Patents

Literature

31results about How to "Variability" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

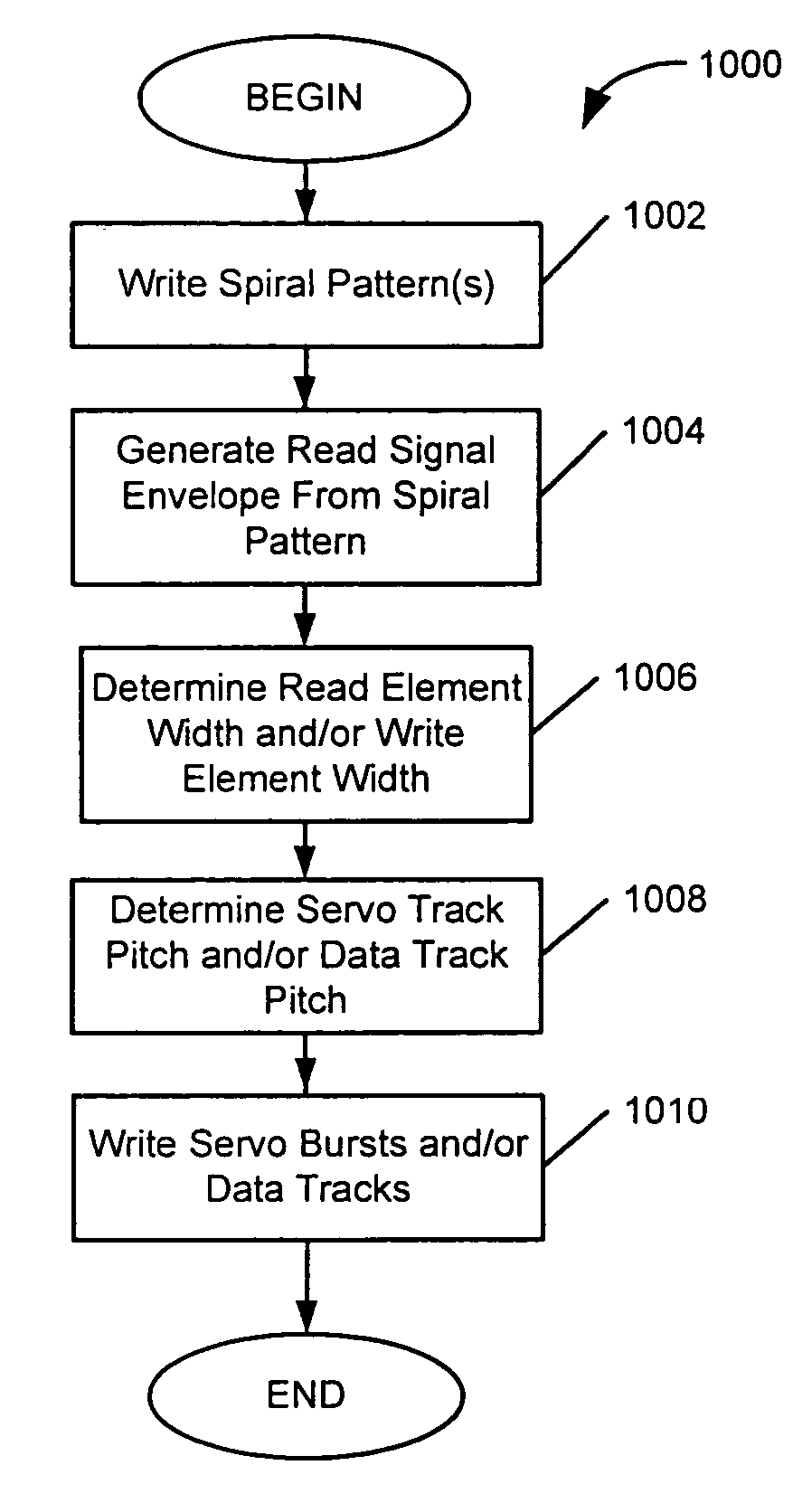

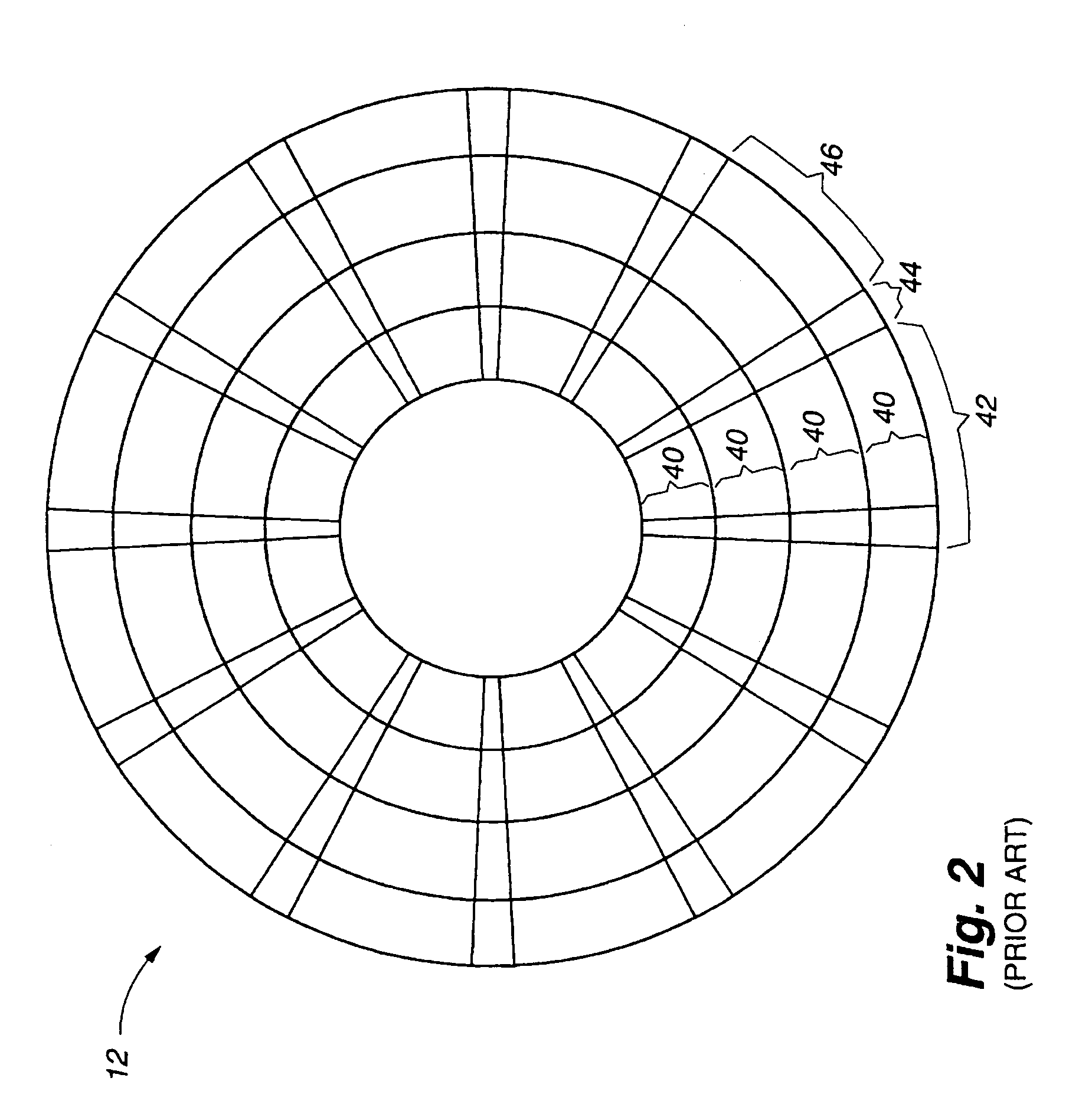

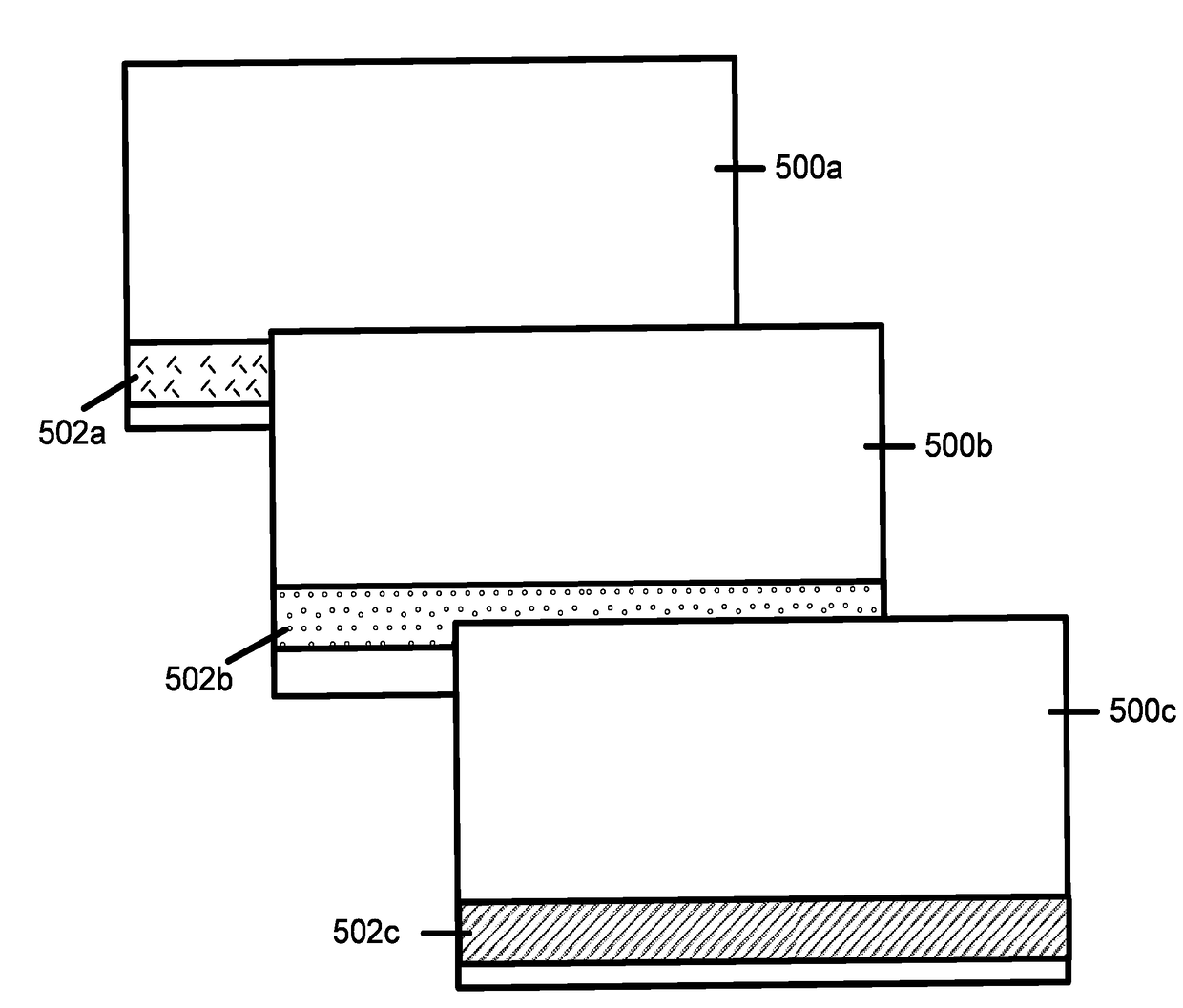

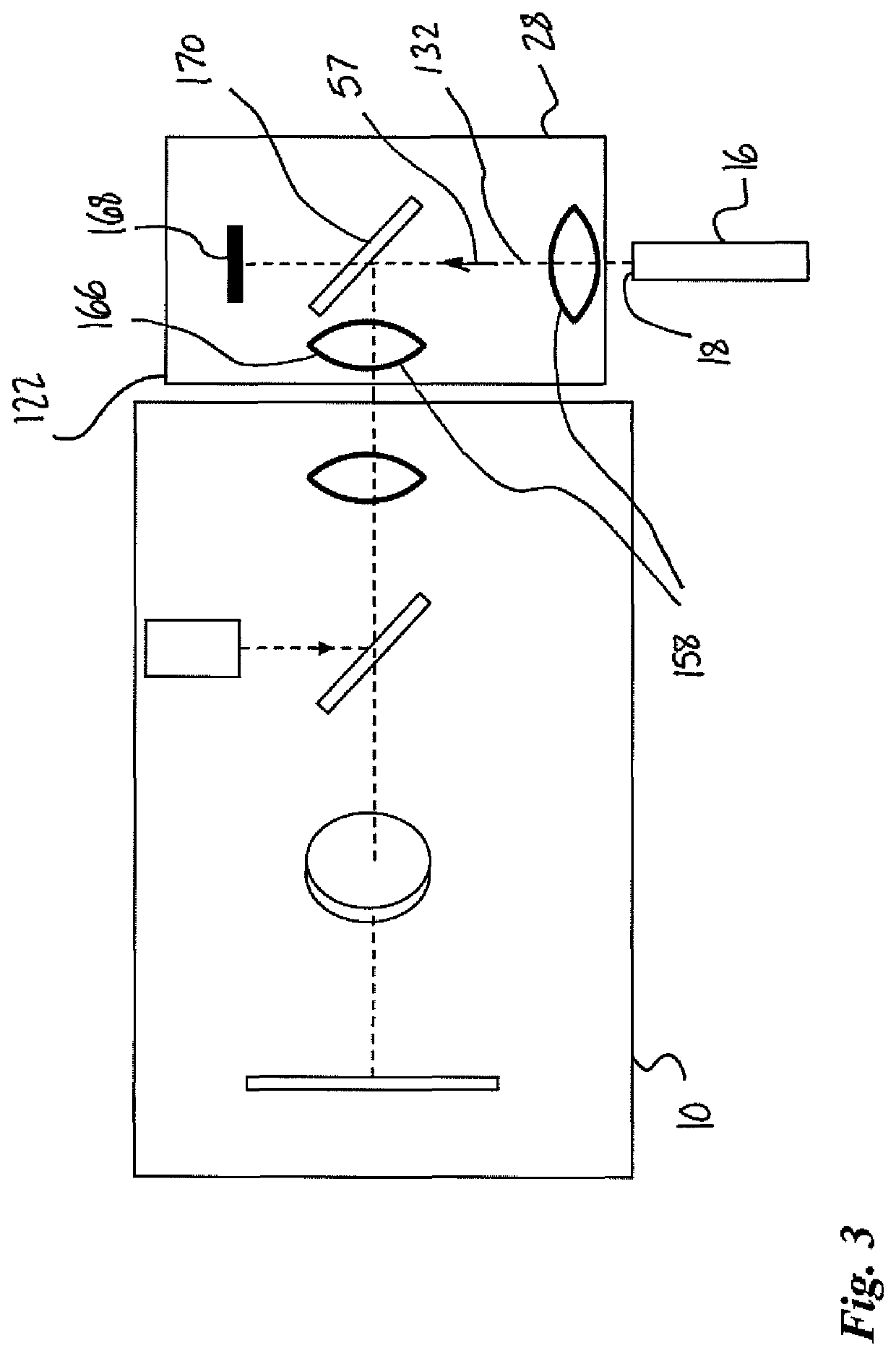

Apparatus for writing servo bursts on a disk with servo track pitch based on read element width and methods of manufacturing same

InactiveUS7154689B1VariabilityImprove manufacturing yieldDriving/moving recording headsRecord information storageTransducerEngineering

Methods for making a disk drive, apparatus for writing servo bursts on a disk, and disk drive apparatus are provided. The disk drive includes a disk and transducer adjacent to the disk. The transducer includes a read element and a write element. A width of the read element is determined. A servo track pitch is determined based on the read element width. Servo bursts are written in servo tracks on the disk with the write element based on the servo track pitch.

Owner:MAXTOR

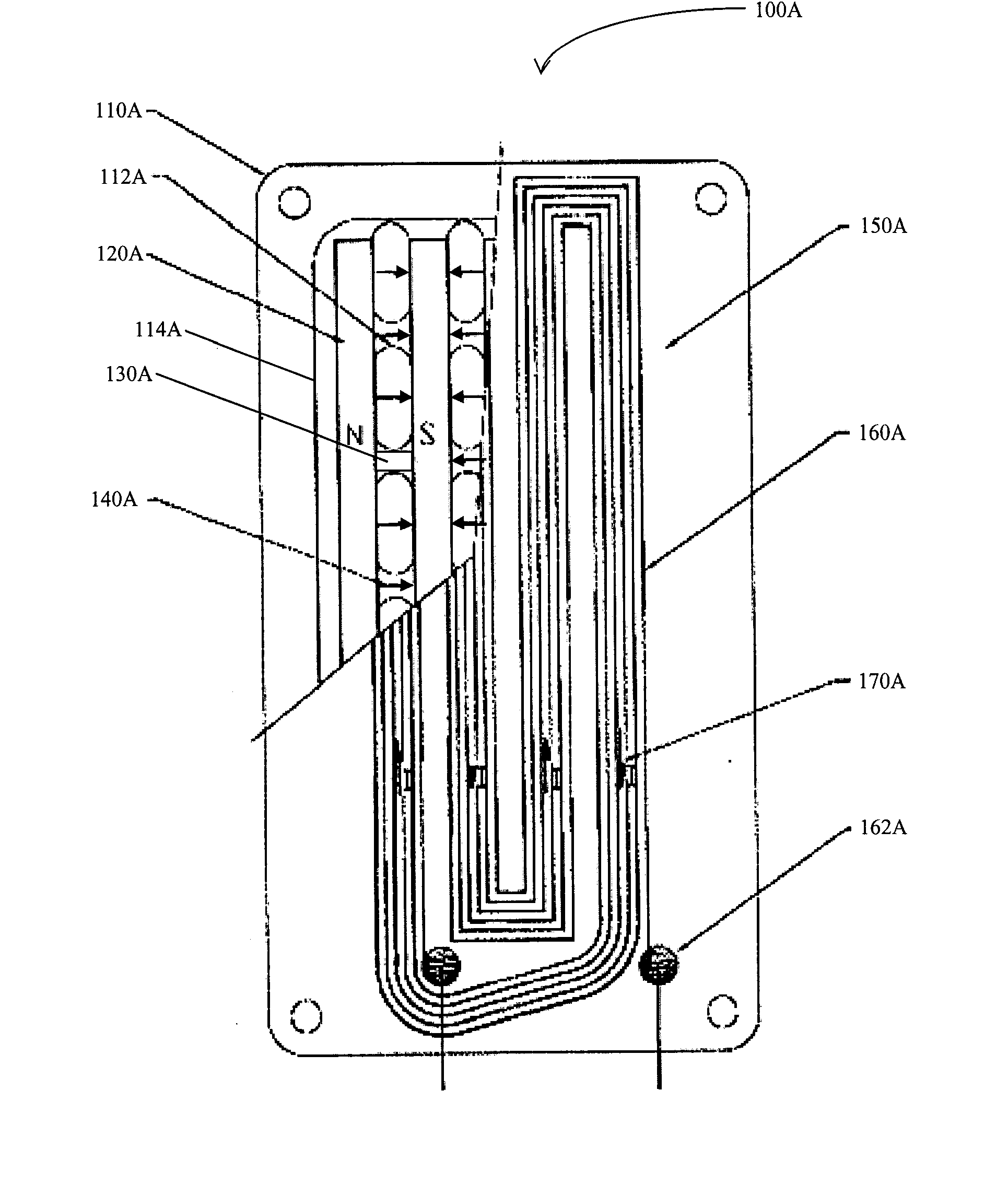

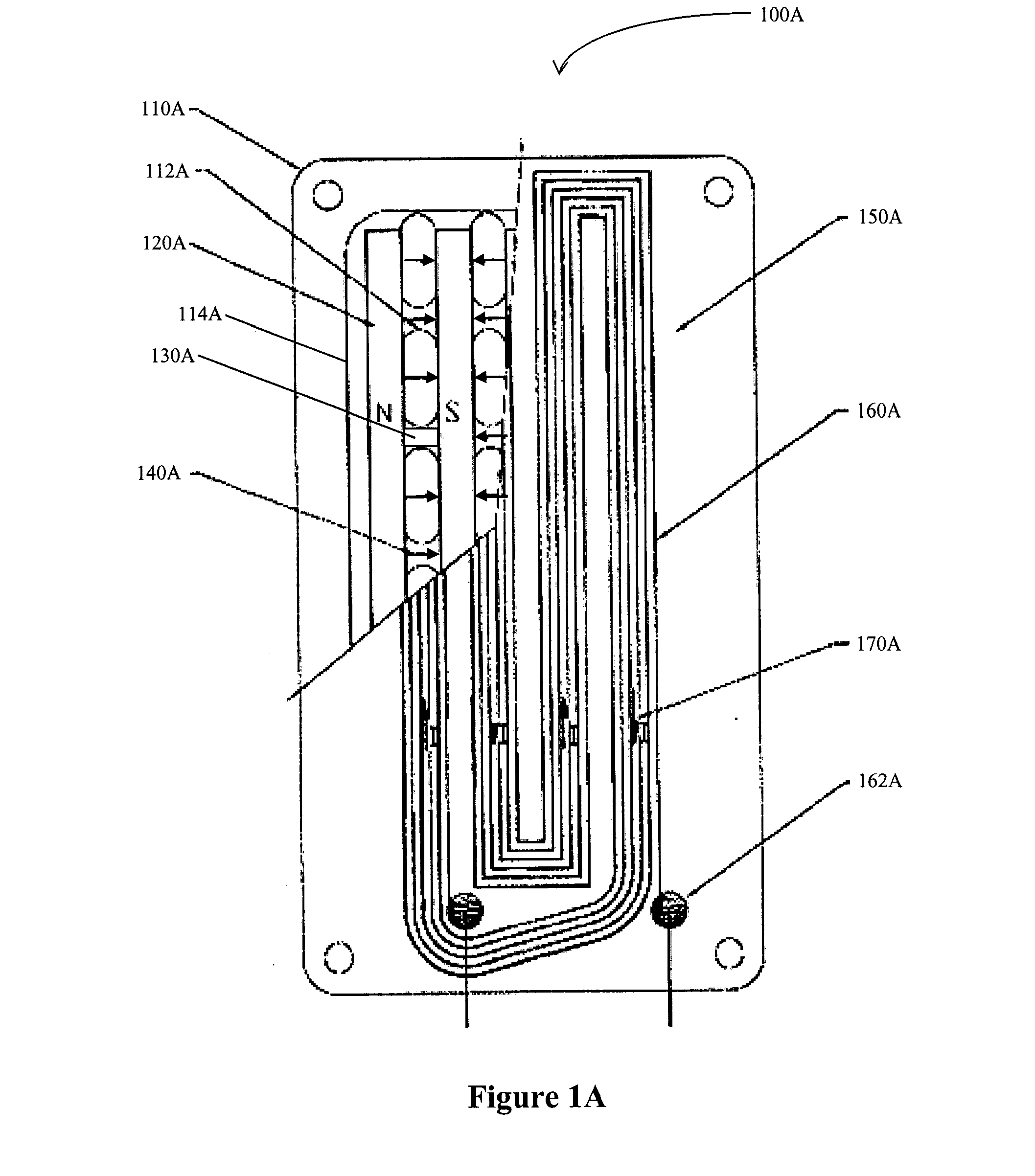

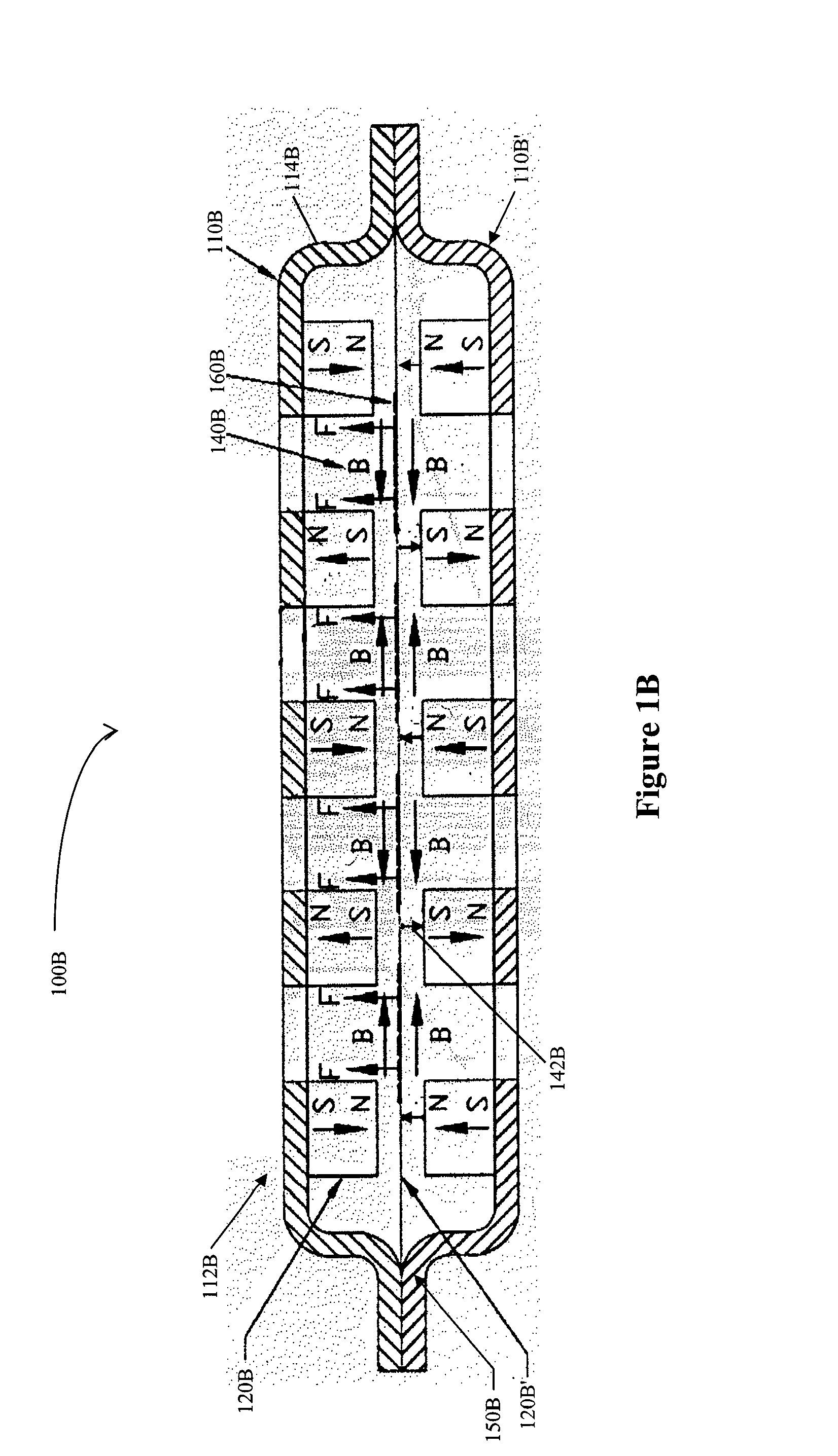

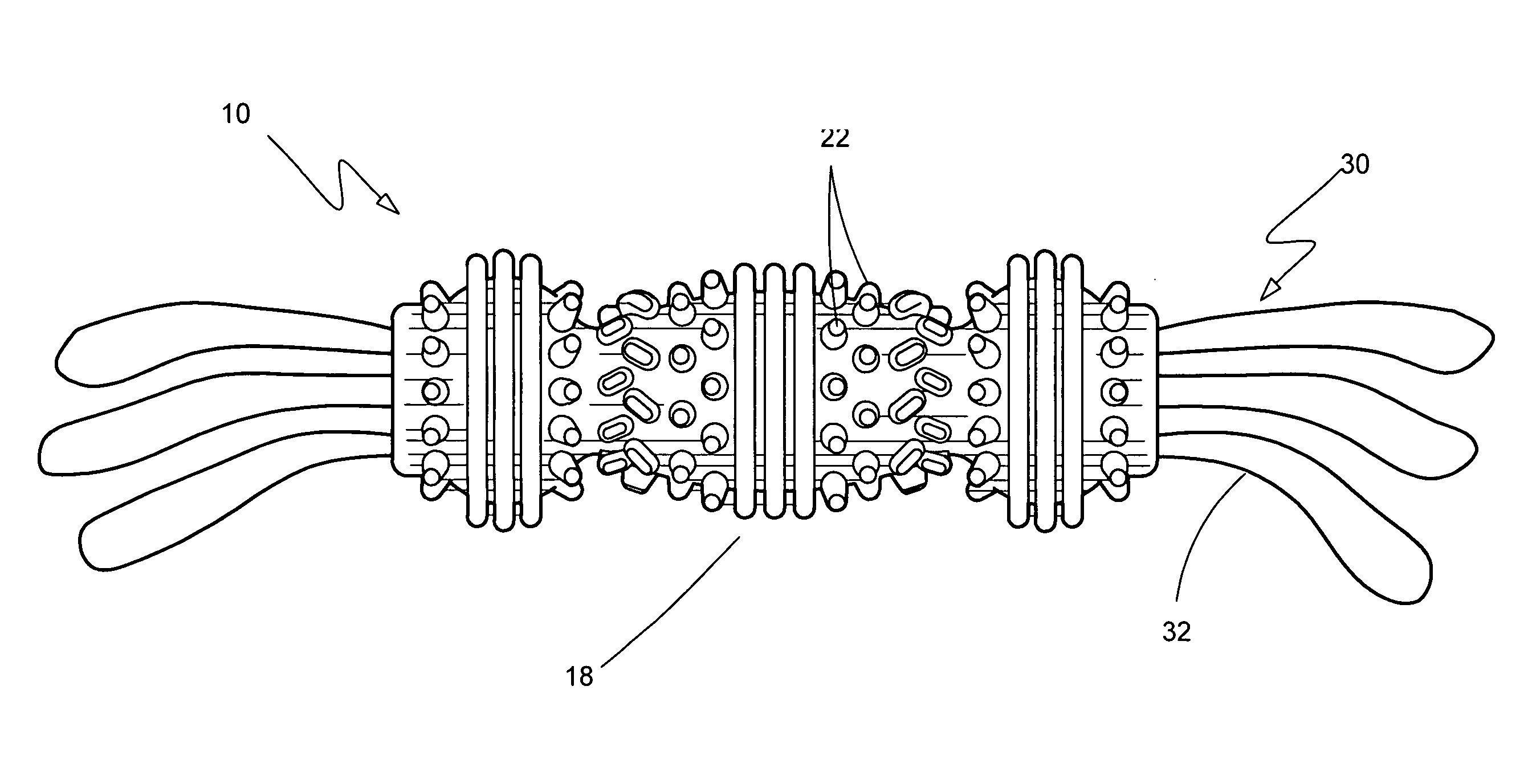

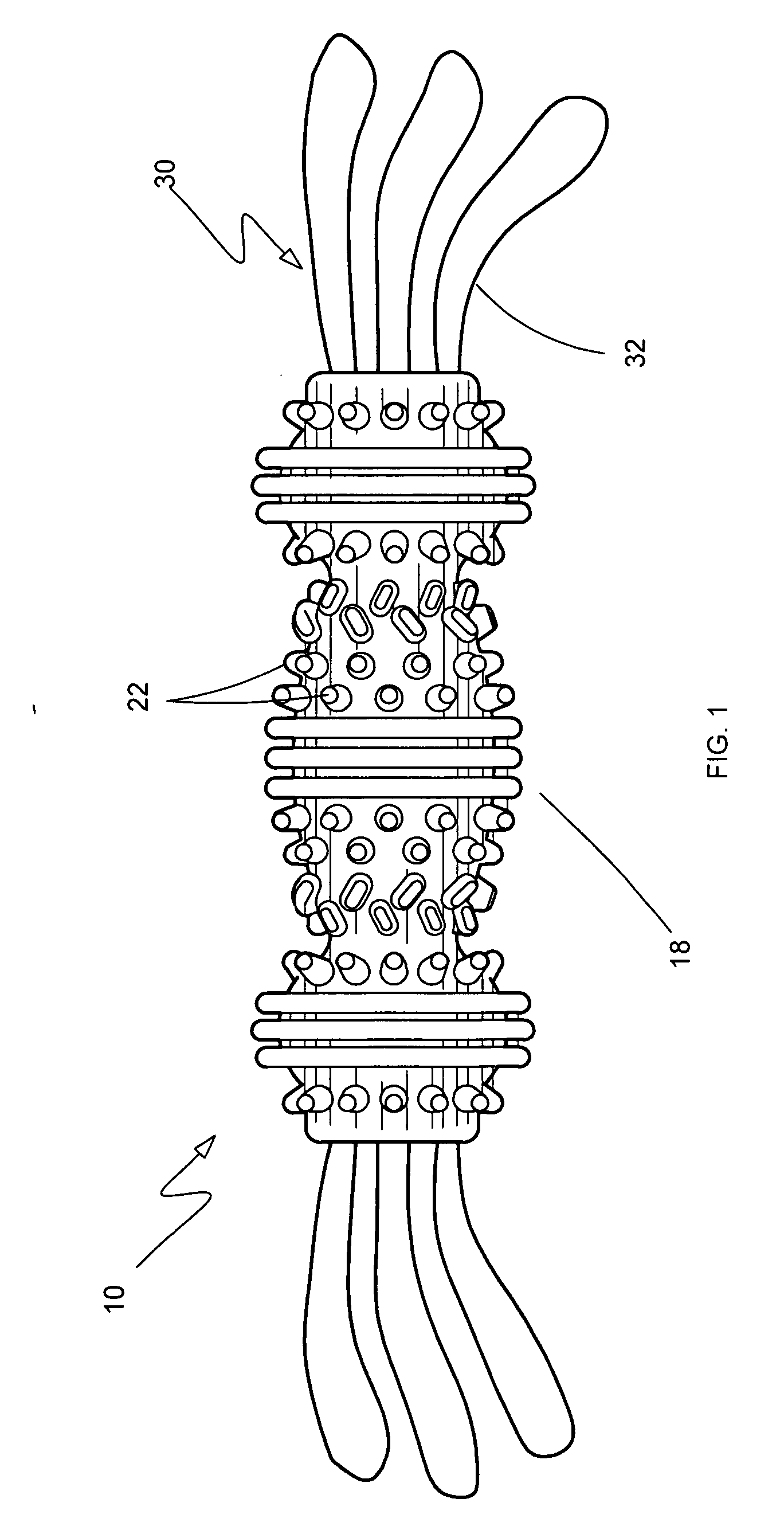

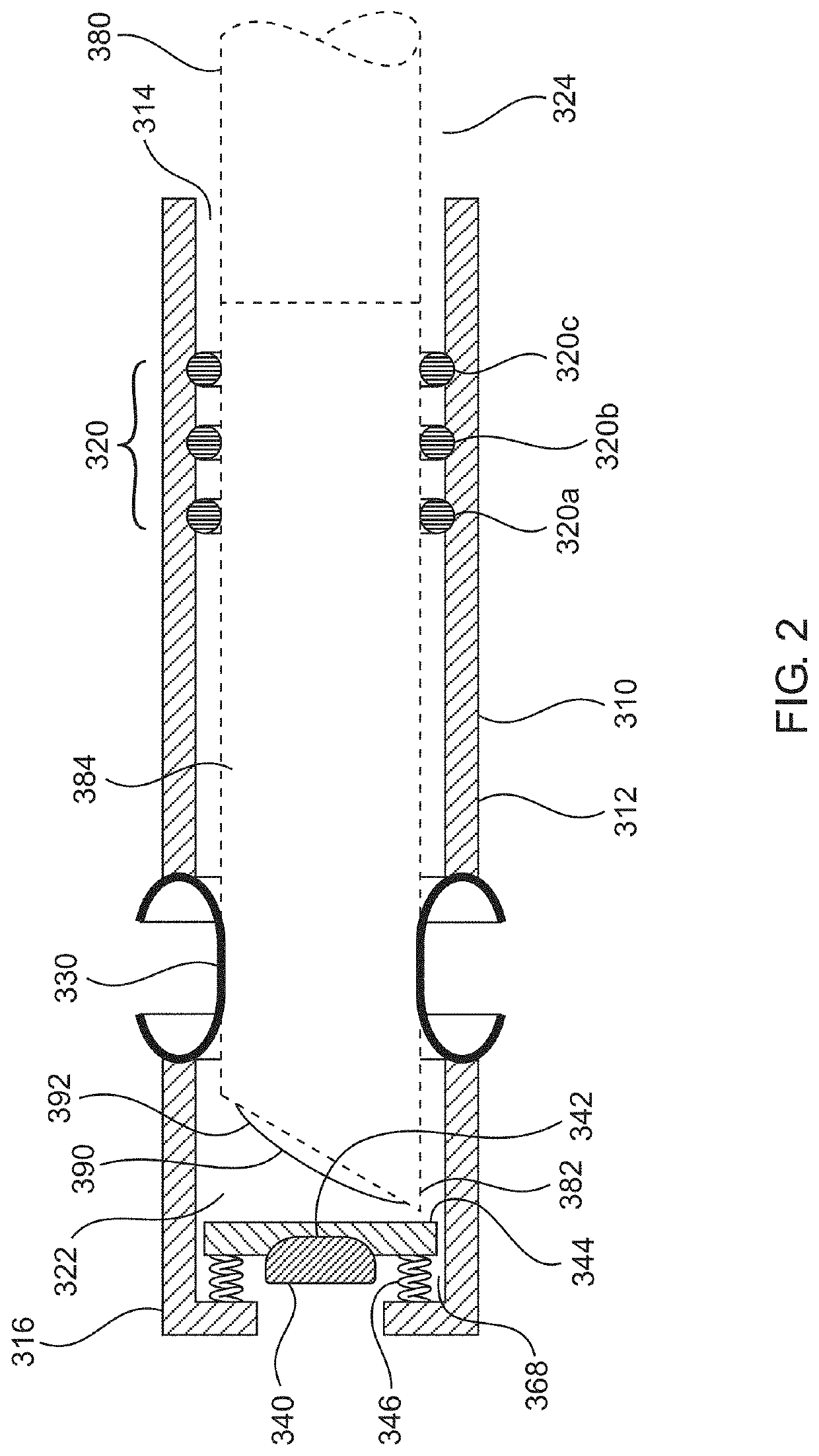

Full Range Planar Magnetic Transducers And Arrays Thereof

InactiveUS20080019558A1VariabilitySuitable for productionTransducer detailsMagnetic transducersRare earth

Contemplated planar magnetic transducers include a magnet and diaphragm arrangement such that substantially homogenous vertical and high horizontal magnetic flux density is realized in the inter-magnet space. Most preferably, the diaphragm is a tensioned polymer membrane in which the voice coil covers a significant portion of the active portion of the membrane, and the magnets are rare-earth metal-type magnets of ultra-high strength. Particularly preferred planar magnetic transducers allow for exceptionally large excursion of the diaphragm in a substantially homogenous magnetic field at virtually no distortion, thereby providing heretofore unachieved sound pressure levels. Arrays of such and other transducers are disclosed that provide a full-range speaker with acoustic plane source characteristics.

Owner:HPV TECH

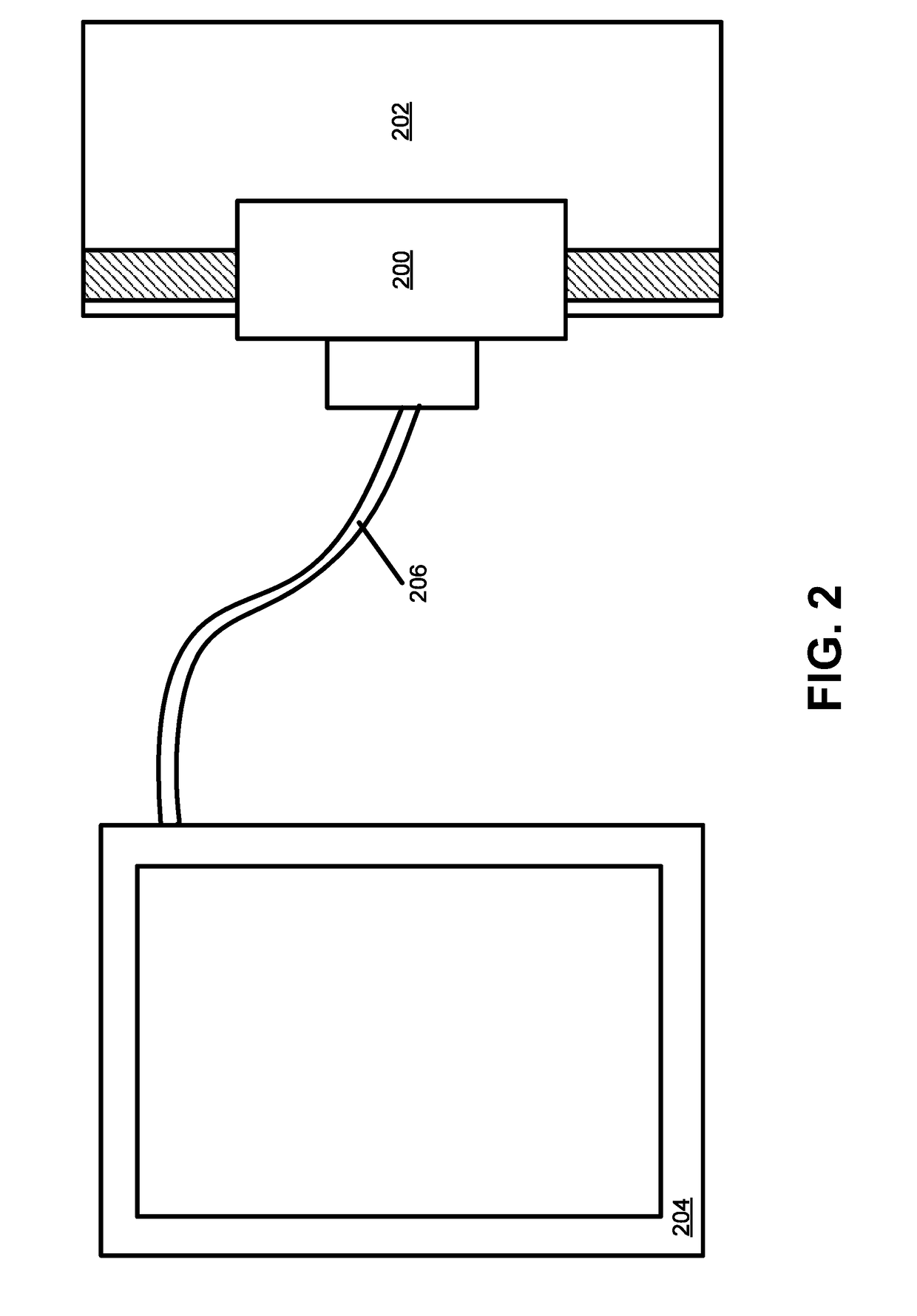

Systems and methods for user identification using graphical barcode and payment card authentication read data

ActiveUS20170262845A1Reduce the possibilityPrevent replay attacksPayments involving neutral partyProtocol authorisationGraphicsUser device

A method for authenticating an online transaction or a log-in process is provided. The method comprises: receiving image data of a visual graphical barcode from a user device, and the visual graphical barcode is configured to be displayed on an unauthenticated device for conducting the online transaction; analyzing the image data to obtain a transaction validation identifier (ID); comparing the transaction validation ID to a pre-stored validation ID; comparing a first set of collection data from the user device to a second set of collection data that is pre-stored; and determining whether to approve or reject the online transaction based on (1) a match between the transaction validation ID and the pre-stored validation ID, and (2) a match between the first set of collection data and the second set of collection data that is pre-stored.

Owner:TRUSONA INC

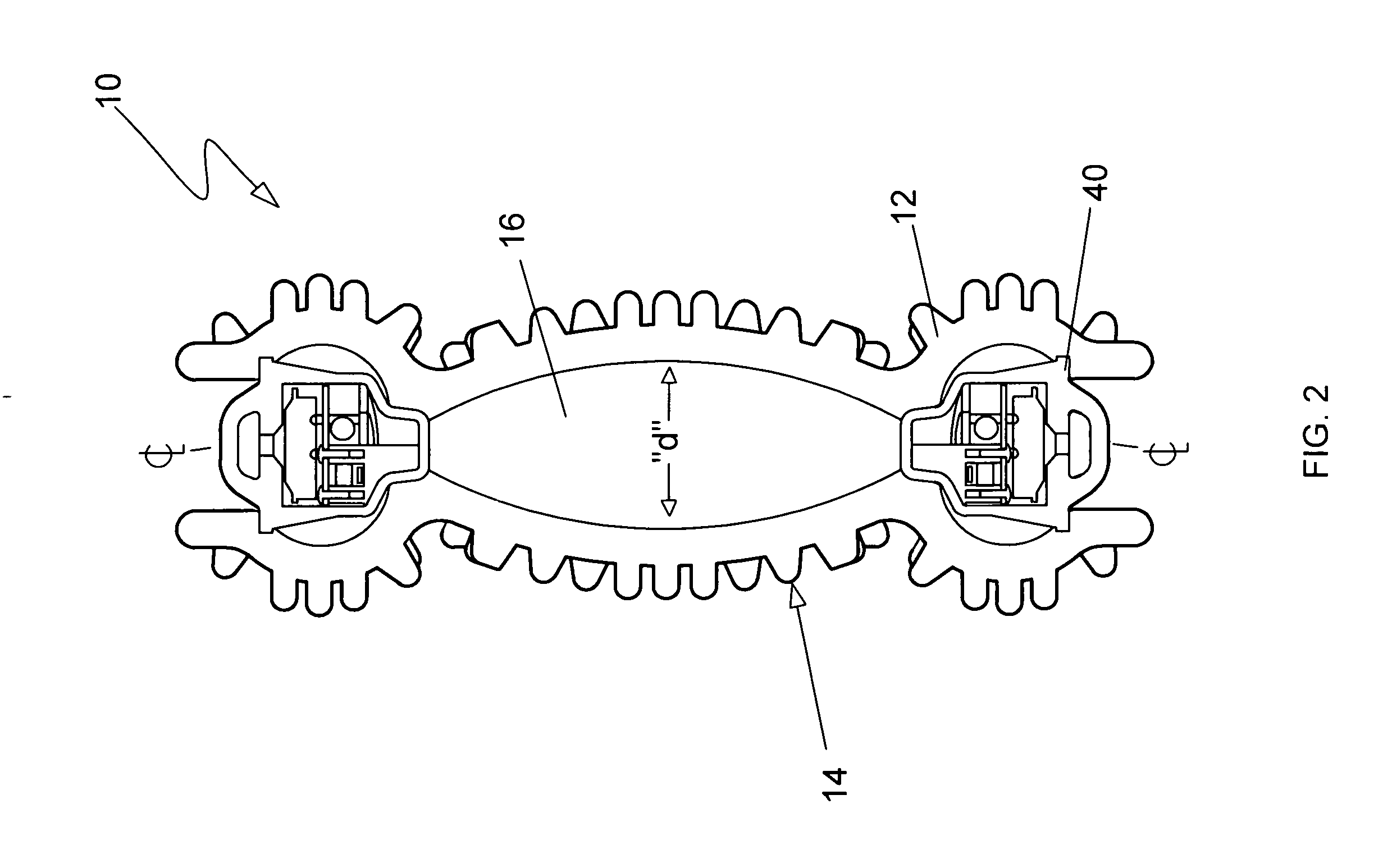

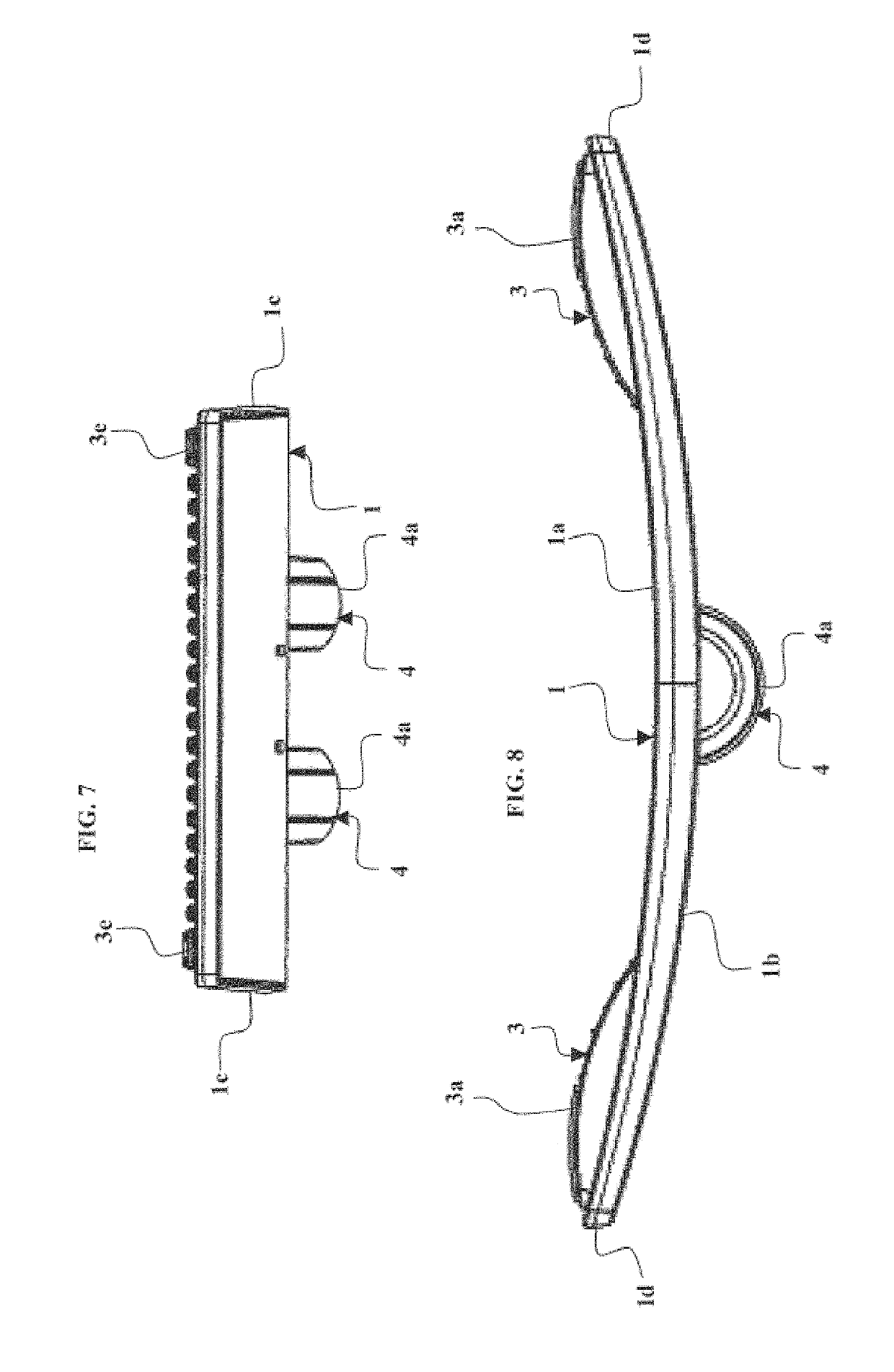

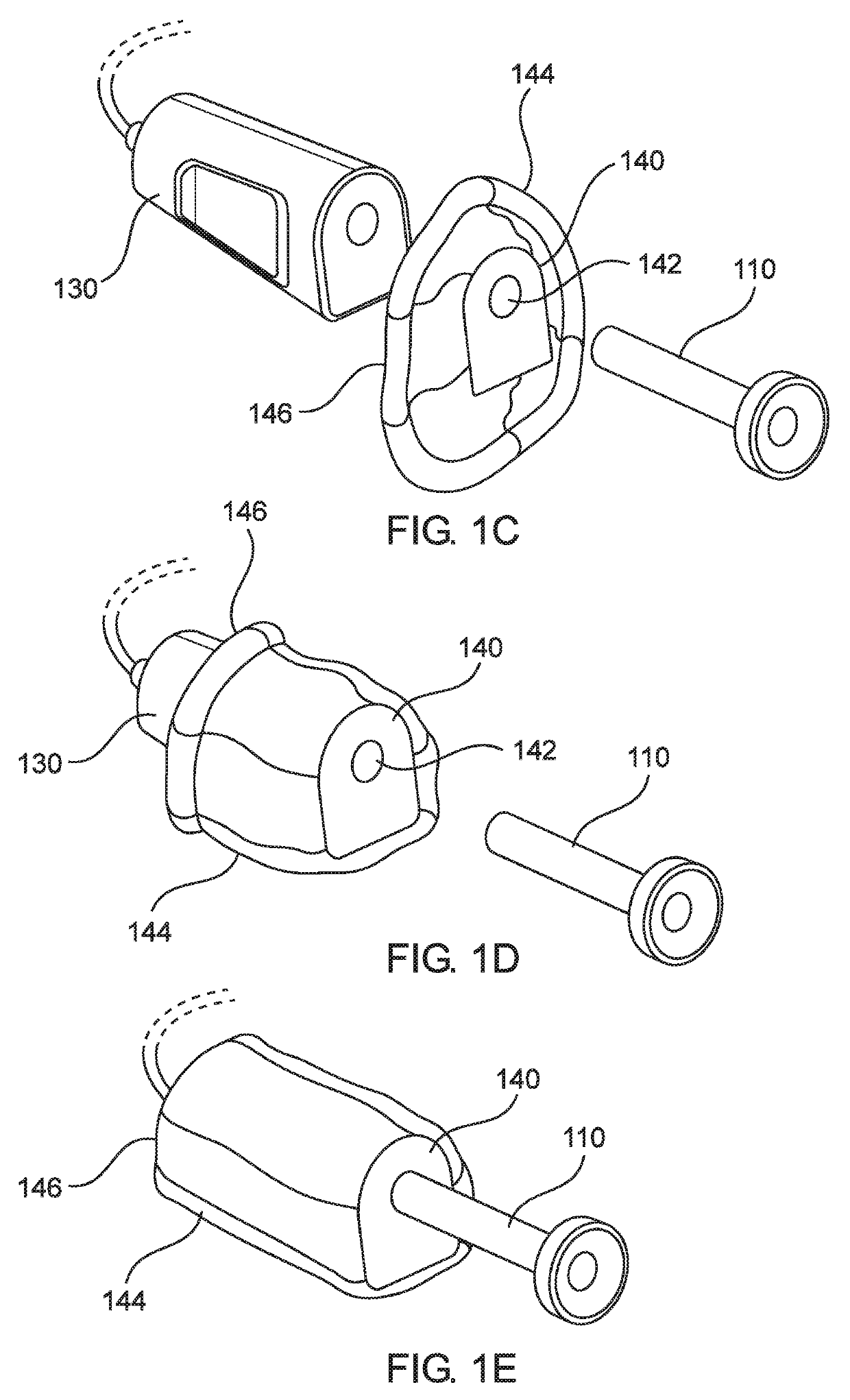

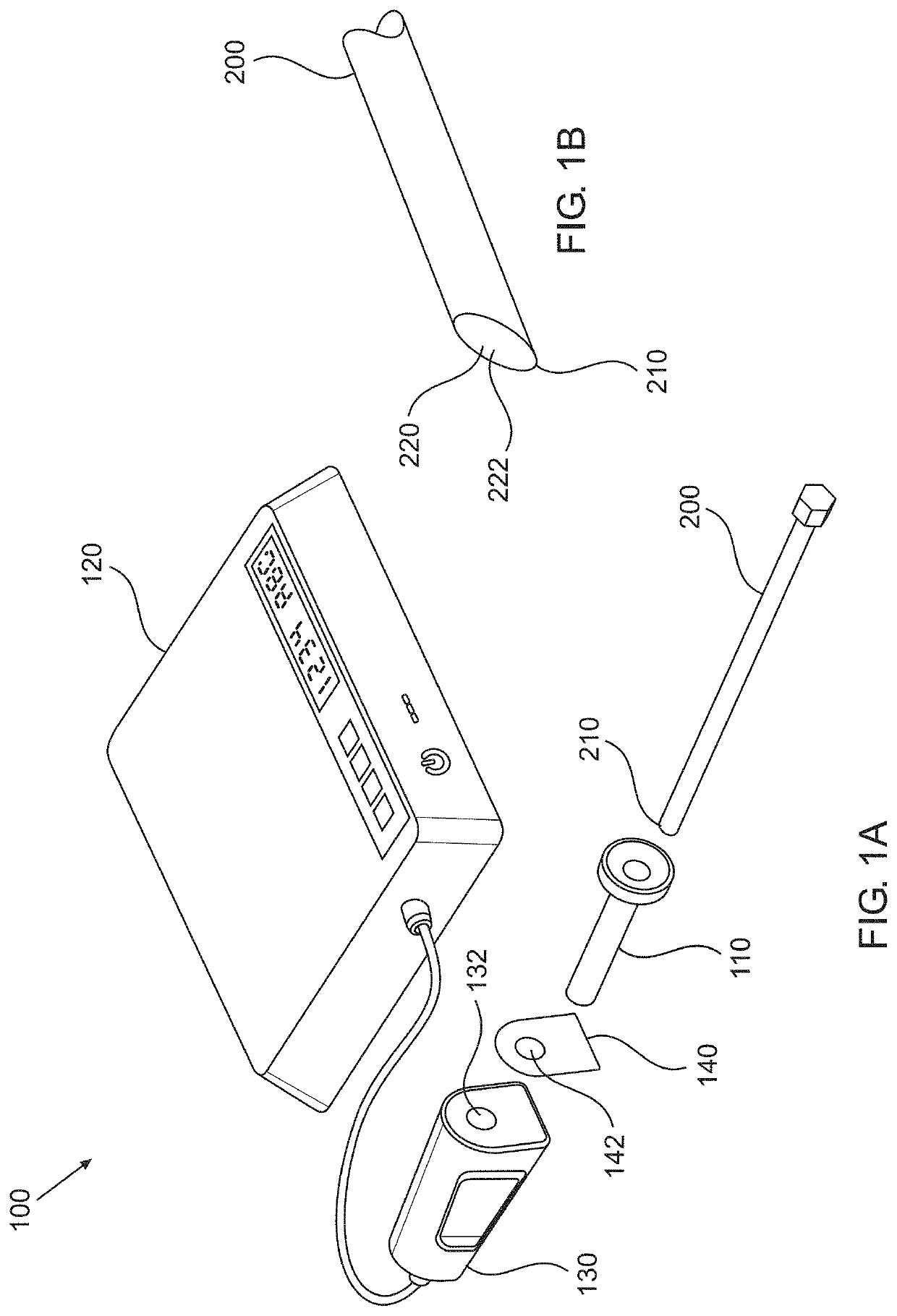

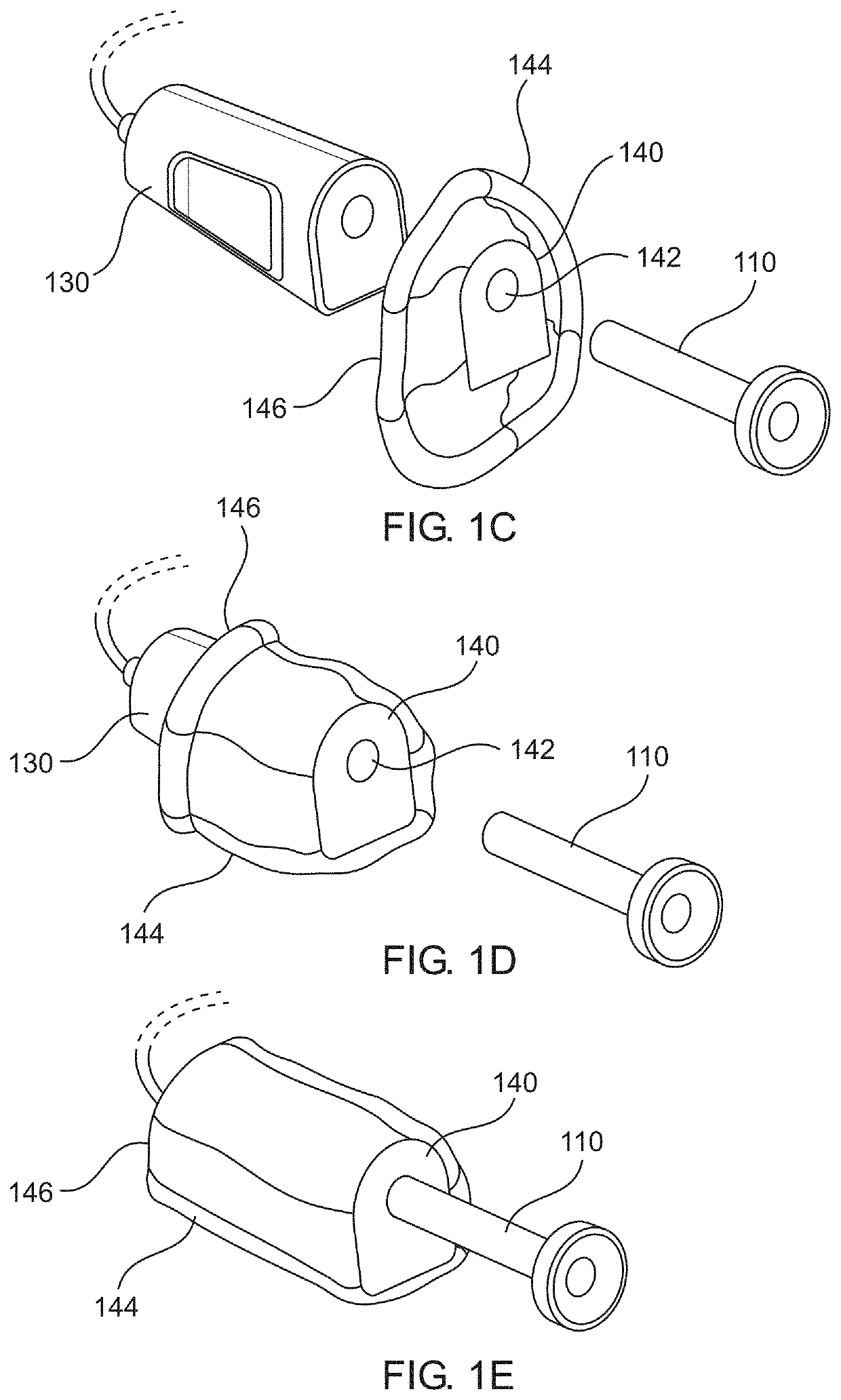

Fetch and Retrieve Tossing Toy

InactiveUS20150237829A1BuoyancyReduce the amount requiredOther apparatusTaming and training devicesSound generationEngineering

A pet toy is provided having a linearly elongated main body terminated at each end by plug forming an anchor plug. A replaceable wing assembly is affixed to each anchor plug. A sound generation mechanism is further incorporated in one said anchor plug. As the toy is flying through the air, the wings provides a visual ‘flapping’ like stimuli, similar to that of the wings of a bird. An audible stimuli is added during the tossing or retrieval of the toy. The instant abstract is neither intended to define the invention disclosed in this specification nor intended to limit the scope of the invention in any way.

Owner:OUR PETS

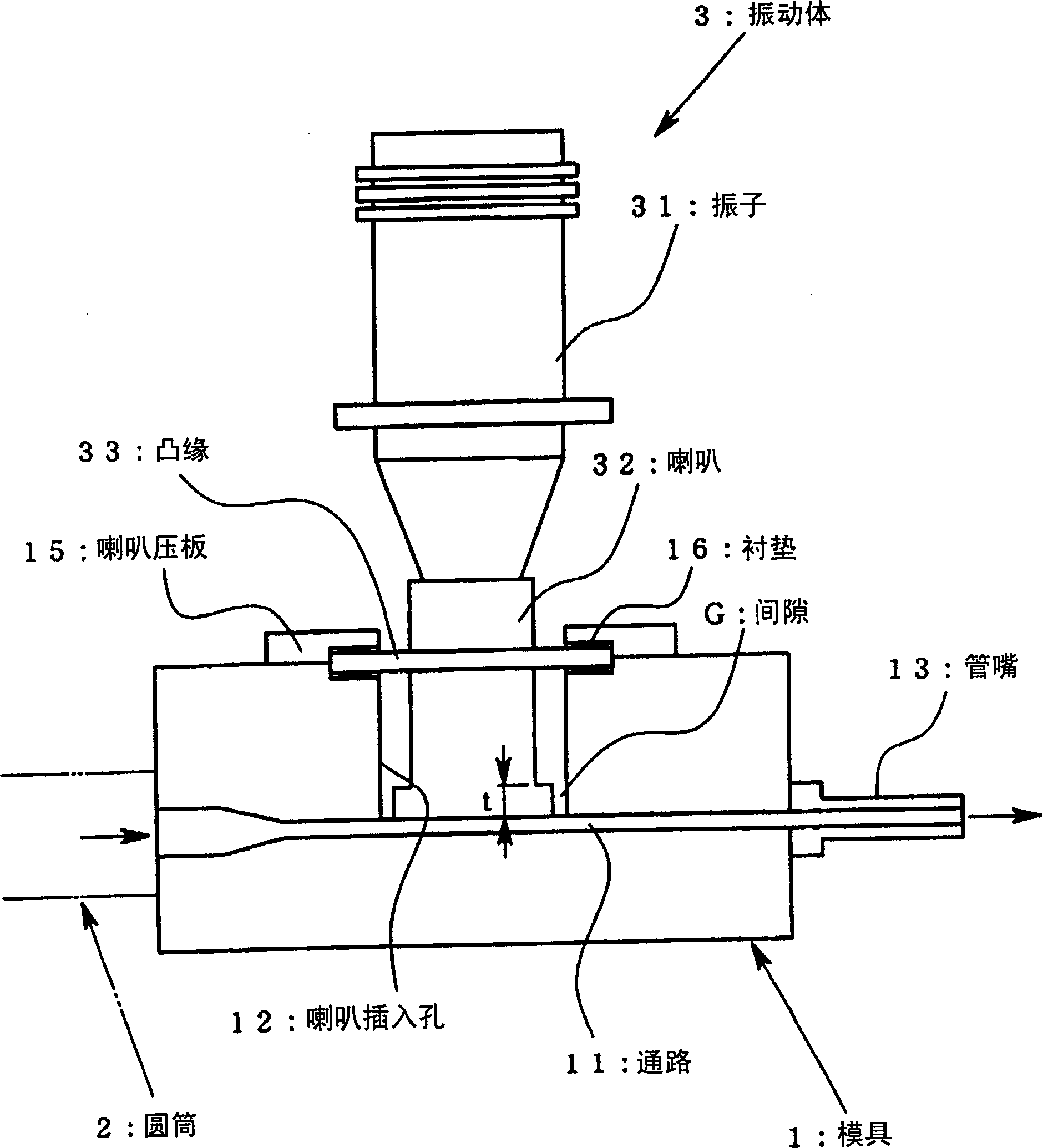

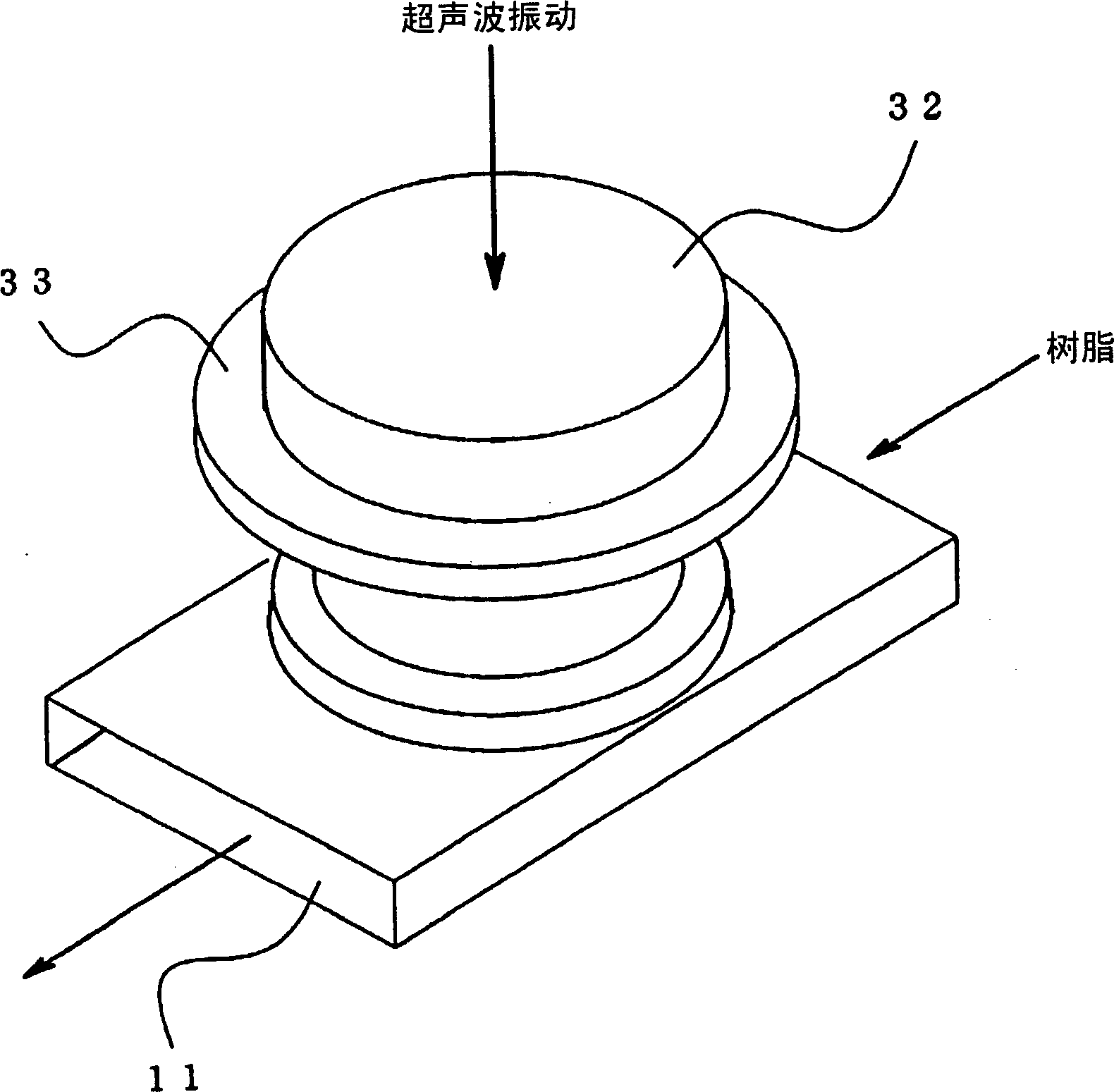

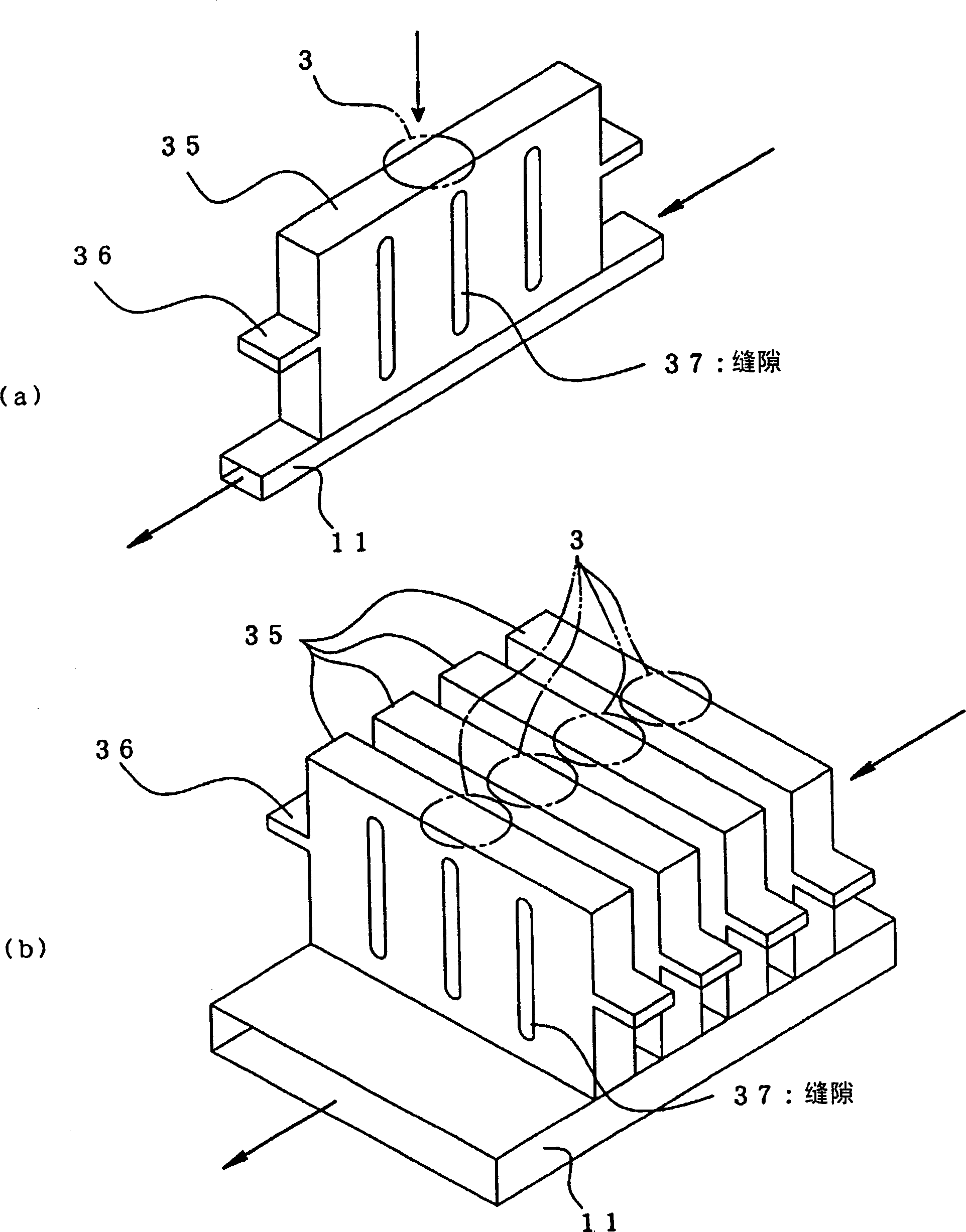

Device for imparting ultrasonic vibration to resin material, method of melt-molding resin material using the device, and resin composition

There is here disclosed a technique which can improve mechanical properties such as strength and impact resistance of molded articles without noticeably changing molding materials and rebuilding a molding apparatus. In a molding method in which the molding materials are fed to a mold disposed at one end of a cylinder while the molding materials in the cylinder are molten and kneaded, the molding materials can be molded while vibration is applied to the molding materials in a direction crossing a flow direction of the resin material at right angles. The vibration does not have to possess any node portion on a surface which contacts the molding material.

Owner:IDEMITSU KOSAN CO LTD

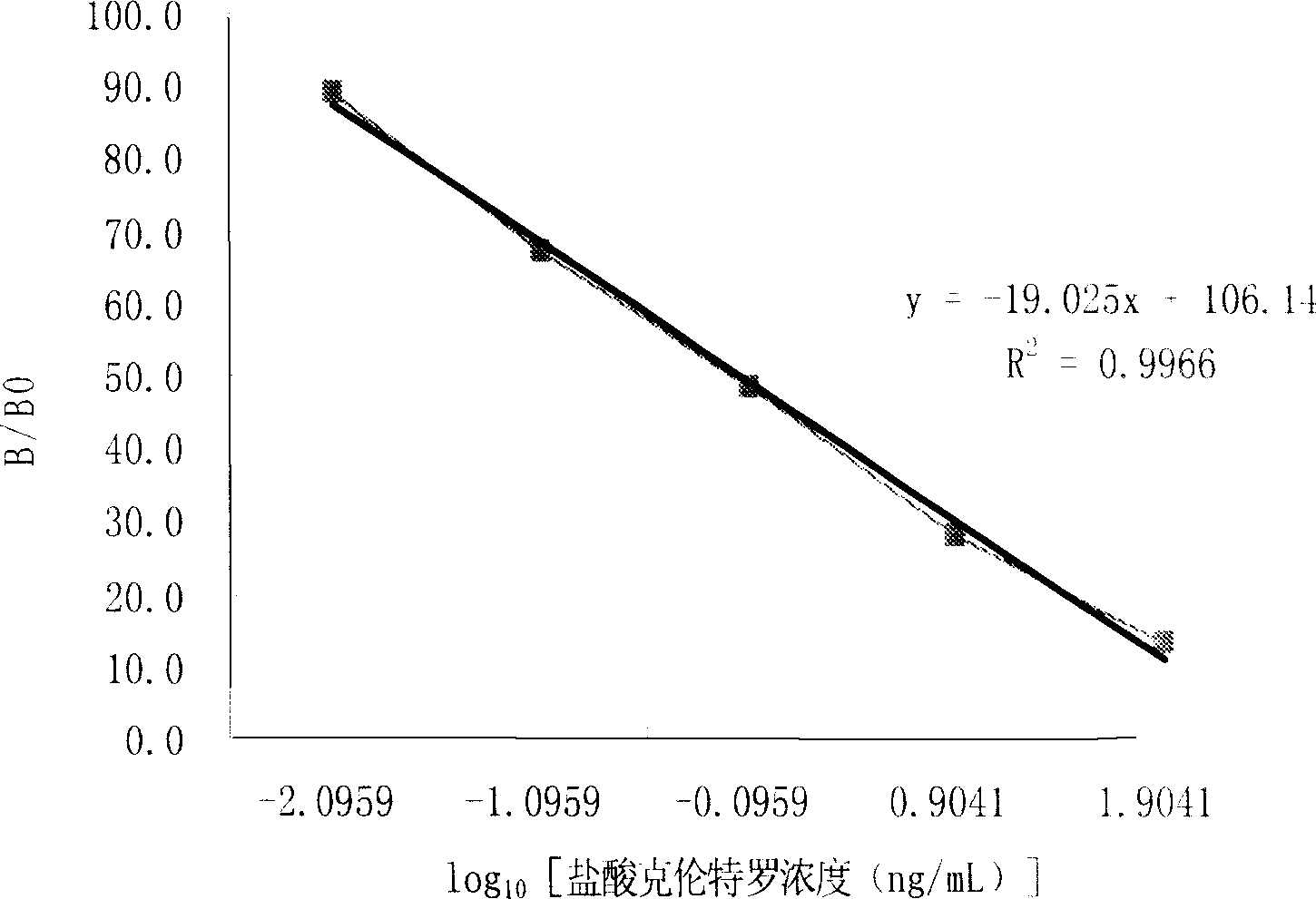

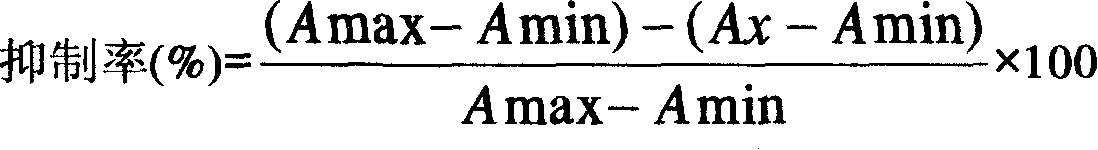

ELISA kit for detecting clenbuterol and detection method thereof, and animal tissue sample preparing method before detection

ActiveCN1885038AReduce dosageHigh sensitivityColor/spectral properties measurementsSpecial data processing applicationsElisa kitImmune adsorption

The invention relates to an enzyme couple immune detecting field, especially disclosing a clenobuterol enzyme immune agent box, relative detecting method, and a method for preparing the sample of animal organism, wherein said box comprises a box body, a 96 / 40 porous enzyme mark plate, a horse peroxide enzyme mark antibody, a clenobuterol standard solution, a substrate liquid, a substrate buffer liquid and a reaction ending liquid; the holes of said mark plate packs the packing antibody that combined with the clenobuterol antibody. The invention uses direct competitive enzyme couple immune adsorption analysis technique, to simplify the operation and reaction time, to reduce error. The inventive method has simple operation, low cost, and short time, while the extracted sample can be directly used in enzyme couple immune method and golden mark immune laminated analysis, to be sample of prior analysis.

Owner:SOUTH CHINA AGRI UNIV

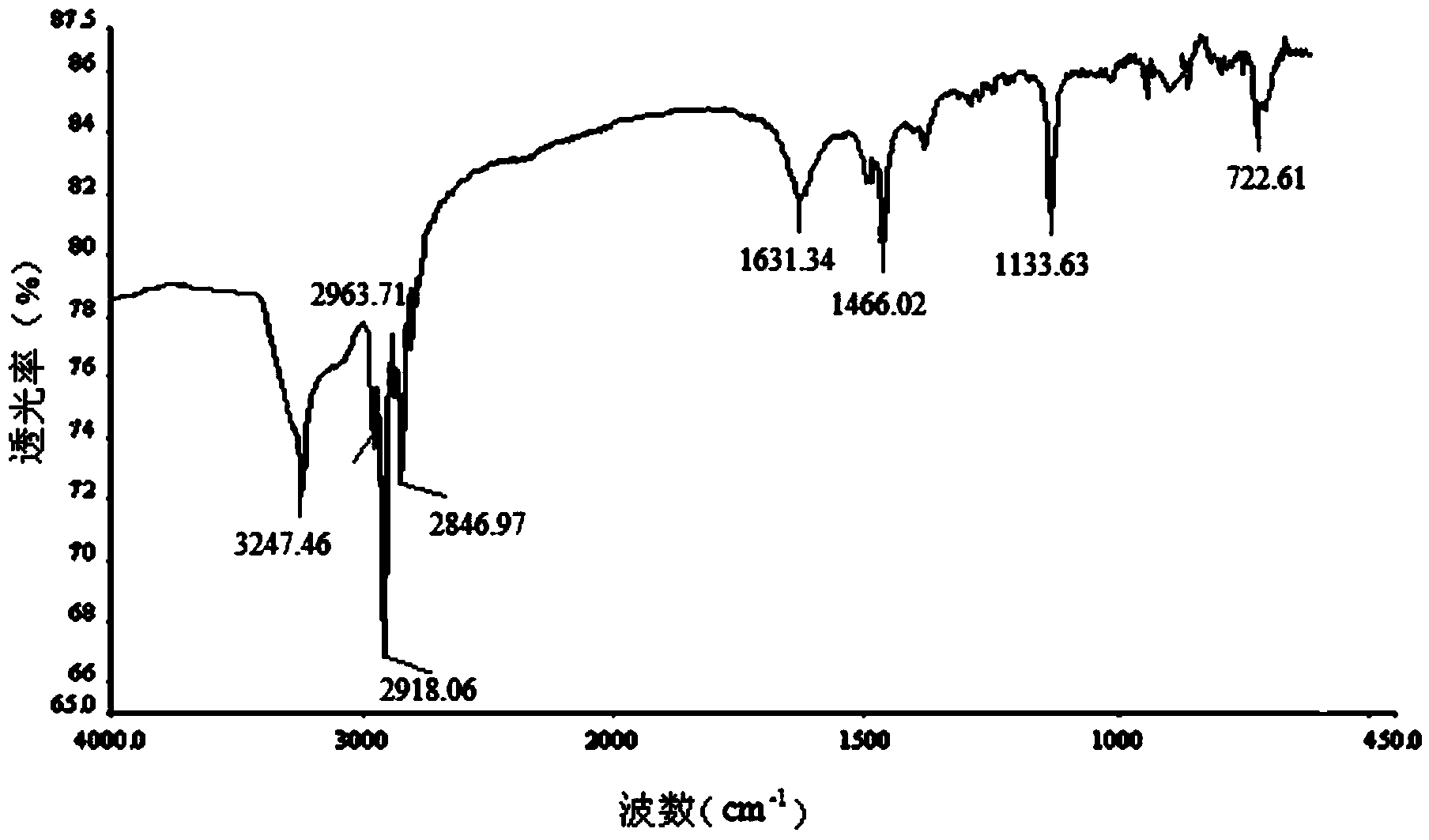

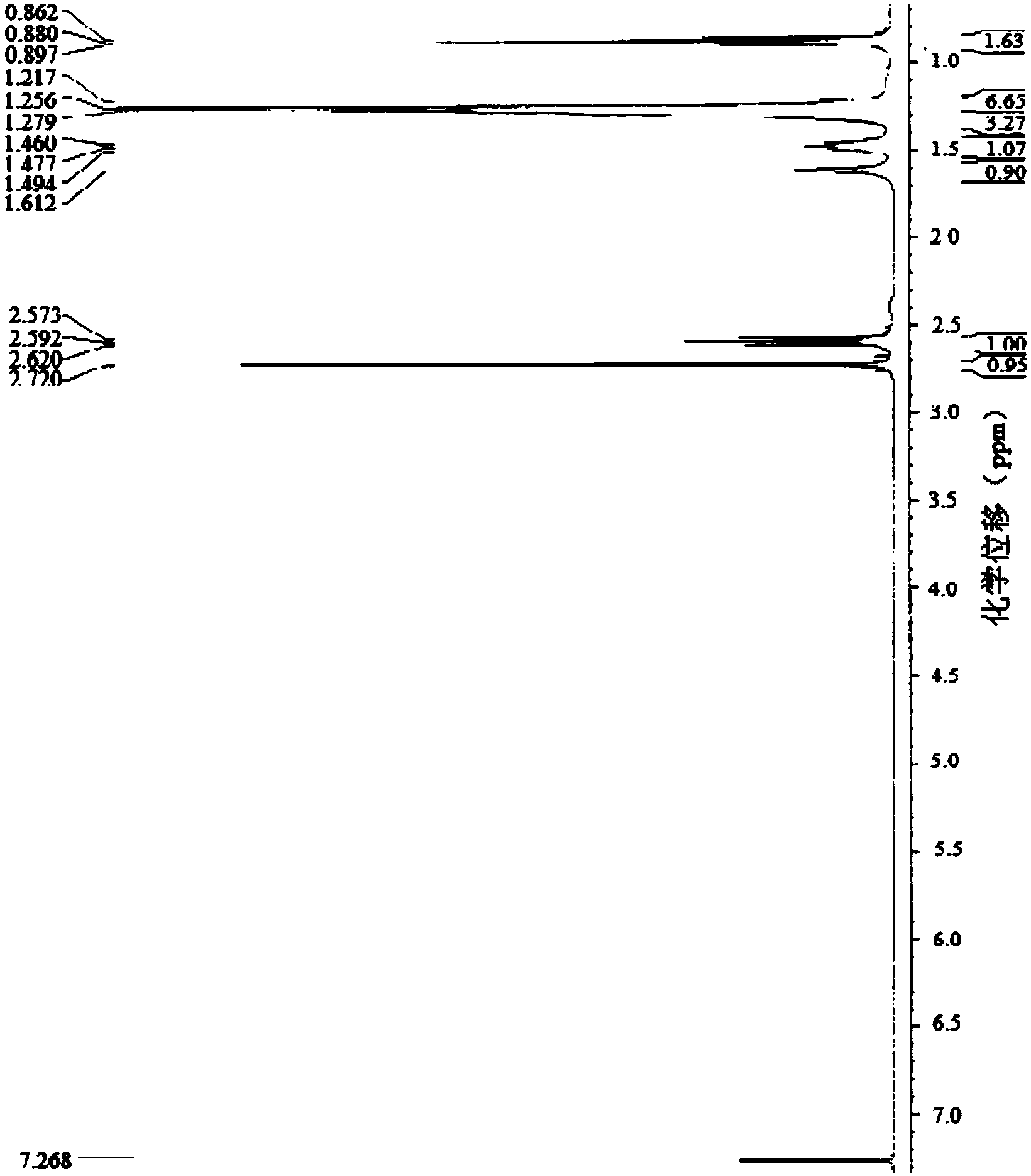

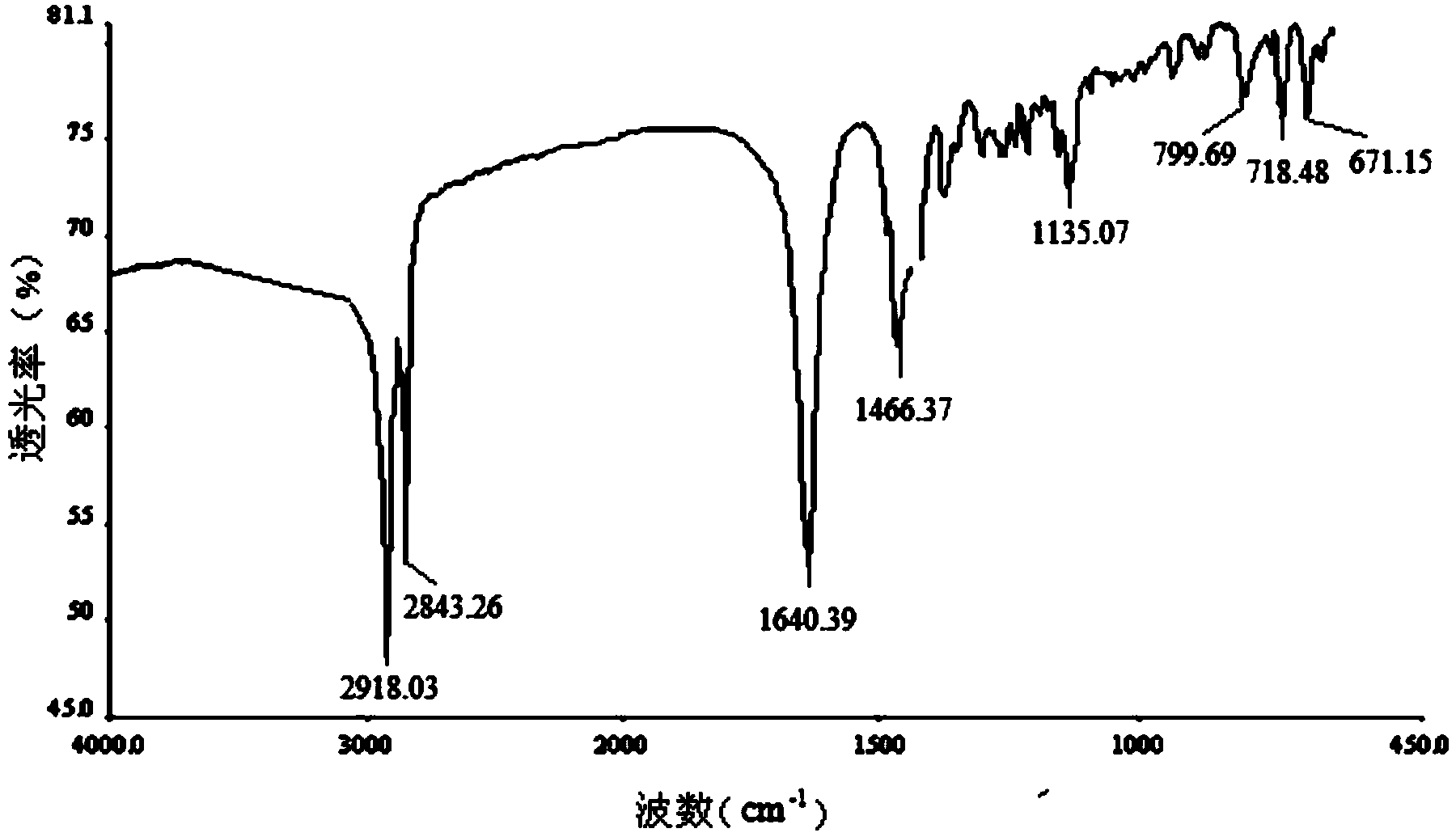

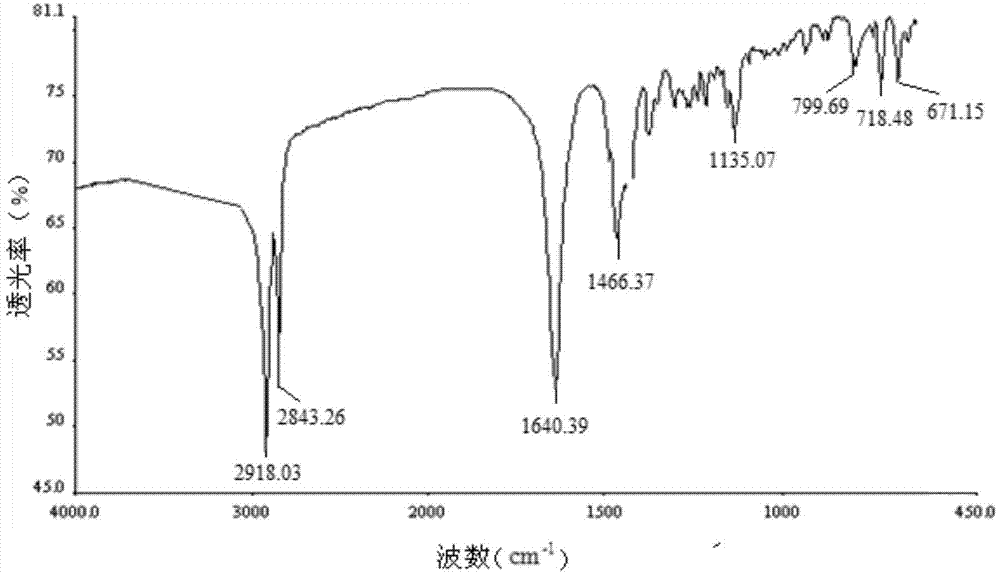

Novel amido-linkage imidazolium salt gemini surfactant and preparation method thereof

InactiveCN103406065ALow toxicityThe three-step reaction is easy to operateOrganic chemistryTransportation and packagingReaction temperatureSolvent

The invention relates to a novel amido-linkage imidazolium salt gemini surfactant and a preparation method thereof, and the preparation method can be used for solving the problems that the existing preparation method of the amido-linkage heterocyclic gemini surfactant is complicated to operate, high in cost and reaction temperature, long in reaction time, and large in solvent toxicity. The preparation method comprises the following steps of: I, N-alkylation; II, amidation; III, quaternization to obtain the product amido-linkage imidazolium salt gemini surfactant. The preparation method is simple for three-step reaction operations, capable of shortening the reaction time, and mild in reaction conditions, the solvent toxicity is small, the raw material cost is low, the hydrophilic property of the novel amido-linkage imidazolium salt gemini surfactant can be greatly improved through introducing strong-polarity amido linkage and two positive nitrogen ion heads, the novel amido-linkage imidazolium salt gemini surfactant has good biodegradability through introducing nitrogen heterocyclic ring and amido linkage, and the environmentally-friendly gemini surfactant can be used in multiple fields of cleaning, sterilization, restraint of metal corrosion, sewage treatment and the like.

Owner:QIQIHAR UNIVERSITY

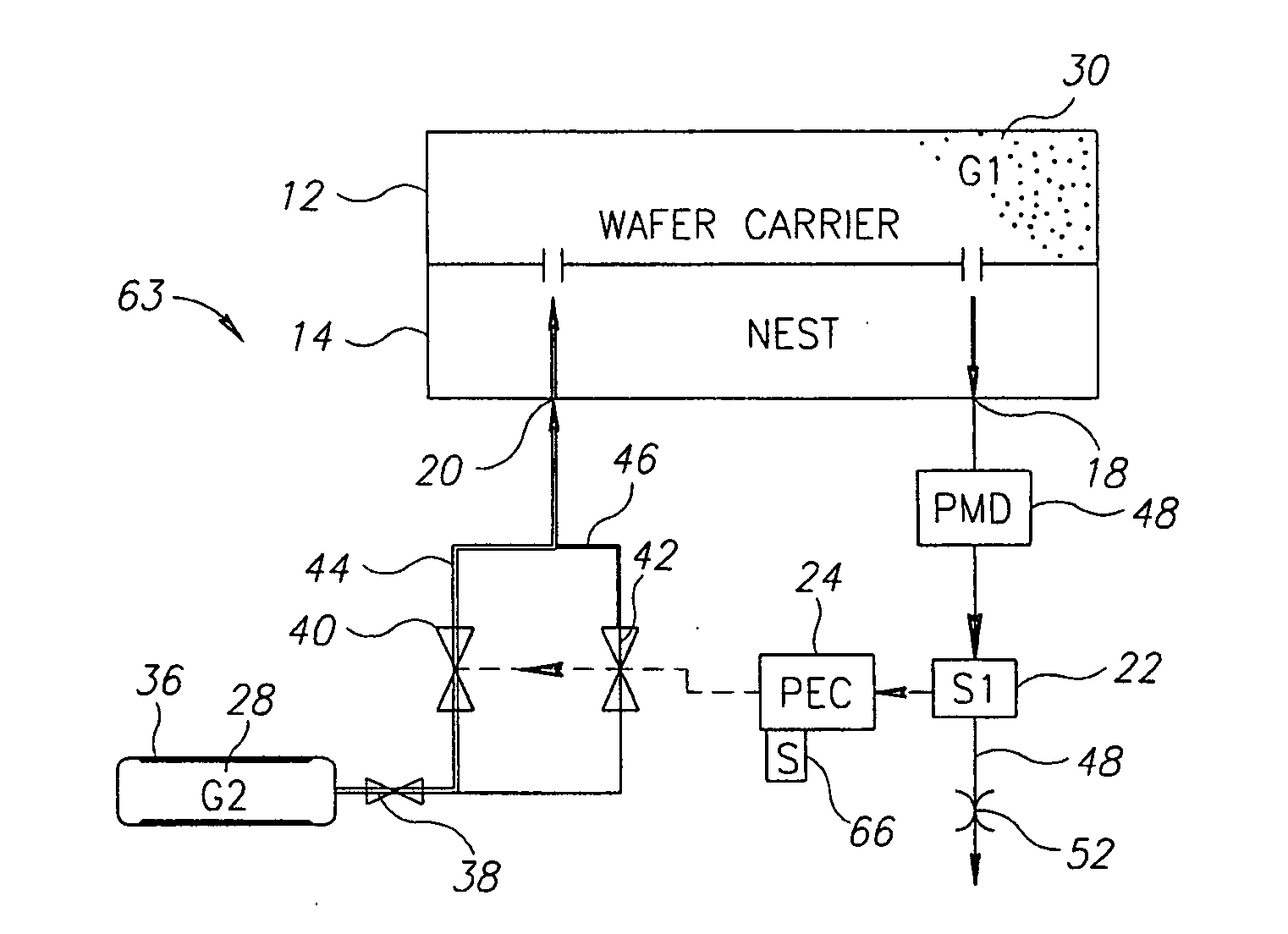

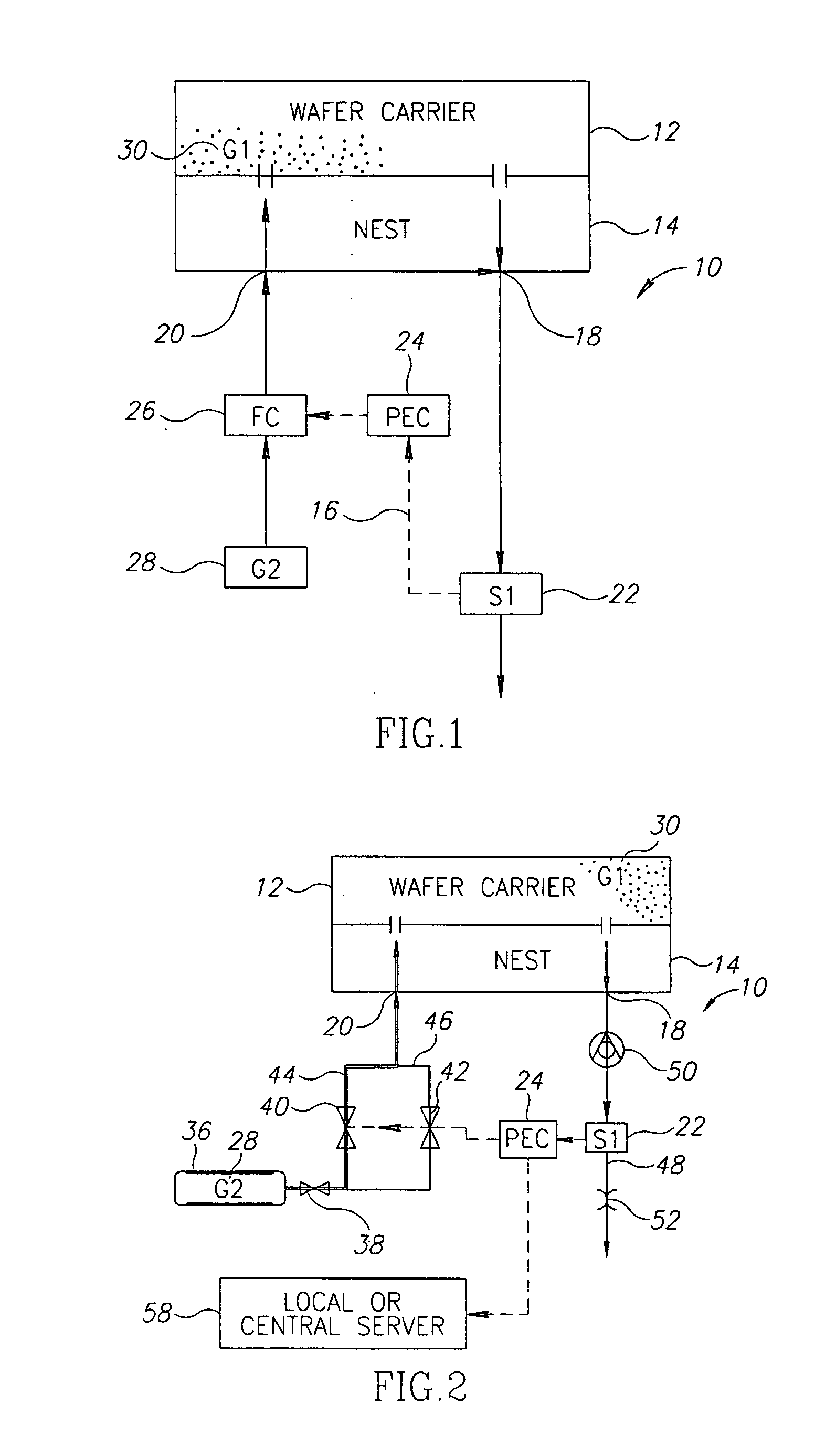

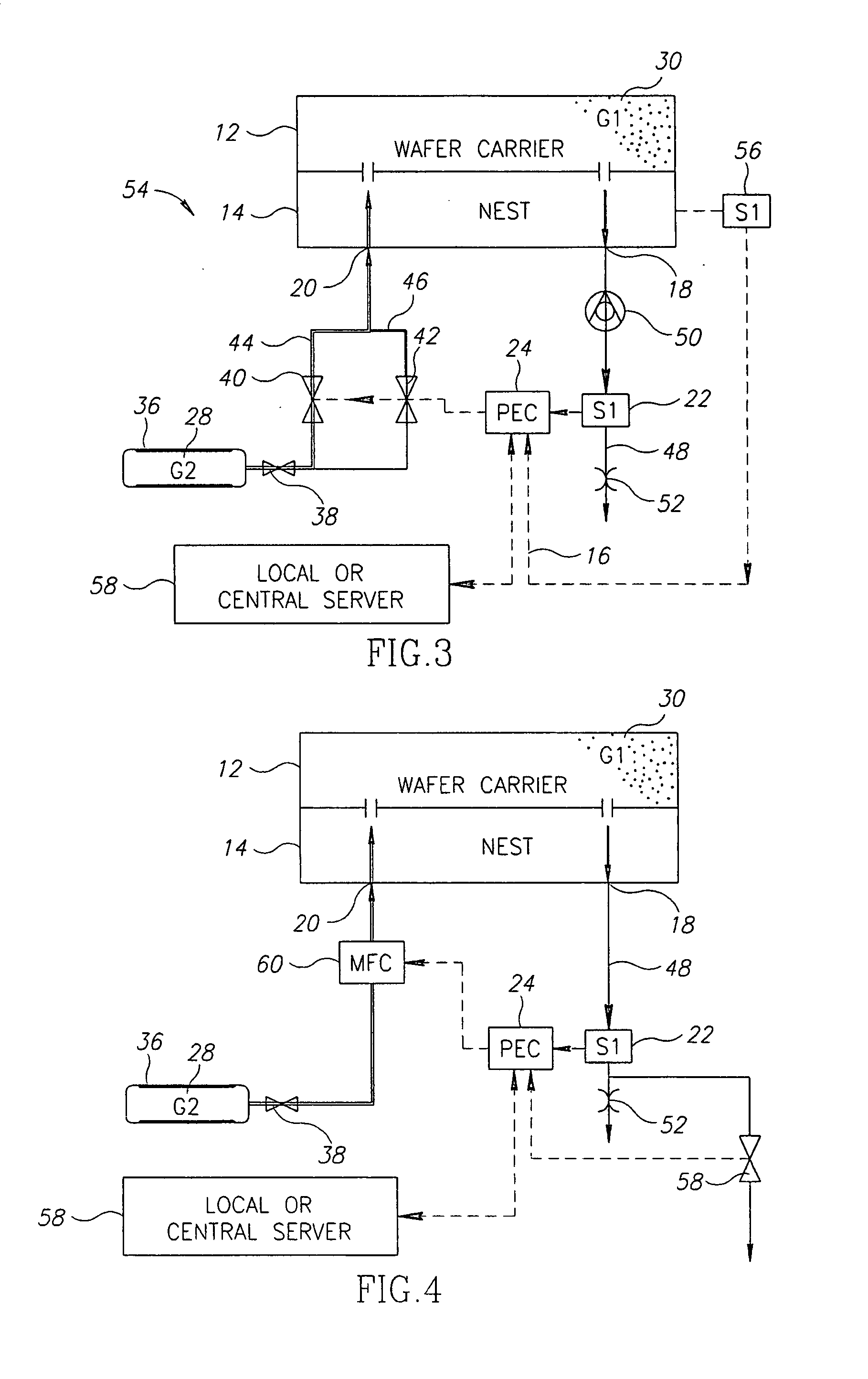

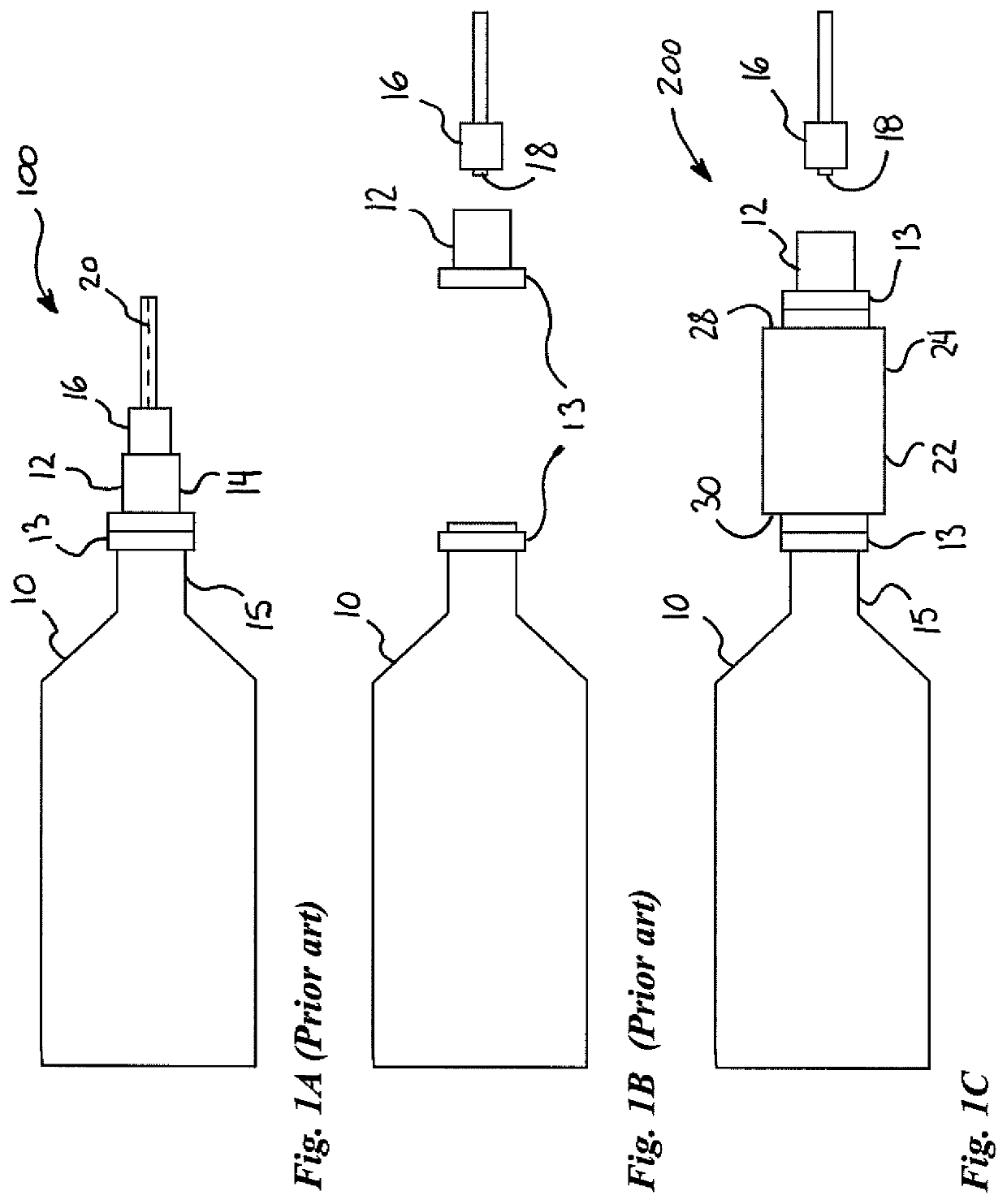

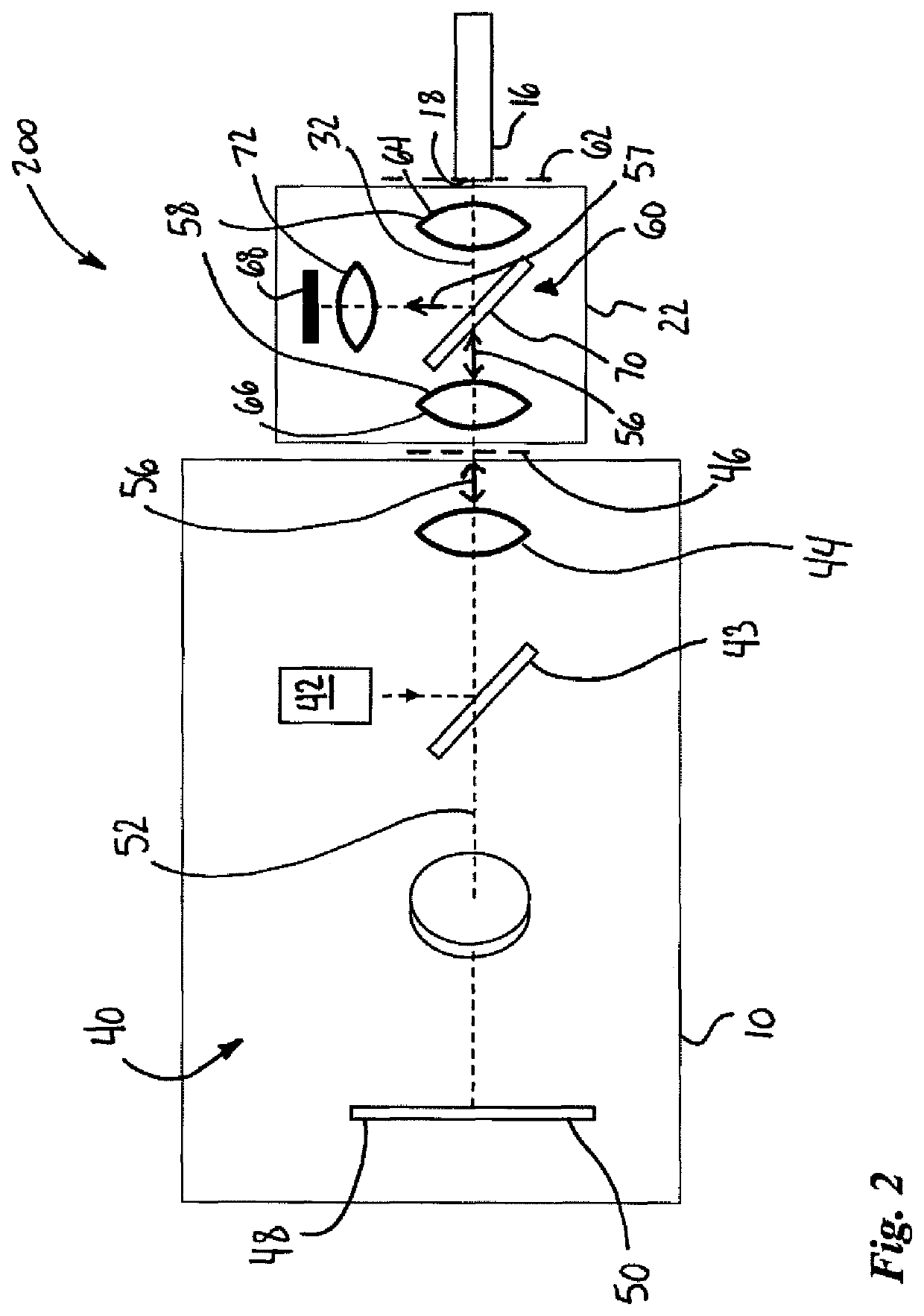

Gas purge method and apparatus

InactiveUS20080177414A1Eliminate disadvantagesPurge very quicklySemiconductor/solid-state device manufacturingSpecial data processing applicationsElectronic controllerInlet valve

The present invention relates to the removal of a gas or of a gas mixture from a closed container.More particularly, the invention provides a method and apparatus particularly useful in the production of semiconductors, for automatically and economically purging a first gas or gas mixture from a closed container.The present invention achieves the above object by providing a method and an apparatus, particularly useful in the production of semiconductors, for automatically and economically purging a first gas or mixture from a closed container, said method having the following steps:step a: providing equipment includinga first sensor in fluid communication with the outlet of said container;a source of a second compressed gas suitable for purging said first gas;at least one remotely controllable inlet valve disposed between said source of said compressed gas and the inlet of said container;a flow restrictor disposed in said outlet of said container;an electronic controller connected to and able to receive data from said first sensor and able to control at least one said inlet valve according to a predetermined program relating valve opening to time and to data from said first sensor;step b: sending a start signal, which optionally may be generated automatically, to said electronic controller;step c: start releasing said second gas into said container, the flow rate being controlled by said electronic controller;step d: measuring a parameter of interest by means of a first sensor at the outlet of said container and sending data relating to said parameter to said controller; andstep e: adjusting inlet flow in relation to purging progress.

Owner:RICOR

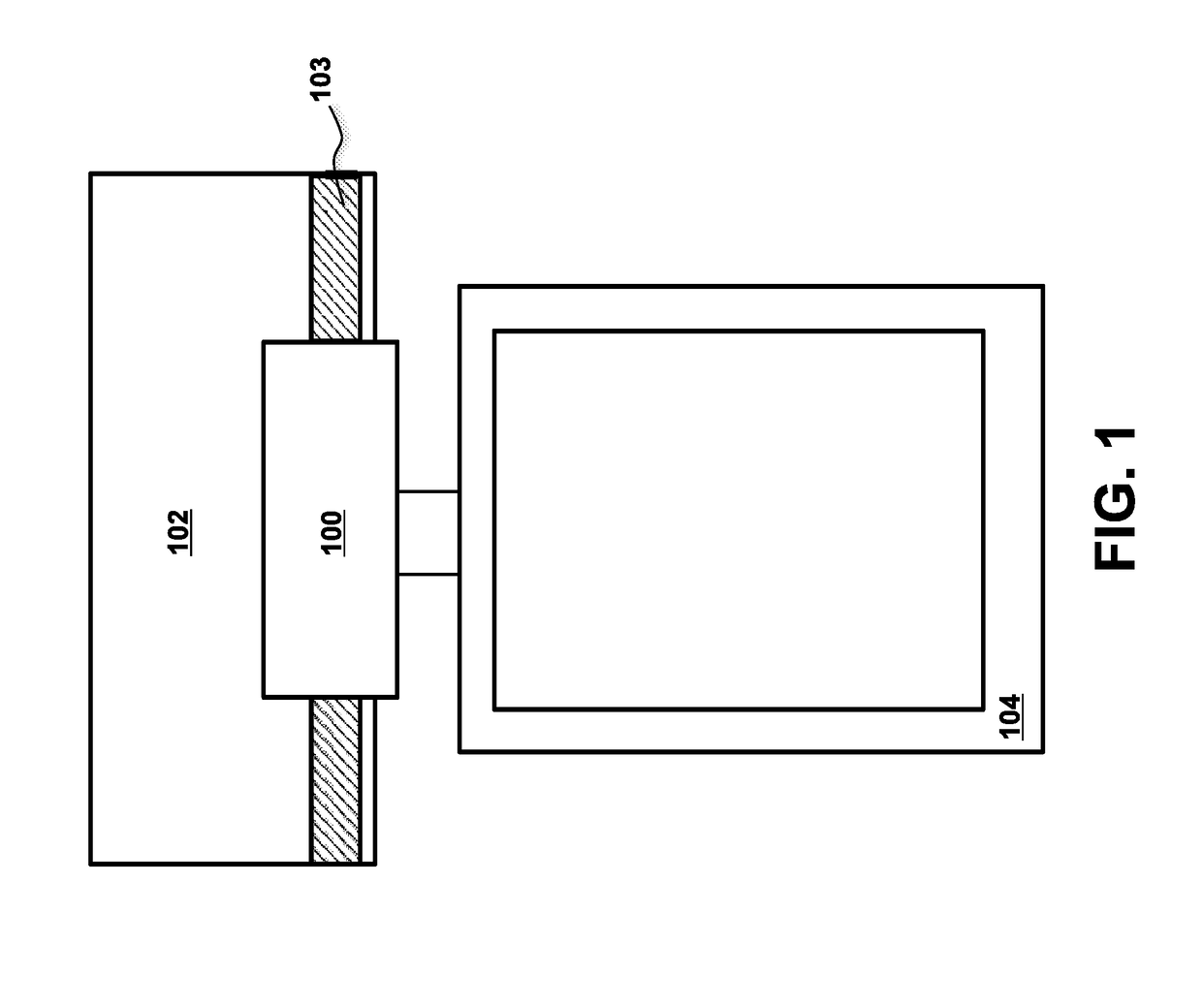

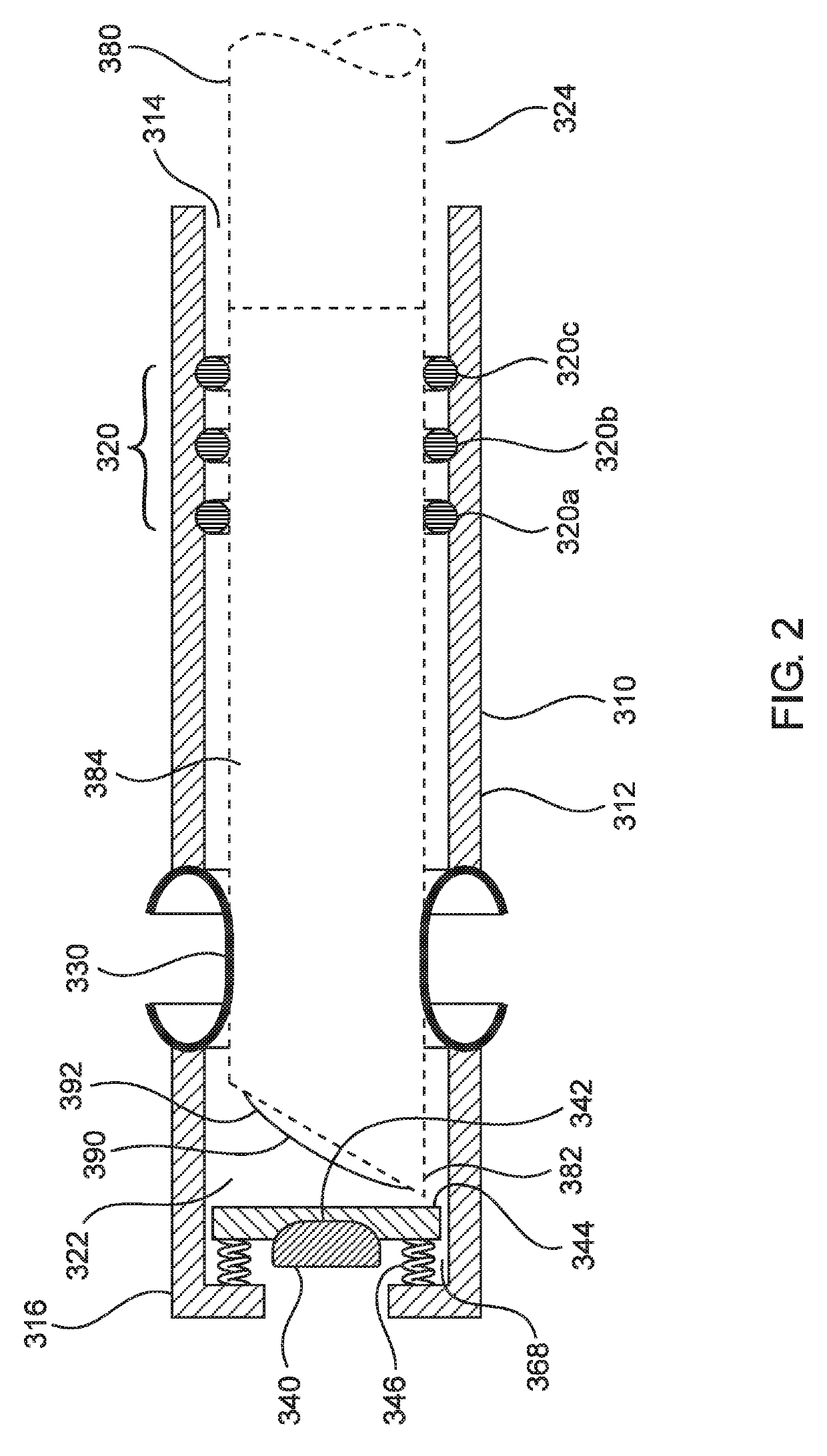

Systems and methods for user identification using payment card authentication read data

InactiveUS20180039983A1Reduce the possibilityVariabilityAcutation objectsSensing record carriersCard readerAuthentication

A payment card may be read by a card reader which may include a sensing unit to read a magnetic component of the card. An authentication read may be used to collect a magnetic fingerprint of the card, and / or swipe characteristics of the authentication read. The magnetic fingerprint and / or swipe characteristics may be used for identification of the card and / or user, which may include authentication use of the card and / or detecting potential fraud.

Owner:TRUSONA INC

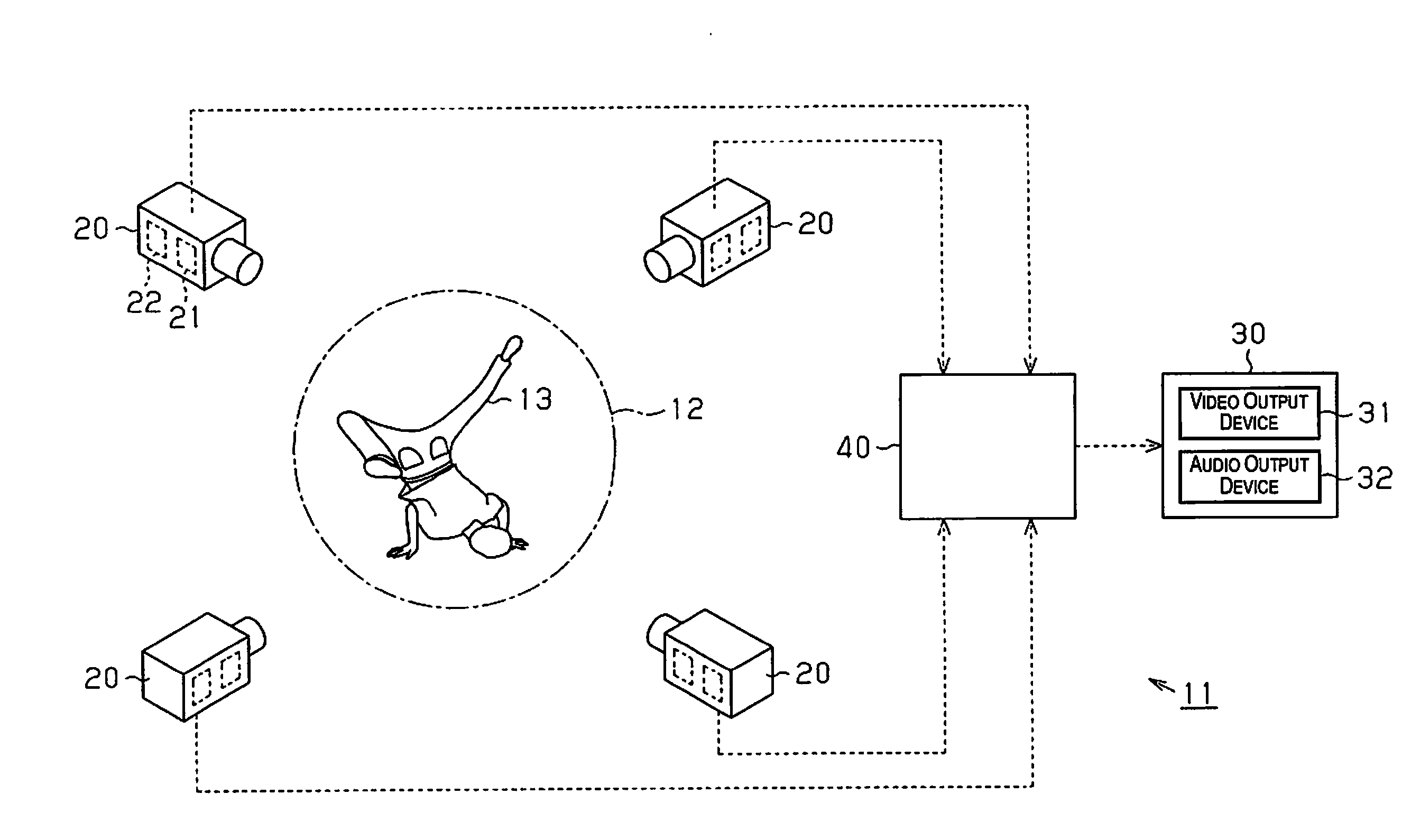

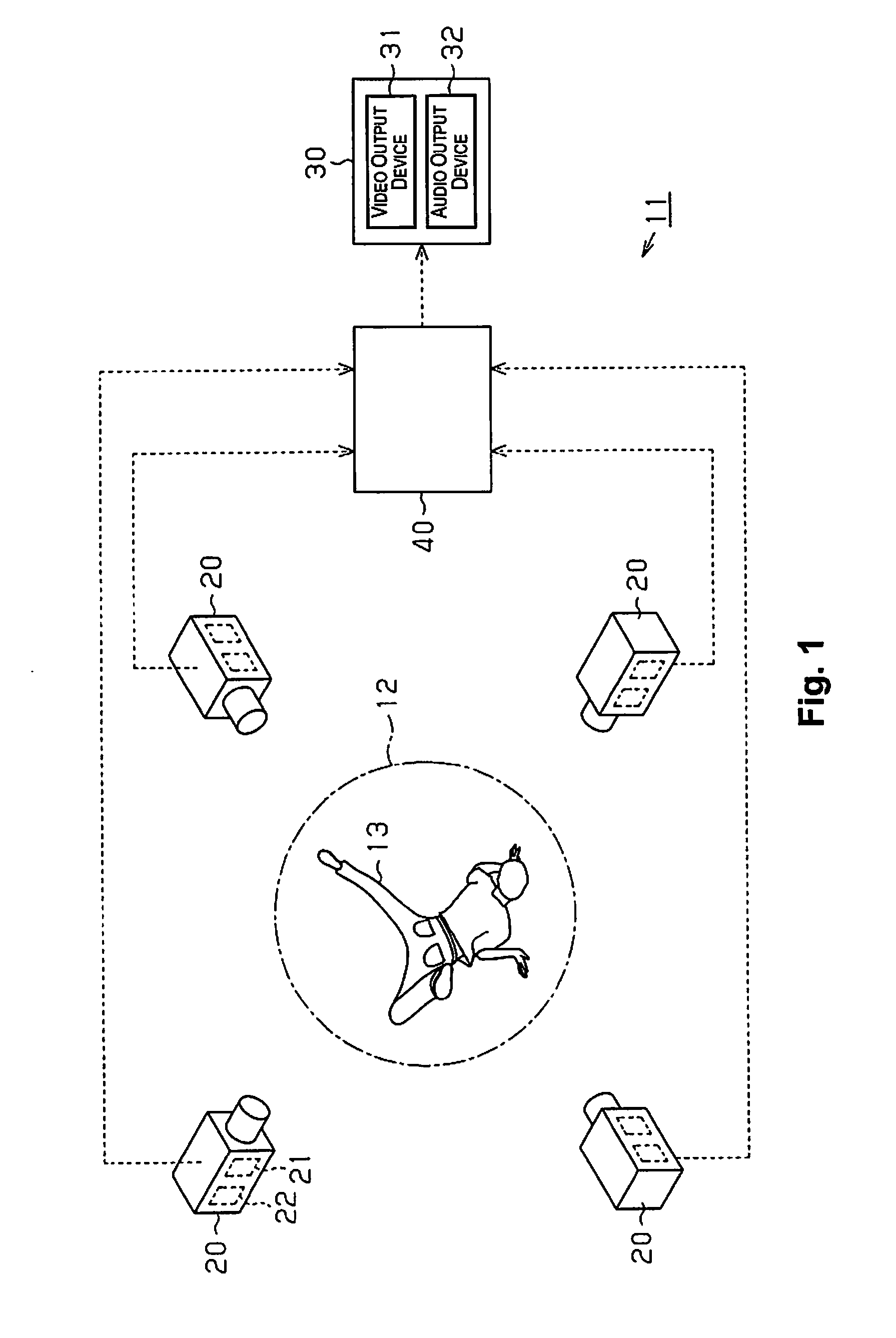

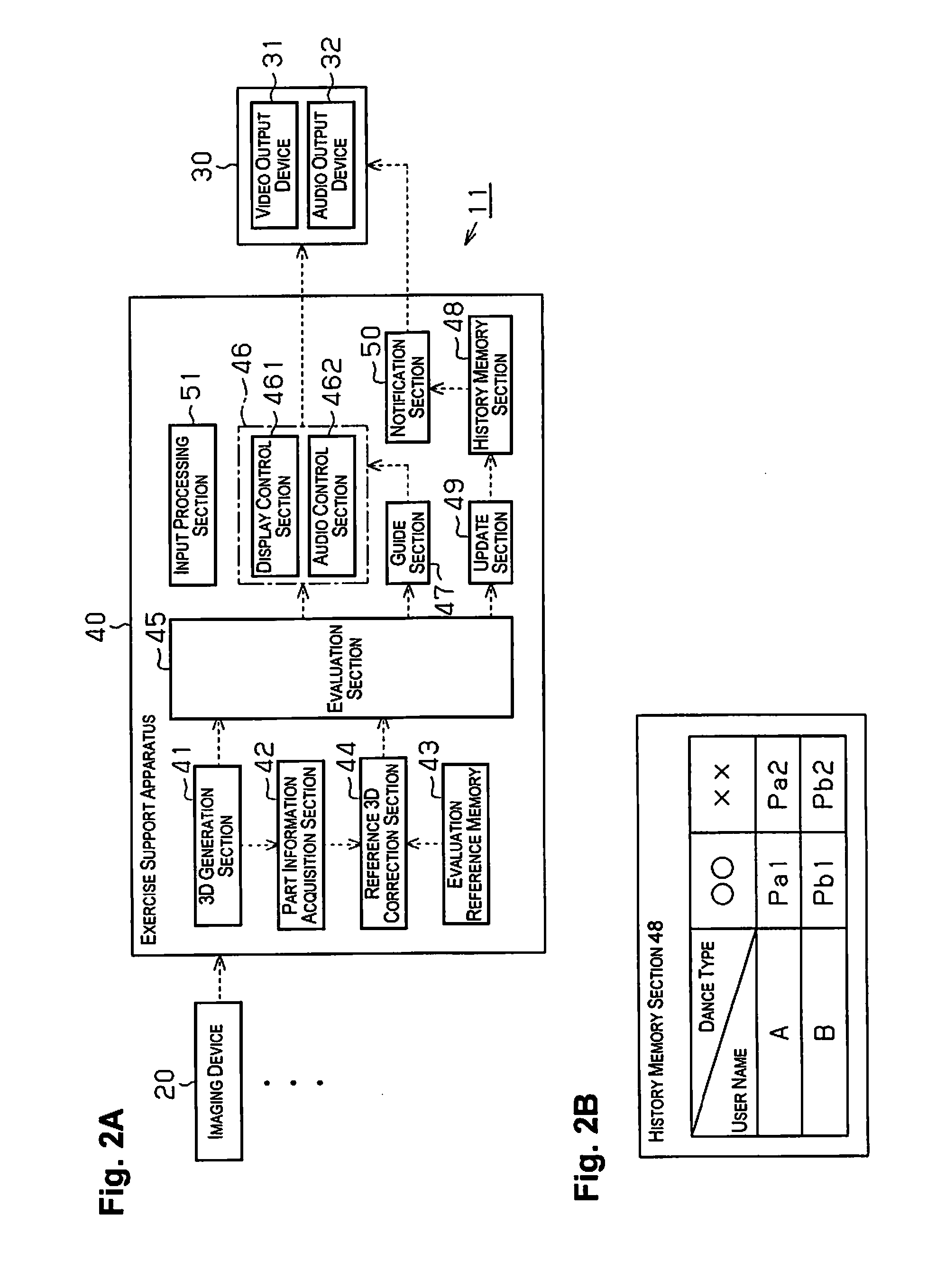

Exercise support system, exercise support apparatus, and exercise support method

ActiveUS20150227652A1Enhance accuracyImprove assessment accuracyAnalogue computers for chemical processesDesign optimisation/simulationPhysical exerciseImaging equipment

An exercise support system includes a plurality of imaging devices, a 3D generation section, an evaluation reference memory, and an evaluation section. The imaging devices are configured to capture videos for movements of a person to be evaluated. The 3D generation section is configured to generate 3D model data of the person to be evaluated based on the video captured by each of the imaging devices. The evaluation reference memory is configured to store reference 3D model data that is 3D model data to become an evaluation reference of an exercise. The evaluation section is configured to evaluate the movements of the person to be evaluated by comparing between the reference 3D model data and the 3D model data generated by the 3D generation section in each body part of the person to be evaluated.

Owner:SEIKO EPSON CORP

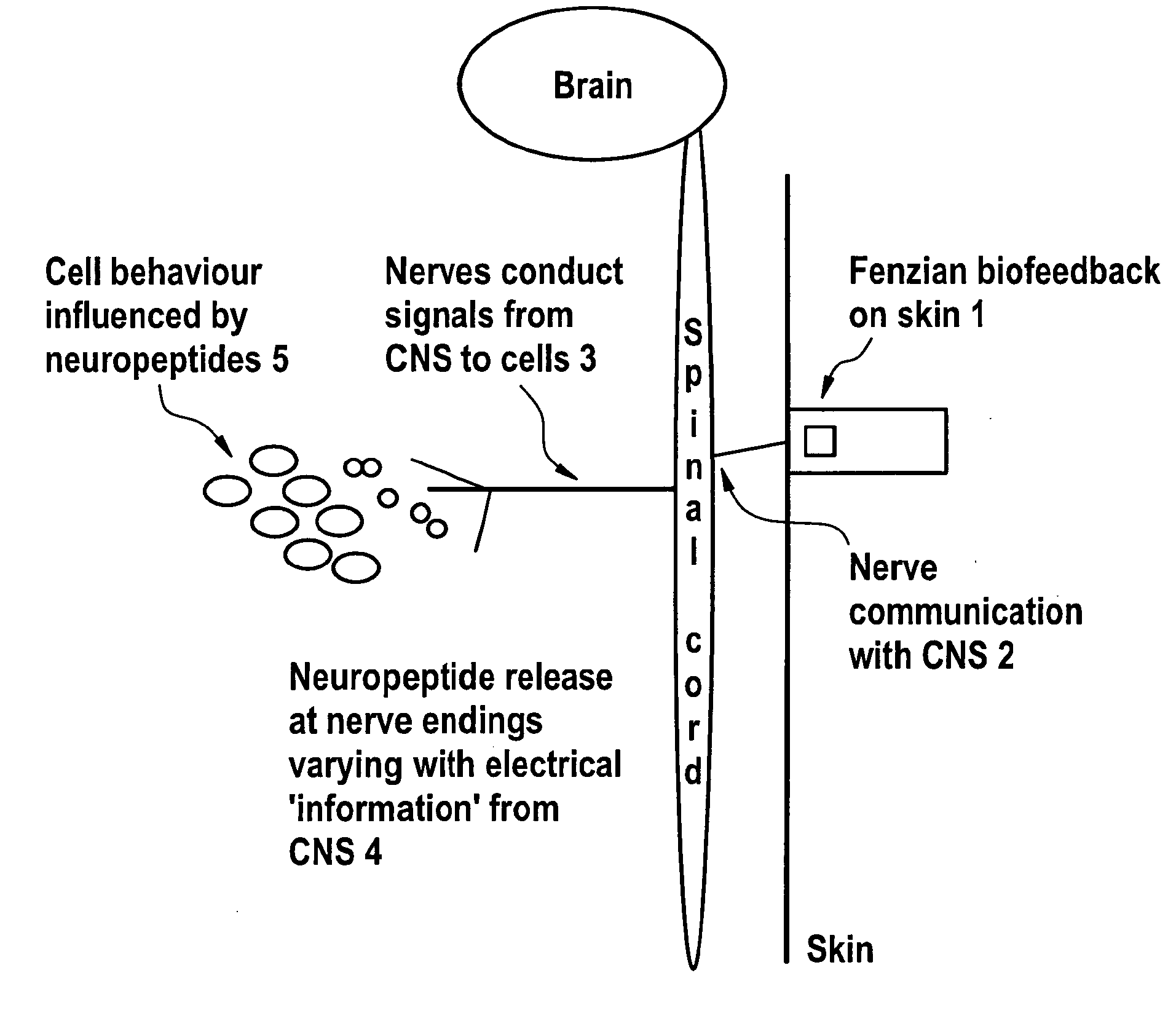

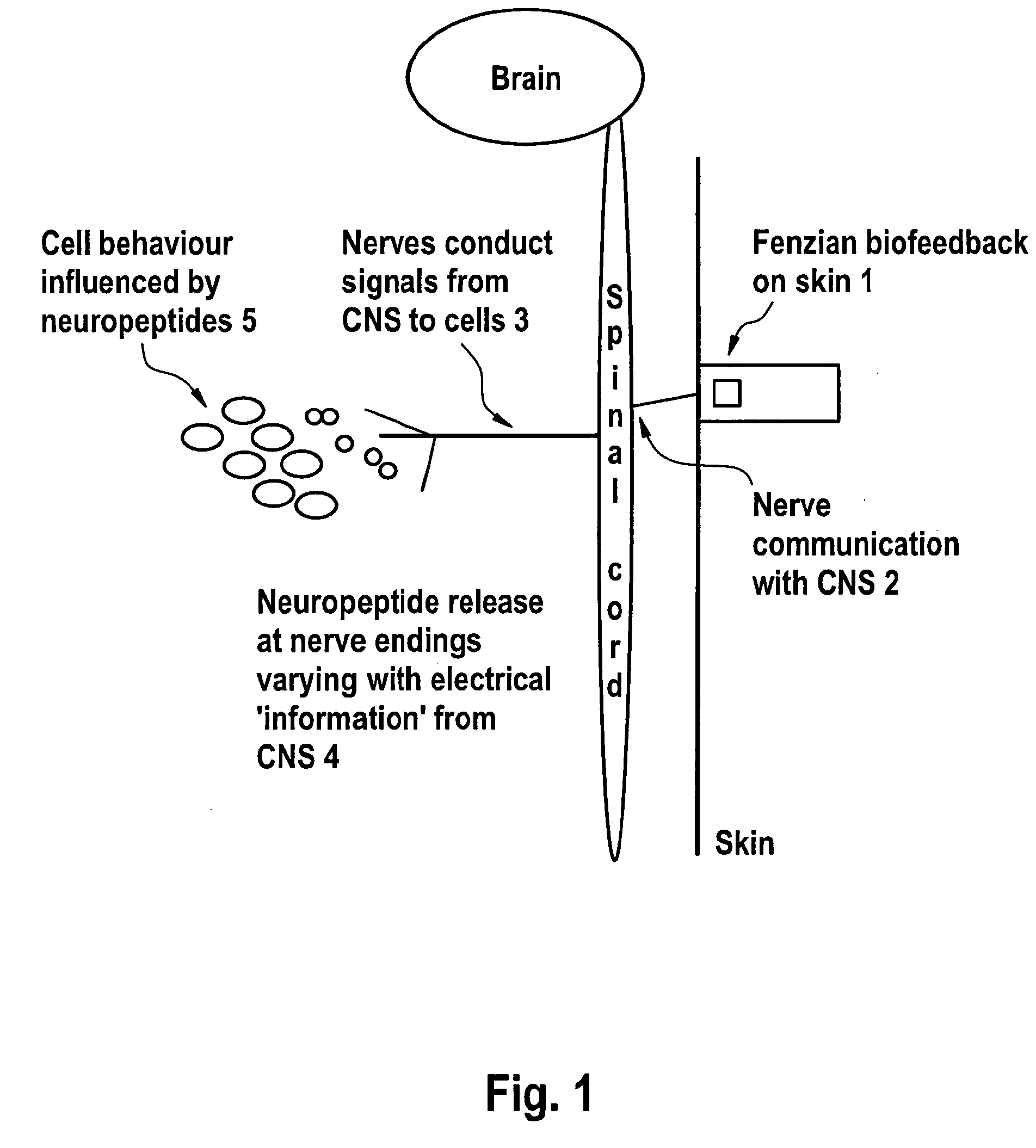

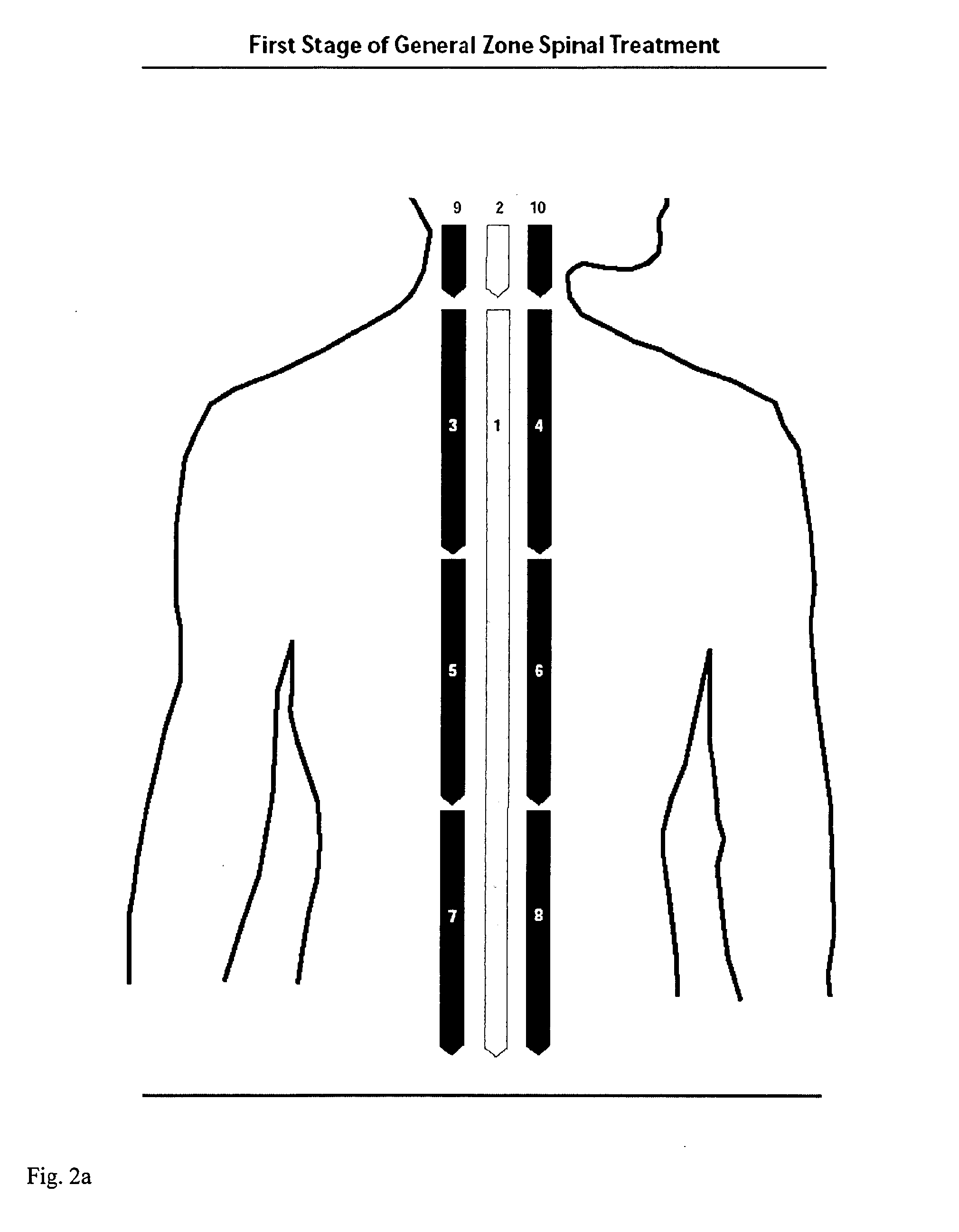

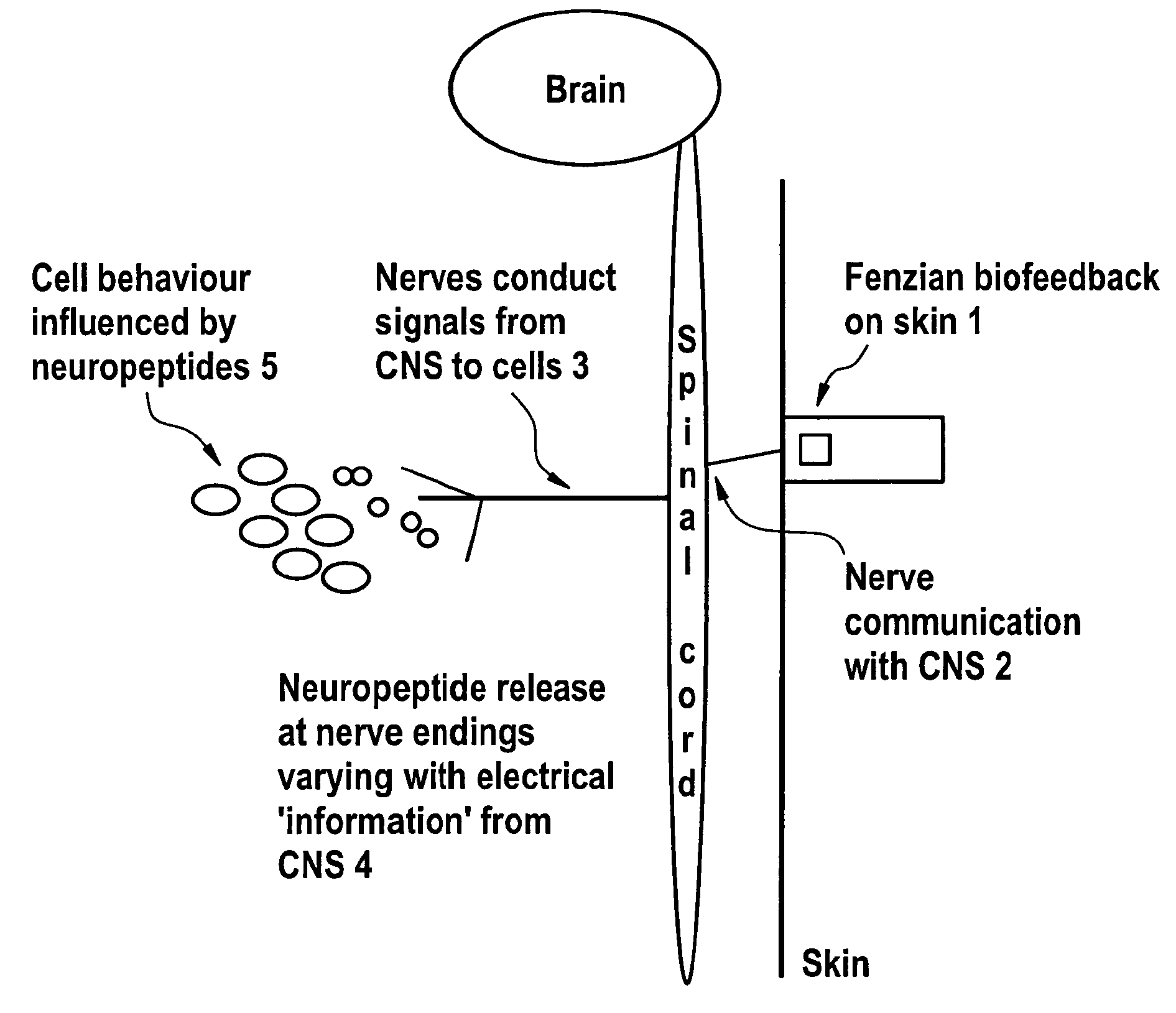

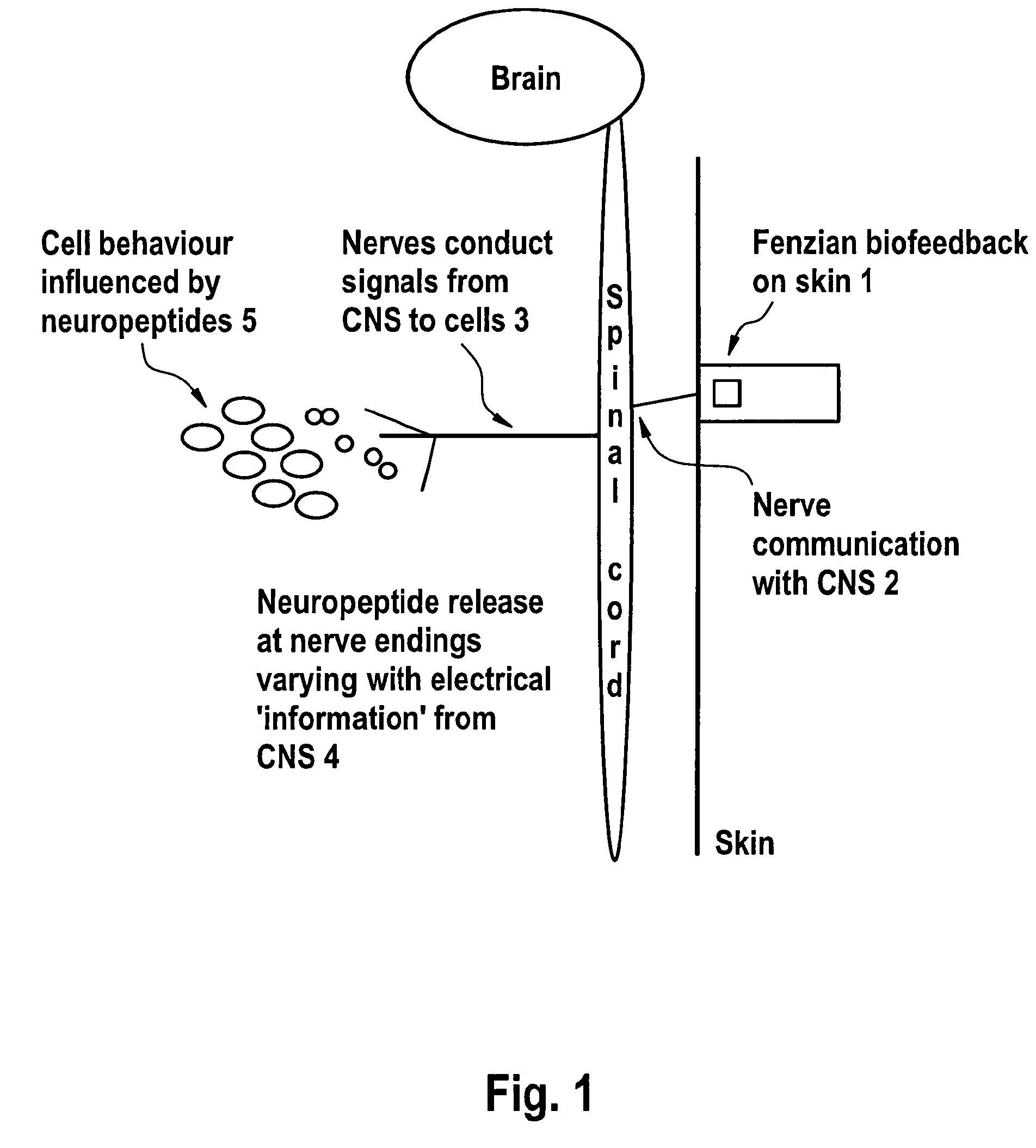

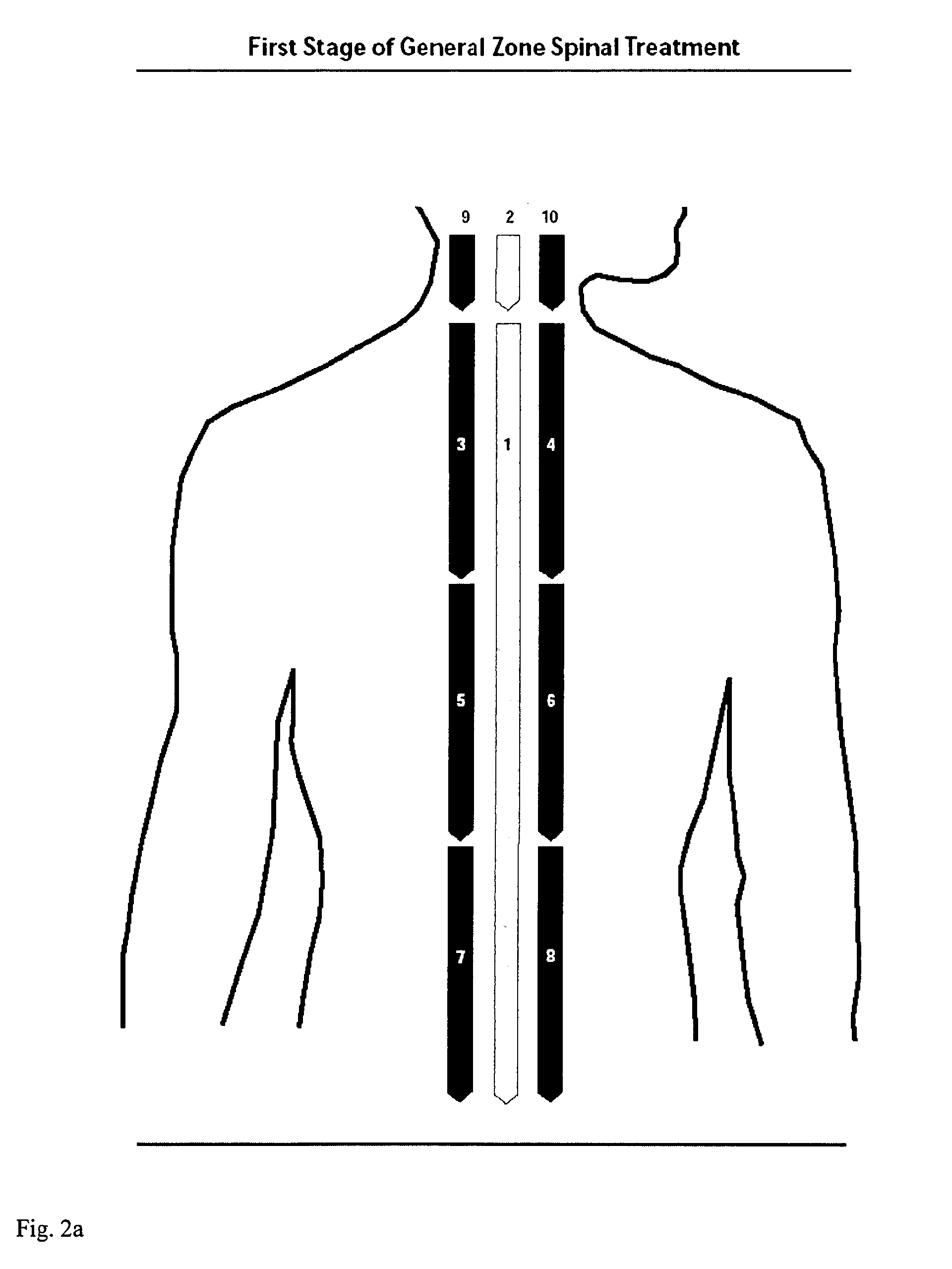

Plurality of Electrons for Use in the Restoration of a Patient's Health

ActiveUS20110152975A1VariabilityElectrotherapyDiagnostic recording/measuringHuman patientTreatment use

Embodiments of the present invention relate to a non-invasive stimulatory adjustment of the body's own self-repair-system using a plurality of electrons. In particular, embodiments of the present invention relate to a plurality of electrons for use in the restoration of a patient's health, preferably a human patient's health in a number of medical conditions. Moreover, embodiments of the present invention relate to a method of treatment using a plurality of electrons for use in the restoration of a patient's health, preferably a human patient's health. Moreover, embodiments of the present invention relate to a method of stimulatory adjustment of the body's own self-repair system using a plurality of electrons.

Owner:OXFORD BIOELECTRONICS

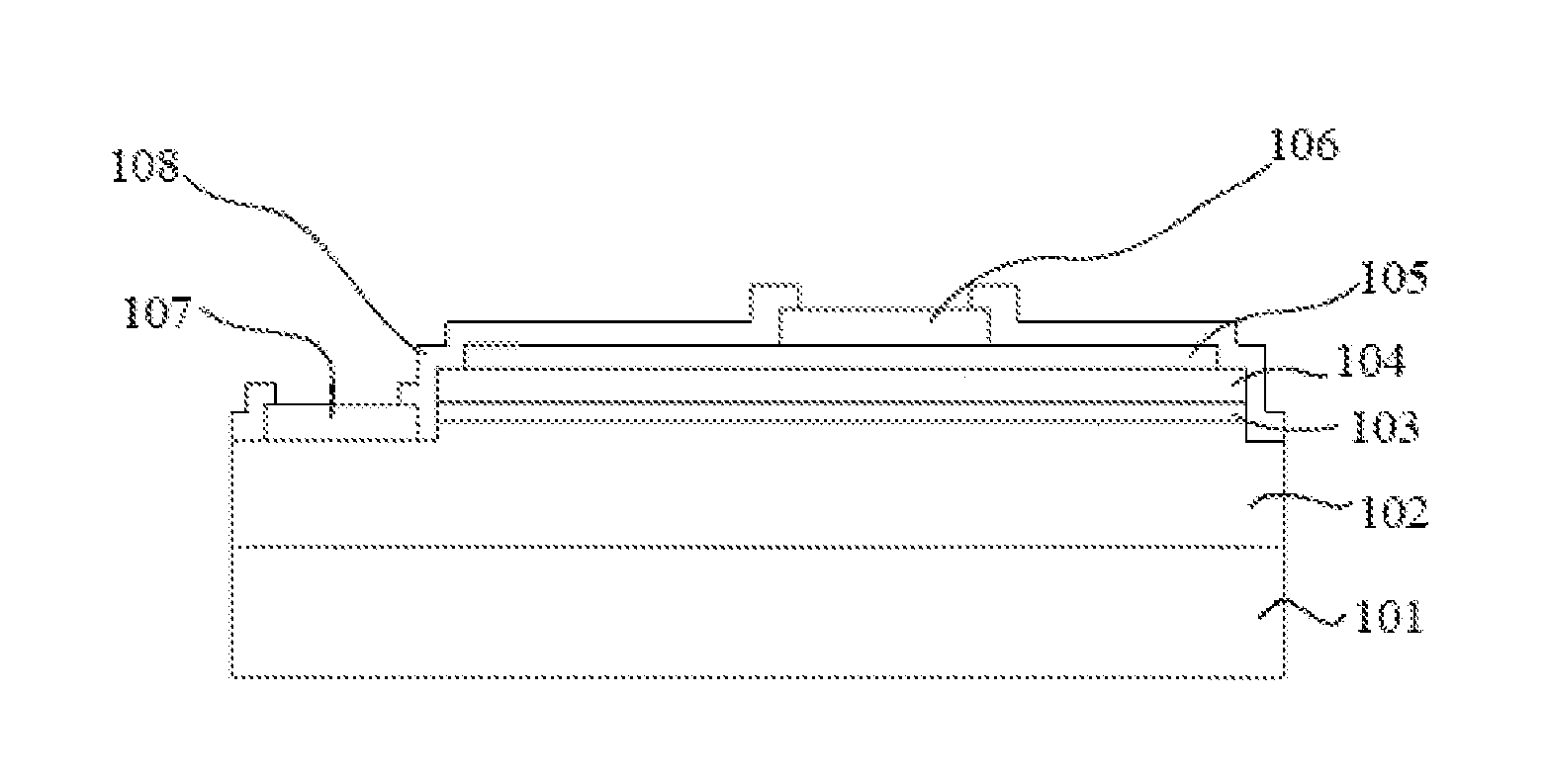

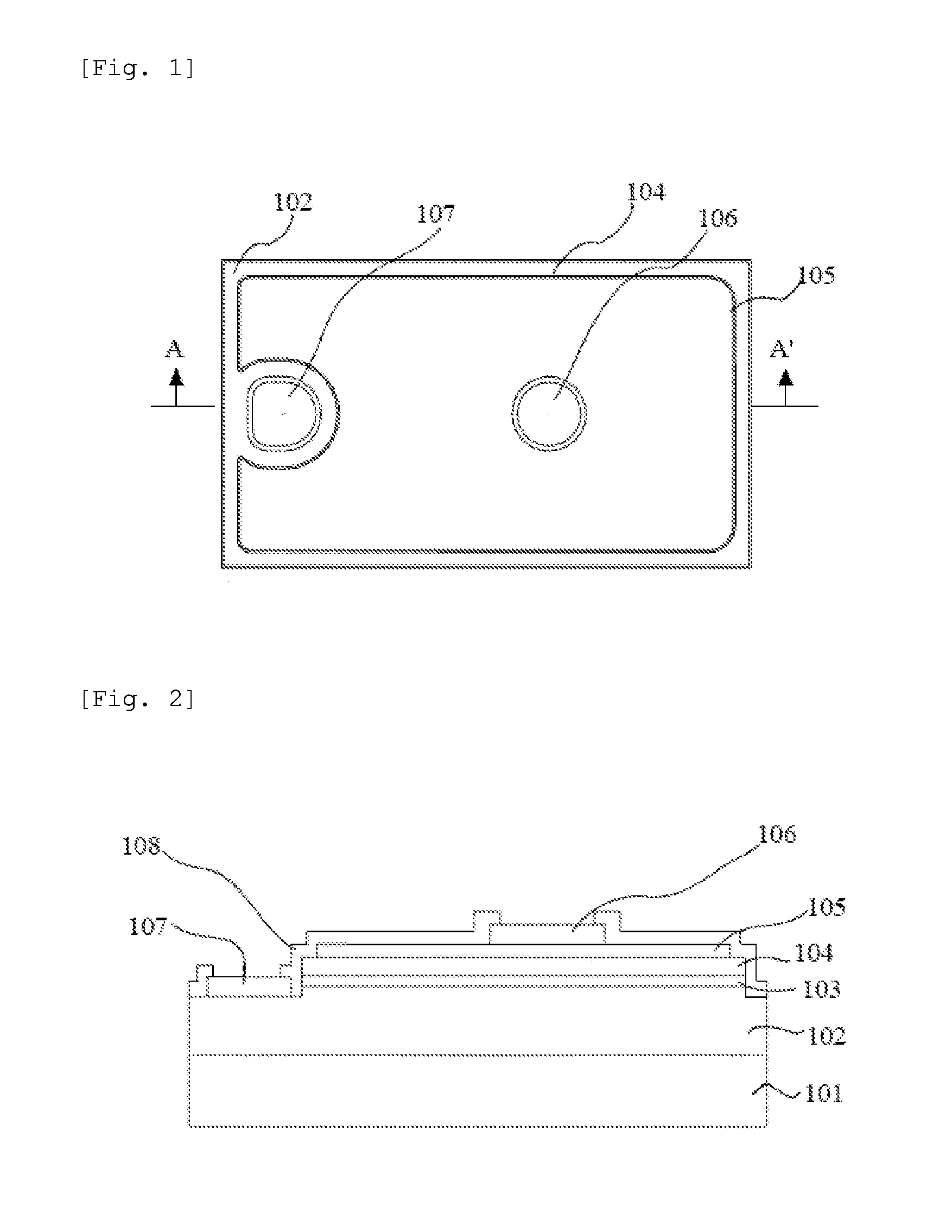

Nitride semiconductor light emitting element

InactiveUS20130026487A1VariabilityLow variabilitySemiconductor/solid-state device manufacturingSemiconductor devicesIndiumOhmic contact

An object of the present invention is to provide a nitride semiconductor light emitting element having a novel transparent electrode. The nitride semiconductor light emitting element has the transparent electrode on a p-type nitride semiconductor layer, wherein the p-type nitride semiconductor layer and the transparent electrode can be in good ohmic contact to each other and wherein the variability of the forward voltage (Vf) within the wafer can be reduced.The present invention is a nitride semiconductor light emitting element including: an n-side nitride semiconductor layer; a p-side nitride semiconductor layer; and a transparent electrode formed on the p-side nitride semiconductor layer, wherein the transparent electrode is made of indium oxide containing Ge and Si.

Owner:NICHIA CORP

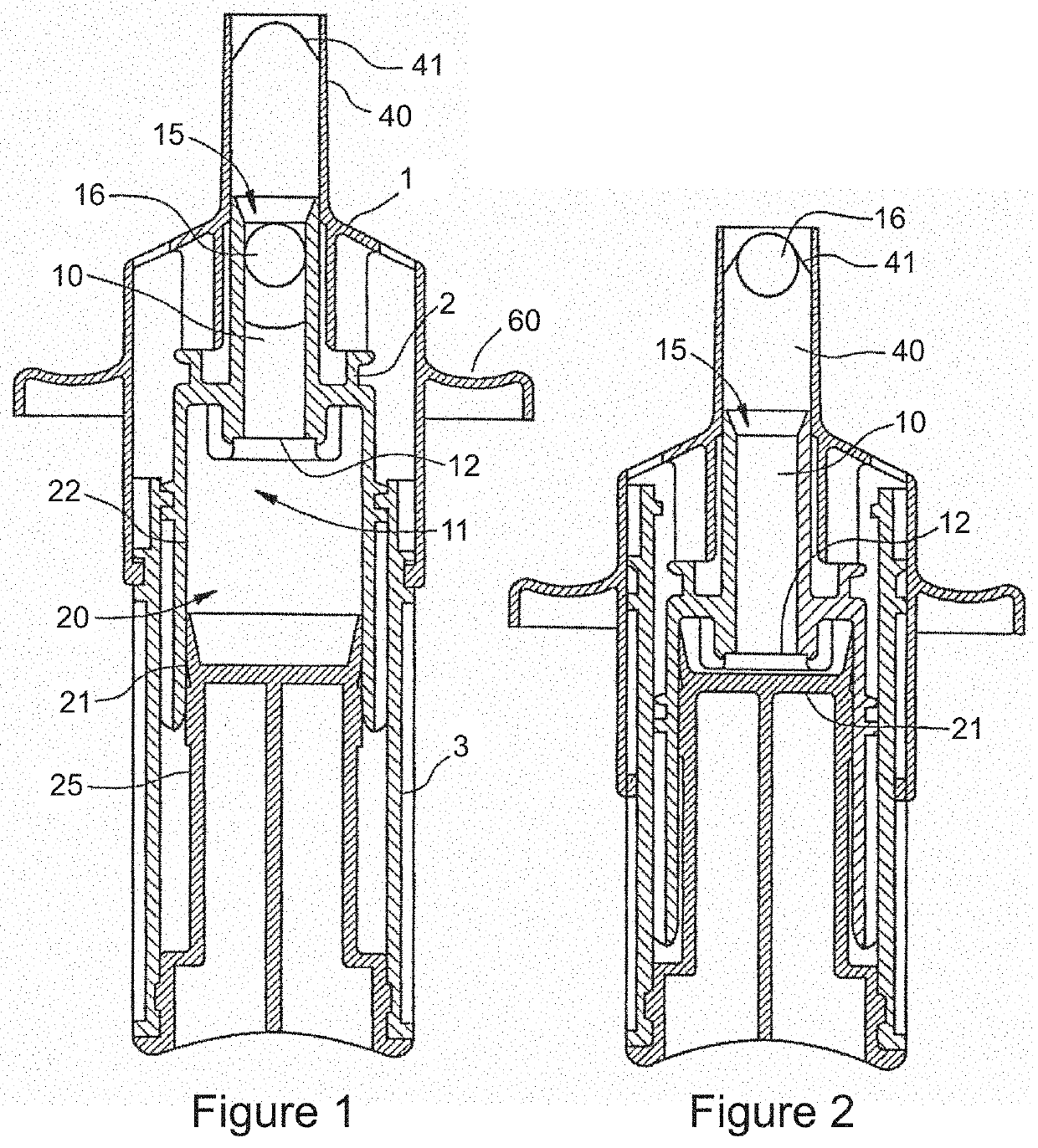

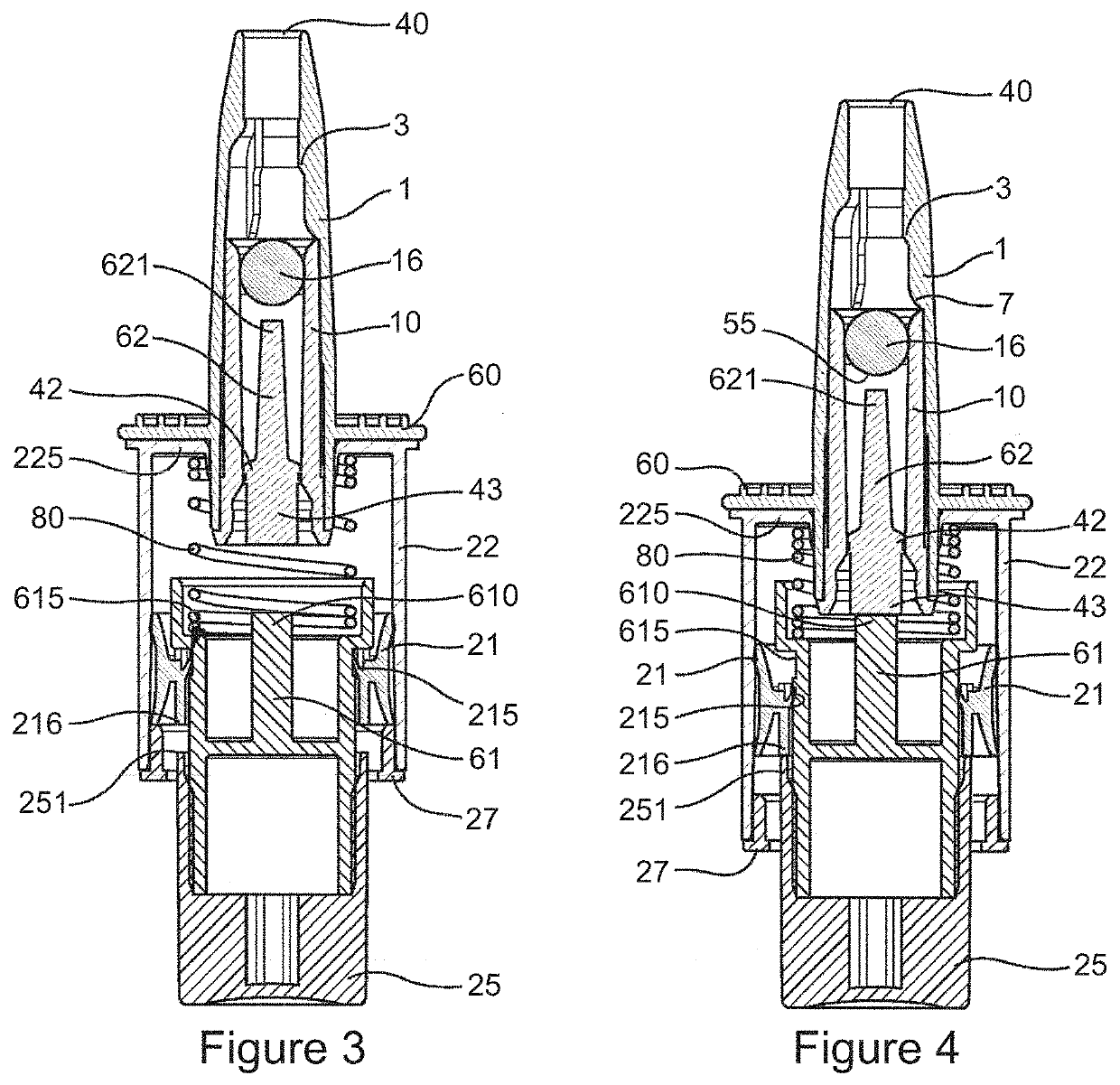

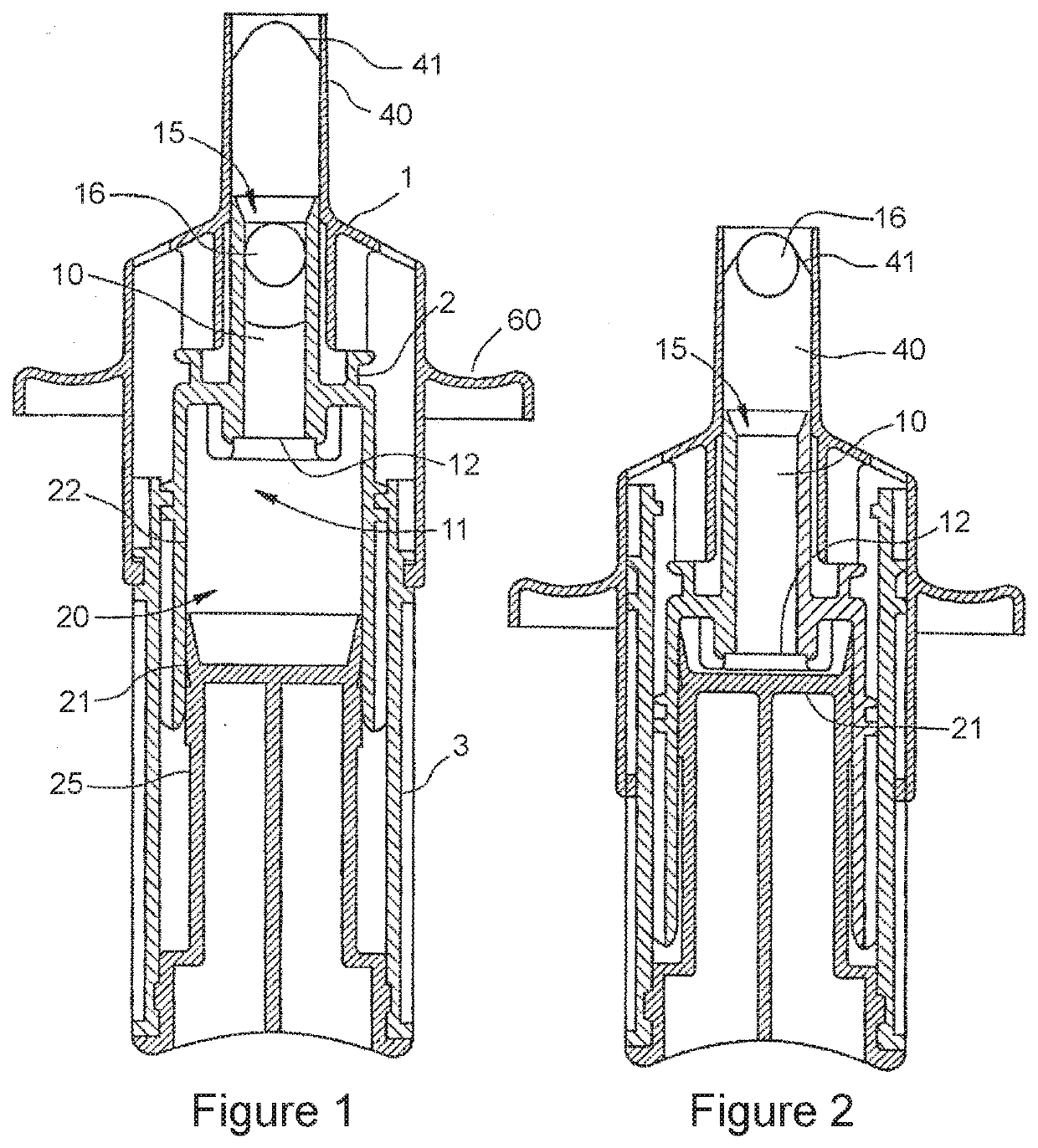

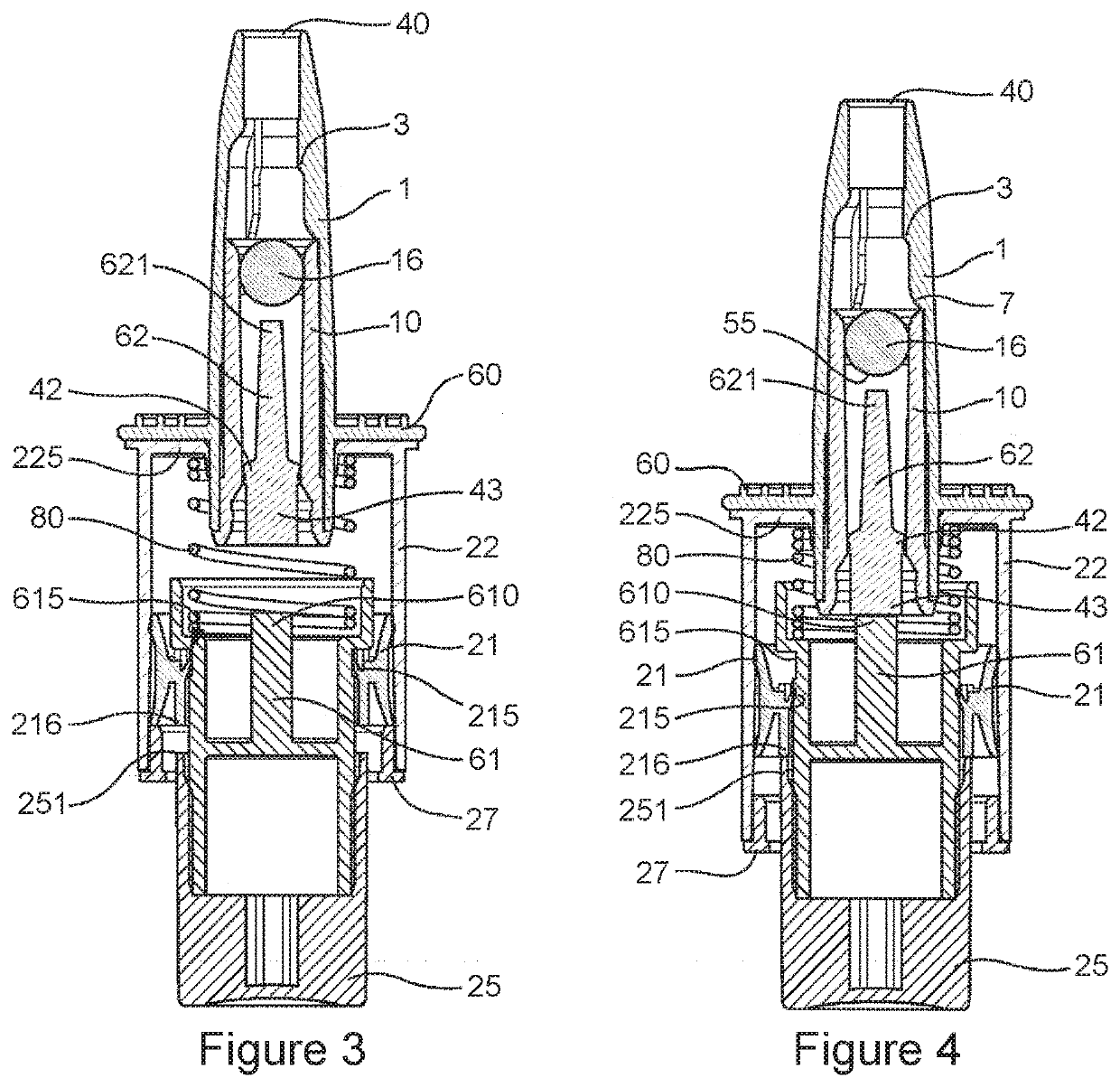

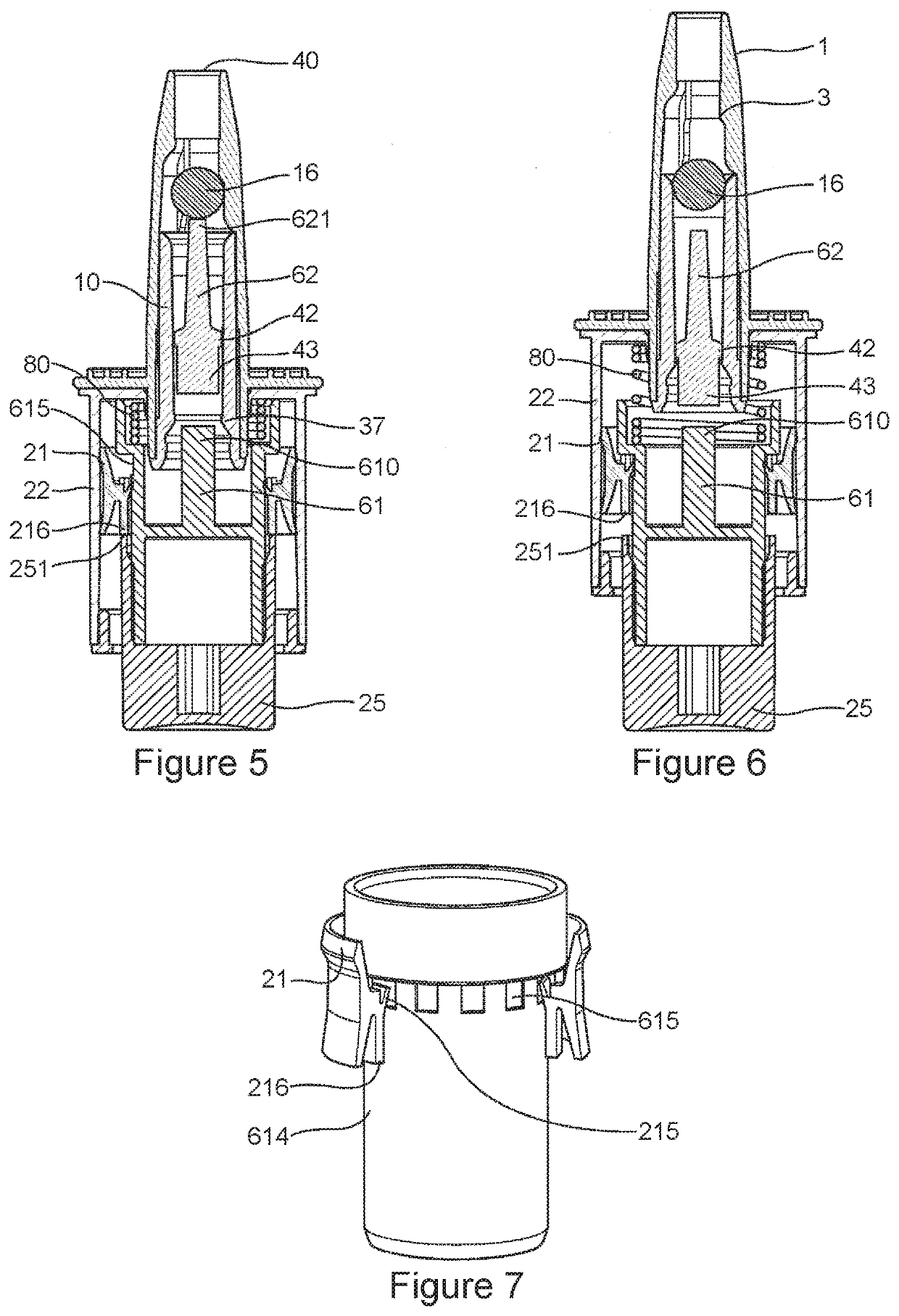

Pharmaceutical composition for nasal delivery

ActiveUS10729687B1Improve bioavailabilityFast absorptionPowder deliveryOrganic active ingredientsOpioid antagonistOpioidergic

According to the invention, there is provided a solid pharmaceutical composition formulation for nasal delivery of an opioid antagonist, comprising a pharmacologically-effective amount of an opioid antagonist and a pharmaceutically-acceptable carrier. The compositions are preferably in the form of a powder produced by spray-drying, which are subsequently loaded into single use nasal applicators. Preferred pharmaceutically-acceptable carriers in this regard include disaccharides (e.g. lactose or trehalose) and dextrins (e.g. cyclodextrins or maltodextrins), preferably spray-dried together in combination. Compositions may further comprise an alkyl saccharide, preferably a sucrose ester, such as sucrose monolaurate. The compositions and applicators may be employed in the treatment of opioid overdose in subjects.

Owner:OREXO AB

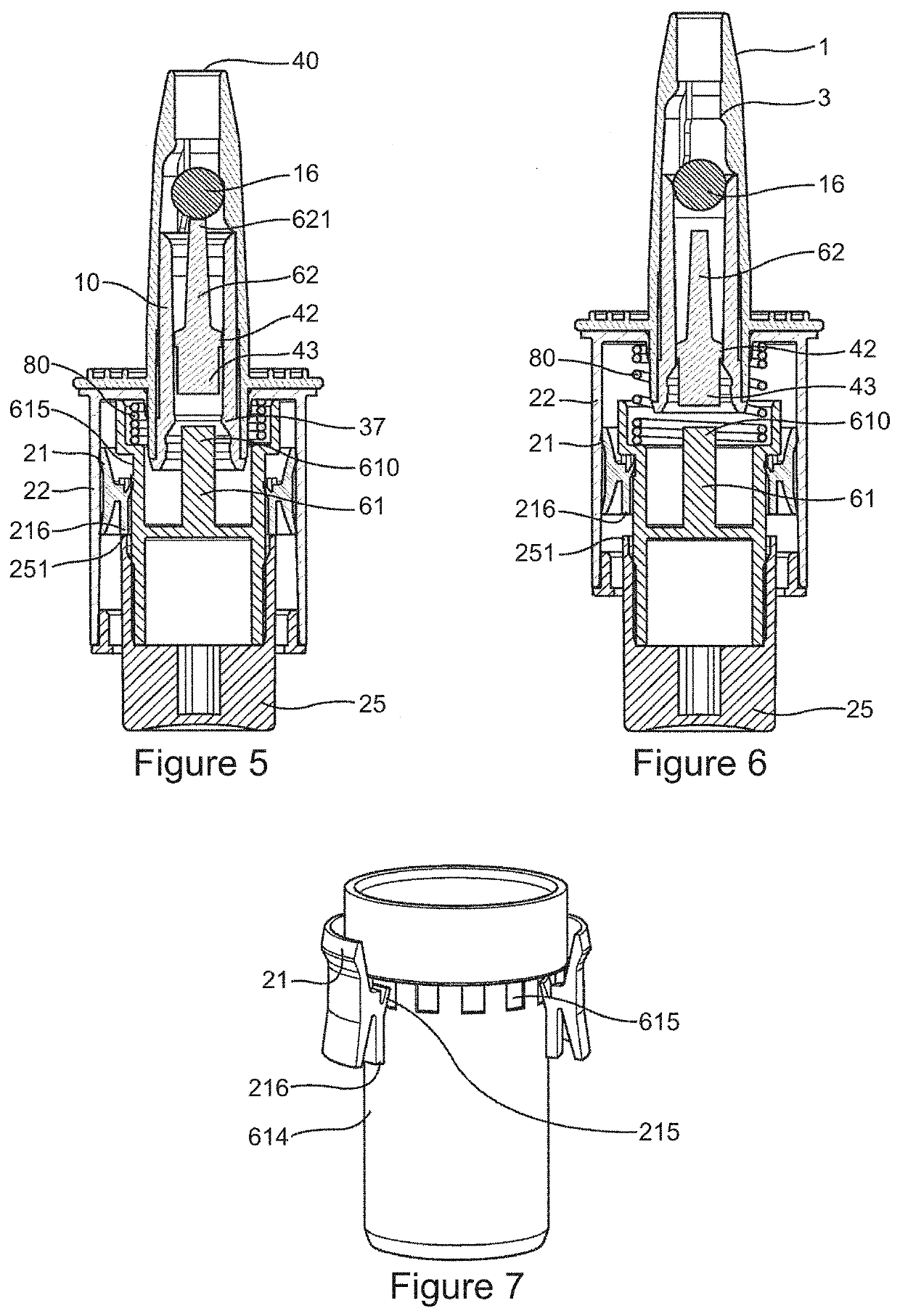

Valve flow distribution ultrahigh-pressure axial plunger pump

InactiveCN103016330AEasy to processSimple structurePositive displacement pump componentsLiquid fuel engine componentsDrive shaftPlunger pump

The invention discloses a valve flow distribution ultrahigh-pressure axial plunger pump which is formed as follows: one end of a transmission shaft integrally arranged is connected with a pump and a pump body in sequence, the pump is connected with and provided with a left rotating bearing and a right rotating bearing, the pump body is provided with a communicating oil duct and an oil discharge outlet communicated with the communicating oil duct, the pump body provided with the communicating oil duct and the oil discharge outlet communicated with the communicating oil duct is connected with a mounted plunger cylinder assembly and an integrated oil suction and discharge valve from the direction of the pump, and then connects the pump casing and the pump body as a whole by connecting bolts, and finally the outer end of the pump body is connected with an outer cover. The valve flow distribution ultrahigh-pressure axial plunger pump is reasonable in design, and convenient to use, and the production efficiency is improved.

Owner:天津市泽华源泵业科技发展有限公司

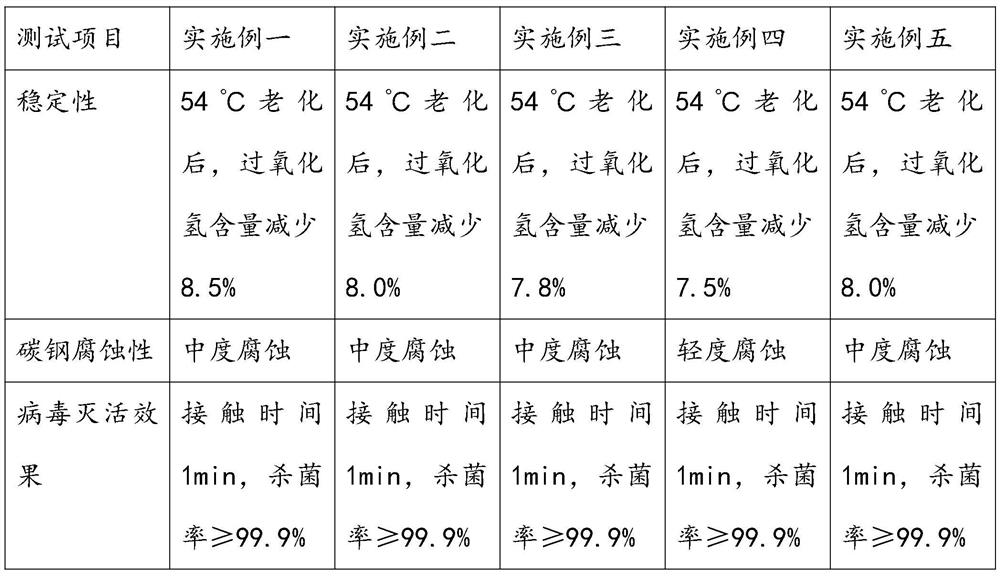

Medical antiviral disinfectant containing low-concentration hydrogen peroxide

PendingCN113519550ASimple preparation processProduct properties are stableBiocideDisinfectantsChemistryBactericidal effect

The invention discloses a medical antiviral disinfectant containing low-concentration hydrogen peroxide, which comprises the following components in percentage by weight: 0.3 to 3.0 percent of hydrogen peroxide, 0.1 to 5.0 percent of surfactant, 1.0 to 5.0 percent of bactericidal synergist, 0.3 to 1.0 percent of stabilizer, 0.01 to 1.0 percent of metal corrosion inhibitor, 0.1 to 1.0 percent of acid-base regulator and 86 to 98.19 percent of purified water. The low-concentration hydrogen peroxide compounded quaternary ammonium salt disinfectant is simple in preparation process and stable in product property, the environment surface can be disinfected in a spraying mode or a wiping mode, the low-content hydrogen peroxide is non-irritant to skin and non-corrosive to various environment surfaces, the disinfectant does not need to be diluted during use, the bactericidal effect is rapid, and the poliomyelitis virus 1mi < n > can be killed, so that the disinfectant is an ideal disinfection product for disinfecting the environment of families and hospitals.

Owner:杭州朗索医用消毒剂有限公司

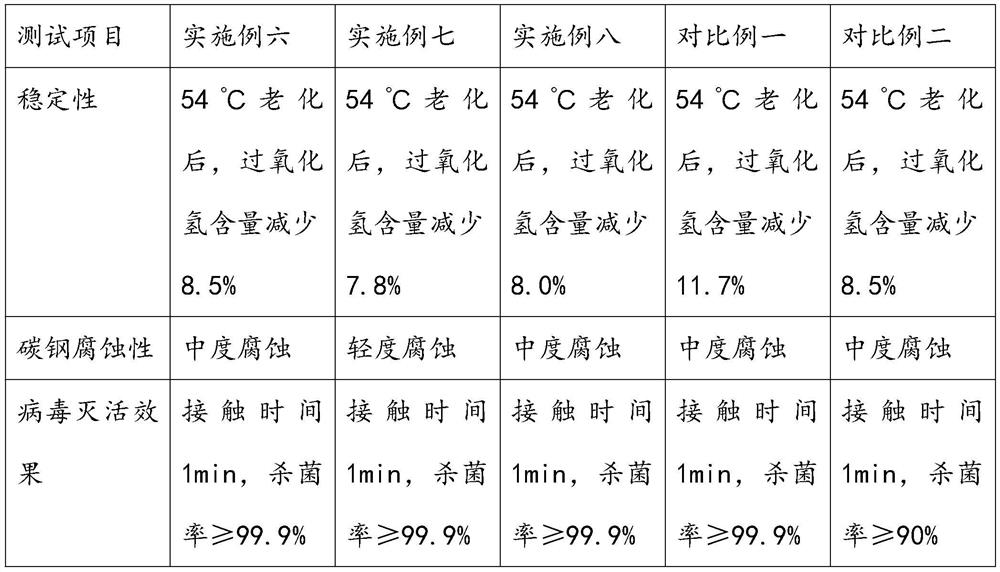

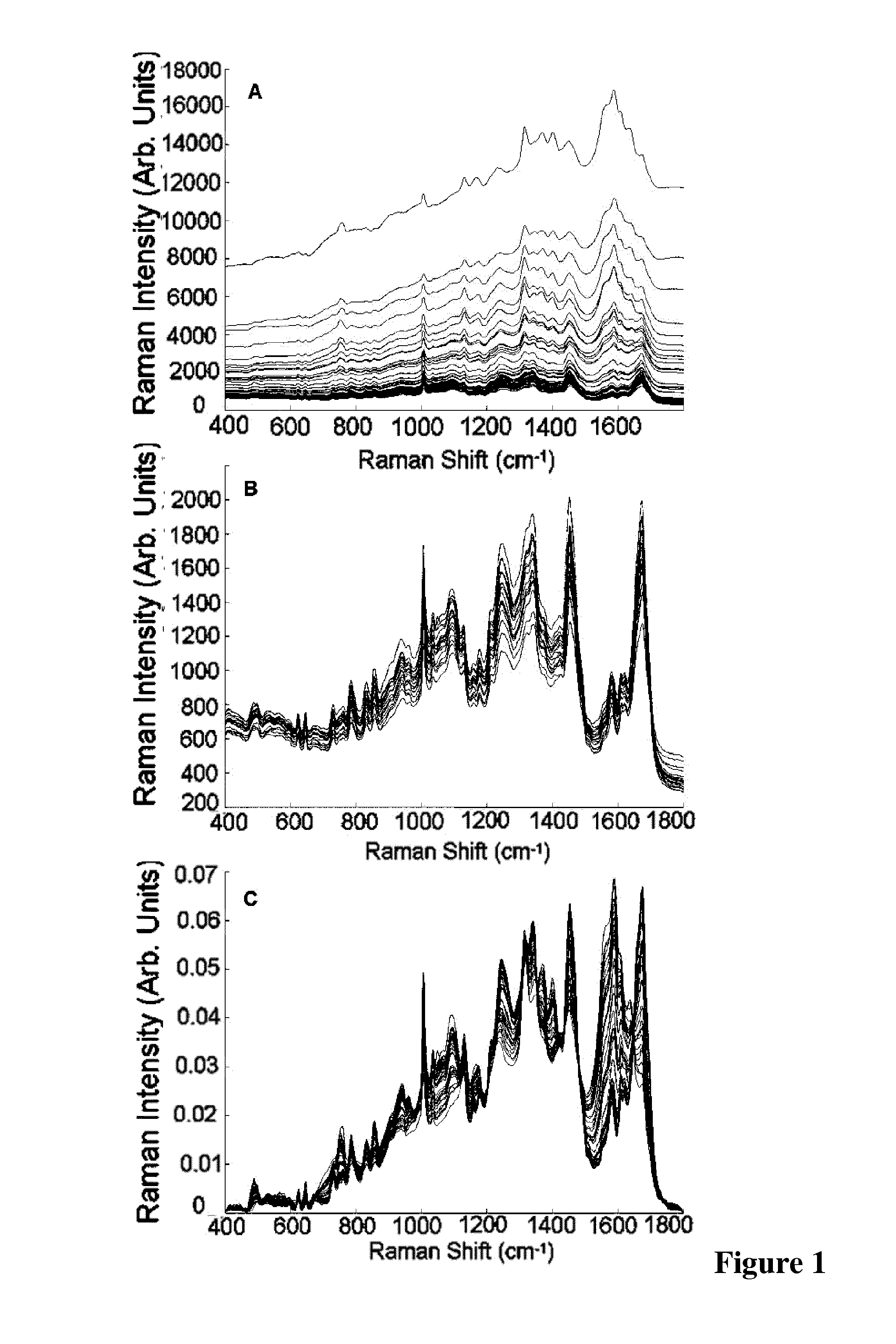

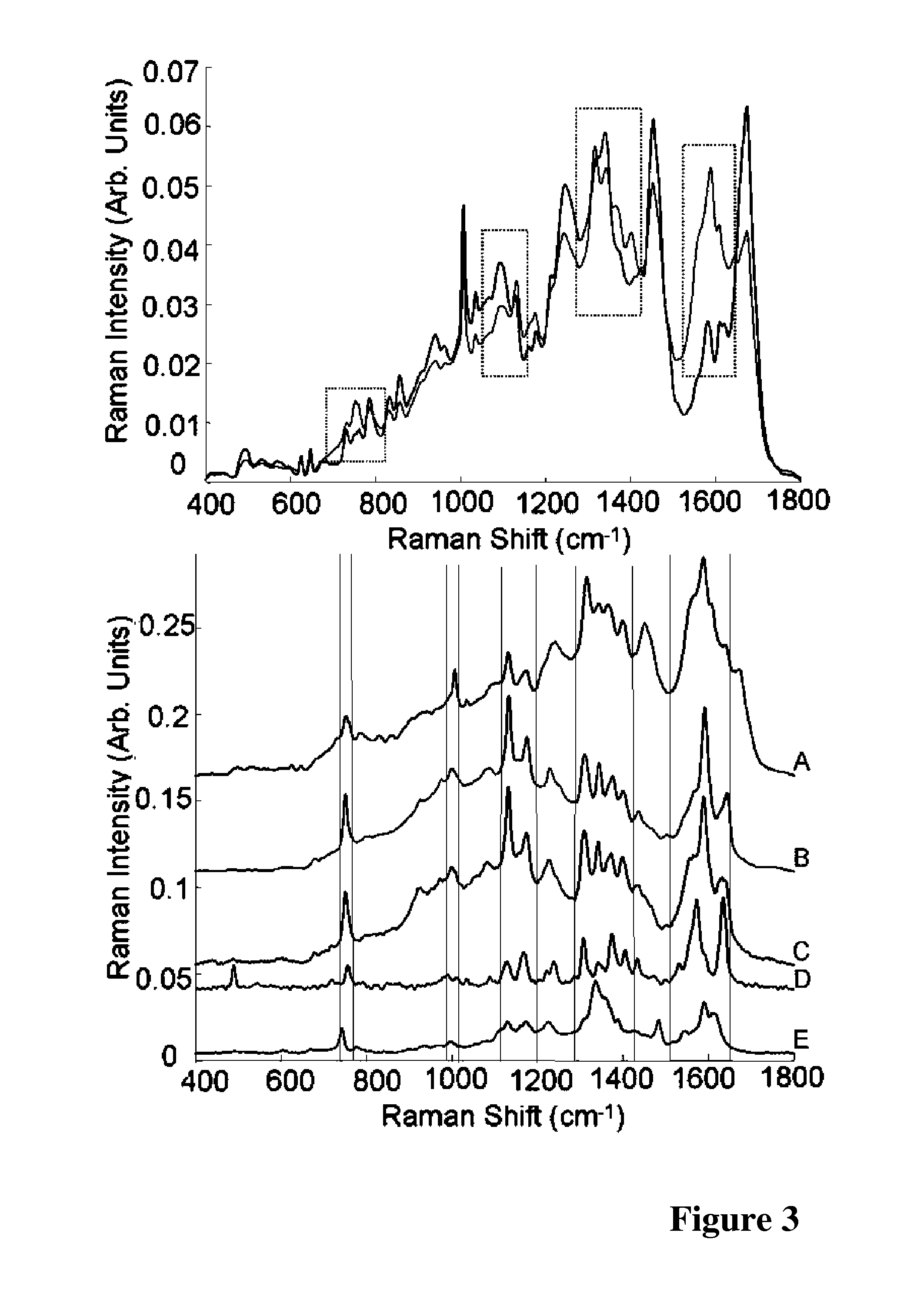

Cervical Sample Preparation For Reduced Variability In Raman Spectroscopy

InactiveUS20160069809A1Easy to integrateVariabilityPreparing sample for investigationRaman scatteringMedicineSpectroscopy

A method of performing a spectroscopy process on a fixed biological sample is described. The method comprises the steps of: (i) treating the fixed biological material to cause oxidation of haemoglobin present in the fixed biological material, and (ii) performing spectroscopy on the treated fixed biological sample. The method is particularly suitable for cervical sample preparation for reduced variability in Raman spectroscopy.

Owner:DUBLIN INST OF TECH

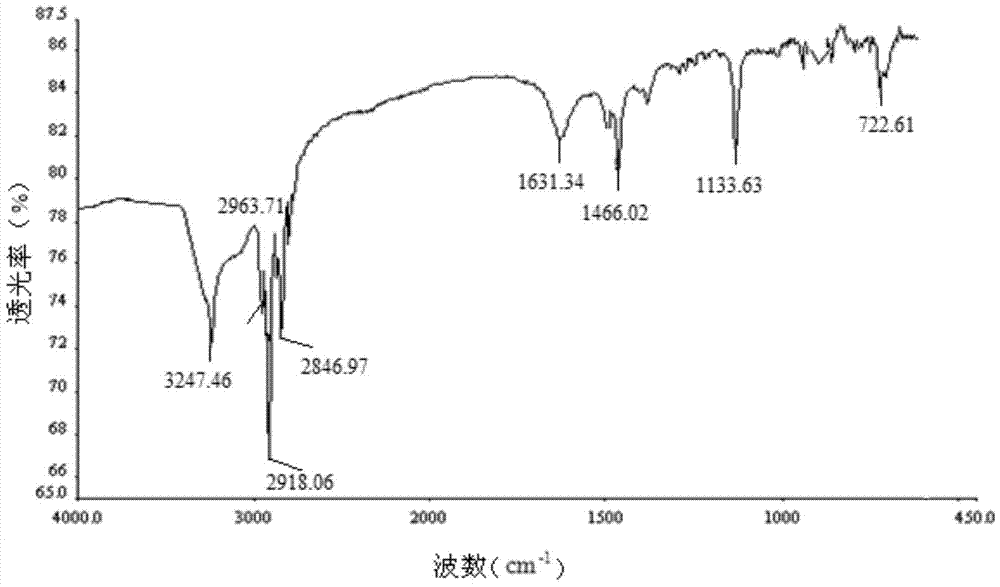

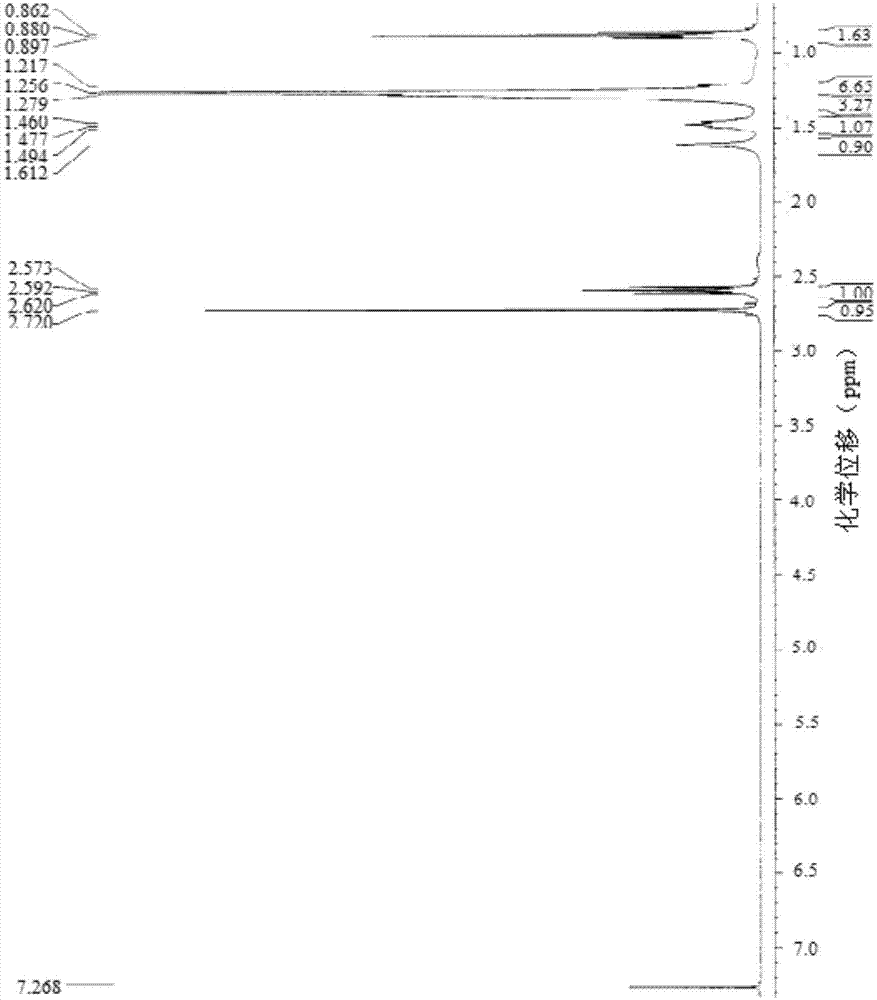

Novel amido-linkage imidazolium salt gemini surfactant and preparation method thereof

InactiveCN103406065BLow toxicityThe three-step reaction is easy to operateOrganic chemistryTransportation and packagingReaction temperatureSolvent

The invention relates to a novel amido-linkage imidazolium salt gemini surfactant and a preparation method thereof, and the preparation method can be used for solving the problems that the existing preparation method of the amido-linkage heterocyclic gemini surfactant is complicated to operate, high in cost and reaction temperature, long in reaction time, and large in solvent toxicity. The preparation method comprises the following steps of: I, N-alkylation; II, amidation; III, quaternization to obtain the product amido-linkage imidazolium salt gemini surfactant. The preparation method is simple for three-step reaction operations, capable of shortening the reaction time, and mild in reaction conditions, the solvent toxicity is small, the raw material cost is low, the hydrophilic property of the novel amido-linkage imidazolium salt gemini surfactant can be greatly improved through introducing strong-polarity amido linkage and two positive nitrogen ion heads, the novel amido-linkage imidazolium salt gemini surfactant has good biodegradability through introducing nitrogen heterocyclic ring and amido linkage, and the environmentally-friendly gemini surfactant can be used in multiple fields of cleaning, sterilization, restraint of metal corrosion, sewage treatment and the like.

Owner:QIQIHAR UNIVERSITY

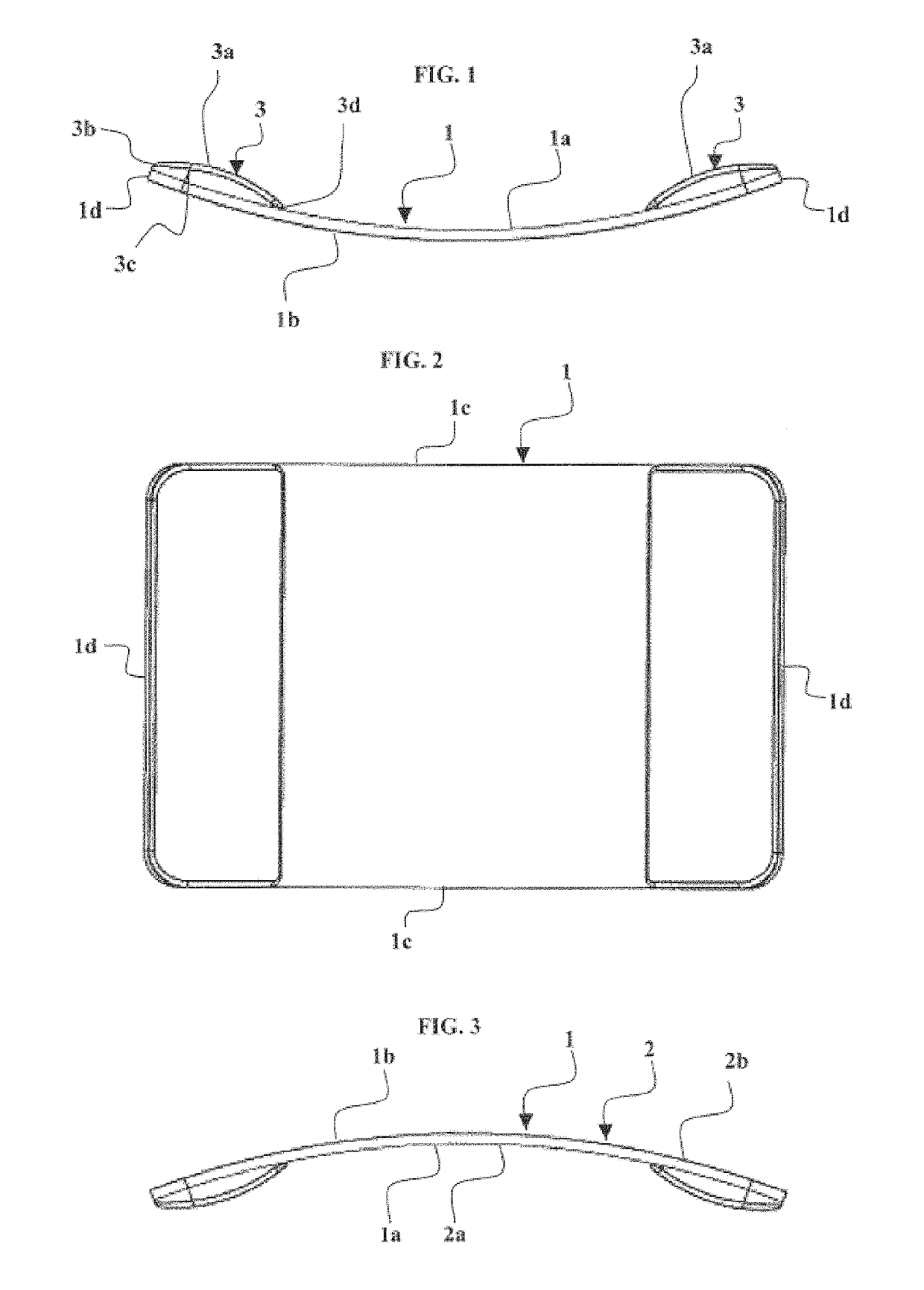

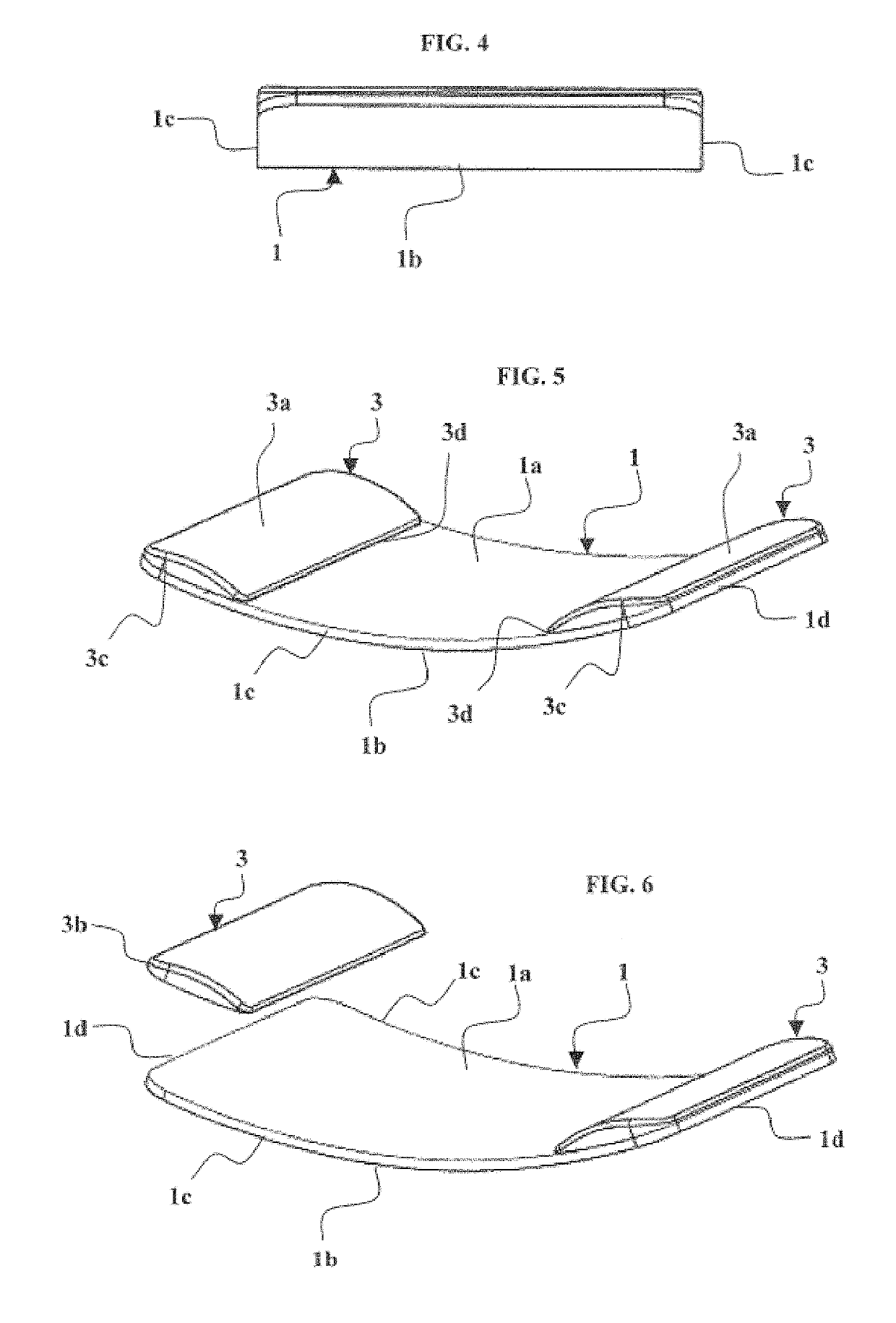

Multifunctional curved board

ActiveUS10363191B2Maintenance savingAvoid uneven tensionChiropractic devicesStiltsMuscle strengthFoot supports

A multi-functional curved board used as a support for legs of a user and for general maintenance of muscle strength, the multi-functional curved board having one or more curved bodies (1) including a radius of curvature, a longitudinal axis, and at least one raised foot support. The multi-functional curved board can be bent in the direction transverse to the radius of curvature to enable the multi-functional curved board to rotate around the longitudinal axis.

Owner:GYMBA OY

Preventing fog on a medical device viewport

ActiveUS10413168B2Preclude obtainingRuining the optical quality of the viewportElectric discharge tubesEndoscopesSurgeryMedical device

Provided are methods of immunizing a viewport of a medical device against fogging before or during a medical procedure, and related apparatuses and devices. The methods comprise applying plasma to the viewport prior to use, thereby rendering a surface of the viewport highly hydrophilic. The methods eliminate or at least significantly reduce blur due to fogging.

Owner:PLASMATICA LTD

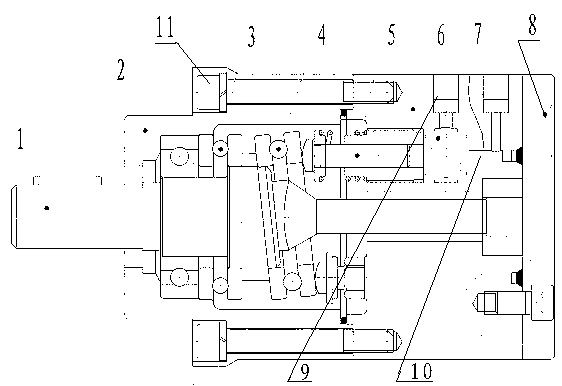

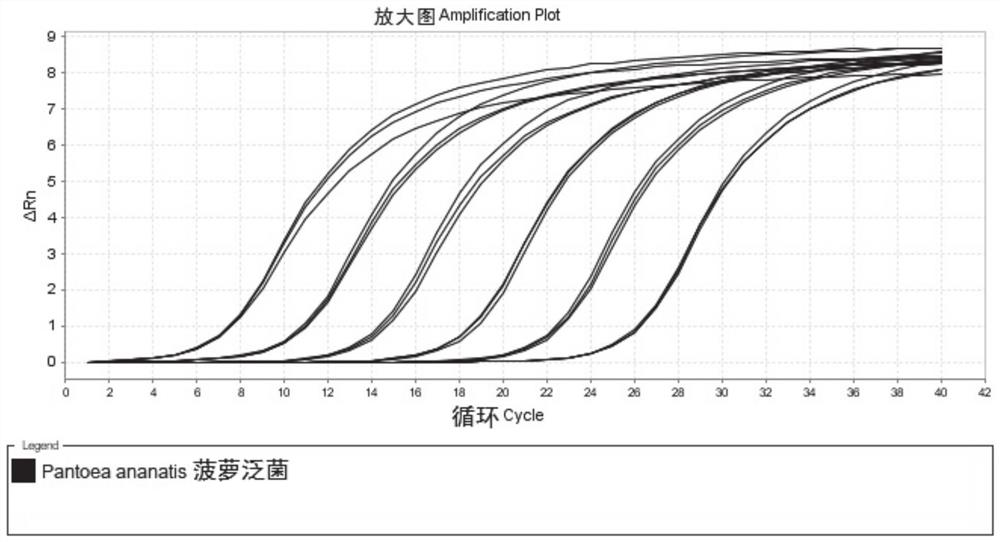

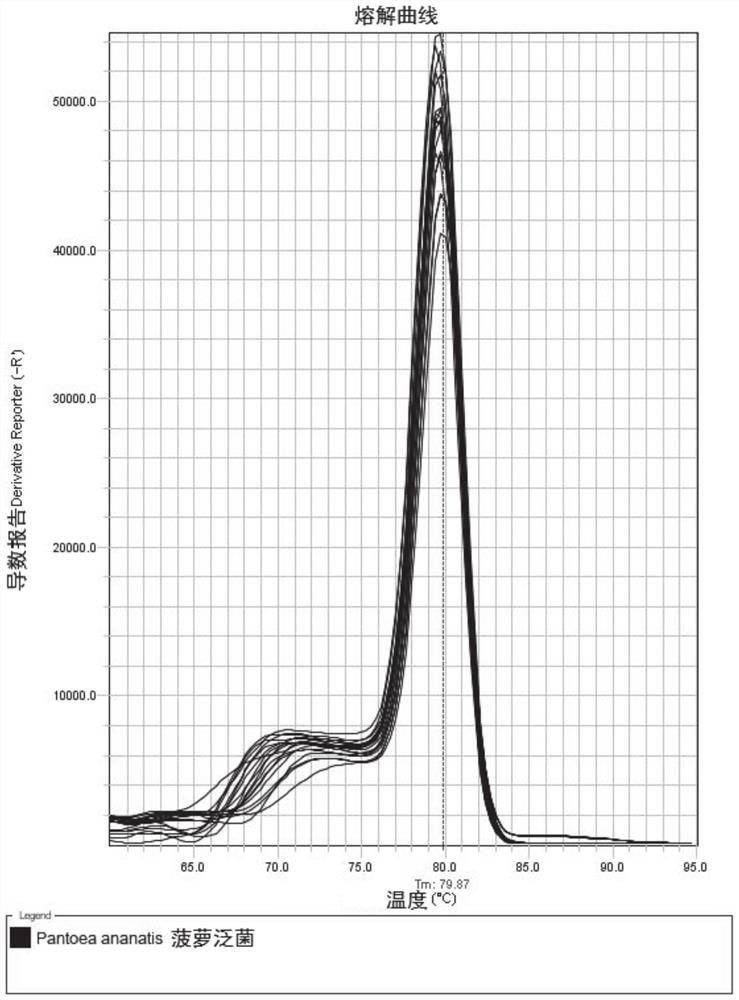

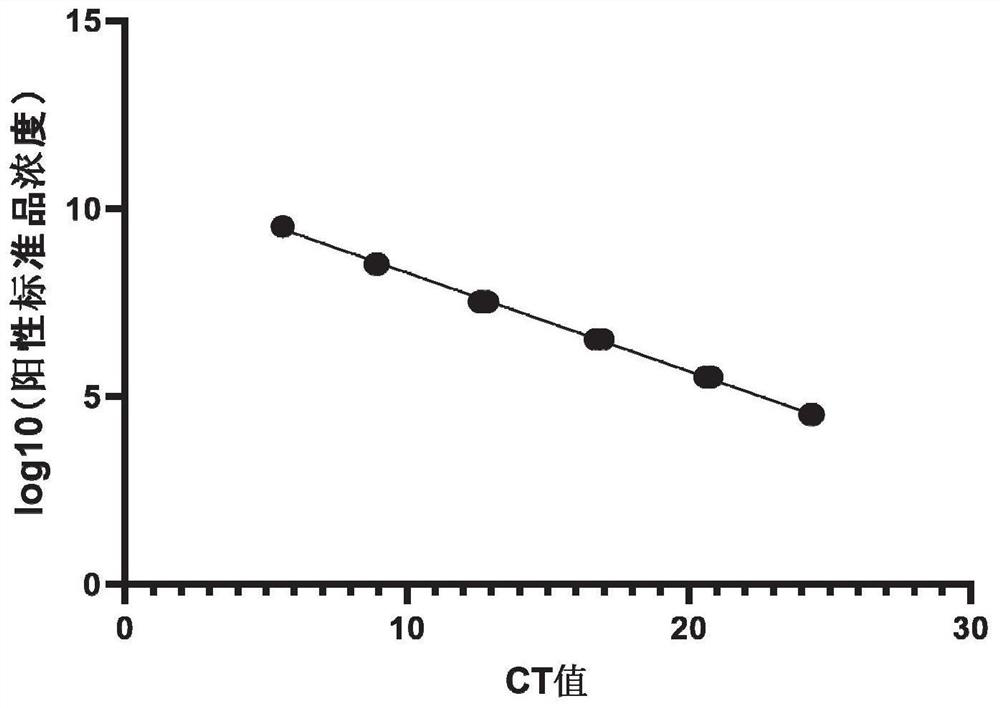

Fluorescent quantitative PCR (polymerase chain reaction) detection method and kit for plant pathogenic bacterium pantoea ananatis

PendingCN113604590AConservativeVariabilityMicrobiological testing/measurementMicroorganism based processesEnzymeCrop

The invention discloses a fluorescent quantitative PCR (Polymerase Chain Reaction) detection method and a kit for plant pathogenic bacteria pantoea ananatis. The kit consists of a PCR reaction enzyme premix solution, a pantoea ananatis specific upstream primer, a downstream primer, a positive control and a negative control. The invention also provides a method for carrying out fluorescent quantitative PCR detection on the plant pathogenic bacterium pantoea ananatis through the kit. The method comprises the following steps of step 1, extracting genome DNA of a sample to be detected; and 2, by taking the genome DNA obtained in the step 1 as a template, setting a positive standard control and a negative control, preparing a PCR reaction system with a Pantoea ananas PCR reaction solution and a specific primer, and carrying out a fluorescent quantitative PCR reaction under optimized reaction conditions. The method has higher specificity, sensitivity and stability when being used for detecting pantoea ananatis in crops and trees, and is a rapid and accurate pantoea ananatis detection method.

Owner:上海沃吉基因科技有限公司

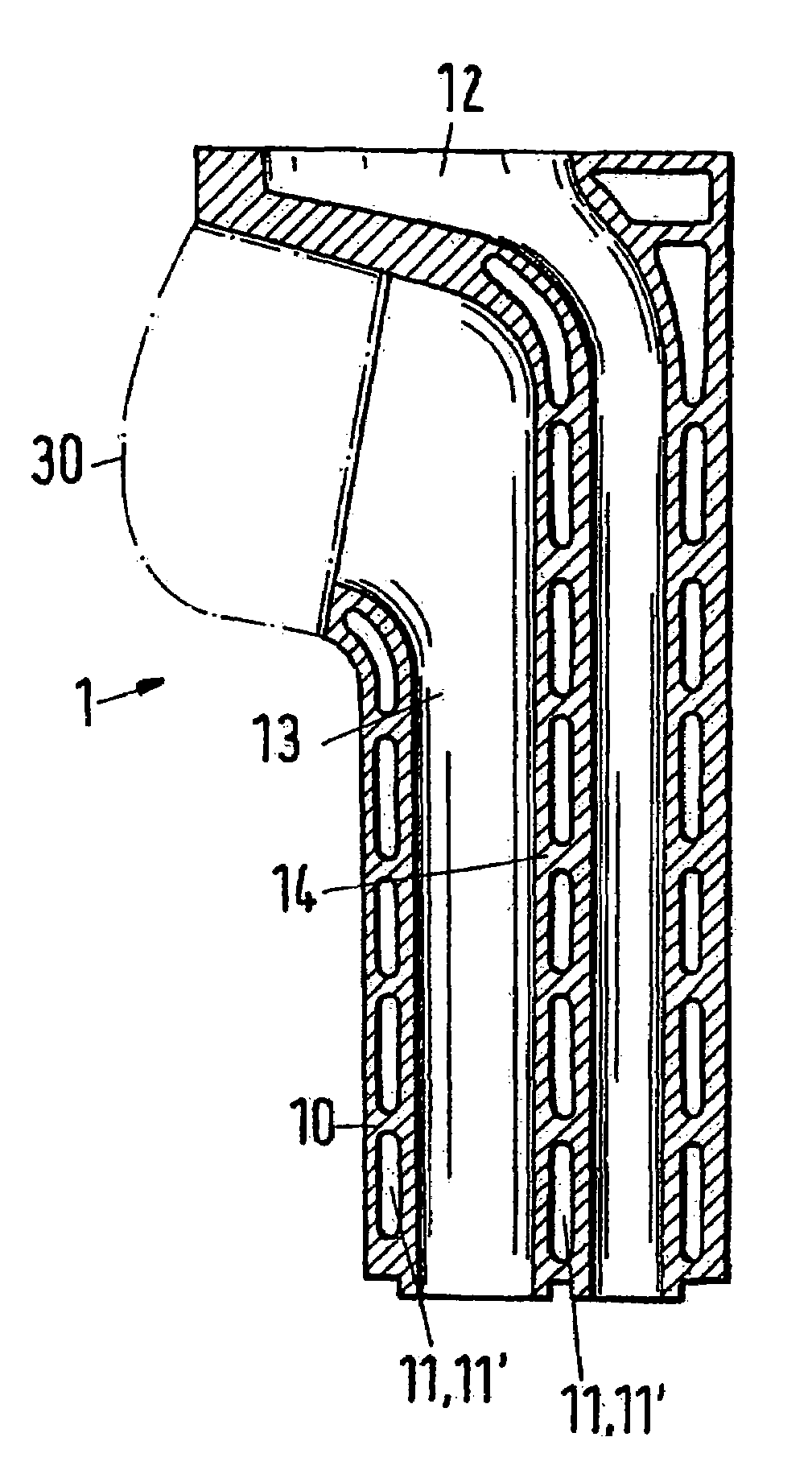

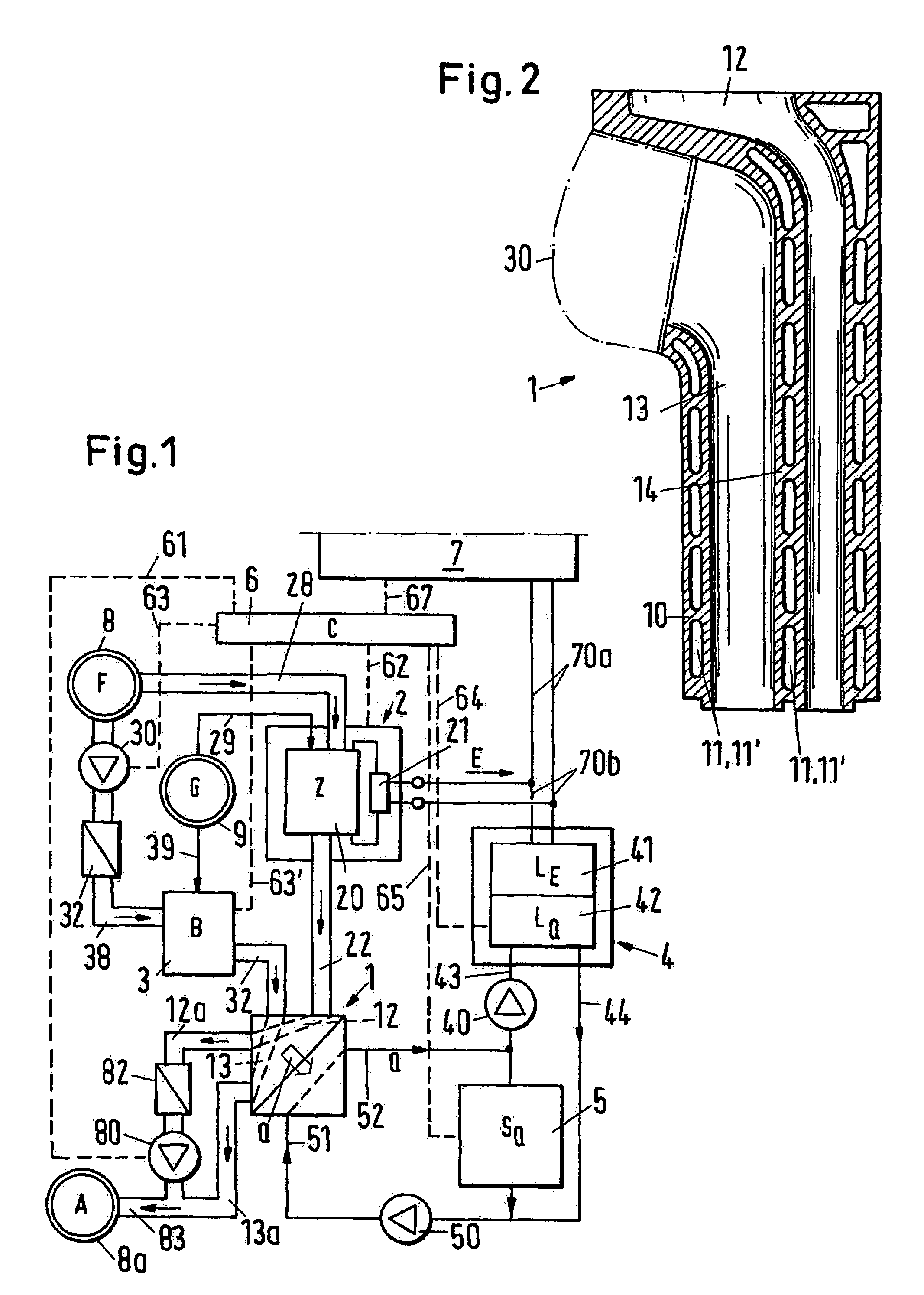

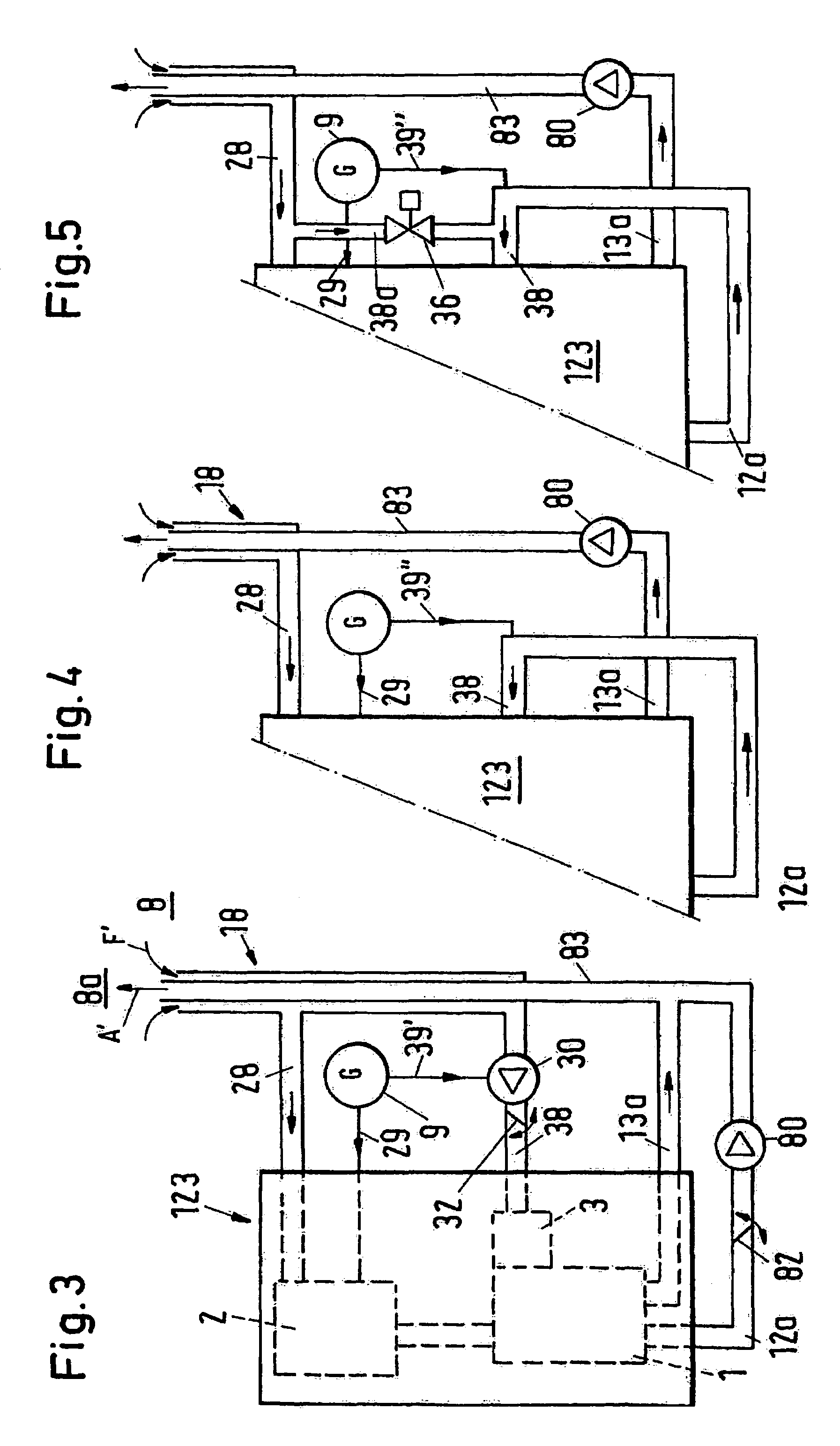

Heat exchanger for a heating system with integrated fuel cells for the production of electricity

Please substitute the following version of the Abstract, with changes shown by strikethrough (for deletions) or underlining (for added matter). The heat exchanger (I) is provided for a heating system with integrated fuel cells (Z) for the production of electricity and with an additional burner (B). Electrical and thermal energy (E, Q) can be produced in this heating system from a gaseous fuel or from a fuel brought into the gas form by means of the fuel cells, and / or thermal energy (Q) can be produced by means of the additional burner. One part of the thermal energy present in the form of hot exhaust gases can be transferred in the heat exchanger to a liquid heat transfer medium, in particular water or an oil. The heat transfer medium is provided for heat transport for the purpose of room heating and / or process water heating. The heat exchanger forms a compact unit which is also made of a material of good thermal conductivity. Two separate passages (12, 13) are arranged in the heat exchanger inside a double-walled jacket (10). The jacket has a structured inner space (11) which forms a communicating vessel. Due to the structuring the heat transfer medium flows through at least a predominant part of the inner space.

Owner:SULZER HEXIS AG

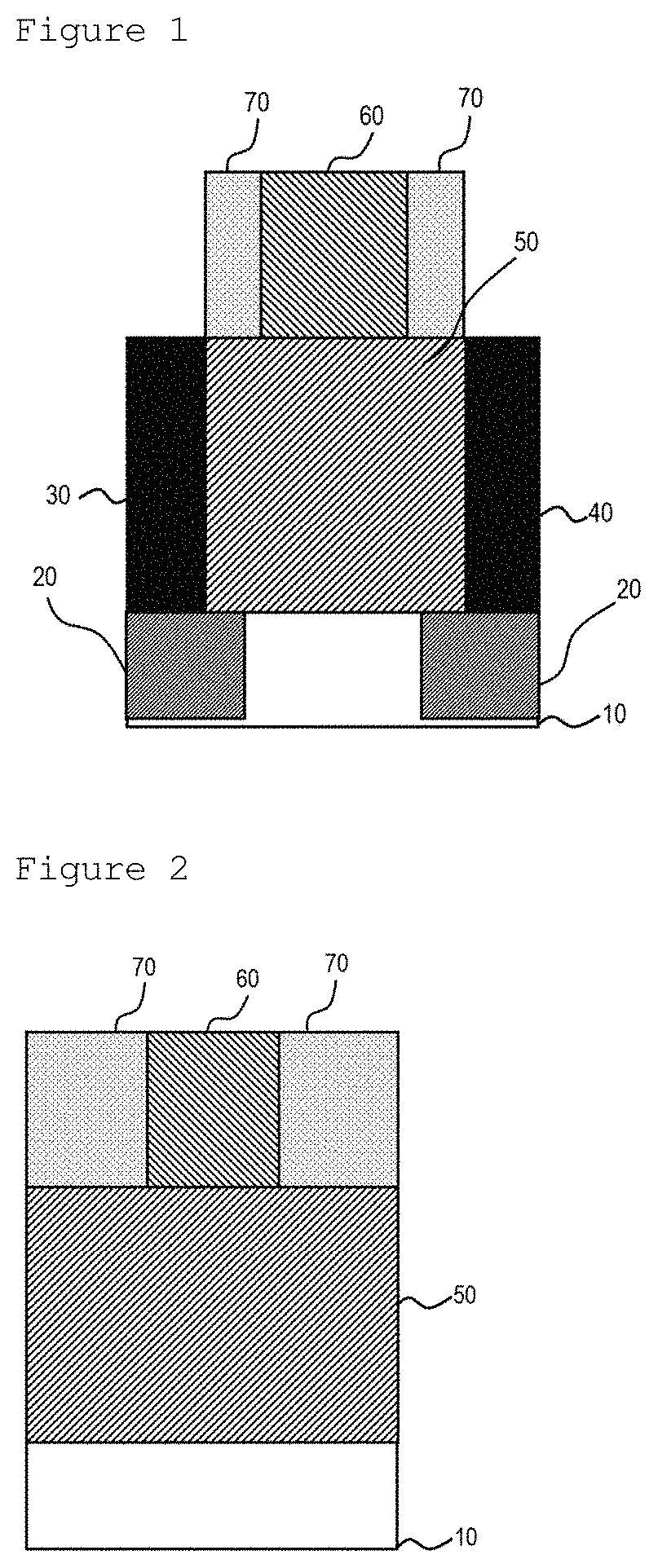

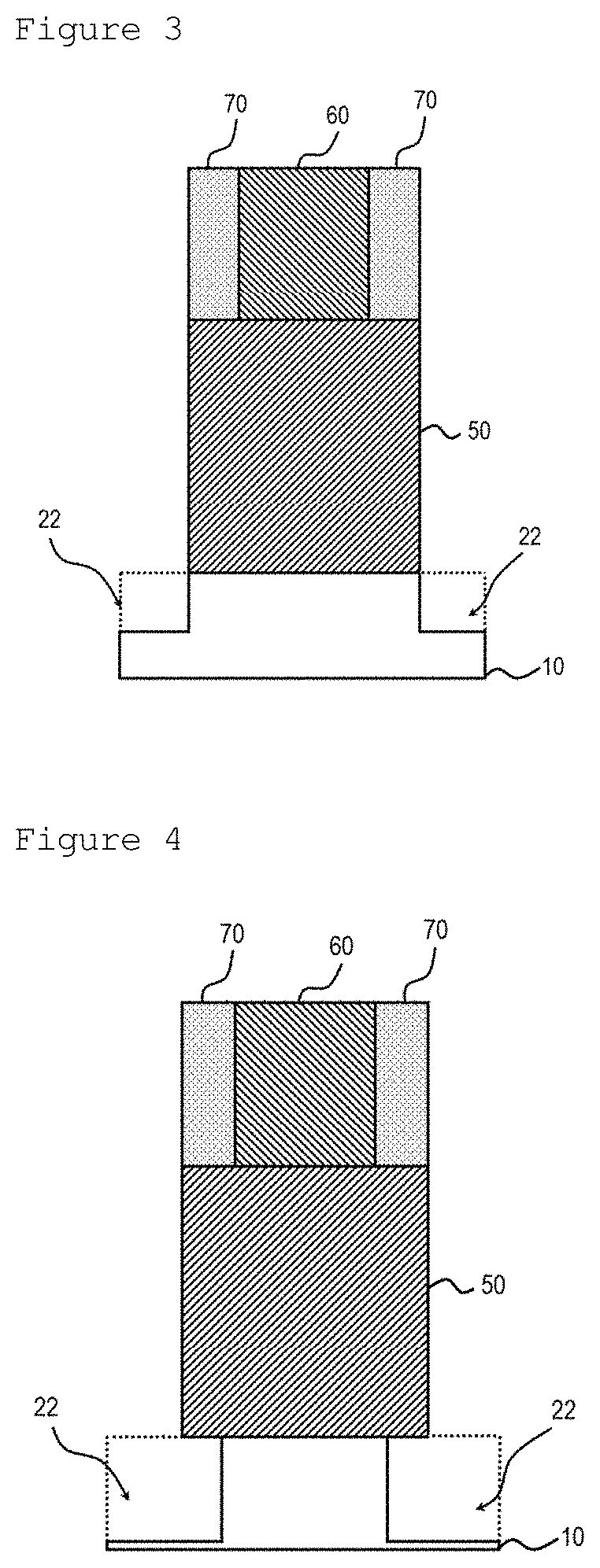

Field-effect transistor without punch-through stopper and fabrication method thereof

ActiveUS11387317B2VariabilityAvoid problemsNanoinformaticsSemiconductor/solid-state device manufacturingField effectField-effect transistor

Disclosed is a field effect transistor including an insulating film disposed between a source / drain region and a substrate. Since the insulating film prevents current leakage under a channel, it is not necessary to form a punch-through stopper. Further disclosed is a method of forming a field effect transistor.

Owner:POSTECH ACAD IND FOUND

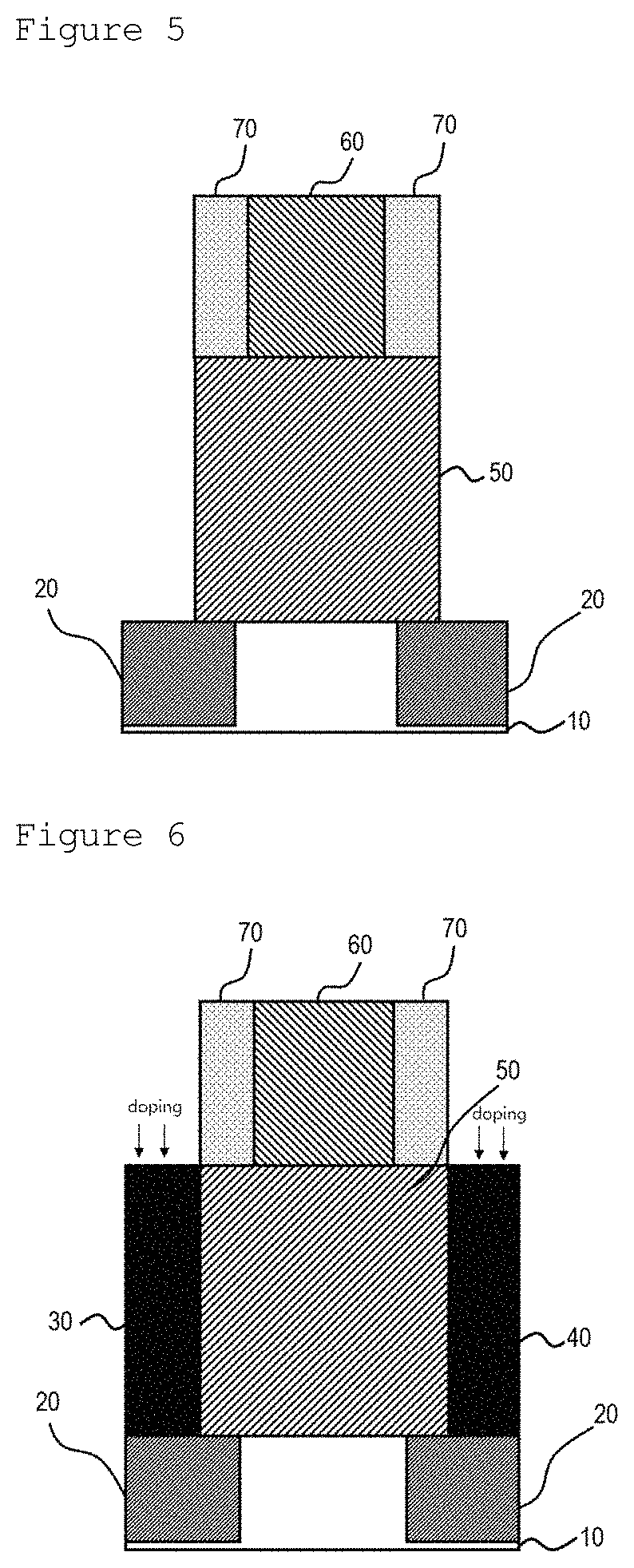

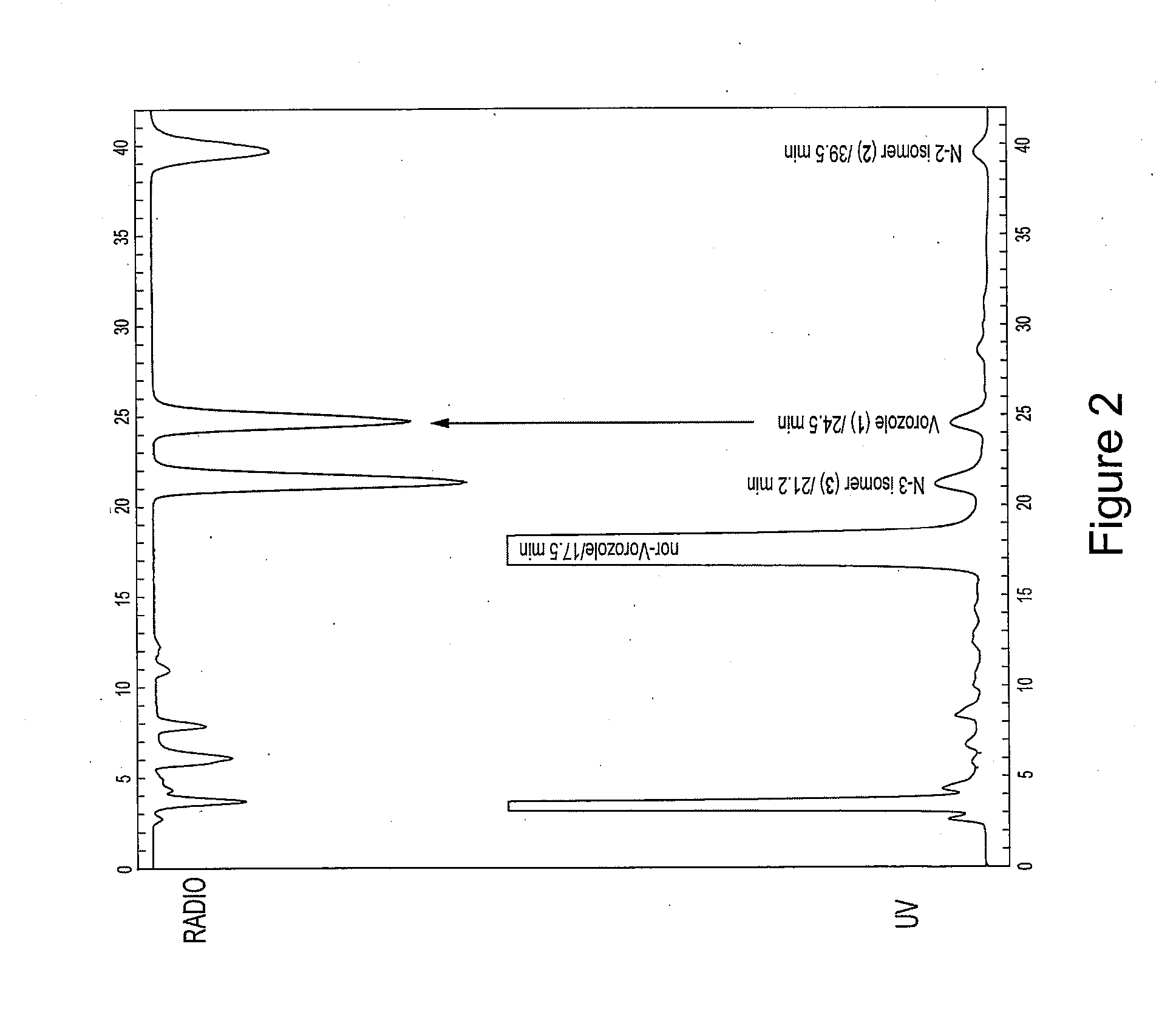

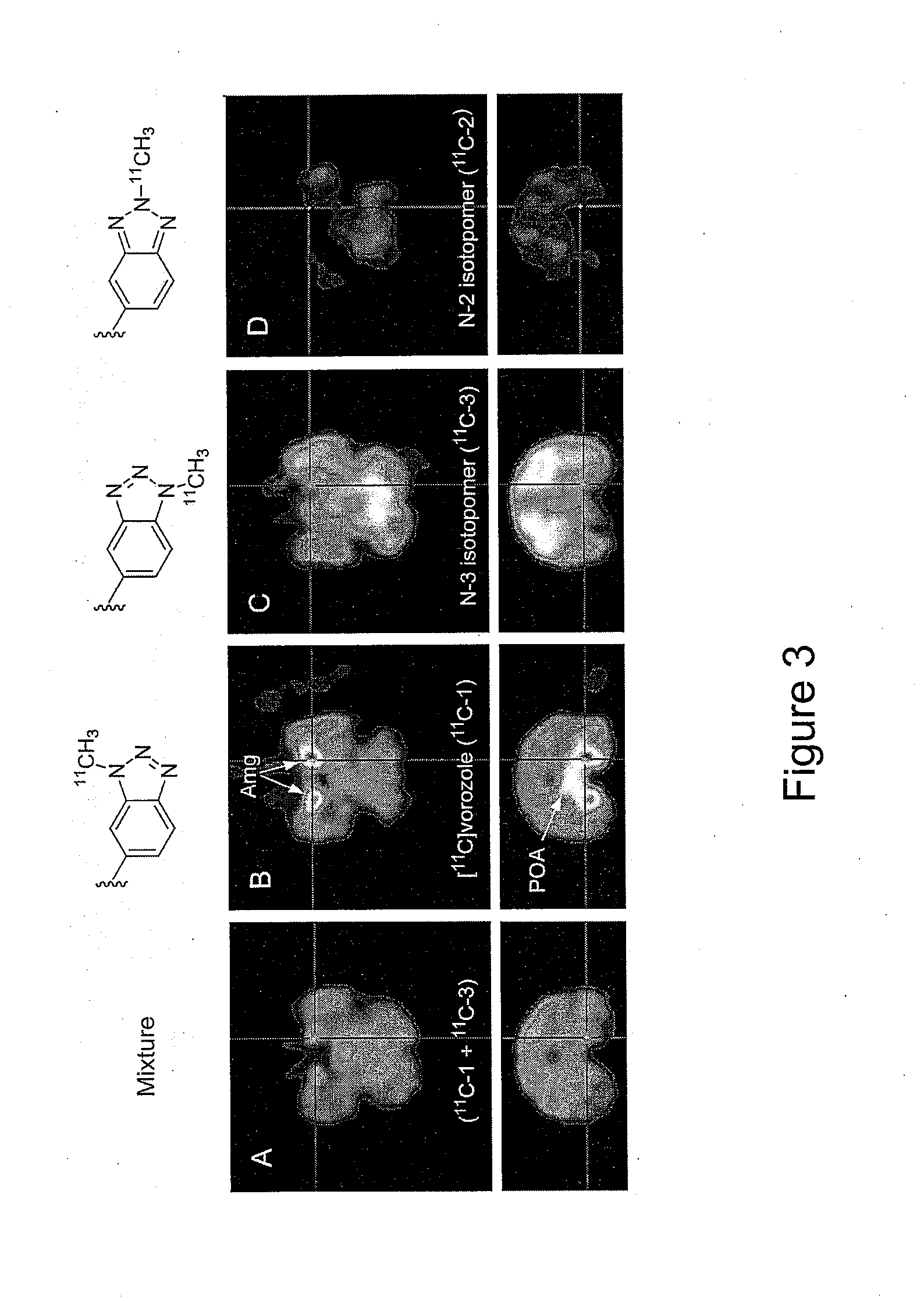

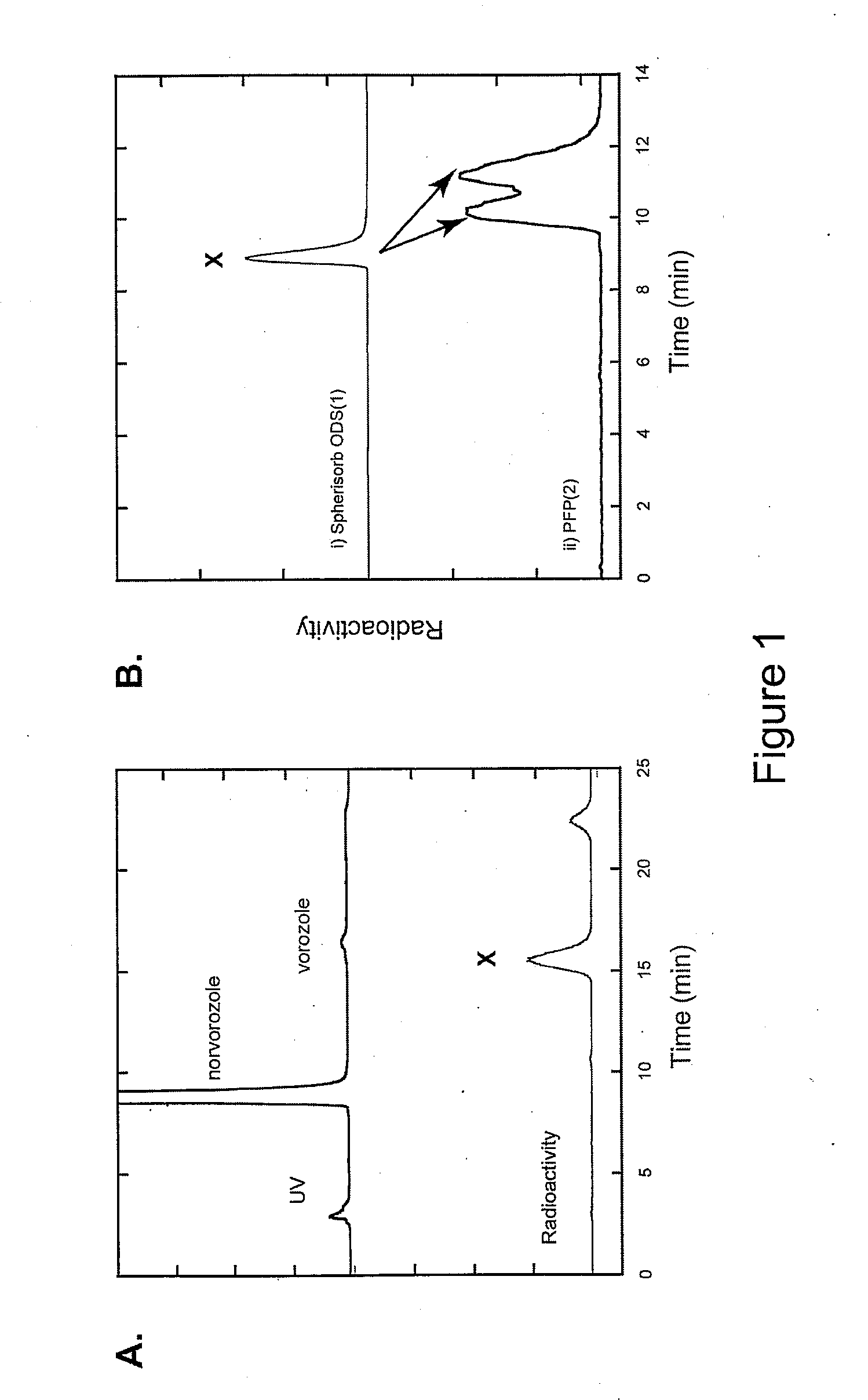

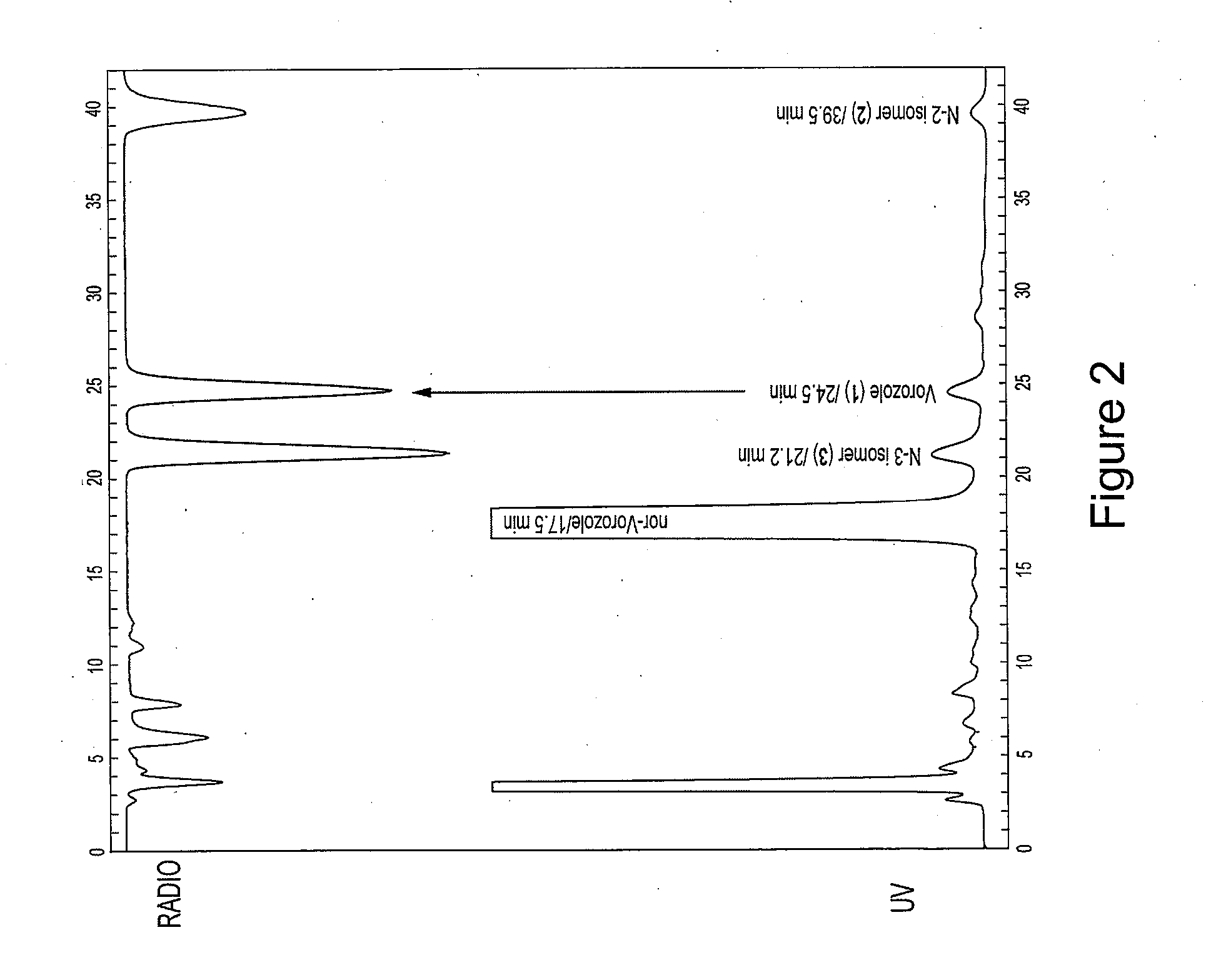

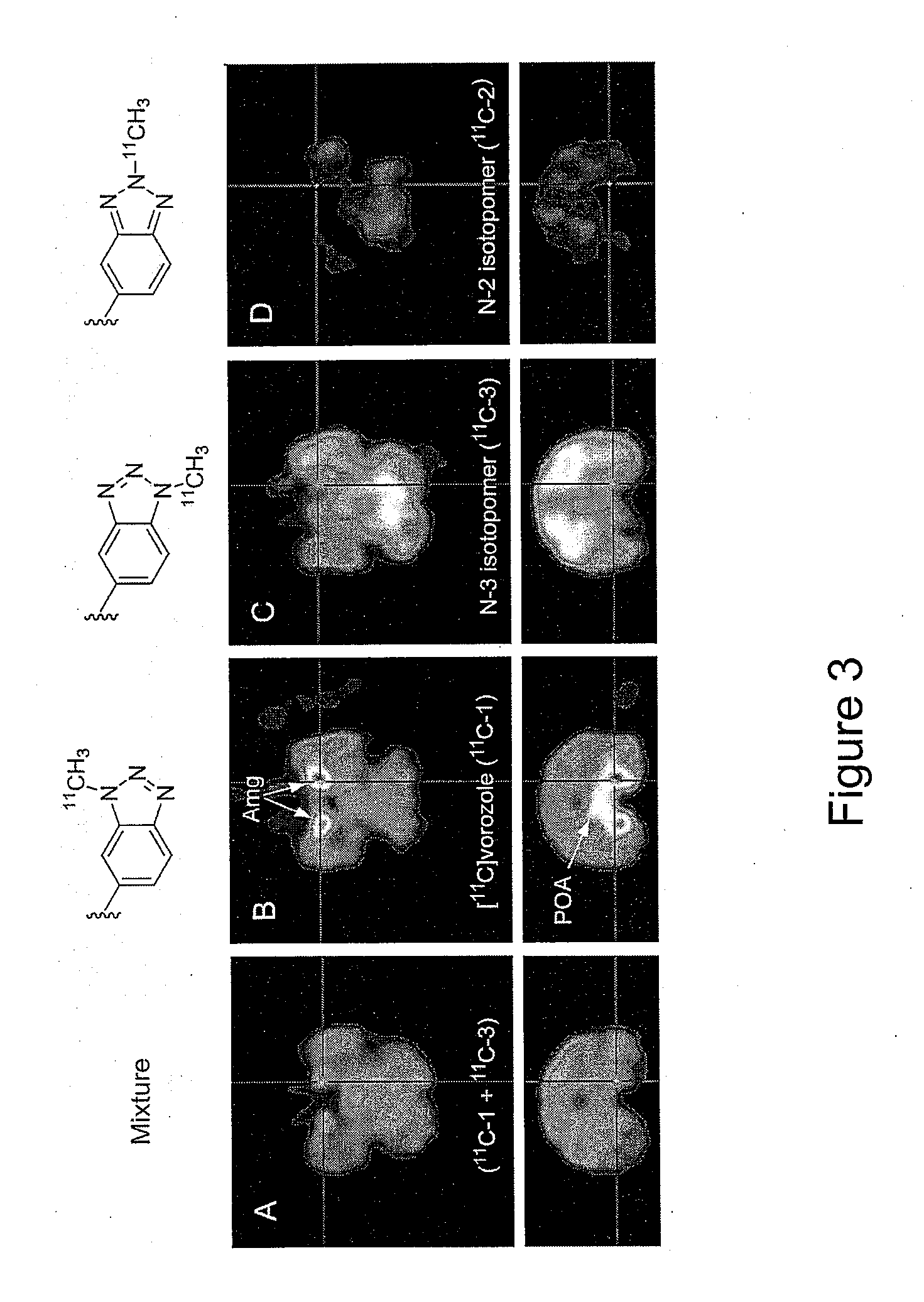

Radio-methyl Vorozole and Methods for Making and Using the Same

InactiveUS20130225831A1High liver uptakeGood metabolic stabilityIn-vivo radioactive preparationsOrganic chemistry methodsRadioactive tracerCytochrome P450

Owner:BROOKHAVEN SCI ASSOCS

Optical fiber endface inspection with optical power measurement

ActiveUS10900866B2Better optimizedImprove stabilityOptical light guidesTesting fibre optics/optical waveguide devicesOptical power meterEngineering

Owner:EXFO

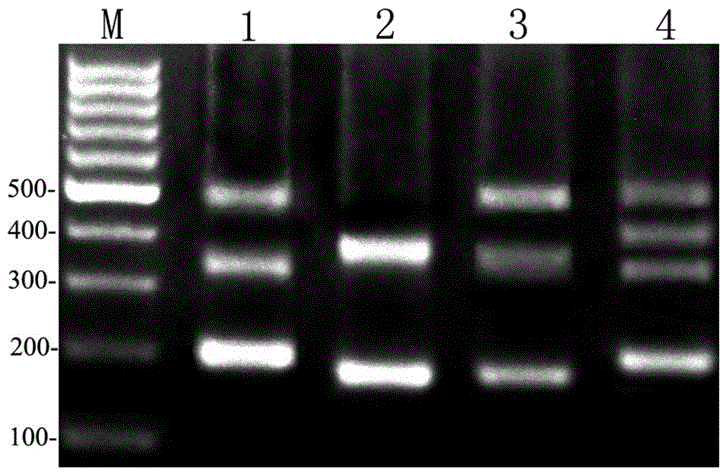

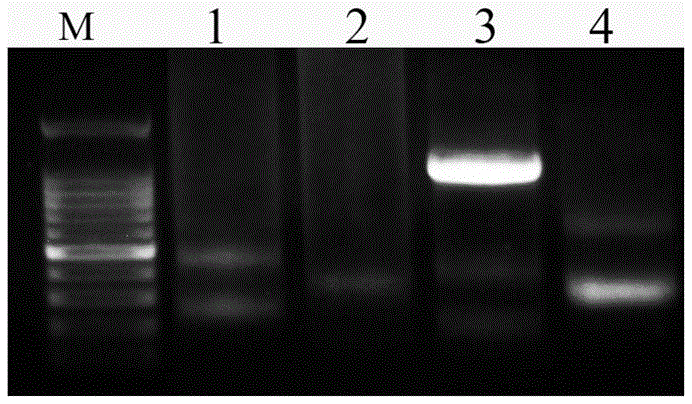

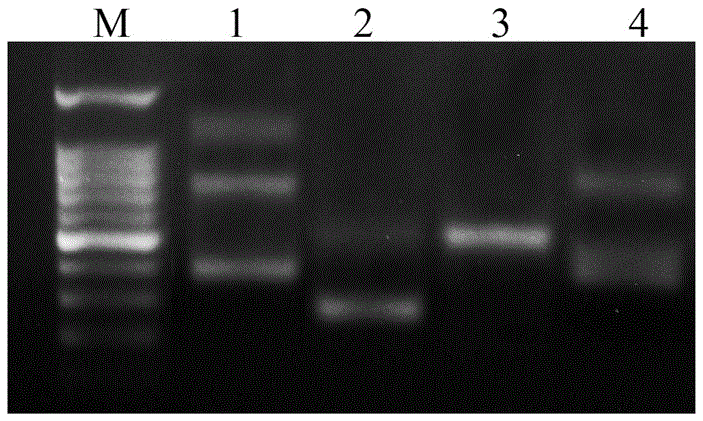

The specific primer sequence that can be applied in the method for identifying different fish and the dna molecular marker method for identifying different fish

ActiveCN103589801BVariabilityFast and accurate identificationMicrobiological testing/measurementDNA/RNA fragmentationGenomic DNAGel electrophoresis

The invention discloses specific primer sequences that can be used in DNA molecular marker methods for differentiating different fish, including upstream primers and downstream primers. Using the specific primer sequences to identify different fish DNA molecular marker methods includes: first according to known 5S of fish? Design specific primers for the conserved coding region sequence of the rDNA gene; then extract the genome of the fish material to be identified; use the genomic DNA as a template to design a PCR reaction system to amplify its 5S? rDNA gene, using 5S? After the polymorphism of the non-transcribed spacer region of the rDNA gene was purified by PCR amplification reaction, agarose gel electrophoresis and DNA gel recovery kit, the sample 5S? The DNA fragment pattern of the rDNA gene; finally, the species of the fish material to be identified was determined by comparing the DNA fragment pattern in the gel imaging with the known fish. The method of the invention has the advantages of quickness, accuracy, easy operation and the like.

Owner:HUNAN NORMAL UNIVERSITY

Radio-methyl Vorozole and Methods for Making and Using the Same

InactiveUS20100209344A1High liver uptakeGood metabolic stabilityOrganic chemistry methodsRadioactive preparation carriersRadioactive tracerCytochrome P450

Radiotracer vorozole compounds for in vivo and in vitro assaying, studying and imaging cytochrome P450 aromatase enzymes in humans, animals, and tissues and methods for making and using the same are provided. [N-radio-methyl] vorozole substantially separated from an N-3 radio-methyl isomer of vorozole is provided. Separation is accomplished through use of chromatography resins providing multiple mechanisms of selectivity.

Owner:BROOKHAVEN SCI ASSOCS

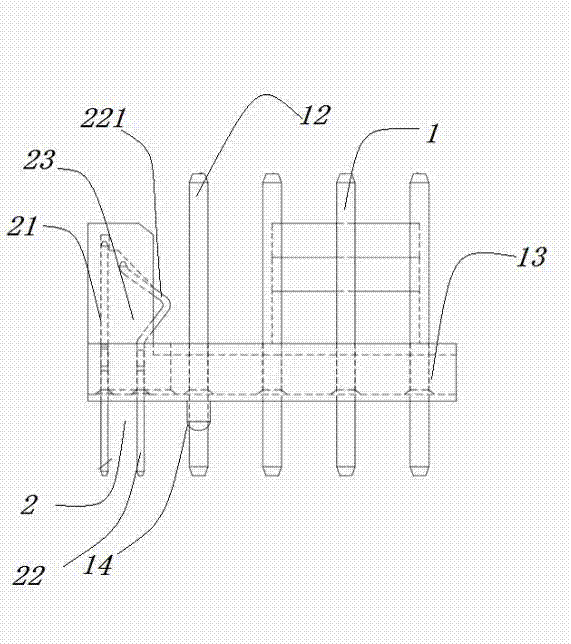

Controllable electronic connector

InactiveCN102931508AAvoid damageNot easy to bend and deformSecuring/insulating coupling contact membersCoupling contact membersControl signalControl electronics

The invention discloses a controllable electronic connector, comprising a plurality of first pins, wherein the first pins are mutually connected, and are fixedly arranged through a plastic piece, so as to form a first pin group; at least two heads of each first pin are exposed. The controllable electronic connector further comprises a control pin group connected on the first pin group; and a plurality of control pins are arranged on the control pin group. The first pin group is connected with an electric system, and the control pin group is connected with the other electric system so that two electric signals can be received simultaneously. When the two electric systems send the electronic signals, the controllable electronic connector provided by the invention controls an electronic connection piece to transmit the signals, so that the combination of the control signals and the working signals can be realized.

Owner:JIH VEI ELECTRONICS KUSN

Plurality of electrons for use in the restoration of a patient's health

Owner:OXFORD BIOELECTRONICS

Pharmaceutical composition for nasal delivery

InactiveUS20210008060A1High binding affinityLow degreeOrganic active ingredientsGranular deliveryOpioid antagonistOpioid overdose

According to the invention, there is provided a solid pharmaceutical composition formulation for nasal delivery of an opioid antagonist, comprising a pharmacologically-effective amount of an opioid antagonist and a pharmaceutically-acceptable carrier. Said compositions are preferably in the form of a powder produced by spray-drying, which are subsequently loaded into single use nasal applicators. Preferred pharmaceutically-acceptable carriers in this regard include disaccharides (e.g. lactose or trehalose) and dextrins (e.g. cyclodextrins or maltodextrins), preferably spray-dried together in combination. Compositions may further comprise an alkyl saccharide, preferably a sucrose ester, such as sucrose monolaurate. Said compositions and applicators may be employed in the treatment of opioid overdose in subjects.

Owner:OREXO AB

Preventing fog on a medical device viewport

ActiveUS11246480B2Preclude obtainingRuining the optical quality of the viewportSurgeryEndoscopesMedical deviceBiomedical engineering

Provided are methods of immunizing a viewport of a medical device against fogging before or during a medical procedure, and related apparatuses and devices. The methods comprise applying plasma to the viewport prior to use, thereby rendering a surface of the viewport highly hydrophilic. The methods eliminate or at least significantly reduce blur due to fogging.

Owner:PLASMATICA LTD

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com