and then stick the metal block to the workbench with silver glue, and put it into the vac...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com